I waited for this moment... I finally changed them... Probably around 90 thousand my support bearings (VBF) started to cover up again, I’ve already changed them 3 times, it’s always the same thing, water + dirt gets into the cage and they cover up, the spring starts to jam When turning the wheels, the steering wheel becomes heavier. There were thoughts of getting rid of the Vologda bearing design option and buying SS20 Supports, but their price is 3900-4200 rubles and I still didn’t dare. Then an acquaintance in Kalina decided to switch to Granto supports and bought Balakovo supports + bearings for such a set for only 890 rubles. I went to the website of the local “Lada Detail” and looked at whether they were in stock))) I went and bought 2 of them -5% discount = 1691 RUR

The difference from Anvis is very good, the support is adjacent to the glass with its entire plane, and not 3 points, and now there are no holes between the support and the glass. They seem to be made well and with high quality, the bearing included is the same one from Vologda. By the way, at 65 thousand I changed the supports to Anvis and they broke 1 stud, I decided to remove them, throw them out and install the factory ones, and in the end I drove about 100,000 km on the factory ones. In addition to the wedging of the springs, the supports made a terrible knock, every joint on the road was hammering into the body. I was able to start replacing them only a month later, almost after purchasing them, this time everything was already a bit complicated, everything was sour, rusty... I didn’t suffer much. I took off the old ones and put on new ones, nothing complicated, on one of the supports from the bottom a piece broke off from the bushing, apparently they had definitely come off a long time ago))) I checked the racks, they are in excellent working condition (I thought they would already die) oiled SAAZ. I collected everything, tested it now, there is no knocking, nothing, the steering wheel is light without jamming, it’s beautiful, all that remains is to do the alignment) otherwise I’ll soon have to wear felt boots for the winter. It seemed to me that the supports were softer than the Anvises and there are still ones, since the new ones I was infuriated by the right side, on recumbents for example - it was the right side that constantly hammered the rebound post, not the left one, right now there is no such problem, I don’t know what the support has to do with it, if This is a bug of Granto-racks, but the problem has gone away))) I hope they go away normally, thanks to everyone) The photos I was able to take, I took again on the tapik and every now and then the bastard is discharged at inappropriate moments. By the way, there are BRT and BMRT both in the recording, and while climbing D2 I found a recording about these supports and there a person advised not to install BRT, but to install BMRT. Front strut support for VAZ 2190 Granta with EUR with bearing (21900-2901031-10)

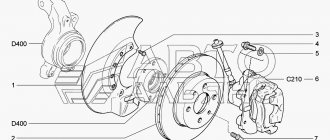

Hello, reader of the blog RtiIvaz.ru. Today we will look at the front suspension strut supports of the Lada Granta SEVI expert from the manufacturer AT-Holding LLC. First, let's look at a schematic representation of the Grant strut support to see where this element in question is located:

FIGURE 1 Grant front suspension strut

1. Upper rack support. 2. Spring cup. 3. Shock absorber rod. 4. Front strut spring. 5. Upper shock absorber rod mounting nut. 6. Support bearing. 7. Top cushion under the spring. 8. Front bumper. 9. Protective cover. As can be seen from Figure 1. Using the upper support, the front shock absorber strut is attached to the car body. These mounts support the weight of the entire front end of Grant's car. And at the same time they must also provide effective noise insulation. For this purpose, rubber cushions are built into them.

Next, look at the internal structure of the support:

FIGURE 2. Internal structure of the support

1. Rubber cushion. 2. Studs securing the support to the body. 3. Internal metal sleeve. 4. Bearing support. 5. Metal support body. What the support and packaging looks like is shown in the figure below. On the hood of the car there is a SEVI expert support for the Grant strut from the manufacturer AT-Holding LLC:

FIGURE 3. Upper support of the front strut of Lada Granta

Usually the inner metal sleeve (Fig. 2. item 3) is located exactly in the center of the support. And in the Lada Granta they use supports with an offset center. And they come in two types:

- With an offset of 6 millimeters, it is used when there is no EMUR. EMUR-Electric power steering.

- With an offset of 12 millimeters, it is used when the EMUR power steering is installed.

The advantage of the strut support from the Lada Grant is that the center is shifted back. This is good because in this case the stand stands at an angle and absorbs impacts more effectively. The caster angle is increased and the steering is better.

FIGURE 4. Visual representation of displacement

Caster angle is the angle at which the front strut is tilted along with the vehicle's movement. Caster is considered positive when the stance is tilted back and negative when the stance is tilted forward. The higher the caster, the better the car's handling. But you can’t increase this angle too much either. That’s why rubber cushions were made with an optimal offset of 6 mm and 12 mm.

FIGURE 5. Caster angle

- The surface to which the support bearing adjoins is covered with rubber, which improves the sound insulation of the body.

- The repair kit includes a high-quality support bearing.

- The rubberized surface improves shock and vibration absorption.

- New technologies used in the production of AT-Holding LLC, namely the chemical composition of rubber, make it possible to increase the resistance to destruction and reliability of the cushions.

- The reinforced frame reduces the possibility of body deformation at the points where the rubber cushions are attached.

- The offset allows you to increase the caster angle, thereby achieving sharpness and precision in car control. The response time to turning the steering wheel is significantly reduced.

In addition to the advantages, the manufacturer of supports SEVI expert LLC AT-Holding front strut provides a guarantee of up to 2 years.

I liked the SEVI Expert supports, the quality of their workmanship and the positive feedback on the forums of VAZ 2190 car owners. And 100 percent on the forums, the feedback about the SEVI Expert rubber cushions is only positive!

Replacing the front strut support on a Lada Grant on your own

The upper support bearing is an important element in the design of the Granta front strut. The “supports” are involved in the rotation of the front strut during a turn, and also absorb axial loads and provide rigidity to the mechanism.

The “support” itself is a housing of two cups, inside of which the bearing itself is located, consisting of a rubber separator with balls inside. It also contains gaskets (vibration and noise insulators). The listed elements, as well as the design of the front support, are presented in the photo.

overview of the SS20 suspension (front struts, springs, bearings).

: “SS20 suspension: briefly about the main thing”

Causes and signs of failure, diagnostics

The node takes a dynamic (variable) load, and failure, as well as replacement, is usually required for several reasons:

- Part wear, time to failure (service life);

- Accidents, frequent driving in potholes, aggressive driving style;

- Contamination of the support bearing from the inside, ingress of moisture and dust;

- Malfunction of suspension (shock absorbers, springs).

The design of the “support” and the front pillar is complex; the following elements can fail:

Attention: To decide which element needs to be replaced, you should disassemble the entire assembly, the diagram of which is presented below.

Diagnostics of support bearings

To diagnose a breakdown, do the following:

How to check support bearings

Preparatory measures for replacing the support bearing Do-it-yourself grants

Replacing the support bearing of the Lada Granda strut can be done in two ways.

- Removing the front strut and unscrewing the wheel alignment bolts.

- Removing the strut module along with the rotating mechanism and brake disc assembly without unscrewing the adjusting fasteners.

Both methods cannot be performed without removing the strut, but using the second method, which is described below, you can avoid another wheel alignment.

Preparation for repair

It is advisable to carry out the replacement in an inspection hole, so you will save time on the convenience of performing operations to remove/install the unit. The car is in first gear; to comply with safety regulations, use wheel chocks.

Tools for work

- Any jack.

- Large wrench to remove chassis bolts.

- A long 30mm wrench for unscrewing the hub nut.

- Clamps for tightening shock absorbers.

- Tool for removing tie rod ends.

- Hammer, chisel, core.

- Set of keys (22, 17, 13).

- "Ratchets" on 13, 17, 19.

- Hex key for unscrewing the rod nut.

- Special heads. "Eshki" E8 and E12.

- Large negative screwdriver.

- Pliers.

- Penetrating lubricant such as WD-40.

- Torque wrench for tightening the rod nut.

Required set of new parts

- Supports or individual support bearings, depending on the breakdown;

- Rubber gaskets (if you are only changing the bearing);

- Boot with tie rod cotter pin (if replacement is required).

Removing the front pillar

- Before raising the car on a jack, loosen the hub nut with a 30 mm wrench.

- Don’t forget to first straighten the jammed collar at the locknut.

- Next, we also loosen the wheel bolts, only then raise the front of the car.

- We remove the wheels and proceed to dismantling the brake caliper.

- Carefully pull out the stand from below. This completes the dismantling.

Disassembling the rack and replacing parts

- We place the mechanism on the table and attach the ties to the springs, as shown below.

- Lightly compress the spring (1.5-2 cm) and move on to the support nut. We unscrew it, if the rod turns, use a hexagon; there is a groove for it at the end.

Be sure to install the clamps in parallel, that is, with the edges on the same line.

Hot topics on DRIVE2:

- Now we remove the support and see what condition it is in inside.

- If only the bearing is faulty, we replace it, along with the rubber inserts.

- In 70% of cases, the entire support is replaced, so we install a new part. Reassembly is presented in the form of slides with a description.

Recommendations for repair and assembly

will help you make a replacement and speed up the process of repairing your “Granta”.

Replacing the front shock absorber strut support:

Replacing the support bearing on Grant:

- If the shock absorbers are oil, then the rod goes down to the bottom. Therefore, we assemble the mechanism quickly. It is easier with gas and combined models, since the rod only rises upward. In the case of an oil product, do not forget to pump them and remove air.

- If you are installing the original front mount, replace the factory metal washers on both sides of the damper. When installing “supports”, for example SS20, this is not required; they are included in the kit.

How to choose a support bearing for the Lada Granta

To choose and buy spare parts for the Lada Granta correctly, consult with auto mechanics or experienced car enthusiasts. The video provides an overview of journal bearing manufacturers. The products were assessed, a detailed inspection and quality check were carried out. We described in more detail about the selection of parts in the article “How to check support bearings.”

If you purchase a separate bearing, it is recommended to pay attention to:

The best manufacturers of journal bearings

No. Manufacturer, country Catalog number Price, rubles

| 1 | SKF, Sweden | D 35032 | 800 |

| 2 | VBF, Vologda | 11180-2902840 | 650 |

| 3 | SS20, Russia | SS10113 | 990 |

| 4 | CS 240, trialli | 2190-2902840 | 390 |

| 5 | Sevi Expert | 1118-2902840 | 450 |

| 6 | Original from AvtoVAZ | 11180-2902840-01 |

see also

Comments 50

I installed several washers; there probably aren’t thick ones like this in construction ones?

Two for each rack

What if I have a plaza stand and need it at all?

Hi, did you install bushings between the upper limit washer and the M14 nut? Which are included here in the list at the very bottom

Hi, it's not a bushing, it's just a thick washer. Of course I used it, it wouldn’t be possible without it. In stores building materials, 5 rubles per piece. It is only necessary if you have a rack 1118, not 2190. And since the grant support is slightly lower in height relative to the Kalinovskaya, there are not enough threads on the rod to completely tighten the nut

Cool. One of these days I’ll also do this kind of alteration...everything has already been bought. I’ve heard that after such an alteration many people put mustaches from VAZ 2110 and tips on the steering rack...haven’t heard of that?

So on Kalina 2 they have been installed from the factory since 2110, the Kalinovsky mustache showed itself badly, I bought myself a rail with the tenth mustache. But the 2110 rack does not fit, the fastenings are different, either viburnum or 2112. Structurally, the changes between them are small, the comb and worm are different, everything else is the same. The difference is in the price tag. I set myself with 2112 and have already reeled off 100,000, the main thing is to disassemble and lubricate it all before installation. Otherwise, at the factory they skimp on the lubricant, and then after 30,000 it starts knocking. By the way, for the chassis, for these 100,000, I only replaced the stabilizer struts and the support bearings at the 80th thousand, and so everything is alive. So I don’t believe those who say that the Grant chassis does not fit on Kalinov struts, everything is good. The only thing is, if you are a fan of landing, then look for Grant struts, because when you install the Grant kit on the Kalinov strut, the ground clearance increases. I like it better this way.

Damn, this is bad... 3000 km ago I bought viburnum struts for 6000 rubles... I wouldn’t want to invest that much more

So on Kalina 2 they have been installed from the factory since 2110, the Kalinovsky mustache showed itself badly, I bought myself a rail with the tenth mustache. But the 2110 rack does not fit, the fastenings are different, either viburnum or 2112. Structurally, the changes between them are small, the comb and worm are different, everything else is the same. The difference is in the price tag. I set myself with 2112 and have already reeled off 100,000, the main thing is to disassemble and lubricate it all before installation. Otherwise, at the factory they skimp on the lubricant, and then after 30,000 it starts knocking. By the way, for the chassis, for these 100,000, I only replaced the stabilizer struts and the support bearings at the 80th thousand, and so everything is alive. So I don’t believe those who say that the Grant chassis does not fit on Kalinov struts, everything is good. The only thing is, if you are a fan of landing, then look for Grant struts, because when you install the Grant kit on the Kalinov strut, the ground clearance increases. I like it better this way.

I would have made it even lower, on the contrary... I don’t like the high one... I got my brother’s grant and his old supports for free. They’re whole...—I’ll install 12mm and then we’ll see

If you hang the car on a lift, you won’t be able to turn the steering wheel (the steering ends touch the window). When the car is on wheels it’s normal. I found the parameters of the racks (only the housings for now) - 1119 and 2190 are different. Today I’ll redo it back, I’ll take a picture of everything and post it so as not to make a fuss.

To all readers and dreamers, like me, about such a modification, I want to tell you what I encountered after reading such posts... When I bought all this and installed it, it turned out that this design is dangerous to ride on! Granta's support is several centimeters lower than Kalina's support, and accordingly the entire rack and everything that hangs on it drops these centimeters down in the lowest position (the car is jacked up or the wheel falls into the hole while driving). The steering rod also lowers, and in its lowest position it almost rests on the window of the apron in which it walks. And on the steering tip, the bolt for fixing it is located below the tip itself and when turning the steering wheel it clings to this window cut out in the body (there are no rubber seals)!

Read also: Low-bed trawl for transporting special equipment

In addition, when the stand goes down, the lever greatly changes its angle of inclination and clamps the boot of the outer grenade, which will saw through itself within two days maximum!

CONCLUSION: Kalina and Granta have the same body, but different struts. To install supports from Granta, you also need to install racks from Granta (they have different strokes and rod lengths).

PS I spent 2000 rubles. and spent the whole day fiddling around until 12 at night. I removed the rack three times and thought about how to modify and solve the problem... NO FUCK! And I was only fiddling with one side (there wasn’t enough time for the second side ) Tomorrow I will remove the Grantovskaya support and return the Kalinovskaya one. You can imagine how much pleasure all this gave me I’ll post photos later...

I've been using these supports for over a year, I've driven 60,000 miles, no problems. I gave it to my father before, no problems either. Nothing gets stuck, nothing gets blocked. Analyze all the posts dedicated to this modification and you won’t find such problems. The stand remains at the same level as on the drain, only the rod goes down two centimeters, and the upward stroke of the stand increases, but not critically; if it gets into a hole, the rod still does not open completely, in the lower position due to the installation of a bumper from the vases 2110, the rod does not reach the stop. So I don’t know what kind of problems you have there, everything is fine for me, my father has been riding on such a system for two years, on his viburnum there was an experiment. Which didn’t fail, unfortunately, during the first rework there were not big problems, there is a link in the post, but not as dramatic as yours.

I'll get better, castor is not 1.5 degrees but 1 g 50 min)))

Thanks for the info. I switched to granto supports and did everything on the list. It's time to change the factory struts. The mileage is 140,000, the left strut exploded in the cold during the next jump on a policeman))) the oil just came out like a fountain. I installed DEMFI comfort grant struts, my own barrel springs, Sevi-expert supports 12 mm offset, new bearings from Vologda. I arrived an hour ago from having the wheel alignment adjusted. Until I noticed a miracle))) castor is now 1.5 degrees, I don’t know how it was. Those who want to switch, first of all, ask for the availability of the cheapest part, namely 4 washers, for some reason there is a shortage.

And if the spring is barrel-shaped, are these Prior glasses needed?

Of course, in any case, the glass is placed in the Priorovsky type, only the cushion on the spring has its own for each type of spring. Under a cone-shaped pillow with a protrusion, under a barrel-shaped flat

Damn, I already bought a ssss20 pillow, it has a step and barrel springs, won’t it fit?

I described it in detail, it won’t work. The support bearing will become misaligned, as in the 9th photo.

12. Telescopic stand GRANT (or equivalent).

The sleeve directly under the nut.

When attaching the support to the body, it is necessary to correctly orient it relative to the direction of movement of the car, guided by the arrows on the rubber element.

Lada Granta support bearing replacement

Domestic car owners quite often have to take measures to repair the chassis of the Lada Grant. The reasons that prompt repair procedures are the same well-known knocking, creaking and other upsetting factors. “As soon as I grabbed the levers, the racks made themselves felt”! This is not surprising, since most domestic roads leave much to be desired in terms of quality.

The chassis of the Lada Grant is sensitive to potholes and other irregularities, which gradually affects its condition in a far from good way. Blaming the roads is a valid idea, but not entirely fair. Here we need to remember the valiant designers of VAZ, who are aware of the state of the roads, but also continue to develop suspensions without taking into account the possibility of sufficiently strengthening the structure. After all, this could not only have a positive effect on the overall resource of the car, but also sway a larger number of fans, and especially Lada Grant owners, towards the products of the domestic automotive industry.

Today we will talk about techniques for changing the support bearing in the popular and practical VAZ model Lada Granta.

What adds interest to the process is the fact that this is not a simple replacement of the support bearing, but a technology without dismantling the rack.

Only the front strut support bearing that has actually become unusable should be replaced. Read about methods for checking the condition of these rack elements here.

Those owners who have at least once been faced with the need to replace the support bearings of a LADA Granta will, with a significant sense of confidence and a squeal of exclamation, prove the need to remove the strut during this procedure. The very dismantling of struts with springs, of course, adds difficulties associated with the need for special devices, and takes up a much larger time resource. But laziness forces a person to bypass difficulties and develop progress in order to ease his lot.

The illustrations in the photo report show in detail the process of changing the support bearing of the front strut without dismantling the struts in a LADA Granta.

To work you will need to stock up:

- a key set with the following sizes: “13”, “14”, as well as “17” and “22”;

- a hexagon that allows you to keep the rod itself from turning;

- two jacks and supports;

- with special ties of coils of spring liners.

Step-by-step technology for replacing the support bearing without removing the strut

- After hanging the wheel with a jack, remove it and put it aside.

- We dismantle the stabilizer strut in order to prevent restriction of the free movement of the rack assembly.

- Armed with a hexagon, insert it into the recess at the end of the rod and hold it while unscrewing the central nut, which directly fixes the rod itself.

- We roll the jack under the center of the ball pin and raise the stand until the load is removed from the auxiliary jack.

Grant headlight adjustment

Door sills for Lada Granta

How to remove door trim on Grant

Let's sum it up

As we have seen, in order to replace the support bearing on a Lada Granta car, it is not at all necessary to resort to a lengthy procedure involving removing the strut. You just need to use your imagination or find on the Internet the “life hack” indicated in our material for replacing the designated part, which does not involve dismantling the shock absorber strut. This approach will reduce the influence of the time factor on the process itself and will require a significantly smaller set of tools.

Causes of bearing failure

The main cause of support bearing failure is dust and water, which inevitably penetrate inside. The lack of lubrication does not have the best effect. Sharp blows to the rack will not add to the service life. It is worth taking into account the quality of roads, because they have a direct impact on the natural wear of the support bearing. That is why, with us, a part can wear out faster than its manufacturer claims.

Dirt and sand are some of the hardest impacts on a bearing. We remember that a journal bearing is a type of rolling bearing, and it does not have any protection mechanisms against harmful factors. Driving at high speeds and harsh brakes, especially on bad roads, also do not add to the service life of the part in question. However, not only the bearing itself suffers from this, but also all other suspension elements as a whole will soon require repair.

How to change the support bearings of a Lada Granta ⋆ I Love My Lada

Support bearings have a certain resource, which is quite difficult to predict. It all depends on their quality and operating conditions. Replacing the front strut supports on Lada Granta (VAZ 2190, 2191) and Kalina 2 (VAZ 2192, 2194) without removing them from the car will save a lot of time, money and allow you to check the condition of the front suspension.

Front support bearings for Lada Granta. When to change

The service life of the front support bearings for the Lada Grant is even approximately difficult to calculate. A trained ear will immediately detect tapping sounds when driving over uneven surfaces. The original Grant support bearings of the front struts are not particularly reliable, since there are complaints about both the materials and the design of the standard bearing.

Factory standard support bearing for Granta and Kalina 2 assembled

On average, the front strut supports on a Grant have to be changed after 50-60 thousand mileage. Sometimes it is possible to reach 75-80 thousand if used on smooth roads.

Completely worn strut support after 55 thousand mileage

A worn front strut bearing knocks ungodly, and if worn severely, it can cause a broken support cup if the driver has poor hearing or strong nerves. Also, the wear of the support cannot but affect the car’s handling and the behavior of the front end when cornering and when changing lanes. Therefore, there is no point in delaying replacement.

Worn strut mount bearings may seize Cracks in the strut mount rubber bushing

What are the best rack supports for Granta?

Grants support bearing diagram

The dynamic loads of the shock absorber rod are absorbed by a rubber damper. The more reliable it is, the longer the support will last. The spring rests against a support cup with a rubber-coated ball support bearing. However, different manufacturers offer different solutions for support.

Prop with modified caster

Thus, some supports are produced with reinforced bearings (balls of larger diameter), there are supports with a changed caster angle. To do this, the axis of the shock absorber strut is shifted by 6 or 12 mm, which ensures a change in the caster angle to 1°40′ or 2°45′, respectively.

In addition, supports are produced both for Lada Granta and Kalina 2 with electric power steering (article 21900-2902821-10), and for cars without electric power steering (article 21900-2902821-00).

Pillow bearing without support

Standard supports cost about $12 apiece, owner reviews about them are not the most encouraging, so most often you have to buy replacements for the original:

- Pillow bearing SS20 series Master, Gold, Drive, differ in caster angle and damper design. They last quite a long time and are easy to install. The price is about 26 dollars per piece.

- ANVIS 2190 Rack Mounts, $27/pair, 6mm offset.

How to quickly change the support bearings of struts on a Lada Granta

To replace the standard worn support bearings on the Lada Kalina 2 and Grant, according to theory, it is necessary to completely remove the front strut. This is due to a loss of time, a bunch of special tools, and not everyone has experience in this regard. The strut support can be replaced without removing the shock absorber from the car, quickly and with your own hands.

What is needed to replace supports. Tools and accessories

To work, we will need a standard set of heads and plumbing tools. However, here is the complete list:

- Tie for springs of any design.

- Two jacks or a jack and a stand.

- Hexagon to keep the shock absorber rod from turning.

- New strut mounts complete with bearings.

- Magic penetrating lubricant WD-40 or something similar.

- Litol-24 or other grease.

Changing the Grant strut supports with your own hands

The process of replacing support bearings without removing the struts from the Granta is as follows:

- We tear off the wheel bolts, hang the car on a jack, and remove the wheel.

- We unscrew the stabilizer link to untie the stabilizer link from the link.

- We tear off the shock absorber rod nut, holding the rod itself with a hexagon.

- We load the rack; to do this, we place a second jack or stand under it. We load until the entire load is transferred to the second jack (stand).

- We compress the spring using ties, but not completely.

- We remove the stand (second jack), the stand should go down.

- We completely unscrew the support bearing. Now you can remove it from inside the wheel arch.

- We carefully clean the support cup from dirt; if installing the SS20 support, remove the lower support cup, marked in the photo.

- We install a new support and carry out assembly in the reverse order.

Since it is possible, we check the condition of the tie rod ends and ball joints, paying special attention to the condition of the boots. If they are damaged (cracks, tears), it is advisable to replace them with new ones.

It started to die, the service department suggested. Which one would you recommend (preferably an article or a link)? Have you heard that you can just change the bearings or is it better to just take the entire support? What's dying there?!

When to change bearings in Kalina?

On average, the service life of supports (bearings) in a Lada Kalina is 50-100 thousand km, if you know which is better when purchasing them. Its value greatly depends on the operating conditions of the car. Based on this mileage, the owner is recommended to replace the supports (on both sides) without waiting for signs of malfunction to appear.

You cannot neglect replacing worn supports or bearings, as this is guaranteed to cause damage to shock absorbers or other components of the LADA Kalina chassis. How is replacement done without removing the rack?

Step-by-step technology for replacing the support bearing without removing the strut

- After hanging the wheel with a jack, remove it and put it aside.

- We dismantle the stabilizer strut in order to prevent restriction of the free movement of the rack assembly.

- Armed with a hexagon, insert it into the recess at the end of the rod and hold it while unscrewing the central nut, which directly fixes the rod itself.

- We roll the jack under the center of the ball pin and raise the stand until the load is removed from the auxiliary jack. The stand begins to show play.

- Using zip ties, we compress the spring coils. We simulate the compression amount to be insignificant, after which we unload the jack, which was used to lift the rack itself. The stand, following the jack lever, goes down.

- Now is the time to “separate” the support bearing from the rod. We carry out the manipulation - we move the rod down and remove the “support” from it through the void that appears under the body cup.

- We clean the support cup and its rubber seal from dirt accumulations. When installing the “SS-20” supports, there is no need for a lower cup.

- Next, we assemble, taking care to follow the reverse sequence to dismantling. We recommend lubricating the fasteners with graphite substance.

- Having completed the installation procedure, we check the tightening torques on all fastening units.

- We install the wheel in its original place and proceed to a similar procedure on the second side of the car.

Let's sum it up

As we have seen, in order to replace the support bearing on a Lada Granta car, it is not at all necessary to resort to a lengthy procedure involving removing the strut. You just need to use your imagination or find on the Internet the “life hack” indicated in our material for replacing the designated part, which does not involve dismantling the shock absorber strut. This approach will reduce the influence of the time factor on the process itself and will require a significantly smaller set of tools.