Hi all! Dear prior leaders, I want to get an answer, advice or opinion from experienced people and those who have already met him! The situation is as follows. I decided to install an oil separator (from the fuel filter of the carburetor family) to a small deflector (a small circuit of the ventilation system), which goes from the head cover to the throttle valve. For the sake of experimentation, see if oil accumulates there. At first I looked, there were no traces of oil, then over time the filter element began to turn black, I also thought that oil vapors had been caught, and then I forgot to look... And then today I saw it!

I didn’t notice during what period of mileage it accumulated such an amount of oil. I remembered. about 2000-3000 km. The driving style is calm, you don’t accelerate much in the city, I go 100-120 km/h on the highway. Sometimes it happens, I give her pi @ dy! =)) Yes, and here’s another one, the day before I went to the village and ran 160-170 km/h along the highway. Could this affect the oil yield? Oil Castrol Magnatec 5w40, changed 2000 km ago. The move doesn't eat oil. I want to put an oil catcher on the large vent (large vent loop) that goes from the head cover to the throttle body air tube, BUT I can't get around to it! If there is so much oil in the small one, what will there be in the large one?!

So that's it! I look forward to your comments! Thanks in advance!

Particular attention is paid to protecting the environment when creating new car models. Therefore, the crankcase ventilation system (Priora, Kalina) was modernized to meet modern environmental safety requirements. It ensures the removal of combustion products of the air-fuel mixture, which collect in the oil pan as a result of exiting through rubber bands that do not fit very tightly to the cylinder walls.

Operating principle of SVKG

Car engines have a ring exhaust system. The gases produced as a result of the production of diesel fuel, gasoline or liquefied gas are not released into the environment, but are returned to the engine, where they are burned again. The second end of the crankcase ventilation pipe is attached to the intake manifold, which allows gases to flow back into the cylinder chamber for combustion. A significant portion of the gases, if re-entered, are ignited when the fuel is ignited, and the remaining gases are released into the atmosphere through the exhaust system. A small percentage of the gases are returned to the cylinder chamber for re-combustion. This process continues.

How to Remove the Valve Cover on a Priora 16 Valves Video

How to remove the valve cover on a Priora 1.6 16kl

https://www.donationalerts.ru/c/melkiy_nikalek to support the project, a homemade snowmobile, with a Lifan engine, at least 15 hp.

Removing the cylinder head of a VAZ 2112 16 valves

The Auto_Repair channel will help you troubleshoot your car yourself.

how to fix oil getting into the spark plug wells of a vase

Thank you so much for watching my videos, tell your friends, leave comments and subscribe.

Priora repair. VAZ 21126. How to remove the cylinder head from the engine. How to remove the cylinder head from the engine

When you remove the cylinder head for the first time from a car whose engine has never been disassembled before.

installation of cylinder head VAZ 2112 -16 valves

The Auto_Repair channel will help you troubleshoot your car yourself.

How to remove the Cylinder Head of Lada Priora! Part 1. In detail! How to remove the cylinder head

Lada_priora #cylinder head #Ivanova #engine_repair The main symptoms that the cylinder head will have to be dismantled.

Replacing the timing belt and rollers on Priora 16-valve Kalina and Grant

Video review on replacing the timing belt on Lada Priora cars with 1.6 16-cl engines, Lada Granta, and Kalina.

removing the VAZ 16 valve ramp without removing the manifold

The Auto_Repair channel will help you troubleshoot your car yourself.

replacing timing belt 16 valves VAZ 2110-2112

The Auto_Repair channel will help you troubleshoot your car yourself.

Replacing the timing belt and pump with your own hands - nuances on Priora! Timing marks VAZ 2170, 2171,2172!

Replacing the timing belt and pump on a Priora! Do-it-yourself timing marks in street conditions from and to the nuances of VAZ 2170, 2171,2172!

Replacing the timing belt on Lada Priora 21126 2013 LADA Priora

Thank you for watching and for subscribing, all the best to you.

How to clean the valve cover (breather mesh) of a VAZ

Subscribe to the group on VK https://vk.com/public120461485 Instagram https://www.instagram.com/nik86_youtube/

Replacement of timing belt and pump 16kl.! Timing marks 16kl. VAZ 2110,2112,2111

Replacing the timing belt on a Priora! Timing marks VAZ 2170, 2171,2172! https://www.youtube.com/watch?v=T3DOAWfKt_k This video shows the work.

How to remove and wash injectors on a sixteen-valve VAZ 2110 engine. Cleaning the injector

Lada Kalina, Priora. How to remove the intake manifold without removing the engine on a 126 engine (16 valves)

We encountered difficulty in removing the receiver manifold on a 126 Priora motor, but found a way to do it, no.

Broken timing belt on Priora 21126 head repair.

Bent valve on Priora 21126 DIY repair. Thank you for watching and for subscribing, all the best to you.

How to quickly and correctly remove and install the Generator from Priora Lux

Diagnostics and repair of timing belt. Timing marks. VAZ (LADA) 16v

Do-it-yourself diagnostics and repair of timing belt of 16 valve VAZ engines. The video shows methods for finding faults.

oil in the air filter and bellows cause and solution

The Auto_Repair channel will help you troubleshoot your car yourself.

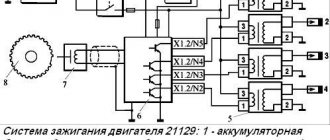

How to identify a faulty coil on a 16 valve engine

The video is aimed more at car owners rather than mechanics. A simple lifehack by definition of a malfunction.

Oil in the intake of Priora (problem 21126)

If you are not satisfied with the price of OSAGO, correct KBM - discount on OSAGO up to 50% FIX KBM HERE https://osago-kbm.blogspot.ru/p/bl.

Priors cylinder head analysis, part 2

Replacing the timing belt and rollers on 16 valve VAZ 2110, 2111 and 2112

How to replace the timing belt and rollers on a 16-cl. VAZ 2110, 2111, 2112 cars with engines 2112 and 21124. https://remont-vaz2110.r.

Differences 16th grade. VAZ engines detailed review

The review includes engines 2112-1.5 family ten, 21124-1.6 family ten, 21126-1.6 Priora/2114, 11194-1.4 viburnum. Differences.

Replacing valve cover gasket Daewoo Nexia 16v

https://avto.pro - auto parts for foreign cars without intermediaries. Greetings, dear car lovers, you are watching.

How to remove, disassemble and reassemble the starter on a Priora!

Detailed video report on disassembling and assembling a gear starter for VAZ cars! Removal and installation of retractors.

Repair of VAZ 2110. Replacement of cylinder head gasket, etc.

Communication, commercial inquiries: Channel assistance: PrivatBank 5168 7556 3188 1725, WMZ Z318291300563, WMU.

How to replace the LV without removing the generator on a Priora Luxury with air conditioning (voltage regulator)

Subscribe to the channel – https://www.youtube.com/user/TechBoyRus?sub_confirmation=1.

How to remove the VAZ crankshaft gear if it cannot be removed! How to remove gear crankshaft.

VAZ #2109 #21083 #Ivanova When replacing the crankshaft oil seal, which is located behind the Crankshaft gear, on a car.

Timing marks 16kl. VAZ! Checking timing marks on a VAZ

Timing marks 16kl. VAZ 2110, 2111, 2112. IF YOU CARRY OUT WORK ON THE VAZ 2112 1.5I 16cl ENGINE. or from 16kl. engine on.

HOW TO REMOVE THE TRANSMISSION OF VAZ 2110 2111 2112

How to fix an oil leak on a v16 engine

High-quality used spare parts for Daewoo – avtolanos.com.ua.

How to remove the crankshaft gear if it cannot be removed!

The need to replace the crankshaft oil seal or remove the oil pump requires first removing the gear.

The steering rack on a Priora is knocking - how to tighten it?!

Detailed video review of tightening the steering rack on a Lada Priora car. How to determine what is knocking.

Replacing the front crankshaft oil seal VAZ 21099, VAZ 2109, VAZ 2108

The video shows the process of replacing the front crankshaft oil seal of a VAZ 21099. At the same time, the timing belt was replaced (code 2108-100604.

Replacing the brushes of a VAZ 2112 generator without removing the generator

Well, there you are. LIKE AND DON'T FORGET TO SUBSCRIBE)) Brotherly My Instagram: https://www.instagram.com/sasha_058 We are changing.

How to check the thermostat? On VAZ 2110-2115 and 2170-2172-Priora.

How to check the thermostat? On VAZ 2110-2115 and 2170-2172-Priora. In this video I conduct an experiment on what temperature.

Replacing hydraulic lifters Hyundai Accent

In this video I show the process of replacing the ever-clacking hydraulic valves on a Hyundai Accent (TagAZ). Tools: ordinary.

Oil pump VAZ, INSTALLATION, Oil pump VAZ, INSTALLATION.

VAZ2109 #sealant #ingarage Video on how to properly install the VAZ front-wheel drive oil pump! Video.

How to remove the Cylinder Head of Lada Priora! Part 2. Details!How to remove the cylinder head

The main symptoms that you will have to dismantle the cylinder head will be an oil leak that is observed in the area.

REPLACEMENT OF THE TIMING GAME ON THE LADA VESTA LADA VESTA. REASON FOR THE BEND OF THE VALVES.

DISCOUNT ON AUTO PARTS shop motorring.ru promo KAIGRAVE: https://motorring.ru/?utm_source=kaigrave YouTube channel of the car shop.

That's how VAZ valves knock

The Auto_Repair channel will help you troubleshoot your car yourself.

REPAIR OF GEARBOX VAZ 2110,2111,2112,2114,2170,1118.

VAZ, gearbox, repair, VAZ 2110, 2112, 2110, gearbox, VAZ timing belt, VAZ clutch, VAZ repair, VAZ 2109, auto show (event), box.

VAZ 2112 stove replacement

Replacing the generator on VAZ 2110-2112 and 2114-2115

Video instructions for removing and installing a generator on VAZ 2110-2115 cars with your own hands. Description also.

Air in the Kalina cooling system - expansion tank cap needs to be replaced!

One of the reasons why the cooling system on Kalina may become airy is because the stove will be damaged.

ENGINES VAZ 21124 and VAZ 2112 16 VALVE MAIN DIFFERENCES

VAZ 2112 and VAZ 21124 What are the main differences between 16 valve engines. What are the differences between VAZ 2112 or 21124 16v engines. Diff.

Replacing the generator bearing

Replacing the front generator bearing on a Chery Tiggo with a Mitsubishi 4G64 2.4 and 4G63 2.0 engine. Bearing number – 6303.

Replacing the thermostat on a VAZ 2114.

In this video I will tell you how to change the thermostat on a VAZ 2114 with your own hands. Similar to Priors, Kalinas, and Grants.

How to remove the crankshaft pulley (using the example of a VAZ car)

Anacondaz – about Russia and the Motherland / vDud

MARCH 18 RUSSIAN KIRISH TAKILANDI. ANDY CHEGARAlar epildi

@Little Big – UNO Eurovision 2022 (Live @ Radio ENERGY)

Coronavirus / News / Myths / Comments | Doctor Komarovsky

MOSCOWADAGI UZBEKLAR DIKKATIGHA RASMIY YANGILIK..

Coronavirus in Russia and the world. New infections in Russia, increased mortality and vaccine trials

24 hours EAT food only on PROMOTION! Who will save the MOST? Elfinka

Kuji Live: self-restraint, happiness and the virus (Karginov, Konyaev, Saburov)

Navidi bomdodi 17-umi marti salt 2020

Nevsky. Shadow of the Architect. Episode 22

HOW TO SURVIVE IN THE ICY WATER CHALLENGE?! TESTING 3 WAYS!

UNCLE YURA'S KITCHEN IS COMPLETELY READY REVIEW / Maslenitsa WE BURN A SCARED AND MAKE PANCAKES FROM THE 90s

Lyubov Sobol announced her nomination to the State Duma

SARYCHEV vs KISHKOBLUD – EAT 150 KHINKALI IN 10 MINUTES – EPIC STOMACH FUCK

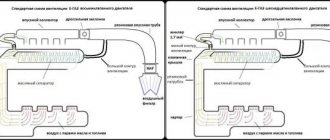

SVKG device in Lada Priora

In all brands of cars, the SVKG is built on a similar principle. Only small details differ. At the top of the crankcase there is an oil separator that looks like a hollow plug. Under the cover there is an oil deflector designed for maximum purification of crankcase gases from oil particles. The oil separator has an outlet for the crankcase breather tube.

To ensure that gases return to the cylinder chamber, a ventilation valve is placed in their path. The valve has three modes that allow you to maintain a certain level of gas vacuum in the crankcase.

When the engine is idling, gases move through the small circuit tube through a special passage in the throttle assembly. At this time, a high vacuum is created in the intake tube, allowing crankcase gases to be effectively sucked out of the throttle valve. The throttle hole regulates the amount of gas intake.

This allows the engine to stabilize at idle. When the car starts moving, the throttle valve opens, causing gases from the crankcase to flow through the large circuit pipe into the cylinder for combustion.

Oil flows through the breather, reasons, how to fix the problem

Today we will talk about the crankcase ventilation system and look at the reasons why oil begins to flow through the breather.

Crankcase ventilation system

The power plant of any car is a very complex device, including mechanisms and systems that interact with each other. At the same time, the engine is not a closed hermetically sealed circuit and it also has ventilation.

Crankcase ventilation is a scheme that ensures the removal of gases from internal cavities.

The fact is that during combustion of the working mixture in the cylinders, exhaust gases are formed, which are under pressure, due to which part of them penetrates into the sub-piston space - the crankcase, where it mixes with oil mist and moisture formed as a result of condensation.

This whole mixture is called crankcase gases.

If the engine were sealed, with an increase in the amount of gases in the crankcase, the pressure inside it also increased. Because of this, a breakthrough of gases along with oil through the breather, oil seals, seals or the hole in the oil dipstick is possible.

Based on this, it follows that the main task of the ventilation system is to maintain pressure inside the engine and prevent it from exceeding the permissible norm by removing crankcase gases.

Features of ventilation design, operating principle

The simplest diagram of the crankcase ventilation system used on internal combustion engines previously consisted of only one fitting - a breather installed in the crankcase.

This breather connected the internal cavity of the cylinder block with the external environment, and crankcase gases simply escaped through it into the atmosphere.

But this scheme had one significant drawback - the exhaust gases contained oil particles, which also entered the external environment. And this is not only loss of lubricant and the need for periodic refilling, but also air pollution.

On modern cars the ventilation system is closed. It also has a breather, but a pipe is connected to it, allowing gases to be vented into the intake manifold or air filter housing, from where they enter the cylinders and burn. That is, the atmosphere is not polluted by them.

Additionally, the system includes elements that ensure oil separation and return back to the crankcase so that it does not enter the cylinders along with the gases.

There are several options for oil separators, and on cars from different manufacturers they may differ in design and operating principle.

It is worth noting that part of the exhaust gases enters the supra-valve space, and they must also be removed.

Therefore, the entire circuit of the engine ventilation system on a modern car consists of a breather, an oil separator and two pipes.

Additionally, a special valve can be included in the system to regulate the pressure of gases entering the intake manifold.

The configuration of the system can be very different, but this does not change its purpose and operating principle. For example, consider the ventilation design of the VAZ-2110.

At the bottom of the cylinder block of this car there is a breather, onto which a pipe is attached; the second end of this hose is connected through a fitting to the cylinder head cover. At the same time, an oil separator is located inside this cover at the inlet of the pipe.

On its other side there is another fitting, to which a tube is connected that goes to the air inlet pipe.

The principle of operation of such ventilation is simple - gases enter the cylinder head cover space through the breather and pass through the oil separator, while the separated oil flows to the valve assembly.

After this, the gases are mixed with those that have broken into the supra-valve space and are supplied to the air pipe, and then to the manifold. There is no pressure regulating valve in this car.

POPULAR WITH READERS: DIY starter repair

On other machines, the oil separator may be located immediately next to the breather, and a valve is installed behind it.

Signs and causes of oil leaking through the breather

Despite its simplicity, this system is very important, and it is necessary to monitor its performance. One of the most common ventilation problems is oil leaking through the breather.

This can become a serious problem in the future, since oil particles entering the manifold and cylinders will clog the channels, and during combustion, increase the amount of soot, which will then enter the crankcase, coking the oil channels, and impairing the operation of the lubrication system.

Cleaning SVKG in Lada Priora

After prolonged use, gas deposits collect in the crankcase ventilation system. This deposit makes it difficult for gases to pass through the cylinders. As a result, the gas pressure in the engine increases, which leads to oil leakage. Timely cleaning of the SVKG will help prevent this. The manufacturer of Lada Priora recommends carrying out this procedure every 60 thousand km. This service manipulation can be performed at a car repair shop or independently.

To do this, you will need tools (pliers, 8-mm wrench, Phillips screwdriver).

When cleaning the SVKG, you need to perform the following steps:

- Remove the decorative engine cover.

- Remove the air filter.

- Carefully loosen the clamp on the vent hose clamp on the engine.

While the engine is running, do not break the SVKG seal or remove the oil filler cap.

This will lead to the release of toxic substances into the environment and failure of the crankcase.

Why does oil squeeze out through the breather: how to fix the problem

A fairly common problem on many domestic and foreign-made cars is that oil flows through the breather. In winter, especially with the onset of significant cold weather, you can encounter a malfunction when the breather freezes, oil is squeezed out and streaks are visible on the outer surface of the power unit. Let us immediately note that this symptom, as well as smoke and oil from the breather, are a reason for immediate engine diagnostics, since ignoring this problem can lead to quick and expensive engine repairs.

We also recommend reading the article about what a breather is and what its purpose is. From this article you will learn about the design of the engine breather and other components, the principles of operation of the element and other features.

Note that if there is oil coming through the breather, diagnosing the root cause may be difficult. To accurately determine the underlying problem, skills, special equipment, etc. will be required. However, in some cases, the driver can understand why oil is leaking from the breather without the involvement of third-party specialists. In other words, diagnostics are carried out independently in a garage environment. In this article we will talk about why oil drips from the breather, as well as what a car owner should do if oil comes out through the breather.

Breather oil: what to do and how to find the cause

Let's start with the fact that during engine operation, so-called crankcase gases accumulate in the crankcase. To prevent excess pressure from being created, there is a special valve for ventilation. This solution allows the closed crankcase to communicate with the atmosphere. This valve is the breather. In simple words, a breather on an internal combustion engine is actually needed to equalize the pressure inside the engine.

It should be noted that in the crankcase gases mix with oil mist. As a result, lubricant particles enter the breather. Although there is a special oil trap inside the device, a certain part of the oil may escape out. Given this information, minor contamination of the system is acceptable, which is normal. In cases where a lot of lubricant leaks, you should look separately for why oil is leaking from the breather.

Oil leaks through the breather lead to clogged channels, in some cases soot is formed, etc. Excess soot gets into the engine crankcase, and the lubrication system becomes coked. As a result, loaded parts are less well lubricated and engine wear accelerates. Let us add that traces of oil will not necessarily be visible from the outside in the engine compartment. On engines with a carburetor, if there is a leak through the breather, oil in the air filter housing or on the filter element itself is a characteristic sign of a malfunction.

On injection engines, traces of oil getting into the throttle area are noticeable, the power unit also loses its throttle response and power, and fuel consumption increases noticeably. It turns out that to check it is necessary not only to inspect the outer surfaces under the hood, but also to remove the air filter, throttle assembly, etc.

Why does oil leak through the breather?

If oil appears from the breather, there may be several reasons. Given the various features, before self-diagnosis, you need to pay attention to additional symptoms.

Drives oil through the breather: diesel and gasoline internal combustion engines

Engine diagnostics for oil leaks through the breather requires an integrated approach. There is no need to disassemble the power unit to check. It becomes clear that at the initial stage you should assess the condition of the breather, make sure it is working and clean the device if necessary. The oil level is also checked using the dipstick. If everything is fine with the level and there are no other additional signs of a problem, then it is optimal to replace the breather with a known good one.

After making sure that the breather is working properly and ventilation is at an acceptable level, you will need to make a series of measurements and assess the condition of the CPG. As already mentioned, the cause may be failed rings, that is, you will need to measure the compression in the engine.

We also recommend reading the article on how to correctly measure compression in cylinders. From this article you will learn about why, how and with what tools this procedure is carried out to obtain accurate data.

Also, the color of the exhaust gases can additionally indicate the need to measure compression. To check, just start the engine and then evaluate the exhaust. If the engine smokes blue or gray smoke, then this may be a sign of engine oil getting into the cylinders due to worn piston rings.

When checking compression, you need to take readings in each individual cylinder. In the normal state of the CPG, compression should be at 11 MPa and above (it is recommended to consult the technical literature in relation to a specific type of internal combustion engine).

If a run-up is detected according to the readings in the cylinders, the differences should not exceed 1 MPa.

Failure to reduce compression will indicate that further checks will be related to the ventilation system. The method for testing this system will be considered using the example of the domestic VAZ 2110 model. Other cars may have some individual features, but the general principle will be similar.

Let's sum it up

Taking into account the above, it becomes clear that an increase in crankcase gas pressure and oil leakage through the breather indicate a number of problems with the breather or internal combustion engine. Quick detection and elimination of faults will reduce the cost of repairing the power unit. This is true if the problem is eliminated at an early stage, that is, without the consequences that arise after a long period of ignoring the malfunction and further active operation of the engine.

We also add that cleaning the crankcase ventilation system is not a complicated procedure, so in some cases such an operation can be carried out in the garage with your own hands. Moreover, it is recommended to clean the ventilation system regularly during each scheduled maintenance in parallel with changing the engine oil.

Finally, we note that quite often heavy oil leaks through the breather do not appear immediately. In other words, the lubricant may leak slightly, which is sometimes unnoticeable. In other cases, about 0.5 or a liter of lubricant can escape through the breather from the lubrication system, taking into account a short mileage (on average, 1-3 thousand km). With such a significant leak, the operation of the internal combustion engine is stopped, diagnostics and repairs are carried out.

Source

Cons of SVKG in Lada Priora

Having cleared the atmosphere of the emission of toxic substances, the SVKG creates problems with the engine. The gases leaving the crankcase, despite the presence of an oil separator, are saturated with microscopic oil particles, which after some time leads to contamination of the fuel intake system.

This leads to engine stops. Gas particles settle on the valve parts, which leads to its failure. This stops the fuel injection system in the combustion chamber and increases oil consumption. In case of severe contamination, fuel injection does not occur. In this case, the valve must be completely replaced. It is necessary to periodically inspect the crankcase ventilation pipes, as they age and break under the influence of the environment.

If you notice oil stains, an increase in oil consumption, an increase in fuel and lubricant consumption, as well as engine malfunctions (stopping, does not start for a long time, emitting exhaust gases and other unusual sounds), be sure to contact a service center to have the engine checked and repaired. Timely treatment will reduce the cost of engine repairs and extend its service life.

Alternative options

The next version of the improvement involves installing a hose with a small diameter into the crankcase ventilation circuit of the EPK valve of the “Cascade” model. In idle mode, the valve for standard exhaust gas outlet should be opened. Considering the fact that when installing the system in question, the supply of harmful impurities through the throttle valve stops due to the circuit opening. This is very important in the case of a transition of the engine operating mode from idle to light loads, when a lean air-fuel mixture is categorically unacceptable. Ventilation is carried out through the entire line, including the carburetor unit.

After further replacing the durite with a hose from the vacuum ignition advance device, it is reasonable to increase the diameter of the main jet of the first combustion chamber or simply reduce the input fuel flow to 4.5 mm. The scheme under consideration was tested on a model of the domestic VAZ 2101. At the same time, the following positive aspects became noticeable:

- The pedal drop during acceleration has disappeared;

- The engine's operation became smooth;

- There are no intermittent oscillations at idle.

Using the recommendations of specialists and folk craftsmen, it is possible to independently correct a number of malfunctions and shortcomings of a personal vehicle. Modification of the crankcase ventilation is appropriate for some vehicle equipment, regardless of the year of manufacture and country of manufacture. This problem is most pressing for domestic cars with carburetor engines.

Source

VAZ 2170 | Cleaning the crankcase ventilation system

Over time, tarry deposits of crankcase gases accumulate in the crankcase ventilation system, making it difficult for these gases to be vented into the engine cylinders for combustion. Because of this, the gas pressure inside the engine increases and oil flows out of the seals. To avoid this, periodically clean and flush the system.

According to the manufacturer's recommendation, the crankcase ventilation system should be cleaned every 60 thousand kilometers.

Before each oil change, clean the crankcase ventilation system.

You will need: 8" wrench, Phillips screwdriver, needle nose pliers.

1. Remove the decorative engine cover (see “Removing and installing the decorative engine cover”).

2. Remove the air filter (see “Removing and installing the air filter”).

3. Loosen the clamp...

4 . and disconnect the large crankcase ventilation system pipe from the air supply pipe.

5. Loosen the clamp...

6... and disconnect the air supply hose from the throttle valve.

7. Loosen the clamp, disconnect the large pipe of the crankcase ventilation system from the cylinder head cover and remove it.

8. Similarly, remove the small crankcase ventilation pipe by disconnecting it from the starter assembly and cylinder head cover.

9. Loosen the clamp...

10 . and remove the supply pipe of the ventilation system by disconnecting it from the cylinder head cover pipe...

eleven . as well as from the cylinder block fitting.

12. Rinse the pipes with gasoline or kerosene, blow with compressed air and dry. Clean openings of fittings and pipe fittings.

13. Remove the cylinder head cover (see Replacing the cylinder head cover gasket).

14. Remove the six bolts holding the spacer in place from inside the head cover...

15 . and remove the separator.

16. Using pliers, tighten the separator line clamps...

17. and remove the oil deflector from the oil separator.

18. Using a screwdriver, pry out the rubber O-ring.

19 and remove it. Replace a badly twisted or missing snap ring with a new one.

Before installing the cylinder head cover, clean (old sealant) and degrease the mating surfaces of the cylinder head and cylinder head cover. Apply a thin layer of sealant to the cylinder head mounting surface.

20. Install hoses and parts in the reverse order of removal.

Replacing the crankcase ventilation valve

There are several symptoms that indicate the need to replace the ventilation valve.

Basic:

- the appearance of a whistle in the engine compartment;

- swimming XX;

- increasing the oil volume in the intercooler;

- reduction of boost pressure;

- the appearance of traces of oil on the spark plug “wells” and the area around the oil filler neck;

- dark gray smoke at idle from the exhaust pipe.

We described the issue of testing and signs of malfunction in detail above, so let’s immediately move on to the principles of replacement.

For example, here is the replacement process for a BMW X5:

- Remove the air filter completely.

- Unclip the air flow meter.

- Remove the DIC damper so that it is not in the way.

- Unscrew and remove the air duct.

- Unscrew and remove the second section of the air duct.

- Discard the brake vacuum tube.

- Unscrew the throttle valve (fixed on four bolts). Also remove the connectors from the sensors to keep them out of the way.

- Discard the breather and remove the pair of screws holding the valve in place.

- Remove the breather (pull the tube up).

- Dismantle the manifold to remove the outlet tube (there is no other way to get to it).

- Remove the valve.

- Install the new device and put everything back in place.

Please consider the following points before carrying out work:

- the space around the PCV valve must be cleaned by supplying air under pressure;

- unscrew the valve counterclockwise;

- check the dismantled element, clean it and blow it through;

- The frequency of replacement should be at least every 100,000 km.

Have spare parts ready before replacing. In particular, it is recommended to change the intake manifold and throttle valve gaskets. A new VCG valve will also be required. With the right approach, the entire work takes no more than two hours.

Repair of VAZ 2170 (Priora): Cleaning the crankcase ventilation system

- Repair manuals

- Repair manual for VAZ 2170 (Priora) 2004.

- Cleaning the crankcase ventilation system

Over time, tarry deposits of crankcase gases accumulate in the crankcase ventilation system, making it difficult for these gases to be vented into the engine cylinders for combustion. Because of this, the gas pressure inside the engine increases and oil flows out of the seals. To avoid this, periodically clean and flush the system.

According to the manufacturer's recommendation, the crankcase ventilation system should be cleaned every 60 thousand kilometers.

Before each oil change, clean the crankcase ventilation system.

You will need: 8" wrench, Phillips screwdriver, needle nose pliers.

1. Remove the decorative engine cover (see “Removing and installing the decorative engine cover”).

2. Remove the air filter (see “Removing and installing the air filter”).

| 2170 (Lada Priora) |

| AudiBMWCheryChevroletCitroenDaewooFordHondaHyundaiInfinitiIsuzuJeepKIALexusMazdaMercedes-BenzMitsubishiNissanOpelPeugeotRenaultSaabSkodaSubaruSuzukiToyotaVolvoVolvo |

SIGNS OF OIL RUTTER.

There are not many of them. In a carburetor engine, these may be leaks of lubricant inside the air filter housing and significant traces of oil on the filter element itself.

As for injection engines, the problem manifests itself in the form of deposits on the throttle body and the internal surfaces of the intake manifold. In this case, there may be a drop in engine power and an increase in fuel consumption.

Cleaning the crankcase ventilation system of the VAZ-2170

- Round Nose Pliers

- Small Phillips screwdriver

- 8 mm spanner

Spare parts and consumables:

Over time, tarry deposits of crankcase gases accumulate in the crankcase ventilation system, making it difficult for these gases to be vented into the engine cylinders for combustion. Because of this, the gas pressure inside the engine increases and oil flows out of the seals. To avoid this, periodically clean and flush the system.

According to the manufacturer's recommendation, clean the crankcase ventilation system every 60 thousand km

Before each oil change, clean the crankcase ventilation system.

1. Remove the decorative engine cover (see “Removing and installing the decorative engine cover”).

2. Remove the air filter (see “Removing and installing the air filter”).

3. Loosen the clamp.

4. Disconnect the large crankcase ventilation system outlet hose from the air supply hose.

5. Loosen the clamp.

6. Disconnect the air inlet hose from the throttle body.

7. Loosen the clamp, disconnect the large pipe of the crankcase ventilation system from the cylinder head cover and remove it.

8. Similarly, remove the small crankcase ventilation pipe by disconnecting it from the starter assembly and cylinder head cover.

9. Loosen the clamp.

10. Remove the ventilation system supply hose by disconnecting it from the manifold cover fitting.

11. Similarly with the cylinder block fitting.

12. Rinse the pipes with gasoline or kerosene, blow with compressed air and dry. Clean openings of fittings and pipe fittings.

13. Remove the cylinder head cover (see “Replacing the cylinder head cover gasket”).

14. Using an 8 mm wrench, remove the six cage bolts from inside the head cover.

15. Remove the separator.

16. Use pliers to tighten the separator line clamps.

17. Remove the oil deflector from the oil separator.

19. Take it off. Replace a badly twisted or missing snap ring with a new one.

Before installing the cylinder head cover, clean (old sealant) and degrease the mating surfaces of the cylinder head and cylinder head cover. Apply a thin layer of sealant to the cylinder head mounting surface.

20. Apply a thin layer of sealant to the cylinder head mounting surface.

21. Install hoses and parts in the reverse order of removal.

Article missing:

- High-quality photo of the repair

- Tool image

,. -. ,. — 60 .

: eight, , . 12.

… 2… 4… 6. eighteleven. 12,… 13... 10… 12.. 14… 16(0) (6954) sirob | 2010 27

3. Loosen the clamp...

4 . and disconnect the large crankcase ventilation system pipe from the air supply pipe.

5. Loosen the clamp...

6... and disconnect the air supply hose from the throttle valve.

7. Loosen the clamp, disconnect the large pipe of the crankcase ventilation system from the cylinder head cover and remove it.

8. Similarly, remove the small crankcase ventilation pipe by disconnecting it from the starter assembly and cylinder head cover.

9. Loosen the clamp...

10 . and remove the supply pipe of the ventilation system by disconnecting it from the cylinder head cover pipe...

eleven . as well as from the cylinder block fitting.

12. Rinse the pipes with gasoline or kerosene, blow with compressed air and dry. Clean openings of fittings and pipe fittings.

13. Remove the cylinder head cover (see Replacing the cylinder head cover gasket).

14. Remove the six bolts holding the spacer in place from inside the head cover...

15 . and remove the separator.

16. Using pliers, tighten the separator line clamps...

17. and remove the oil deflector from the oil separator.

18. Using a screwdriver, pry out the rubber O-ring.

19 and remove it. Replace a badly twisted or missing snap ring with a new one.

Before installing the cylinder head cover, clean (old sealant) and degrease the mating surfaces of the cylinder head and cylinder head cover. Apply a thin layer of sealant to the cylinder head mounting surface.

20. Install hoses and parts in the reverse order of removal.

Download information from the page

Article: 2112-1014056, additional articles: 2112-1014056Р

Order code: 006580

- Buy with this product

- show more

Passenger cars / VAZ / VAZ-21101 drawing

» href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2110-10/sistema_smazki_i_ventilyacii-105/#part40486″>Lower hoseEngine / Lubrication and ventilation system

- Passenger cars / VAZ / VAZ-21121 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2112-12/sistema_smazki_i_ventilyacii-105/#part49102″>Lower hoseEngine / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Priora 21701 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_priora_2170-480/sistema_smazki_i_ventilyacii-77/#part1578912″>Lower hoseEngine / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Kalina 2192, 21941 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_kalina_2192__2194-1646/sistema_smazki_i_ventilyacii-56/#part3652972″>Lower hoseLubricating system / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Kalina 21941 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_kalina_2194-1886/a501__sistema_smazki_i_ventilyacii-130/#part4210486″>Lower hose Lubrication system / A501. Lubrication and ventilation system

- Passenger cars / VAZ / Lada Granta 21901 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_granta_2190-1893/a501__sistema_smazki_i_ventilyacii-122/#part4242903″>Lower hoseLubricating system / A501. Lubrication and ventilation system

- Passenger cars / VAZ / VAZ-21111 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2111-11/sistema_smazki_i_ventilyacii-105/#part44794″>Lower hoseEngine / Lubrication and ventilation system

- Passenger cars / VAZ / VAZ-2110, 2111, 21121 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2110__2111__2112-415/sistema_smazki_i_ventilyacii-120/#part1302912″>Lower hoseEngine / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Kalina 1119 Sport1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_kalina_1119_sport-1556/sistema_smazki_i_ventilyacii-33/#part3438987″>Lower hoseLubricating system / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Priora 21728 Coupe1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_priora_21728_coupe-1878/sistema_smazki_i_ventilyacii-80/#part4190138″>Hose lower Lubrication system / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Priora 2170 FL1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_priora_2170__fl-1889/a501__sistema_smazki_i_ventilyacii-146/#part4224085″>Lower hoseLubricating system / A501. Lubrication and ventilation system

- Passenger cars / VAZ / Lada Vesta1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_vesta-1883/141010__separator-148/#part4202781″>Crankcase VENTILATION HOSEAdsorber, separator / 141010. Separator

There are no reviews for this product yet.

Today, in the next article in the series “Crystal VAZs or typical breakdowns of domestic cars,” we will talk about the latest developments of the Volzhsky Automobile Plant: Lada Grante and Lada Largus. Let's talk about the history of the creation of these models, as well as their characteristic malfunctions.

How to replace the pump

Replacing a part will require you to spend a lot of time, so set aside a few free hours, say, on a weekend. The work consists of several main stages. Let's look at the procedure step by step.

- Basic procedures: disconnecting the negative battery, draining the oil.

- Removing the timing belt.

- Disconnecting the wiring harness from the crankshaft position sensor, removing the pulley.

- Removing the key and removing the protection.

- Twisting the fasteners and removing the clutch housing cover.

- Removing the crankcase.

- Removing the crankcase gasket.

- Removing the oil receiver.

- Twisting the oil pump fasteners.

That's all, actually. Assembly work is carried out in reverse order. During the work, try to replace consumables. First of all, we are talking about the crankcase gasket. Install the new part and seal it, having first cleaned the mating surface of dirt and old sealant. At the same time, you can clean the oil receiver. For this you will need white spirit. If the part cannot be cleaned, it will have to be replaced.

This must be done, as there is a risk of ignition of the lubricant. The next element to be inspected and replaced is the oil receiver seal. If the ring breaks or loses its elasticity, you need to install a new part.

see also

- Useful improvements to the priors

- Improvement of the Priora interior

- Refinement of piston prior

- Do-it-yourself modification of Priors hatchback

- Priora hub diameter

How to install fender liners on Priora- Priora drives jerkily reason

- Priora does not move at low speeds

- Priora water pump 16 valves

- How much oil is in a Priors box with 16 valves?

- Removing the valve cover of Priora 16 valves

Symptoms of a Stuck PCV

- Engine misfires at idle

- Lean air-fuel mixture

- Presence of engine oil in PCV valve or hose

- Increased oil consumption

- Hard engine start

- Rough, unstable engine operation at idle

Additionally, a stuck PCV valve can cause a check engine light due to increased air flow. And the diagnostic computer may mistakenly show this error due to the mass air flow sensor or oxygen sensor, making it difficult for you to identify the real source of the problem.

Typical breakdowns

There are only two main oil pump malfunctions.

In one case, repair is possible, but in another it is much easier to remove the part, throw it away and install a new one. Typical problems are:

- clogging of the oil receiver. In this case, it is necessary to drain the liquid from the crankcase, remove the pan, oil receiver and rinse them completely;

- mechanical damage to the pump or any of its components. The valve responsible for maintaining pressure in the system especially often fails. In this case, repair is impractical; it is better to replace it.

An alarm signal is a drop in oil pressure. In this case, it is recommended to temporarily stop operating the vehicle and thoroughly diagnose the entire system.