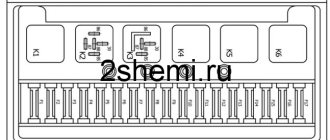

List of contact relays

If we open the main fuse box of Kalina 2, we will see a set of electrical relay housings. There are no other blocks containing relays in the car. We list the elements used in the “Lux” package (21927/21947):

- K1: radiator fan relay;

- K2: relay switching on door locks;

- K3: additional starter relay;

- K4: additional relay (switches current 50A);

- K6: wiper relay;

- K7: relay that turns on the high beam;

- K8: signal relay;

- K9: relay that turns on the low beam;

- K10: rear window heater relay;

- K11: main ignition relay;

- K12: relay turning on the fuel pump;

- K13: additional relay;

- K14: radiator fan relay 3;

- K15: windshield heater relay 1;

- K16: windshield heater relay 2;

- K17: relay that turns on the air conditioning compressor.

You can compare the layout of elements in “Lux” and in “Norm/Standard”:

Let's consider the data relevant for the “Normal/Standard” configurations:

- K1-K12: as above;

- K13: radiator fan relay 3;

- K14: windshield heater relay 1;

- K15: windshield heater relay 2;

- K16: air conditioning compressor relay.

The last list is also relevant for Kalina Cross Norma. And in more expensive trim levels of the crossover, the “Lux” scheme will probably be used.

Where are the fuses and relays located?

Depending on the generation of the car, the fuse blocks have differences, and, consequently, different installation locations.

Location of fuse and relay blocks on Lada Kalina 1

The first generation Kalinas were equipped with several fuse blocks at once. Their location has several places and they are all in the cabin:

- The main unit is located under the panel, to the left of the steering column.

- Another block was mounted under the cigarette lighter, next to the gearshift lever.

- Another mounting block is located under the dashboard, inside the central tunnel.

Where are the mounting blocks located in Lada Kalina 2

The second generation Lada Kalina has two fuse blocks. The main one is located inside the cabin, and in some trim levels it is also installed under the hood.

- One is located in the cabin, to the left of the steering column, under the cover.

- The additional fuse box is located in the engine compartment, to the right of the battery.

It is worth considering the location of the mounting block to avoid mistakes in diagnosing the car.

Checking and replacing the Kalina cooling fan resistor

Removing the additional fan resistor is done as follows:

- put the car on the “handbrake”;

- open the hood;

- remove the ground wire from the battery;

- remove the engine splash guard;

- unscrew and remove the engine crankcase protection (if installed);

- press the block latch and unplug the electric fan power supply wiring harness;

- Using a Phillips screwdriver, unscrew the two screws holding the additional resistor;

- move aside the resistor mounting bracket together with the block;

- pull out the resistor.

Checking the resistor consists of two stages:

- visual inspection of the integrity of the spiral;

- checking the resistor winding for open circuit using an ohmmeter.

If a winding malfunction is detected, the resistor must be replaced with a new one. If the thermal fuse is faulty, then all you can do is replace it. To do this, you will need a soldering iron to remove the burnt fuse and solder a new one in its place. All that remains is to put the parts in their original places. Installation of the Kalina cooling fan resistor is carried out strictly in the reverse order of removal.

Removing the fan sensor

DVV is a non-separable product and cannot be repaired. However, to ensure that it is fully operational, it must be removed from the vehicle. To do this proceed as follows:

- The car is placed on level ground with the handbrake lever raised.

- Start working after the engine has completely cooled down, removing the terminals from the battery.

- Having squeezed out the plastic clip, remove the chip with the cable from the DVV glass.

- Remove the plug from the expansion tank, otherwise when the sensor is removed, a small amount of antifreeze will splash out.

- Use a spanner wrench or a 19 DVV socket to unscrew it from the seat. If the thread does not lend itself well, then apply WD 40 lubricant under the sensor nut (you can buy it at any auto store or gas station).

Removing the chip from the sensor:

How to find the reason

Let's start by checking the electric motor. Disconnect the electrical wires and connect directly to the battery, observing the polarity. If the fan doesn't start, that's the problem. If it works, you need to look for another reason.

Check all contacts on the connectors, as well as behind the relay and fuse. They are located in an additional mounting block, which is located on the right side of the instrument panel next to the lower heater duct.

The fuse (50A) can be checked with a tester; it is better to take a working relay and install it in the appropriate socket. If the problem is not resolved, continue.

Check temperature sensor. Warm up the engine to operating temperature, stop the engine and disconnect the sensor. It is located on the top of the thermostat housing. When the sensor is disabled, the controller must independently start the fan for continuous operation.

Start the engine and wait until the fan starts. If the coolant temperature has reached a critical temperature and the fan does not turn on, look for a broken wiring.

Do I need to change the fan?

If you determine that the problem is in the fan itself, or more precisely in its motor, you can try to fix it. Most often it stops working due to broken brushes or problems with the rotor bearings. The commutator or winding crack is rarely damaged.

If the fan cannot be repaired, it must be replaced.

Under no circumstances should you drive a vehicle with the fan not working. Overheating of the engine inevitably leads to the destruction of rubber hoses of the cooling system, seals, and can also cause failure of the piston group elements.

Why do fuses blow and what are the symptoms?

Fuses never blow without a reason, and the Lada Kalina is no exception. Fuse links protect circuits from the following faults:

The task of the fuse is to save the electrical circuit: wiring, consumers and to prevent a fire caused by melting of wires or other parts of the electrical circuit.

A short circuit is one of the reasons for the melting of the insert, which most often occurs due to damage to the wires, a short circuit of the “plus” to body ground, or during an accident, as a result of which the harness or a separate wire was cut by a part of the body.

Overloads can be caused by the simultaneous operation of many consumers or when using low-quality compressors to inflate tires, powered from the cigarette lighter.

There is another reason, which occurs extremely rarely - the use of Chinese fuse-links, the operating current of which is slightly lower than that provided by the electrical circuit. Despite the fact that 15A may be indicated on the insert body, in fact, this figure may be lowered to 10.

The symptom of a blown fuse is complete failure of the consumer. For example, if the cigarette lighter does not work, then in 90% of cases, a blown fuse is to blame. To make sure of this, just open the lid, take out the fuse-link, guided by the table, and check its integrity. If this cannot be done visually, you can use a multimeter in dial mode.

A serviceable fuse should ring, but a blown fuse will show an open circuit on the device. If replacing the insert does not help, you will have to diagnose the fuse box or look for the problem elsewhere.

It is prohibited to use wire to repair the fuse! This may cause the wiring in the vehicle to catch fire.

Installing a new fan sensor

After dismantling the old device, a new DVV is installed:

- The sensor is inserted into the mounting socket, having previously lubricated the threads of the device skirt with oil.

- Screw in the meter with a spanner wrench or a 19mm socket without applying excessive force.

- The cable block is inserted into the glass of the new sensor.

- After unscrewing the radiator cap, pour antifreeze into its neck until the fluid level in the expansion tank is between o and “Max”.

- The radiator cap and expansion tank plug are returned to their place.

- Start the engine and wait until the arrow on the instrument panel approaches the red zone. If the fan turns on at this moment, this means that the repair was completed correctly.

Experts advise purchasing a new coolant temperature sensor only from a brand model. Savings when buying a cheap product can result in exorbitant financial costs for engine overhauls.

At the first overheating of the Kalina engine, you need to stop and stop driving to allow the engine to cool. If the problem is a breakdown of the engine, then you need to get home, making stops and watching the coolant temperature arrow along the way. To avoid this, remove the fan motor cable and directly connect the fan with additional wires to the battery. This way you can return to the garage without letting the coolant boil.

What to do if replacing the fuse does not help

There are additional faults due to which the device on Kalina may break. These include.

- Bad contacts. Over time or from heavy use, the connection inside the device may become compromised. Incorrect installation of devices leads to loose sockets and poor contact. The fuse trips. This can be treated by bending the metal tendrils on the cartridge, as well as by resoldering the contacts.

- With age, oxides or rust appear on Kalina's cigarette lighter, which has a bad effect on its operation. The situation can be corrected by treating the contact areas with a needle file. It is necessary to clean them and remove all traces of corrosion. Another malfunction is a burnt-out nichrome spiral. It is recommended to replace the device here.

The price of a new cigarette lighter for Kalina is 300 – 750 rubles. When choosing, you need to buy original parts. They must be carefully packaged, and quality certificates and certificates of conformity must be located inside. When buying cheap Chinese analogues, be prepared for the fact that the fuses may burn out, and the device itself may not work for long and incorrectly.

Video “How to properly replace the thermostat on a Lada Kalina?”

If the problem of a non-functioning sensor in a Lada Kalina car lies in the failure of the thermostat, then this unit will also need to be replaced; detailed instructions for replacing it at home are presented below (the author of the video is Alexey Golubkov).

Why doesn't the cooling fan turn on on Kalina? Several reasons to choose from

Within the city limits this is not so serious: if you are in a hurry, you can leave the car and get where you need to go by public transport in order to deal with the cooling system later. But between cities, a non-working fan is a great headache. If you don’t find the cause and don’t eliminate it, it can take 8 hours to drive 40 kilometers without a tow: you drive 2-3 km, then you stop and wait for it to cool down. It's going to be a fun trip! Especially if there are tired children behind you who were planning to quickly get there and start resting.

Why doesn't the cooling fan turn on on Kalina?

There are several reasons for this. Some can be fixed on site, while others will require additional spare parts. But even if you can’t start the fan right away, you can at least assess the prospects and start waving the cable as it passes a couple of hours earlier, while you still have the strength to do something.

Before checking the remaining components of the cooling system, you need to make sure that the worst has not happened to you, and. I must say that in Kalina this is an extremely unreliable unit and for some reason it breaks down often and frequently. There are cases when it stopped working, even if it was changed the day before yesterday. Therefore, many experienced owners of this car, when going on a long trip, take a spare one with them. Yes, just in case!

You can make sure that the thermostat is normal (or not) by touching the lower radiator pipe. If it remains cold, it means that the thermostat is no longer alive, and you need to get a backup one or ask for a tow. In the absence of both fellow travelers and supplies, you will have to crawl slowly and sadly to the nearest service station.

Having excluded the thermostat from the list of probabilities, we check the electrical circuit. First - fuses

(how to check them correctly,).

The first is the one that is directly responsible for the electric fan. It is located on the side of the console, where the front passenger's feet are. It’s not difficult to get to it: unscrew the screw that secures the cover with deflectors for blowing warm air - and in front of you is the required spare part.

If this fuse is intact

, you will have to climb further into the additional block. Use a ten key to unscrew the fastening bolt and pull out the entire assembly. At this stage, you need to be patient and careful: extraction is significantly hampered by a whole bunch of wires going to the block. If you pull one out, you will be stuck on the highway for a long time. But it doesn’t take long to look for a fuse in the block: there is only one there, exactly the one you need.

If this part is normal, we immediately check the relays - they are located in the same block and transmit voltage to the fan motor. There are 2 of them: located above the mounting strip on the left edge is responsible for the operation of the fan at low speeds, the one on the far right turns on its high speed. Both must be in working order.

If no faults are found here, you will have to crawl under the hood.

You need to check both it and the temperature sensor. Let's take a look at the electric fan first. To ensure that the engine is working, its terminals are connected directly to the battery. If it starts, it means everything is fine with the fan. Let's move on to the sensor. Depending on what engine is on your iron horse, the actions will be different:

With carburetor:

We remove the plug connector of the temperature sensor (it is located, by the way, on the right radiator tank) and close its terminals with a jumper. The fan started spinning - the sensor is working, the terminals just came off. Left dead - it's time to change the sensor; With injector

We look for the sensor next to the thermostat and remove the connector from it. If the fan starts spinning, it means that the emergency mode has turned on, and your sensor has already burned out.

Owners of popular Lada Kalina models often encounter situations when the cooling fan does not turn on. This situation forces the driver to periodically stop to allow the engine to cool down. If a malfunction occurs in frosty weather, then it has almost no effect on the functionality of the system, but in warm periods it significantly prevents the LADA Kalina from moving smoothly.

Most Lada Kalina owners are not able to independently diagnose the reasons why the cooling fan does not turn on, much less eliminate them. Tow trucks and services, as well as a switching diagram, are happy to come to their aid.

Correct selection and replacement of fuses on Kalina

The fuse in a car is a plastic product with two contacts, inside of which there is a fuse link.

Different fuses are designed for different current values and if this parameter is exceeded, the insert burns out. It is very important to install the same one in place of the required fuse and not make a mistake.

For example, if a 15 Ampere fuse is installed on the cigarette lighter, then it is no longer possible to install a 60 Ampere or 5 Ampere insert.

The fact is that with a high operating current, the device can burn out or melt the wiring in the event of a malfunction. And with a high current of 15 Amps, a 5 Ampere fuse may blow immediately after turning on the device, since it is not designed for such work.

Fuse links differ in color and amperage. Currently, the following colors and fuses are used in cars:

| Color | Clearly | Operating current |

| Brown-yellow | 5A | |

| Brown | 7.5A | |

| Red | 10A | |

| Blue | 15A | |

| Yellow | 20A | |

| White | 25A | |

| Green | 30A | |

| Orange | 40A | |

| Red | 50A | |

| Blue | 60A |

Lada Kalina cars of the 1st and 2nd generations use blade fuses of the Norma and Maxi standards. The latter are used on Kalina 2 in the engine compartment and several of them are used on Lada Kalina 1 in the cabin.

To replace fuses, there is a special puller in the main unit, which is located in the lower right corner.

The main reasons why the radiator cooling fan does not work

Let's look at the main options and places to look for faults:

- Thermostat.

If it fails, this is the reason why the cooling fan does not work correctly. To diagnose this malfunction, you should touch the lower pipe. If it is cold, then the thermostat is dead. Many Kalina car owners are accustomed to this phenomenon, since it often breaks down, and they carry a spare one with them.

- If it's not the thermostat, then the next step is the fuses. You need to make sure that they are working and all controllers too. The easiest way is to test them using a tester or ohmmeter. The fuse diagram is here.

If the fuse is alive, then you will have to remove the additional fan control unit. To do this, it is worth moving the warm air duct and using a 10 mm wrench to unscrew the fastenings of the unit. Now you can get it freely. It has two relays that are responsible for turning on the fan and for high speeds. Let's diagnose both.

- Now, we can move on to the darkest option - we climb under the hood and “ring” the contact wires of the fan itself. Of course, there may be a break or break in the wire, but there is nothing worse than a burnt winding inside the fan. Most likely the fan in this case will need to be replaced.

- Another reason for the fan not turning on may be a broken thermostat sensor. In order for the fan to start in emergency mode, you will have to remove the connectors from it. You can check the sensor by removing the thermostat and placing it in a pan of hot water; the thermostat should open.

- The last reason why the fan may not work is a break in the switching circuit itself.

Why did it happen so?

Perhaps the automatic requests do not belong to you, but to another user accessing the network from the same IP address as you. You need to enter the characters into the form once, after which we will remember you and be able to distinguish you from other users exiting from this IP. In this case, the page with the captcha will not bother you for quite a long time.

You may have add-ons installed in your browser that can make automatic search requests. In this case, we recommend that you disable them.

It is also possible that your computer is infected with a virus program that is using it to collect information. Maybe you should check your system for viruses.

If you have any problems or would like our support team, please use the feedback form.

If malfunctions occur related to the operation of electrical accessories on the Lada Kalina, do not rush to get into the mechanical part. Maybe the problem lies in the combustion of fuses. But not all motorists know where the Lada Kalina fuse box is located and their markings.

Design of the LADA Kalina cooling system

Cooling system: 1 — expansion tank;

2 — radiator outlet hose; 3 - inlet hose; 4 - radiator; 5 — steam exhaust hose; b — radiator supply hose; 7 — electric fan; 8 — electric fan casing; 9 — coolant temperature sensor; 10 — coolant temperature indicator sensor; 11 — throttle assembly; 12 — bracket for the coolant pump pipe; 13 — coolant pump; 14 — coolant pump pipe; 15 — heater radiator supply hose; 16 — heater radiator outlet hose; 17 — exhaust pipe; 18 — coolant pump pipe hose; 19 — thermostat housing Expansion tank. Coolant is poured into the system through the expansion tank. It is made of translucent polyethylene, which allows you to visually monitor the liquid level. To do this, the marks “MAX” and “MIN” are marked on the wall of the tank. In the upper part of the tank there is a pipe for connecting to the radiator steam exhaust hose, in the lower part there is a pipe for connecting to the inlet hose. Expansion tank viburnum

Expansion tank cap with valves. The tightness of the system is ensured by the inlet and outlet valves in the expansion tank cap. The exhaust valve maintains increased (compared to atmospheric) pressure in the system on a hot engine (due to this, the boiling point of the liquid becomes higher, steam losses are reduced}. It begins to open at a pressure of at least 1.1 bar. The intake valve opens when the pressure drops to system relative to atmospheric pressure by 0.03-0.13 bar (on a cooling engine).Expansion tank cap with valves

The coolant pump is a vane, centrifugal type, driven from the crankshaft pulley by a timing belt. The pump housing is aluminum. The roller rotates in a double-row bearing. The bearing is lubricated for its entire service life. The outer ring of the bearing is locked with a screw. A toothed pulley is pressed onto the front end of the roller, and an impeller is pressed onto the rear end. A thrust ring made of a graphite-containing composition is pressed to the end of the impeller, behind which there is an oil seal. The pump housing has a control hole to detect fluid leakage when the pump fails. It is recommended to replace the pump as an assembly. The redistribution of liquid flows is controlled by a thermostat. Coolant pump Kalina

The cooling system consists of two so-called circulation circles:

- The movement of liquid through the cooling jacket and radiator forms a large circulation circle.

- The movement of liquid through the engine cooling jacket, bypassing the radiator, is a small circle of circulation.

The cooling system also includes a heater radiator and a throttle body heating unit. Liquid circulates through them constantly and does not depend on the position of the thermostat valves.

Thermostat. It has a solid temperature-sensitive element and two valves that redistribute the flow of coolant. On a cold engine, the main thermostat valve blocks the flow of fluid from the radiator and the fluid circulates only in a small circle, bypassing the radiator. At a temperature of (85±2) °C, the thermostat valves begin to move, allowing liquid flow into the radiator and closing the bypass channel. At a temperature of about (100±2) °C, the main valve opens completely and the bypass valve closes. Almost all the fluid circulates in a large circle through the engine radiator. Thermostat viburnum

Coolant temperature sensor. To monitor the coolant temperature, a sensor is screwed into the engine cylinder head, connected to the temperature indicator in the instrument cluster. In the outlet pipe, next to the thermostat housing, there is a coolant temperature sensor that provides information to the controller. Coolant temperature sensor viburnum

The heater radiator is built into the engine cooling system and is designed to heat the passenger compartment by circulating hot coolant through it.

The radiator consists of two vertical plastic tanks (the left one is with

baffle) and two horizontal rows of round aluminum tubes passing through the cooling plates. The tubes are connected to the tanks through a rubber gasket. The liquid is supplied through the upper pipe and discharged through the lower. Next to the inlet pipe there is a thin pipe for the steam removal hose. The radiator has a casing with an electric fan. There is a drain plug at the bottom of the right tank. radiator viburnum The fan maintains the thermal operating mode of the engine and is switched on via a relay based on a signal from the controller.

Modernization of Kalina SOD

The main problem of the Kalina cooling system is the formation of air locks. Today there are a number of effective ways to eliminate this defect. The reason lies in the design features of the SOD. The operation of the cooling system is based on the interconnected functioning of many parts. The use of the large and small circuits depends on the temperature of the antifreeze circulating through the system. The normal operation of the entire power plant depends on this.

You can modify the cooling system yourself or at a service center. Professionals rarely engage in all sorts of modifications, recommending replacing or repairing a particular component. This method may be more expensive, but not always more effective.

Classic ways of improvement

In order to solve the problem with the formation of air locks, you need to remove the expansion tank cap and start the engine. Then wait until the coolant temperature rises to the critical red zone until forced cooling by the fan comes into operation. After this, you need to press the gas pedal several times and turn off the engine.

If the method is ineffective, there is another method. To do this, you need to dismantle the engine protection, loosen the clamp and remove one of the tubes of the throttle body heating fitting. Then unscrew the cap of the expansion tank and, applying a rag, start blowing into it until antifreeze begins to flow from the removed pipe. In order to modify the standard cooling system, many car owners install a more efficient 6-hole thermostat, install a coolant filter and another heater faucet.

To increase circulation efficiency, an additional pump is often installed.

Other upgrade options

If the car is equipped with an electronic gas pedal, the hose that previously went to heat the throttle assembly is now looped into the cooling system. To prevent the formation of air pockets, an additional pipe with a smaller diameter is used, which is installed instead of the above hose. The hose for the air duct is placed near the thermostat; for this, a tee is used, mounted in the pipe fitting to the radiator. The second end of the pipe is connected to the steam removal hose near the expansion tank (you will need another tee).

The modification ensures a stable operating temperature of 90 degrees in urban conditions, and the stove begins to warm up at 50 degrees.

The next improvement method is to equip the steam outlet with a special hydraulic fence. To do this, a tube from a dropper is mounted in the steam removal hose, which is immersed in antifreeze at the bottom of the expansion tank. As it cools, the antifreeze is drawn into the outlet pipe, which prevents air from the cooling system. If desired, you can combine both methods.

Forced fan activation

One of the shortcomings of the cooling system of the Lada Kalina is the late activation of the electric fan. Any car owner, even with minimal car repair and maintenance skills, can solve this problem if desired. On most internal combustion engines, the operating temperature should be maintained at 90-95 degrees. On Kalina, the forced cooling fan turns on at a temperature of 100 or 105 degrees. That is, intensive cooling begins at the moment when the engine has already begun to overheat, and this negatively affects the service life of the power unit. To solve this problem, you can install a button to turn on the fan in the cabin, which, when pressed, starts cooling at any time. To work you will need the following parts:

- connection terminals;

- 4-pin relay with mounting bracket;

- contact blocks for connecting the button and relay;

- wire with a cross-section of at least 0.75 mm.

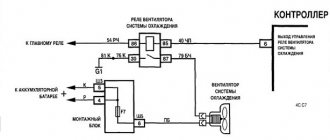

Connecting the forced (manual) mode of fan operation is carried out according to the following scheme:

- On the button connection block, all unnecessary wires are cut off, leaving only two in the center for illumination and two on the edge for connection.

- Now you should connect the relay and button. On the passenger side, the protective trim of the center console is removed; there are several relays there. To find out which one is needed, you should start the engine and disconnect the wire block one by one from the temperature sensor on the thermostat.

- In this case, the fan should work; now you need to disconnect the relay. If after disconnecting one or another relay the fan stops, then this relay is responsible for turning on forced cooling. If the car stalls when the relay is removed, it means that it is responsible for the fuel pump; you should replace it and start the engine again.

- Now you should find the pink and white wires, strip their ends and twist them together, the connection is insulated.

- The relay wires are connected to the prepared wire block. White - to contact 87, pink - to 85, contact 86 is connected to the power button, contact 30 is assigned to ground. After completing the connection, all that remains is to find a place to secure it, for example, under a dashboard.

- All that remains is to connect the button. The two remaining wires are connected to any backlight lamp, which lights up when the ignition is turned on.

The modification allows you to turn on the cooling fan on the Lada Kalina at any time, not only while the engine is running, but also when it is turned off.

Any modernization can be done with your own hands; it is not at all difficult if you follow the step-by-step instructions. For normal operation of the cooling system, all components and elements must work properly. The fan, although simple in design, is important; without it, you can end up with a major engine overhaul. For this reason, you need to carefully monitor the performance of all components and, if malfunctions are identified, fix them immediately.

Main reasons

- Coolant temperature sensor malfunction. There are two of them on the Lada Kalina. One provides data to the instrument panel, the second to the car's ECU.

- The fuse in the fan circuit has blown.

- Motor malfunction.

- Lost contact in electrical wiring connectors.

Verification algorithm

- Disconnect the connector from the temperature sensor, which is located near the thermostat. When the sensor is disconnected and the ignition is on, the cooling fan should run constantly. If the fan does not turn on, it may be the fan fuse or the fan itself.

- The fan relay and fuse box on the Lada Kalina is located under the decorative trim near the left foot of the front passenger. The block consists of three relays, two of which (1 and 3) are responsible for operating the fan at high and low speed. There is a fuse nearby. The fuse is checked visually (the integrity of the fusible link) or with an ohmmeter, which should show zero resistance. The relay can be checked by connecting the device to the terminals of the contact group and applying voltage from the battery to the switching terminals. You should not install a “bug” made of wire instead of a blown fuse. Fires in cars are not uncommon. It is necessary to find the cause of the burnout; perhaps a short circuit in the electric motor or wiring. Install a similar fuse. If everything works fine, then everything is put back in place; if the fuse blows again, then the reason is a short circuit. The fuse rating is 50 A.

- The serviceability of the fan itself is checked by applying voltage from the battery directly to its connector. If it rotates and all other elements are working properly, then the only reason is the electrical wiring. Fortunately, this is quite rare. When the engine does not work even when directly connected to the battery, there is only one way out - replacing the fan. Repairing the engine does not make sense, since the cost of a new one is not that high, and the reliability of the repaired one is unlikely to be high.

Sensor check

For a complete check, the sensor will have to be removed, which involves draining a small amount of coolant.

You can check the sensor with a tester in resistance mode. The probes of the device are connected to the connector terminals and the tip of the sensor is immersed in hot water. Table of indications.

| Temperature (°C) | Resistance (Ohm) |

| 100 | 177 |

| 90 | 241 |

| 80 | 332 |

| 70 | 467 |

| 60 | 667 |

| 50 | 973 |

| 45 | 1188 |

| 40 | 1459 |

| 35 | 1802 |

When checking, you need to check the condition of the connector contacts. If the contact is poor, they will overheat and the contact will weaken even more, until it completely disappears. Connectors must be dry, clean and free from overheating.

What if the fan completely stopped working?

To determine the cause of such a malfunction, you first need to check the condition of the fuse in the electrical circuit. It can be found on the side console, near the passenger seat. It is hidden under the deflector cover. By unscrewing the screw, the cover can be easily removed and the fuse will be available for examination.

To remove the entire safety block and connected relays, the mount must be released. You can't do this without wrenches. You need to remove the unit carefully without haste, as you can damage the wires that are connected to it. Only the single fuse of the unit is responsible for the operation of the fan.

If the fuse is intact, it is necessary to check the operation of the relay that powers the fan motor. There are two such relays installed. The left one turns on low fan speed. And the one located on the right is responsible for the high speed of its operation.

Another problem that relates to the cooling fan relay is that the cooling fan continues to operate when the ignition is turned off. This may drain the battery. “Kalina” then simply won’t start. The main reason is sticking contacts. The block is exposed to antifreeze leaking from the radiator installed above the stove.

When the relays and fuses are working properly, you need to check the operation of the temperature sensor. It is he who orders the fan to start working. This sensor is located on the right side of the radiator tank.

To check its functionality, you need to remove the plug connector, take a jumper, and use it to short-circuit the connector terminals. The fan turning on indicates that the sensor is in good condition. If the fan does not react at all, then before changing the sensor, you need to check the functionality of the fan motor. To do this, the electric motor terminals must be connected to the battery contacts. The engine should start working. In case of failure, you will have to install a new electric motor.

Replacing the cooling fan Lada Kalina

To replace the cooling fan, it is not necessary to go to a service station. You can do this without much difficulty on your own.

Required tools:

- head with ratchet or socket wrench 10;

- spanner or open-end wrench 8;

- screwdriver with Phillips bit;

- pliers.

Work order

- Place the car on a level surface.

- Raise the hood, disconnect the ground wire from the battery.

- Using a 10mm wrench, unscrew the two air filter mounting bolts.

- Disconnect the mass air flow sensor connector by pressing the latch.

- Disconnect the purge valve connector located on the air filter housing.

- Using a screwdriver, unscrew the bolt of the air duct fixation clamp and remove the corrugation.

- Unscrew the 4 screws securing the air filter cover.

- Remove the cover and remove the filter element.

- Using a size 8 wrench, unscrew the nut securing the air intake and remove it.

- Using a size 10 wrench, unscrew the two nuts securing the fan casing on the right in the direction of travel of the car, and then with a size 8 wrench, unscrew the two nuts on the left.

- Disconnect the fan power connector.

- Carefully, so as not to damage the radiator fins, remove the fan along with the housing.

- Using a 10mm wrench, unscrew the 3 bolts securing the electric motor and remove it from the housing.

- Install a new electric motor with impeller in its place.

- Screw the casing assembly with the fan to the radiator.

- Connect its connector.

- Carry out the rest of the installation work in reverse order.

Engine control unit

This unit is located in the center console.

p, blockquote 13,0,0,0,0 —>

The fuses responsible for engine operation are located on top under the protective cover.

p, blockquote 14,0,0,0,0 —>

Photo - diagram

p, blockquote 15,0,0,0,0 —>

p, blockquote 16,0,0,0,0 —>

Designation

p, blockquote 17,0,0,0,0 —>

- Diagnostic connector

- 15A - Main relay circuits (winding of the cooling system electric fan relay, canister purge valve, air flow sensor, speed sensor, oxygen concentration sensor, ignition coil)

- 15A - Fuel pump, viburnum fuel pump fuse.

- 15A - Constant power supply circuits of the controller (ECU)

The relays are located in the lower right part of the console, where the fuses for the electric cooling fan are also attached.

p, blockquote 18,0,0,1,0 —>

p, blockquote 19,0,0,0,0 —>

Scheme

p, blockquote 20,0,0,0,0 —>

p, blockquote 21,0,0,0,0 —>

The diagrams do not fit or you own a different generation of the model, study this description for the Lada Kalina 2.

We have also prepared video material on this material on our channel. Come in and subscribe.

Article on the topic: Which leather conditioner to choose

p, blockquote 23,0,0,0,0 —>

p, blockquote 24,0,0,0,0 —> p, blockquote 25,0,0,0,1 —>

And if you have any questions, write them in the comments.

Vehicle maintenance

A catalog of consumable spare parts required for maintenance is given in Chapter 3b of this manual.

Periodic Maintenance

Timely and regular maintenance of the car in accordance with the technological map (see the service book attached to the car upon sale) can significantly extend the life of the car.

A message appears in the notification center indicating the mileage remaining until the next service. This message appears and remains for 4 seconds each time the ignition switch is turned to position 2.

The display begins to show mileage - 10,000 km. This distance gradually decreases (every 50 km) until zero remains (in this case, service must be performed). After each service the display is reset again to 10,000 km.

Note

Service intervals are based on 50 km intervals, so short journeys may not be shown on the display.

The vehicle must be serviced every 10,000 km or every 6 months (whichever comes first).

Note

If service has not been performed (or the display has not been reset), the distance indicator will remain at that value after reaching zero until reset.

The service center employee must make the appropriate notes, stamp and sign the vehicle’s service book for each maintenance service.

Replacing brake fluid

Brake fluid requires replacement every two years, regardless of the vehicle's mileage.

Note

Replacing brake fluid is included in scheduled maintenance and is paid for.

Coolant replacement

Engine coolant must be replaced every three years, regardless of the vehicle's mileage.

Note

Coolant replacement is included in scheduled maintenance and is paid for.

Monitoring the content of harmful emissions in exhaust gases

This vehicle is equipped with a system to control harmful emissions and fuel vapors. Incorrect engine settings can affect exhaust emissions, engine performance and fuel consumption, and can cause elevated temperatures that damage the catalytic converters and engine.

Attention Please be aware that replacement, modification or counterfeiting of these devices is punishable by law. In addition, outside interference in engine settings is strictly PROHIBITED!

What is clearance and how important is it?

This value shows the possible deviation of a given series from the specified nominal value. A correctly calculated circuit must take this indicator into account, or appropriate adjustments are made after assembly. As you understand, our friends from the Celestial Empire do not bother themselves with this, which has a positive effect on the cost of their goods.

The result of such a policy was shown in Figure 4; the part works for some time until the limit of its safety margin is reached.

- We make a decision by comparing the readings of the multimeter with the nominal value; if the discrepancy goes beyond the error limits, the part definitely needs to be replaced.

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

General diagram of VAZ-1117, VAZ-1118, VAZ-1119

1 — right headlight; 2 — engine compartment lamp switch; 3 — sound signal, 4 — Lada Kalina starter; 5 - battery; 6 - generator; 7 — windshield wiper electric motor; 8 — left headlight; 9 — power window switch of the right front door (passenger); 10 — power window motor of the right front door; 11 — right front door lock; 12 — connection block to the right front column; 13 — windshield washer motor; 14 — air temperature sensor; 15 — connection block to the injection system wiring harness; 16 — left front door lock; 17 — brake fluid level sensor; 18 — connection block to the left front column; 19 — right front door power window switch (driver); 20 — left front door power window switch; 21 — door lock switch in the switch block; 22 — electric window motor of the right front door; 23 — mounting block; 24 — immobilizer; 25 — power accessories control unit; 26 — instrument cluster; 27 — right side turn signal; 28 — glove compartment lighting lamp ; 29 — glove compartment lamp switch; 30 — brake light switch; 31 — ignition switch; 32 — lighting control module; 33 — steering column switch; 34 — left side direction indicator; 35 — connection block to the right rear column; 36 — rear door lock; 37 — rear window heating switch; 38 — reverse lock switch; 39 — alarm switch; 40 — heater motor switch; 41 - additional resistor; 42 — heater electric motor; 43 — block is connected to the left rear column; 44 — electric fuel pump with fuel level sensor; 45 — reverse lamp switch; 46 — handbrake sensor; 47 — cigarette lighter; 48 — reverse lock; 49 — connection block to the radio device; 50 — backlight lamps for heater control levers; 51 — Kalina illuminator; 52 — control unit for electromechanical power steering; 53 — interior lighting unit; 54 — right rear light; 55 — trunk locking motor; 56 — switch in the trunk lock; 57 — license plate lights; 58 - additional brake signal; 59 — rear window heating element; 60 — trunk lighting; 61 - left rear light

Elements of the instrument panel harness connection diagram

1, 3, 4, 5 — blocks of the tidy wire bundle to the front harness; 2, 8 - the same for the rear “pigtail” of wires; 6, 7, 9, 10 - continuation of the direction to the assembly unit; 11 — power supply for the lighting control device; 12 — set of instruments; 13 — toggle switch for the electric motor of the stove; 14 — power supply to the air supply box; 15 — ignition switch Lada Kalina; 16 — immobilizer block; 17 — block of the dashboard wiring harness to the ignition system wire bundle; 18 — cigarette lighter power supply; 19 — alarm switch; 20 — rear window heating switch; 21 — brake light switch; 22 — alarm light breaker; 23 — adjustment of computer modes; 24 — windshield wiper control; 25 — VAZ horn switch; 26, 27 — heating and ventilation control lighting lamps; 28 — glove box lighting; 29 — power supply to the on/off button in the glove compartment; 30, 31 — pinout for the standard radio; 32 — power supply to the electric motor of the stove; 33 — heater resistor network; 34 - electric amplifier control unit.

Block under the hood

It is located next to the battery.

Photo - diagram

Purpose

- 30A Low beam headlights or main relay, circuits protected by fuses F1 and F21 of the mounting block in the passenger compartment 50A Windshield heater

- 60A Generator

- 60A Generator

- 30/40A Heater fan (heater fuse grants)

- 50A Electromechanical power steering

- 60A ABS block