April 20, 2017 Lada.Online 185 946 65

If, while operating a LADA car, you notice that during load (when the air conditioner is running, the heating is on, etc.) in a traffic jam, the engine begins to operate unstably (troits, pulls poorly, etc.), perhaps the reason lies in the ventilation system crankcase The article proposes to solve the problem by installing a PCV valve from a foreign car.

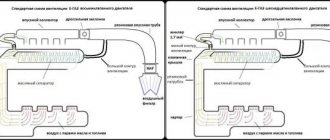

Diagram of the standard crankcase ventilation system

The crankcase ventilation system of VAZ engines consists of two circuits that operate at different load modes and speeds:

- The small ventilation circuit is connected to the valve cover and the intake manifold (behind the throttle body). This connection diagram provides intensive crankcase ventilation due to the vacuum that occurs in the intake manifold when the throttle is closed. To avoid an effect such as hyperventilation, the cross-section of the small circuit is limited by a jet in the cable throttle body with a diameter of 1.7 millimeters. This circuit operates in the region of 800-1500 rpm.

- A large ventilation circuit is connected to the valve cover and the air pipe (in the pre-throttle space). This scheme provides intensive crankcase ventilation at high speeds. The cross section of the large contour is 16-18 millimeters

Examples demonstrating the shortcomings of the standard crankcase ventilation system:

- A car is going down a hill with the gear in gear. In this mode, the engine operates at higher speeds with a reduced load. A high vacuum is created in the crankcase, and a large ventilation circuit is connected, in which there are no control valves. Since both circuits are connected to one volume of the oil trap, a strong vacuum in the crankcase will draw a fresh portion of air bypassing the throttle. The mass air flow sensor will show increased air flow, and the ECU will try to close the throttle. Having realized that this is not possible (it is already closed), the lean mixture will be corrected by increasing the fuel supply (fuel consumption will increase). As a result, the entire internal volume of the engine will work as a parallel receiver of very significant volume, connected to the intake, bypassing the throttle. It is this volume that will interfere with the formation of a high-quality mixture.

- A car in a traffic jam drives under tension with additional consumers (for example, the air conditioner is on). The compressor clutch is connected, the load increases abruptly. The engine does not have enough air, it begins to pull it from the crankcase, bypassing the throttle. But the ECU is also aware of the clutch engagement and also supplies more air by opening the throttle. The vacuum drops sharply, the vacuum brake booster (VBR) does not have enough strength to hold the car. Leap forward. The ECU sees an increase in oxygen and closes the throttle. A sharp increase in vacuum, VUT seizes. The car jerks, the transmission hits. And so on ad infinitum.

As a result, in both cases, when the engine is running, speed jumps occur and the engine choke under the load. Jerking and vibration are possible on manual transmissions, automatic transmissions and automatic transmissions. To eliminate these shortcomings, it is proposed to modify the design according to one of the presented schemes.

Difficult to eliminate causes of oil leakage from the gearbox

To eliminate an oil leak, you will have to spend time and sweat. The reasons require the participation of car repair specialists, but if you set a goal, you can cope without them.

Replacing oil seals.

If the obvious causes of oil leakage have been eliminated, but leaks continue to appear with enviable frequency, the seals are examined.

Special rubber seal in a metal frame. Serves to prevent leaks and oil on the moving elements of the engine and gearbox.

Long-term use of the oil seal wears out the rubber base. Oil pressure does not hold. If the oil seals have been replaced recently, you need to think about the quality of the oil used.

The replacement procedure is as follows:

- oil is drained;

- the wheel bearing mount is dismantled;

- the bolts securing the ball joint are unscrewed;

- the steering knuckle is retracted;

- the axle shaft is dismantled;

- remove the oil seal using a regular screwdriver;

- Before installation, the oil seal is lubricated with oil;

- Installation of the cuff is carried out by lightly tapping the hammer through the mandrels.

Schemes for upgrading the crankcase ventilation system

Schemes for modifying the crankcase ventilation system, as well as a description, are provided by IgorRV.

For LADA cars with manual transmission and AMT (“robot”), scheme No. 1 “Crankcase ventilation scheme with PCV valve for E-GAS and cable throttle” is suitable:

It is necessary to install a PCV valve (article 94580183, price about 400 rubles) from a foreign car into the small crankcase ventilation circuit. When connecting the PCV valve to a small circuit on an E-GAS, use a new hose (petrol-oil-resistant 8 mm without fabric reinforcement). On a cable choke, connect to the receiver, not to the choke.

As a result, the valve will shut off the circuits in transient modes, which will allow:

- Accept the load without jerking or dropping engine speed (for example, when the compressor is running, heated windows, seats, etc.).

- Reduce vibration load at idle

- Increase traction from the bottom (noted by owners of automatic transmission with VAZ-21126 engine, manual transmission with VAZ-21227, 21126 and 11186 and AMT with VAZ-21127).

- Get a sharper response to the gas pedal and faster shifts (on AMT). Perhaps due to the fact that the valve does not allow the engine to slow down, maintaining a more optimal switching algorithm.

- Reduce oil consumption through ventilation.

The valve replacement period is 40,000 km.

For LADA cars with automatic transmission (Jatco) and AMT (“robot”), scheme No. 2 is suitable:

Description of scheme No. 2: The pressure reducing valve is connected in series to a large ventilation circle. Thus, it regulates the flow of crankcase gases at high speeds and during transient processes. This allows:

- Exercise full control over the flow of crankcase gases between the small and large circuits.

- Improve engine operating mode.

- Reduce vibration load.

- Reduce oil release into ventilation.

For LADA cars with automatic transmission (Jatco) and AMT (“robot”), scheme No. 3 is suitable:

Description of scheme No. 3: To improve the operation of the braking system and facilitate the process of holding the car on the brakes in mode “D”, an “Ejection Pump” was used. Due to the flow of crankcase gases from the small circuit, the vacuum in the tube leading to the vacuum booster increases. This happens at low speeds, which is very helpful when driving in traffic jams. Keeping your foot on the brake all the time is not very easy, but this pump makes the task easier.

- Getting rid of vibrations, failures, transmission shocks.

- The engine begins to operate more calmly and softly.

- The force on the brake pedal becomes less.

- The air conditioner turns on almost imperceptibly.

Required:

- ejection pump (article 10793 VIKA, price 546 rubles);

- pressure reducing valve (article 1117701500 JP GROUP, 422 rubles);

- PCV valve (article 94580183 GENERAL MOTORS, 400 rubles);

- clamps (about 10 pieces, 600 rubles);

- thin, petrol-resistant 8 mm hose 50 cm (100 rubles);

- standard ventilation pipe.

Installing the PCV valve on Granta

:

Installing the PCV valve on Vesta:

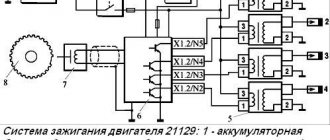

By the way, there are other ways to modify the crankcase ventilation system. Are you ready for such modernizations? Let us remind you that modification of the ignition system (installation of capacitor ignition coils in the harness) is also common among owners of LADA cars.

Keywords: lada xray engine | Lada Vesta engine | Lada Largus engine | Lada Granta engine | Lada Kalina engine | Lada Priora engine | Niva engine | universal article

0 0 0 0 0 0

Share on social networks:

Article: 2112-1014056, additional articles: 2112-1014056Р

Order code: 006580

- Buy with this product

- show more

- Passenger cars / VAZ / VAZ-21111 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2111-11/sistema_smazki_i_ventilyacii-105/#part44794″>Lower hoseEngine / Lubrication and ventilation system

- Passenger cars / VAZ / VAZ-2110, 2111, 21121 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2110__2111__2112-415/sistema_smazki_i_ventilyacii-120/#part1302912″>Lower hoseEngine / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Kalina 1119 Sport1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_kalina_1119_sport-1556/sistema_smazki_i_ventilyacii-33/#part3438987″>Lower hoseLubricating system / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Priora 21728 Coupe1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_priora_21728_coupe-1878/sistema_smazki_i_ventilyacii-80/#part4190138″>Hose lower Lubrication system / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Priora 2170 FL1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_priora_2170__fl-1889/a501__sistema_smazki_i_ventilyacii-146/#part4224085″>Lower hoseLubricating system / A501. Lubrication and ventilation system

- Passenger cars / VAZ / Lada Vesta1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_vesta-1883/141010__separator-148/#part4202781″>Crankcase VENTILATION HOSEAdsorber, separator / 141010. Separator

- Passenger cars / VAZ / VAZ-21101 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2110-10/sistema_smazki_i_ventilyacii-105/#part40486″>Lower hoseEngine / Lubrication and ventilation system

- Passenger cars / VAZ / VAZ-21121 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2112-12/sistema_smazki_i_ventilyacii-105/#part49102″>Lower hoseEngine / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Priora 21701 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_priora_2170-480/sistema_smazki_i_ventilyacii-77/#part1578912″>Lower hoseEngine / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Kalina 2192, 21941 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_kalina_2192__2194-1646/sistema_smazki_i_ventilyacii-56/#part3652972″>Lower hoseLubricating system / Lubrication and ventilation system

- Passenger cars / VAZ / Lada Kalina 21941 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_kalina_2194-1886/a501__sistema_smazki_i_ventilyacii-130/#part4210486″>Lower hose Lubrication system / A501. Lubrication and ventilation system

- Passenger cars / VAZ / Lada Granta 21901 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_granta_2190-1893/a501__sistema_smazki_i_ventilyacii-122/#part4242903″>Lower hoseLubricating system / A501. Lubrication and ventilation system

- There are no reviews for this product yet.

Today, in the next article in the series “Crystal VAZs or typical breakdowns of domestic cars,” we will talk about the latest developments of the Volzhsky Automobile Plant: Lada Grante and Lada Largus. Let's talk about the history of the creation of these models, as well as their characteristic malfunctions.

Why is there smoke coming from the breather?

There can be only one malfunction of the breather: it began to poorly pass accumulated gases, comparing the pressure inside the engine with atmospheric pressure. But the smoke coming from it can say a lot:

- The cylinder oil scraper rings were stuck or worn out. Simple decarbonization using traditional methods or special chemicals will not help here, so you will have to disassemble the engine.

- Likewise, if one/several exhaust valves burn out. A simple compression test will help determine this.

- Oil seals. Just replace them when it's time or they show signs of increased wear.

- The shaft seals, which allowed oil vapors to pass through, were worn out. Change them without hesitation, preferably without shelving them.

- The oil in the engine is old and needs replacing for a long time. No comments: as practice shows, repairing the “heart” of a car is tens of times more expensive than replacing it.

- White smoke on a hot engine - coolant enters the lubrication system. You'll have to look for where exactly the leak is.

- Oil overflow. In an internal combustion engine, it is just as dangerous as underfilling: engine wear/fuel consumption increases significantly, so check its level with a dipstick on a level surface when the engine is well warmed up. Then you will see how well the technicians at the service station (or you yourself) performed its replacement/topping up.

- The oil is of poor quality/not suitable for the car/counterfeit. There is only one way out - replace it. Likewise, if you filled up with fuel at an unknown gas station: just don’t do it again.

- Finally, the breather itself clogged from time to time, not working at 100%. Simple cleaning and preventive maintenance will eliminate this.

Breather device

Typically, the internal structure of the breather is very simple. Let's look at it using the example of a breather for a gearbox/axle.

- External breather housing. It is made of metal, so it cannot be damaged while driving.

- Pressure spring. Thanks to it, the mechanism does not need an electrical/mechanical drive, everything is autonomous.

- Rubber gasket. It is this that ensures tightness when excess pressure is not released.

- Lock nut. The simplest method of fixation: although in other models there are a variety of options.

- The breather body itself. The through hole allows the unit to “breathe”, relieving excess pressure.

Although this breather is not used for engines, the principle is the same. An elementary module that you simply cannot do without.

What is an engine breather and why is it needed?

Everyone knows that the internal combustion engine, the same one that is installed under the hood of your car, does not run on gasoline, diesel or gas, but on their mixture with air. Moreover, it is air, which costs nothing (unlike fuel, for which we regularly pay a tidy sum at the gas station), that is required many times more. But in addition to the influx of clean air and the removal of exhaust gases through the exhaust pipe, parasitic gases are formed during the operation of the internal combustion engine.

A breather is nothing more than a breathing valve that constantly relieves excess pressure that forms inside the engine during operation. The need for this simple, relatively inexpensive part is difficult to overestimate.

Cleaning on VAZ 2101-VAZ 2107

Breeding

1. Remove the air filter housing from the car engine (for more details, see the article “Replacing the air filter housing”)

The note! Be sure to remove the flame arrester from the crankcase ventilation hose and wash it with kerosene in case of severe contamination.

2. Release the clamp by attaching the additional hose to the breathing cap (marked with a red arrow) and disconnect the additional hose. Continue unscrewing the main hose clamp (marked with the blue arrow) and remove it from the cover.

3. Remove the engine oil level sensor.

4. Unscrew the bolt securing the fan cover and remove the cover from the car engine.

5. Dampen a cloth with kerosene and wipe the inside of the oil separator.

The note! Be careful when wiping; Do not allow dirt to get inside the engine. If you are not comfortable cleaning dirt from the installed oil separator, remove it from the vehicle by unscrewing the lock nut (indicated by the red arrow). Place the removed oil separator in a prepared container with kerosene.

6. Clean the surface of the air filter from dirt by wiping it with a cloth soaked in kerosene.

The note! Remove the gasket from the filter housing and clean it of dirt.

Installation

This is done in the reverse order of removal.

The note! Replace broken or cracked gaskets with new ones. Make sure the metal shims are inserted into the air filter housing gasket (shown in photo).

READ Alarm Installation Map for VAZ 21214

Important! If a large amount of kerosene gets into the crankcase, change the engine oil! (Read more in the article “Changing Engine Oil”)

For beginners! Question: What does the oil separator look like? Answer: in the photo.

Welcome! The crankcase ventilation system is necessary to ensure that the atmosphere is not clogged and the exhaust gases are allowed to burn out again, this system has been implemented in many cars, from VAZ 2101 to cars such as Lada Priora, Lada Granta, etc., but when the engine is worn out, This system is removed by people themselves by removing all the PCV hoses, usually in a bottle or just outside, we will break it down in this article, so if your car has already been driven quite a lot, this article will be sent to you.

The note! We will look at cleaning the ventilation only on 16 valve engines, if you have 8 valves, then we will move on to the article: “Cleaning the crankcase ventilation on a VAZ 2114”, this engine is described in this article, you will need to clean the ventilation, crankcase 16 drain: pliers are not large , screwdrivers with different heads and all kinds of wrenches, in addition, you will need sealant for the cylinder head cover and a new gasket!

Breather repair and maintenance

Due to its low cost, as well as ease of removal/installation, breather repair almost always comes down to replacing it. But even forgetful car owners who carry out its maintenance from time to time will not need this, since there is simply nothing to break.

All its maintenance comes down to timely cleaning. It is enough to wipe the outside with a rag, and if the stains are old, you will have to use a knife, screwdriver or scraper.

Cleaning the inside is a little more difficult, but still very simple. The breather must be removed (it can be bolted or firmly seated “in tension”) and cleaned with a primitive cleaning rod, which can be made from a piece of wire. We do the same with the oil trap mesh: in rare cases, when it is very clogged, mechanical cleaning will not be enough. And then you need to burn it by pouring just a little gasoline, or soak it in aggressive chemicals for several hours.

Assembly, as is quite predictable, is in reverse order. Therefore, the entire process will not take much time and will not require special tools or skills.

However, this is best done during a seasonal oil change or when undergoing regular maintenance. On most cars with average mileage, it is enough to carry out this simple operation twice a year. But it is the engine breather that confirms the immutable truth: there are no small details in a car, especially a modern one.