The Lada Vesta engine has a thermostat, which is designed to maintain a constant temperature and prevent overheating. The factory thermostat of the Lada Vesta car is set to an operating temperature of 95 degrees. This part, together with others, is called the engine cooling system (CO). When the heating temperature rises to its maximum value. The thermostat activates and opens, the temperature drops to 80 degrees. If movement in a large circle does not begin, then the thermostat needs to be replaced. In this way, the engine temperature and the heating system of the car interior are regulated, that is, on a hot engine, the stove warms up well, despite the frosty weather. In summer, on the contrary, the cooling turns on at full power.

The cooling system of a Lada Vesta car manufactured by AvtoVAZ is fundamentally the same type. Cooling is carried out by circulating coolant - in a large and small circle. If the temperature is less than 95 degrees, antifreeze circulates in a small circle, as soon as the temperature exceeds 95 degrees, the thermostat opens and the fan turns on. Antifreeze begins to move in a large circle in order to reduce the temperature of the engine. Read the article and find out all the details about the thermostat and the cooling system in general!

Lada Vesta thermostat: replacement checklist and cooling system

The Lada Vesta engine has a thermostat, which is designed to maintain a constant temperature and prevent overheating.

The factory thermostat of the Lada Vesta car is set to an operating temperature of 95 degrees. This part, together with others, is called the engine cooling system (CO). When the heating temperature rises to its maximum value. The thermostat activates and opens, the temperature drops to 80 degrees. If movement in a large circle does not begin, then the thermostat needs to be replaced. In this way, the engine temperature and the heating system of the car interior are regulated, that is, on a hot engine, the stove warms up well, despite the frosty weather. In summer, on the contrary, the cooling turns on at full power. The cooling system of a Lada Vesta car manufactured by AvtoVAZ is fundamentally the same type. Cooling is carried out by circulating coolant - in a large and small circle. If the temperature is less than 95 degrees, antifreeze circulates in a small circle, as soon as the temperature exceeds 95 degrees, the thermostat opens and the fan turns on. Antifreeze begins to move in a large circle in order to reduce the temperature of the engine. Read the article and find out all the details about the thermostat and the cooling system in general!

Cooling system composition

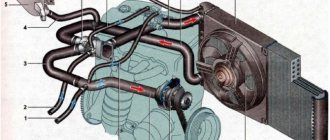

The Lada Vesta engine cooling system consists of:

- Engine radiator;

- Pump or CO pump with thermostat;

- Stoves;

- Electric fan;

- A tank designed to expand ethylene glycol;

- Patrubkov.

When cooling, a special liquid is used, a mixture of ethylene glycol and water in a certain proportion. The minimum outside temperature depends on its density. If there is a leak, the driver should know what actions to take in this case.

It is possible to add distilled water, but it is necessary to replace or restore the density of ethylene glycol as soon as possible.

How does the Lada Vesta engine cooling system work, what are the components?

- The pump is a CO pump;

- Engine radiator;

- Air conditioner heater radiator;

- Electric fan;

- Expansion tank;

- Thermostat;

- Connecting tubes.

Antifreeze is used to cool the engine. You need to use the same brand. And mixing liquids from different manufacturers is unacceptable. If the liquid runs out suddenly, you can add distilled water, but this should not be done in winter - it is better to constantly monitor the antifreeze level. As a rule, in winter, with the arrival of frost, the pipes begin to leak.

Antifreeze constantly leaves the expansion tank on the new Lada Vesta: where to look and what to do

Fresh cars are the basis of the risk group. If there are practically no requests to the OD regarding the elimination of the knocking of hydraulic compensators on a new Lada Vesta, then there are a lot of complaints about leaks after the first 3,000-10,000 km. Dealers are reluctant to take on the work, and the quality suffers. Despite the new condition, it is not recommended to delay in finding out the causes and eliminating leaks - leaks are sometimes dangerous.

Of the major troubles, there is only one - a defective pump. Most often, antifreeze leaves the expansion tank through a crack in the body of the Lada Vesta centrifugal pump; the bearing seal fails less often. In all cases, replacement under warranty is approved.

Lada Vesta engine cooling device

The engine CO has two circulation circles, which are regulated by a thermostat.

- Small circle, does not pass through the engine radiator. Antifreeze only flushes the cylinder block, cylinder head and radiator of the heating system.

- A large circle passes through the engine radiator, and there it is cooled by oncoming air flows.

What is a water pump and how does it work?

A pump is a pump that circulates liquid in CO.

The pump is fixed in the cylinder block; it circulates the anti-freeze agent into the CO. On VAZ engines, the pump is driven by a timing belt.

The operating principle of the Lada Vesta 21129 engine thermostat. It is characterized by switching from a small to a large coolant circulation circuit.

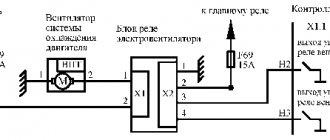

Electric fan, turning it on

The cooling fan turns on and reduces the temperature of the circulating fluid when oncoming air flows are ineffective. It is located behind the radiator and is triggered by a signal from the electronic engine control panel. The fan start temperature is usually 95 degrees. The fan signal is activated even when the vehicle's ignition switch is keyless.

Expansion tank Lada Vesta

An expansion tank is provided to compensate for the expansion temperature in CO. There is a lid on the neck of the barrel that has safety valves.

No. 3 Modification of the thermostat on the Lada Grant - heating the throttle valve

The throttle valve on the Lada Granta is not heated. In winter, in severe frosts, metal structures slightly grab, which is noticeable while driving a car.

There is only one way to protect the unit from freezing - to run the circuit from the cooling system.

Sequencing

- We place the car on the inspection hole and remove the metal protection of the oil pan.

- Drain the antifreeze.

- We release the clamps - ties, remove the rubber supply and return pipes.

- We dismantle the flow regulator, fix it in a vice, and disassemble it into its component elements.

- In the back of the case we drill an additional hole at “10”.

- Using argon welding, we weld the fitting to the hole for partial intake of antifreeze from the thermostat (Luzar).

- We assemble the structure.

- We put the rubber pipe on the fitting.

- We fill the system with antifreeze.

- We start the engine and test the proper operation of the stove heater.

Note to the driver! In this method of modification, the standard studs must be replaced; the body of the fitting rests against the wall of the block. Replace the studs with new ones, 8 mm in diameter, 10 cm long.

Basic faults

The expansion tank on Vesta can fail for two reasons:

- the cap (cork) is broken;

- The plastic container burst.

The plug breaks due to the fact that the exhaust manifold of the coolant system becomes faulty. Operating a vehicle with increased coolant pressure in the system will result in the RB bursting. The hoses connected to it may be subject to destruction.

It is not recommended to add even more coolant - it already works “hard”. If you do this, you can bring your car to repair the cylinder head.

When the tightness of the system is broken - for example, the plug (lid) wears out, or a plastic container bursts, air enters the system, which creates blockages in the lines and increases the pressure in the system.

With such a problem on Vesta there is no point in continuing to drive; you need to start replacing the failed spare part.

Why coolant disappears or weak points of the cooling system: general case

Briefly about the device

The main element in the system is the expansion tank cap. Unlike the range of wheels suitable for Lada Vesta Cross, it has a specific design. The plug body is equipped with two valves: outlet and inlet. The first one serves to release excess air and steam when they reach the maximum pressure in the tank, the second one launches the air mixture from the atmosphere when the engine cools down.

For your information. Excessive pressure in the system pushes the boiling point from atmospheric 105-110°C to 115-125°C. The principle is clearly demonstrated by a kettle of water, which boils at 75°C in the mountains, and at 100°C near the sea.

The expansion tank is the initial component. In addition to it there are a lot of other components:

- Thermostat.

- Cooling jacket for cylinder head and cylinder block.

- Two radiators: for the stove and for the engine.

- Power plant heat exchanger cooling fan.

- Water pump.

Coolant circulation is impossible without linking the elements into a single circuit. By the way, he is not alone: there is a large one, and there is also a small one, from which the engine radiator is excluded. The thermostat switches between fluid flow paths.

Where might it leak?

Rubber pipes are the only means of communication between the components of the cooling system. Each joint of a tube with a metal or plastic fitting, under the influence of heating-cooling cycles, leaks over time. Leakage of this kind is favorable: easy to detect + no harm to the engine.

Outside

The presence of a puddle with a slight oily tint on the engine protection or area under the car is a clear confirmation of a decrease in the level of antifreeze in the expansion tank of the Lada Vesta cooling system, a phenomenon that is not safe in all respects:

- Engine radiator. A cracked plastic sidewall, traces of natural corrosion, mechanical damage to the working part - the heat exchanger begins to sweat as soon as any of these defects appear. Repairs are practiced less and less, and sometimes are impossible.

- Defective pump: defective housing or damaged bearing seal. A leak in this unit is dangerous - in the case of a wedge, the timing belt breaks without looking back. The meeting of pistons with valves is inevitable on both the VAZ 21129 and the VAZ 21179. The verdict is the same - replacement immediately.

- Crack in the thermostat housing. Unit to be replaced.

- Expansion tank. A barely noticeable crack, when the part expands while it is hot, gives rise to a noticeable leak. Conclusion - install a new component.

- Tank cap. Constant contact with the atmosphere if one of the valves malfunctions or is not tightened tightly leads to boiling of the coolant and splashing of the liquid out. Replacement only.

In the cabin

A damp mat in dry weather is a reason to look under the center console. If the heater core is damaged, coolant drips onto the carpet. Indirect signs:

- Oily coating on the inside of the windshield.

- Sweating windows when it's dry outside.

- Smell of antifreeze in the cabin.

Into the combustion chamber

A cracked cylinder head, poor tightening of the bolts securing it, or a broken gasket between the cylinder block and the cylinder head lead to antifreeze entering the combustion chamber. The fact of such a dangerous malfunction is recorded by the symptoms:

- White thick exhaust even in warm weather.

- Sudden increase in the oil level in the engine crankcase (lubricant with antifreeze bubbles).

- Antifreeze smells like exhaust gases + bubbles in the expansion tank when cold.

Having detected a coolant leak inside the engine, it is recommended to stop further operation and begin to eliminate the causes, otherwise the pistons will jam. The first thing to do is tighten the bolts in accordance with the diagram, observing the tightening torque. It will not help to carry out more complex manipulations.

Removing and installing the expansion tank

To replace the expansion tank on a Lada Vesta, start with the actions that the manufacturer recommends before each repair: remove the negative terminal from the battery, stop the car. Next follow the instructions:

- Open the hood. Wait until the car has cooled down to avoid getting burned. To protect your hands during repairs, wear medium-thick gloves.

- Remove the steam hose from the “hero of the occasion” with your hands.

- Behind the part from below, unscrew the two bolts and one self-tapping screw that secure it in place.

- In place of the old part, put a new one, connect the hose, establish a strong connection, tightening it with a new clamp.

No. 2 Modification of the thermostat on the Lada Grant - replacement of the thermal insert

This method involves completely dismantling the flow regulator and disassembling it into its component elements. The detailed process is described above.

We troubleshoot the thermostat cavity, wipe it with a rag, and inspect it for cracks and other defects.

Removed spring from thermocouple

We replace the entire “core”. The following cores are suitable for the standard thermostat:

- Wahler: 3017.87 D (at 87°C);

- Behr (Behr) 3091.92V (at 90°C).

We replace the complete set, including the spring, and the modification of the Luzar thermostat on the Lada Grant is completed.

Note to the driver! Such modernization is possible only with thermostats manufactured by BEHR. Products from other companies are incompatible in terms of parameters. Many car owners do not know about these subtleties and end up in ridiculous situations.

As an alternative, use a core from Daewoo or Renault, catalog part number - Vernet 4898.92. The design of the part is somewhat different and requires adjustment. For standard thermostats from Luzar, such an upgrade is not possible.

Subject to the recommendations, fuel consumption will decrease by 1.0 - 1.5% minimum.

How to understand that there is a malfunction in the system

Frequent addition of antifreeze indicates that the connecting hose system is not tight. And this contributes to the penetration of liquid beyond the CO. You should carefully inspect the connecting hoses and their integrity. Be sure to inspect the pump and drain holes. If there are traces of leaks, you need to solve the problem yourself or contact a service station.

To identify problems with the cooling system, you need to warm up the car to a maximum of 85-92 degrees. Then you need to check the lower pipe, when it is cool, this means that only a small circulation circle is working - the thermostat does not open. In this case, the machine cannot be used. To verify that the part is faulty, you need to open the expander cover. Make observations when antifreeze does not flow, you need to clean the pump or replace the thermostat.

Owner reviews

| № | Positive |

| 1. | Vladimir: I’ve been actively using the car for two years now, and there are no comments about the heating system. I know about the problem of premature valve opening, but for me it is not significant. |

| 2. | Kirill: after 45,000 km I noticed that the regulator opens the valve already at 81°C. I visited a service station, after diagnostics the technician said that the defect was known, but had not yet been corrected by the manufacturer. Comrades recommended shortening the stock rod. |

| 3. | Vitaly: after buying the car, I shortened the regulator rod by 2.0 mm, and the valve activation threshold increased to 87°. This is enough for me, I don’t need to increase it any more. |

| 4. | Dmitry: I knew about the problem of underheating even before buying the car, I prepared in advance. Instead of the standard core, I installed 3091.92 V at 90° C. Now the system works properly. |

| 5. | Gennady: at 80,000 km I replaced the flow regulator for the first time, did not install the original core, bought a Wahler: 3017.87 D. I have been actively using it for two months, no comments. |

| 6. | Alexander: a year has passed since the purchase of the car, the valve opens at 80°C. I know that the threshold is low, but it doesn’t matter to me. I did not notice any increased fuel consumption. |

| 7. | Vasily: after purchasing the car, I replaced the antifreeze with imported one, installed a core from Wahler: 3017.87 D. |

| Negative | |

| 1. | Ivan: The car is a year and a half old, but I can’t fix the problem of early activation of the valve. On the advice of my comrades, I changed the cores, sharpened the stem, nothing helps. |

| 2. | Alexey: extremely dissatisfied with the car, the model is crude, there are many flaws and defects. You constantly need to dig around and fix breakdowns. |

| 3. | Vasily: the thermostat was replaced after a mileage of 50,000 km, after which faults were discovered in the ignition system and so on. |

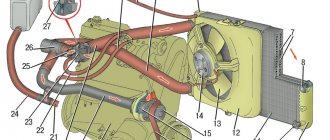

Replacing the thermostat Lada Vesta

To replace, you must adhere to the safety rules and the following algorithm. At the very beginning, you need to buy a new assembled Fenox TS034E7 TS034E7, or another similar spare part.

- You need to tilt the car slightly, that is, reduce reinforcement on one side. The procedure requires a jack. This is done so as not to spill antifreeze.

- Next, you need to partially pour out the antifreeze. The Lada Vesta is different in that the drain plug on the block is closed by the starter, and without removing it it is impossible to pour out the antifreeze; there is no plug on the radiator either. This means you need to pour it through the expansion tank. The amount of liquid drained should be about four liters. Then the jet of anti-freeze becomes smaller, and air begins to lie in its composition;

- Remove the air filter;

- Disconnect all connections to the temperature sensor panel;

- Then loosen the hose clamp. To do this, use a Phillips screwdriver;

- Disconnect the hoses from the nozzles. A hose that acts as a pump supply pipe for anti-freeze;

- It is necessary to unscrew all the nuts from the body (use wrench number 13);

- Remove the spare part from the studs along with the sealing lining.

To install a new spare part, you need to follow the instructions described above, but in reverse order.

- Place the thermostat gasket 21100130301700 LADA. Install the part body on the studs;

- Screw in the nuts using the same wrench;

- Connect the hoses to the pipes;

- Secure the hoses;

- Connect all connections to the control sensor unit;

- Fill with coolant;

- Make sure antifreeze does not leak. Test the cooling system.

Procedure for modifying the standard thermostat on the Lada Grant

- Drive the car onto a viewing hole, a platform with a slope towards the rear.

- Remove the oil pan protection.

- Drain the waste antifreeze into a container.

- Loosen the clamps and remove the pipes.

- Remove the thermostat.

- Install a new filling (method No. 1) / weld a fitting for heating the throttle valve (method No. 2) / replace the entire thermal insert (method No. 3).

- Reassemble the parts in reverse order.

Let's look at how to increase the engine temperature using the example of each method.

Analogues of parts for Lada Vesta and their advantages

- Luzar, produced in Ukraine. The advantages of luzer are that the heating system begins to heat up better and faster. And replacing the thermoelement becomes much easier, you only need to unscrew two bolts and the element on your hands, you don’t need to remove a lot of pipes.

- Pekar article 21900100000000000, manufacturer Russia. It does not have a thorough design, so it does not retain the heat of the engine well.

- The automagnet is designed with new valves that release antifreeze in doses. Almost never overheating.

- Pramo article number 2108210000000000000, although often used, has many negative reviews. Sudden opening of valves and others. Produced in Russia, China.

In order for the thermoelement to last a long time, it is necessary to use antifreeze recommended by the manufacturer. Replace breakdowns only with high-quality auto parts, only from the manufacturer of original parts. Don't buy fakes. Replace broken parts in a timely manner. When operating an engine with a broken spare part, the operating temperature of the engine differs sharply. That is, there are jumps from 79 to 95 degrees, and this can negatively affect the operation of the motor in the future and shorten its service life.

Source