The engine cooling system of a modern car is a complex mechanism equipped with passive and active components. Chevrolet Niva fan relays, responsible for turning on and off the specified elements.

Fuses help the electronics turn active cooling on and off to reduce powerplant temperatures.

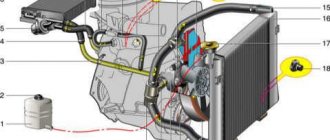

System structure and principle of turning on fans

Everything works as follows.

- The radiator and engine block are looped into a single system using pipes. Between them there is a rheostat - a damper with a temperature-sensitive element inside.

- When a certain temperature is reached, the damper opens and the liquid begins to circulate in a large circle.

- If passive cooling fails, the engine temperature rises. The head cooling fans come into play. When the temperature limit is overcome, the DTOZh sends an impulse to the BC.

- The processed signal closes the relay and the fan turns on. To improve system performance, the devices are paired. Dubbing helps prevent overheating if one of the devices breaks down. At the same time, the connection diagram for active coolers implies their simultaneous and separate activation.

The Chevrolet Niva interior heater fan is also used to cool the engine. Part of the system has a slight effect on the temperature, but in an emergency it can affect the operation of the engine.

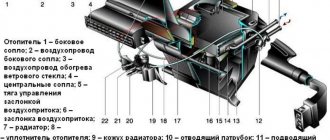

Purpose and design

This is a module designed to be included in the on-board circuit of a motor that consumes high current. The fan motor is powered by electricity with a current of 20-35A, which is unacceptable for inclusion in a low-voltage control system - the wiring will melt. The Niva has only three relays, two for the left and right fans separately and one common. Each device has its own number in the on-board network. The principle of operation and purpose of the relay is relevant for cars of all types 2004, 2010, 2022 and other years of production.

Inside, the relays have an identical design. There is a low part, a transformer and a high part. Also two pairs of contacts, one normally closed, the second open. When a pulse is applied to the lower part, a magnetic field is formed on the windings, and the contact group on the high side closes - power is supplied to the fan motor.

The cooling screw operates in two modes. When the engine heats up to 99 degrees Celsius, the first fan is turned on, after passing the 101⁰C mark, the second one is connected. If the system cannot cope, the motors switch to higher speeds.

Fan relay diagram

The figure shows the power supply circuit for the electric fans of the cooling system of the installation. Design elements are presented by numbers.

- 1/7 – left and right fan motors;

- 2 – additional power relay;

- 3 – fuse;

- 4 – power controller;

- 5 – auxiliary resistor;

- 6/8 – main relay for turning on the right and left electric motor, respectively;

- A/C – negative/positive battery terminal;

- B – to the main ignition relay.

NIVA.RU

[quote=”Sash”]I don’t know how it was before, but in the fields at the end of 2013. both fans turn on at 98 degrees. I installed the BC, and through it (there is a function called “tropical temperature”) I set one fan to turn on at 95 degrees. Now, when it reaches 95 degrees, one fan turns on - there is less noise, the voltage in the car’s network also does not sags as with two fans.[/quote

I have a Niva M 2014, (both fans turn on at 98 degrees), that’s right... How can I set up this mode?

Re: engine temperature

- Quote

Post by ParaLanik » Mar 08, 2014, 11:51 am

How I did it. I have leg No. 29 on a Bosch ECU 7.9.7+, empty. Having set the “tropic” to 97 degrees, 2 vents still turn on (for leg No. 68). Of course, I was perverted and did it (this is a separate topic). I'm asking if you have a simpler solution.

And after adjusting with the Tropic, I stopped, turned off the engine, turned off the ignition - and the fan runs until the temperature drops - without Tropic there is no such thing. I turned off the engine and the fan was cut off.

Re: engine temperature

- Quote

Post by Alena » March 08, 2014, 5:20 pm

I meant nivovodok, I join!

Thanks for the congratulations nivovodok! And nivovods have daughters, wives, mothers-in-law, sisters, etc. Therefore, Nivovodov too.

Re: engine temperature

- Quote

Post by Sash » 09 Mar 2014, 23:48

Re: engine temperature

- Quote

Post by ParaLanik » Mar 11, 2014, 10:21 pm

Sash wrote: (there they are designated No. 1 and No. 2),

Yes, apparently I have different functions

https://shtat-un.ru/site/upload/File/115. oshura.pdf

There are also 1 or 2 fans, but 2 of them still work at the same time. So I got into the email myself. Nivka's diagram found the absence of leg 29. (By the way, there is one in Sh-Niva.). Maybe my car is “transitional” April 2010.

Pulley fan sensor

The coolant temperature sensor plays the role of supplying a pulse to turn on the fans. When a certain temperature is reached, the device sends a signal to the ECU and the fans are activated. In versions where the BC is located in the cabin, you can make adjustments to the sensor response threshold.

Purpose and functions

The device has a single role - to prevent boiling of the coolant and overheating of the power plant. Thus, turning on at a certain moment, the part equalizes the temperature of the engine and stabilizes its behavior.

Operating principle and location

The sensor works as follows.

- The temperature-sensitive sensor is programmed to pulse at a certain temperature.

- When the threshold is reached, the sensor sends a signal to the ECU and the first fan turns on.

- If the motor temperature rises further, the second relay is activated and the remaining fan is connected.

Wind blower

Wind blower

More speed means better cooling, but this is only partly true. As acceleration proceeds, all other things being equal, the engine power and the amount of heat “dumped” into the cooling system grow almost by the cube of the speed, and the wind pressure only by the square. It happens that at the optimal 90–100 km/h there is enough cooling even with a dirty radiator, and at maximum speed the electric fan does not turn off. One step away from overheating - it’s better to let off the gas. Of course, there are heavier driving modes - also associated with the release of high power, but at low speeds, when the oncoming flow is weak or absent (with a tailwind). Driving in first gear in deep sand, on a steep climb of a mountain road, or towing another car through the mud, you cannot do without forced airflow of the radiator! His refusal is like a death sentence for the engine.

There are two types of fan drives - mechanical (usually V-belt drive) and electric. In the first, the speed of the impeller and the engine are strictly connected. At low speeds and heavy loads this is dangerous: the airflow is weak. In other modes, the fan, constantly rotating, unnecessarily consumes engine power and fuel, and after starting in cold weather, it slows down the warming up of the engine. The drive with a viscous coupling is more “conscious” - it monitors the temperature of the coolant in the radiator. UAZ-Patriot received such a system.

An electric fan is more economical: it works only when necessary, and its power is several times less than the power of a mechanical fan cranked up to maximum speed. But at low engine speeds and high loads, a mechanical “wind blower” is inferior to an electric one; the latter is more efficient. At high loads and engine speeds, an electric fan is usually inferior to a mechanical one - at high speeds the latter has a higher air flow. The choice of type is a matter for the designer. Today, electric fans predominate in passenger cars.

There seems to be nothing wrong with a mechanical fan. Unless some people managed to break off the blades or the belt broke due to oversight. The latter was replaced with anything on the road! And how could it be otherwise, if on some cars it also drives the cooling system pump. Electric fan failures vary widely.

Often it does not work due to a failure of the temperature sensor, the vagaries of which (especially on carburetor cars with a sensor in the radiator) we have talked about more than once. Causes? This, for example, is the burning of the sensor contacts in traffic jams, when it becomes unusable by repeatedly turning on and off. The sensor in the head of the block works more stable, as is done on most injection cars. There are, however, exceptions, such as fuel-injected GAZ cars with a traditional sensor in the radiator.

Some craftsmen, not trusting the sensor, install an additional switch to turn on the fan in an emergency if necessary. Our attitude towards the idea is ambiguous. How do you know when it's time to turn it on? God forbid if the temperature sensor really lies or you are forgetful. In the author's opinion, the standard system is more attractive - there is a reason to maintain it in good condition, and not to fence the garden.

Note that the cooling system fan can cause problems that you wouldn’t expect! A wonderful lesson was taught to us by the Chevrolet Niva, which has two electric fans - beautiful plastic impellers with bandages along the outer diameter, rotating for greater efficiency in plastic rings-casings! Everything is “according to science” - the most advanced, they did not take into account only a trivial circumstance: the plastic does not withstand the temperature of the air leaving the radiator. Apparently, they selected it, caring only about the low price! One day, having warmed up well, the impellers lost their rigidity, the bandage rings began to touch the casings and melt at the points of contact. The driver didn't notice this. And the next day the fans turned out to be jammed - the day before, after turning off the engine, they were welded to the casings. Is it a good story? How can one not remember the “good old” metal casings!

A long-known circuit for switching on an electric fan (carburetor VAZ-2104, 2105...2107, “Oka”, “Oda”, etc.). Electric fan 1 is started by a command from relay 3, controlled by a signal from temperature sensor 2, usually located in the radiator. The safety of the system is entrusted to fuse 4. The temperature threshold for turning on the fan is about 100°C or slightly lower. The corresponding numbers are on the sensor body - for example, for Zhiguli 87–92°C.

Fan control, typical of many fuel-injected cars. Electric fan 1 is switched on via relay 3 based on a signal from temperature sensor 2. The latter is located in the engine. Upon reaching the response temperature, contact 85 of the relay through contact 68 of controller 5 closes to ground. The threshold for turning on the fan on these machines can be above 100°C. For example, on a VAZ-2110 it is about 104°C. The decision is made by the ECM by analyzing the temperature sensor signal.

When plastic “decorations” on Russian cars warp even under the rays of the morning moon, it’s not so bad. But often plastics of unsuitable quality are used in critical components - and this is already a disaster. Here is an example: the design “led” - the impellers began to touch the fixed rings of the housing, in these places the plastic was heated until it melted, and after the motor stopped, the impellers were welded to the housing. By the way, at the top between them is that same additional resistor, but how much use is there in a smart system if it was made by defectors?

Job

The Shniva cooling system has two active cooling elements. There is a fan for the heater radiator and the main heat exchanger. The following information is relevant for cars of 2010 and other model years.

Fuses are responsible for the correct, stable operation of devices. Fuse links will protect the device from power surges and short circuits.

Pulley fan fuse: where is it located?

Located in close proximity to the corresponding relays. The stove insert is located in the main mounting block under number F18. A 25 amp fuse protects multiple circuits at once.

Reasons why the cooling fan does not work on a Chevrolet Niva

To maintain the optimal temperature in the engine, a cooling system is installed in the car. One of the main elements in this system are fans, thanks to which the required amount of air is supplied to the engine through the radiator core. If it stops working, the Niva Chevrolet cooling fan overheats as excess heat begins to accumulate. Unlike classic cars, it has two fans, making the functioning of the systems much more complicated. If the arrow that shows the temperature is in the red area, and the cooling system refuses to work, and at the same time the cooling fan does not turn on, then the car should be taken to a car service center as quickly as possible, or you should try to find the cause of the malfunction yourself.

Possible malfunctions and their causes

If the fans do not turn on on time, the problem may be hiding in the following places.

- Relays or fuses have blown.

- DTOZH does not work correctly.

- The wiring of the device is damaged.

- Incorrect ECU settings.

- The fan motor is damaged or shorted.

Checking the functionality of the sensor, relays and fuses

The DTOZH is responsible for the operation of the fans; it is easy to check.

- Prepare a thermometer, multimeter, kettle or bowl of cool water.

- Immerse the sensor in a container and put it on fire, at the same time immerse the thermometer in water.

- When passing thresholds of 5 degrees, you should connect the multimeter to the sensor in resistance mode. At the same time, record the data.

- After heating the water to a boil, take the last measurements and compare the results with the reference table below. If the device indicators differ by more than 10% from the standard, the sensor is changed.

Forced activation of cooling fans

To make this possible, car enthusiasts install an additional switch into the device circuit and power it directly from the battery. The operation of the electronics is disrupted and the on-board computer may generate an error.

To fake the device, users on the network recommend using a scheme.

A relay and a forced switch are added here.

Replacing the Fan Relay

Due to the simplicity of the design, the procedure is performed according to a standard scenario. Access to the mounting block is opened, the terminal of the relay contact group is disconnected. Next, the device is unscrewed from the panel and replaced with a new one.