The Lada Kalina car is a fairly popular model, which has recently been actively in demand in the secondary market. In general, the car is quite simple and reliable, but there are some “childhood diseases”.

In the case of this car, it was the Kalina stove and the cooling system as a whole that turned out to be not entirely finalized. For this reason, owners are often faced with the fact that the engine is warmed up, but the stove on Kalina blows cold or slightly warm air, the engine itself overheats, antifreeze leaks appear, etc.

Moreover, such problems can be eliminated at minimal cost. The main thing is to take into account the nuances and scope of modernization work in advance. Next, we will look at what to do if the Kalina heater does not work well, the engine cooling system (ECS) becomes airy, overheating occurs, etc.

The main causes of malfunction of the Kalina cooling system

As mentioned above, the engine cooling system on Kalina has certain shortcomings that can be eliminated. In fact, the Kalina 1 cooling system turned out to be the most problematic, although there are also complaints about the Kalina 2 SOD.

In any case, if there is overheating, airing of the system or the Lada Kalina stove does not heat, modification of this system is simply necessary. At the same time, you should not immediately change the Lada Kalina thermostat to a “hotter” one when the stove is cold, cut in fittings and “tees” for quick modification of the CO itself, etc., without understanding all the issues.

The fact is that the VAZ-1118 can experience both general malfunctions that are common to all cars, and problems of an individual nature. First of all, among such “diseases” one can highlight frequent airing of the engine cooling system. The result of air ingress is a clear deterioration in the efficiency of the system, as well as poor operation of the stove.

Owners note the following signs of air in the cooling system:

- the stove does not blow warm air at idle, low and even medium speeds;

- the motor overheats, although the temperature gauge shows normal;

- there is a feeling of “emptiness” in the pipes, there is no dense filling;

As a rule, there are several reasons for the formation of an air lock, starting from poor tightness in the area of connection of the pipes and ending with problems with the cooling radiator or heater radiator. At the same time, many people often overlook the expansion tank cap.

Please note that on Kalina this is a weak link, the valve mechanism of the expansion tank cap is not reliable, sticking of the “suction” valve causes airing, and malfunctions of the excess pressure relief valve cause depressurization of the radiators. Of course, it is better to change the cover.

Even at the initial stage, you should know how to ventilate the Kalina cooling system. If the throttle drive is mechanical, with the engine warm, loosen the clamp on the throttle assembly heating fitting. On versions with an electronic gas pedal, it is necessary to unscrew the filler plug and also remove the upper thin hose from the thermostat, after first removing the air filter housing.

Next, you need to wait until the antifreeze appears and put the tube in place. Next, you need to warm up the car until the thermostat opens, and then repeat the steps described above a couple more times.

In the event that the problem cannot be solved by deaerating and replacing the cover, the system needs a complete diagnosis. If, as part of the diagnostics, no obvious problems are identified, then revision will be required.

Traditional Troubleshooting Methods

To solve the problem of airing, you should open the expansion tank, start the engine, press the gas pedal several times until the sensor arrow reaches the red zone. If the fan turns on, you need to squeeze the gas all the way several times and turn off the ignition. If this method is ineffective, the following procedure is used. The plastic motor protection is removed, the clamp is lowered and one of the fitting tubes is dismantled. The expansion tank cap is opened and the system is purged until coolant begins to pour out of the removed tube.

A standard modification to the cooling system involves installing a new 6-hole thermostat, coolant filter and heater valve. To maximize coolant flow and minimize the risk of overheating, you will need to install an additional pump.

Engine cooling system: SOD Kalina and modification

Let us note right away that correct modification begins with the fact that it is necessary to slightly change the distribution of antifreeze flows in the cooling system of the VAZ-1118 Kalina. This will reduce the intensity of airing due to the jamming of the compensation valve of the expansion tank cap.

Please note that simply removing the valve from the cover, as many suggest, is strongly not recommended, as the engine may overheat. It would be better to lower the fan switch-on temperature in the firmware to 98 degrees.

Another method is to embed an adapter into the radiator inlet pipe where the TM-108 sensor from a VAZ 2109 is installed, which is also not recommended. Although these methods are often discussed on specialized forums, they are offered by some car owners and garage specialists, experienced craftsmen still advise going the other way. A more correct method involves upgrading the cooling system on Kalina with both a mechanical throttle and an electronic one.

In general terms, you need to do the following:

- you need to drain the coolant, and then put a plug in the pipe that connects the large cooling circle and the expansion tank;

- then the free fitting is connected to the lower heater hose through a tee. The VAZ 2110 tee is suitable for these purposes;

- the next step is to plug the distant hose (thin outlet hose) designed to heat the throttle assembly;

- then the released fitting must be connected through a suitable tube to the expansion tank. To do this, you need to cut another “nipple” into the upper cavity. You can also connect via a tee to connect to a thin input;

- then you should fill in the coolant, a little higher than that, start the engine and warm up the unit until the fan turns on. The final stage will be to de-air the system and adjust the level of antifreeze or antifreeze.

This modernization allows for steam removal through a small circle, and aired liquid can be collected at the highest point of the cooling system. By the way, as for the version with an electronic gas pedal, in this case the thin thermostat fitting is connected to the top of the expansion tank.

Again, you can connect through a tee or drill in an additional fitting. In this case, the standard tube from the thermostat must be plugged. Next, you need to disconnect and plug the lower hose of the expansion tank of the cooling system, then connect an additional line from the tee. In turn, the tee cuts into the heater return.

We also recommend reading the article on how to replace the Lada Kalina alternator belt tensioner with your own hands. From this article you will learn how to check the belt tensioner of the Kalina generator, as well as how to replace the belt and generator belt tensioner on Kalina with your own hands.

The result of such actions will be active de-airing of the cooling system, the stove will heat normally at different speeds, and the engine temperature will always remain at a normal level, regardless of the mode and load on the engine.

At the same time, it is quite obvious that if the thermostat on the Lada Kalina is working properly, it is not necessary to change it. In other words, it is not the cause of overheating or a cold stove. In turn, a more comprehensive improvement of the cooling system of the Lada Kalina allows us to solve a number of problems.

How to check the operation of the Lada Kalina stove

We carry out all actions with the engine running. Before checking the heater, study the diagram and structure of the Lada Kalina stove.

Checking the ventilation and heating system fan:

- We set the air temperature regulator knob on the control unit to the extreme position of the blue sector.

- We alternately switch the fan speed knob, starting with the first speed and ending with the fourth.

- We check the intensity of the air flow coming from the air ducts. It should get stronger with each switch.

If the heater does not work on the Lada Kalina, check the integrity of fuse F5, as well as its power circuit. If the fan does not operate in all modes, or the air flow intensity does not change linearly, check the additional resistor and switch. If the air flow is weak, replace the cabin air filter.

What's the result?

Taking into account the above information, it becomes clear that if the stove does not heat or the engine overheats, the Kalina thermostat is not always the cause of the problems. Of course, when such symptoms appear on Kalina, the thermostat and coolant level should be checked first. However, it often happens that the thermostat is working, as well as the antifreeze level is normal.

We also recommend reading the article on how to replace the cabin filter on a Lada Kalina with your own hands. From this article you will learn when and why it is necessary to replace the cabin filter on Kalina, as well as how this procedure is performed, which cabin filter to choose, etc.

In this case, the cause is precisely air locks. Moreover, attempts to “expel” air from the engine cooling system using standard methods often do not yield results. For this reason, improvements to the system itself are necessary to eliminate the possibility of an air lock forming in the future.

Finally, we note that the only disadvantage of the method of improving the Kalina SOD discussed above is that the engine may take longer to warm up. Moreover, against the background of the problems that arise when the standard system is aired (overheating of the internal combustion engine, cold stove, etc.), such a drawback practically does not manifest itself at all, even in the cold season.

Symptoms of problems

There are a number of symptoms that indicate a malfunction of the cooling system; if at least one of them is detected, it is worth taking corrective action.

- When the engine is not started and has cooled down (more than 8 hours of inactivity), a residual pressure remains in the cooling lines (this can be understood when the rubber pipes are pressed, they will be hard).

- The release of coolant when the engine is running can be either a small amount or a significant column of steam.

- Coolant leakage from lines or radiators is accompanied by a decrease in the coolant level in the tank.

- When the engine is fully warmed up, cold air blows from the deflectors coming from the cabin heater. The effect may disappear when the crankshaft speed increases.

Functional range of elements of a car cooling system

The standard cooling system consists of the following elements:

- sensors – determine t° in certain auto mechanisms; one of the management elements of the system;

- pump – makes it possible to circulate liquid in the SOD; operates in a forced mode;

- pipes – coolant moves through them;

- expansion tank - compensates for the volume of antifreeze, since due to temperature fluctuations it narrows and expands;

- radiator - a device that discharges excess heat into the environment;

- fan – activates the cooling process by forcing air; With its help, the cooling intensity increases;

- Thermostat - although small, is a very important element that regulates the amount of antifreeze; provides a “comfortable” temperature regime throughout the entire system.

Operating principle

The cooling system operates in a self-regulating mode, which is aimed at maintaining optimal temperature in the power unit. If the oil temperature rises significantly, the system does everything to ensure that the temperature inside the engine decreases.

Thus, with the close interaction of the above elements, the system functions. It automatically sets the necessary conditions for the inclusion and operation of structural parts, which ensures effective cooling of the power unit.

Symptoms and consequences

Like any other mechanism, the thermostat can break down instantly. If this happens, the main thing is to detect the breakdown in time. Most often, a faulty mechanism can be detected when:

- increasing the amount of time required to fully warm up the power unit;

- the presence of elevated temperature in the power unit or even overheating.

The worst consequence of driving a car with a faulty thermostat is an overheated engine. There is no need to remind you once again about the consequences that overheating can cause. Therefore, we suggest that you familiarize yourself with the issue of replacing a problematic thermostat on a Lada Kalina car.

Video “Solving the problem of a leaking radiator”

How to repair a unit at home - detailed instructions for the process are presented in the video below (author - SergSerg).

A side effect of the operation of an internal combustion engine is heat; it is released due to the combustion of the combustible mixture when interacting with rubbing surfaces. If you do not take measures to remove heat from very hot parts, the entire motor will soon fail. Heat removal in water-cooled motors is carried out using coolant. The circulation pump moves fluid from the cylinder block to the radiator. The thermostat is responsible for quickly warming up to operating temperature; it separates two circuits (small and large). Separating the circuits serves to quickly heat the motor to operating temperature and prevent overheating. To prevent the liquid from boiling, the pump creates pressure in the cooling system. If everything is in order, then during normal operation it is impossible to overheat the power plant even on a summer day. If the temperature gauge needle is in the red zone, you should immediately check all components and mechanisms to avoid failure of the power plant.

Important points of improvement

Coolant is considered a toxic substance that adversely affects human health. Auto mechanics recommend draining antifreeze with caution. When carrying out this procedure, you need to remember safety precautions and use rubber gloves. The antifreeze is drained when the engine is cold. Then the tube is put on the fitting, the clamps are tightened. Air masses have been successfully removed from the system under consideration.

Technical features of the system

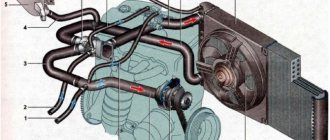

The unified layout and closed design of the engine cooling system (SOD) of the Kalina are also characteristic of other VAZ models. The system is designed to remove thermal energy from heated engine elements using antifreeze or other coolant.

The SOD consists of the following functional parts.

- Cooling radiator. Reduces coolant temperature due to the flow of cold air masses.

- Fan. Used for rapid cooling of antifreeze in the Kalina cooling system.

- Expansion tank. Designed to compensate for the volume of coolant (coolant). The need for this unit is related to the expansion/constriction property of the coolant.

- A pump or centrifugal pump, which is responsible for the forced circulation of antifreeze through the appropriate channels.

- A thermostat whose task is to regulate the volume of antifreeze in the Kalina cooling system.

- Temperature sensor involved in SOD control.

The operation of the cooling system is based on the close interconnection of various parts, elements and sensors, including devices that are designed to measure oil temperature. The passage of coolant in a large or small circle depends on the engine temperature. In the first case, antifreeze passes through all components of the SOD, except the radiator. With such circulation, the thermostat is closed. As the engine temperature rises, this element gradually opens. The antifreeze, having passed a large circle, enters the radiator. The latter device is cooled by oncoming air masses. If this is not enough, a signal is sent to the ventilated unit, which begins to forcibly direct air masses to the cells.

The cooled liquid enters a small circle. Next, taking into account the engine temperature, the antifreeze automatically circulates in a small or large circle. At the same time, the optimal operating temperature is maintained, which should be in the range of 95-105°C. This factor has a direct impact on the performance of the Kalina stove. In this case, it will not be able to supply warm air masses into the cabin.

If there are any doubts about the operation of the ODS, you need to diagnose the car, finding out the causes of the malfunction. You can fix the breakdown either with your own hands or with the help of a car mechanic.

First, it is recommended to check the antifreeze level in the system. To do this, you will need to open the hood and inspect the expansion tank. It should be filled to 1/2 of the total volume. If necessary, antifreeze is topped up or the coolant is completely replaced. In the latter case, you will need to drain the old antifreeze. If there is a fluid leak, you need to inspect the engine compartment.