Replacing the sound signal on a Lada Vesta is a simple procedure that any owner should be able to perform. After all, driving without a properly working horn is a priori unsafe, and taking a car to a service station due to such a breakdown is an unreasonably large amount of time. However, replacement in the event of a malfunction is not the only need. Many people are simply not satisfied with the volume or tone of the sound signal, and they replace the standard Vesta components with alternative ones. Therefore, both of these paths need to be considered in more detail.

The signal on the Lada Vesta does not work

According to traffic regulations, it is prohibited to operate a vehicle with a non-functioning sound signal. It serves to prevent emergency situations on the road when road users, for one reason or another, do not see each other. Therefore, a sudden failure of this device can play a cruel joke on the car owner. If such a malfunction is detected, do not put off repairing the horn for a long time. We will tell you about the main reasons for the breakdown, most of which you can handle on your own.

How to repair mechanical damage to an antenna

Failures can be divided into two types:

- The dipole came off along with the body.

- The elongated part broke in two.

In the first case, you can repair it with sealant. Along the perimeter of the device you need to coat it with special glue, preferably aquarium glue, and then install the housing with the dipole.

In the second case, independent repair is impossible. You can only temporarily repair the broken part. To do this, fix it the way it should stand. Then wrap the joint tightly with electrical tape.

Common main cable tap location:

As for electrical faults, in most cases it is impossible to fix them. If the damage was caused by oxidation of the board, then cleaning and soldering the contacts, as well as replacing rotten elements will only be a temporary option.

Fuse burned out

Many faults associated with the electrical equipment of a car can be eliminated by replacing blown fuses. Therefore, first of all, you should open the mounting block, which is located in the engine compartment, and find the 10A fuse F73 there, see figure:

When inspecting the protective element, pay attention to the integrity of the thread and the presence of signs of burnout. If the element is burnt out, replace it with a similar one. But it is worth noting that fuses do not simply fail; there may have been a voltage overload in the circuit or a short circuit. If the situation repeats after replacement, it is better to contact an experienced electrician.

Steering column contacts

To ensure that the horn works at any steering wheel position, the designers came up with a special contact group. It is located under the steering column cover, so you will have to unscrew a few screws and remove plastic parts. There you will find a metal ring to which contacts on springs are pressed. You should make sure that they fit securely and do not show signs of oxidation. If you find a gap between them, then you need to loosen the contacts and move them towards the ring. After this, be sure to securely fasten the mounting bolts. Oxidized contacts should be cleaned.

Wiring is not ok

Have you checked all the elements in the chain, but there is still no sound? This means that the problem lies in the car's electrical wiring. At this stage, you will have to stock up on a tester to “check” the circuits. You need to make sure that there is voltage at the signal button, for which you will have to open the steering wheel cover. If your car does not have airbags, then there will be no problems, but if they are present, the task will become much more complicated. Therefore, in such a situation, it is better to contact a car service so as not to accidentally activate the “airbag”.

The right way

Finally, they gave me some good advice: check the tube between the canister valve and the intake manifold. In fact, a large vacuum is created in the starting system. If there is air leaks in the tubes, the fuel mixture will become lean. As a result, the engine will jerk.

I checked the fitting of this tube at the entrance to the manifold - it was loose.

At the second end of the hose, the same thing happens - the fitting moves and is not seated tightly.

The adsorber itself, which is made in the form of a white fungus (visible below in the photo), sucks air from the atmosphere. Due to the vacuum in the intake manifold, gasoline vapors are sucked into the intake system through the canister ventilation valve.

There is a green rubber ring installed in the fitting. It should seal the connection well. To check the quality of the seal, we had to conduct an experiment.

Installing “Volgov” signals on Lada Vesta, is it worth the bother and what you need to know

Vesta has a fairly conventional sound signal from the factory, although this is an integral safety attribute. Let me clarify right away that I don’t prefer to honk at everyone, I only use the signal in situations where it can prevent an accident; for other cases, high beams are quite sufficient.

However, how to prevent an accident with such a sound signal, because you need to take into account that there are cars with good sound insulation or with good music, or both. I remember that many of my friends installed pneumatic sound signals, of course they sounded good, but still it’s not something, it looks too massive + questions may arise when undergoing maintenance. In order to do everything neatly, it was decided to follow the path trodden by many - to install the so-called Volgov signals.

Before buying, it is important to know the following information - there are at least two modifications that differ in sound, as well as price, weight and dimensions. The first have numbers 22.3721/221.3721 low and high tone, respectively, the second S302/S303D.

In terms of sound, many people like the latter more, they sound somehow more mature and smoother, at the same time louder, but you need to take into account that they are noticeably larger in size. These signals are produced by two companies - SOATE and LETS.

It is better to buy in trusted and large stores for spare parts for VAZ, GAZ, PAZ, as there are many counterfeits. The original signals must bear GOST, the Quality Control Department stamp, as well as bolts for a slotted screwdriver.

FakeHeader

Comments 39

The lyres fit into the mounting sockets under the contacts - in the empty spaces where you want to install a relay or fuse. I'll draw a diagram later.

The relay has 4 contacts, divided into two pairs. The first pair is “low-current” - for closing and opening the relay. We connect the two wires that went to the signal (pins 85 and 86) in any order. The second pair is power, which will supply current to the signals. The wire from the ring terminal (with +) goes to the fuse contact (4.8 pin is inserted), from the fuse (4.8 pin is inserted) to the relay (4.8 pin is inserted) - any contact for relay 30 or 87, and from the remaining contact to the signal. The principle is that the wires are connected in pairs, two from the previous signal control the relay (85 and 86 on the relay). And the power wire from + to the fuse, from the fuse to the relay (let's say 30), and from the remaining (let's say 87) contact to the signal.

From the signal relay - wires to the relay control, plus from the red screw contact (on the right). The main principle.

I just don’t understand how the standard signal works without an additional relay and fuse? And why can’t you connect the Volgov signal to the standard translation and that’s it? The standard wire already has a plus. Why put a separate plus in the fuse box? Why do we need dances with a tambourine, relays, fuses, additional wiring, etc.?

The standard signal on Vesta does not sound at all respectable. Therefore, I decided to change it to a signal from the Volga. It got much better!

It was once 9. On it I limited myself to installing Zhiguli pipes, the red ones. It seemed to be normal. Then there was 10ka. The VAZ tweeter was a little confusing. I went to the electricians, they blew Volga pipes at her. With relay, as expected. There was generally an atmosphere, but there were also problems. The relays and horns were located behind the radiator grille, the horns pointing downwards. The sound was good, but contact was often lost due to water getting on the relay and pipes. The result is oxidation of contacts. Sometimes I had to disassemble, clean, bend... Fortunately, the grille on 10k was removed with two bolts.

I bought Vesta.

And I was a little saddened by the fact that she signaled in a disgustingly squeaky voice, like Oka some kind of thread or shokha. I rode for six months and endured this matter. And he even seemed embarrassed to honk) To prevent accidents, he beeped, of course. But to acquaintances, for example, he only waved his hand). And I also noticed that I’m stopping by our market. Well, there we have a type of “center”, a wide area, parking lots, cars, a market and the main shops ala “Magnit”. And people walk along the road as they please. And then you’re driving after someone, he’s rushing along the road, you honk - zero emotions. Either he doesn’t hear, or he just doesn’t care...

So I bought everything I needed

. Signal from the Volga, two pipes, two tones - high and low) (s302d and s303d, applicability GAZ, PAZ), four-contact relay 75.3777-10 (with screw fastening) (also suitable, it seems, 904.3747-10) and block for it, wires, terminals, corrugation, mounted fuse 25A, heat-shrinkable tubes. I couldn’t find brackets for the pipes, I cut them out myself from several layers of galvanized steel from an old window sill. Everything cost me about 1,500 rubles, of which 1,000 and a few kopecks were the signals themselves.

Started to use chemicals

. First I removed the bumper. I already talked about this www.drive2.ru/l/465834215582205001/ I received this:

Now about the standard signal key

(on the steering wheel). I found on the Internet that it is a minus. On the standard signal tablet the plus is constant, and the minus is from the button. I checked. It's the other way around for me. The plus on the signal appears when the button is pressed. The plus on the standard one is a red wire with a white stripe. In general, I didn’t bother with the wiring, I took both the plus and minus from the standard signal, from the block, and to the light bulb, what exactly comes there. You can also connect a standard one, it will beep along with the Volgov ones, but I didn’t put on the block - it’s of little use. And I didn’t take it off - it’s hanging in reserve. If anything happens to the Volgov ones, I put on a block and the standard one works.

It was mandatory to remove the “-” terminal from the battery.

And he began to look for a place to listen. Found it, you can see it in the video. I liked the places behind the bumper, just below the headlights. Plus there are ready-made bolts for my brackets. It is not recommended to screw signals directly to the body. It will resonate and bounce into the body when the horn blows, so I had to make brackets. Cut it out and drilled holes. Everything is done by tweaking and tweaking)

I did the wiring according to my same diagram.

I cut in a fuse from the battery to the relay, attached the relay to the body (in any convenient place closer to the battery, so as not to pull the power wire too far), and the wires to the pipes themselves. I insulated everything and put on corrugation. I stupidly tied it to the standard signal block and insulated it, I forgot the warranty. Yes, and you can carefully “minus” the battery and...

That's all, good luck everyone. If you have any questions, ask me, I’ll help you in any way I can. Although I am not an auto electrician myself, I did it without any problems. Bye PS Comparison of signals at the end of the video. Regular, then Volgovsky.

The Lada Vesta has two beeps. One signal is a warning signal, and the other is an alarm signal.

To replace or repair signals, you need to prepare the car for work.

Raise the hood and disconnect the negative terminal from the battery using a 10mm wrench.

In order to remove the signal signal, you need to remove the bumper, as described in the article “Removing and installing bumpers on a Lada Vesta car.”

After this, disconnect block 1, Figure 1, of the front wiring harness from sound signal device 2.

Using a 13mm socket, unscrew nut 3 securing the sound warning device to the car body and remove the sound warning device.

Install the sound signal device in the reverse order of removal.

The tightening torque of nut 3, Figure 1, fastening the sound signal device is 20…30 Nm (2…3 kgf.m).

After repairing or replacing the signal, we install the front bumper.

Mounting block Lada Vesta in the car interior

The mounting block is located in a familiar place - near the driver’s left foot. To access the relays and fuses:

- turn the plastic handles (3 pieces) holding the unit cover from below;

- remove the lock on the upper right side of the cover;

- Pull the bottom of the cover, disconnect its upper holders to the instrument panel and remove the unit cover.

Fuse diagram (Fuse, Rating, Circuit, Purpose, Fuse type)

- F1 15A K15R Windshield washer mini

- F2 30A *1 /5A *2 K15R Left steering column switch (not luxury/luxury) mini

- F3 10A *1 Left high beam headlight (not luxury) mini

- F4 30A *1 /5A *2 K30S Left steering column switch (not luxury/lux) mini

- F5 15A K15R Heated seats mini

- F6 7.5A *1 K30S Right side lights mini

- F7 10A *1 K30S Left side lights mini

- F8 5A *1 K30S Rear fog lights mini

- F9 3A Direction indicator (turn signals) in the right mini mirror

- F10 5A K15S AMT mini robotic gearbox selector

- F11 10A *1 Left low beam headlight (not luxury) mini

- F12 15A K30S BCM controller (turn signals) mini

- F13 10A K30S BCM controller (own power supply) mini

- F14 10A K30S Mini brake pedal switch off

- F15 5A BTP Power supply for D&O (rain and light sensor), mini headlight range control

- F16 5A BTP Mini brake pedal switch off

- F17 5A BTP Lighting (canopy) for the glove box, trunk, thresholds mini

- F18 3A Direction indicator (turn signals) in the left mini mirror

- F19 10A *1 Right low beam headlight (not luxury) mini

- F20 5A Heated exterior mirrors mini

- F21 15A K15S BU SNPB mini

- F22 5A K15S Gearbox (instrument cluster) mini

- F23 5A K30S Gearbox (instrument cluster) mini

- F24 5A ACC ERA GLONASS, radio mini

- F25 5A VTR Controller ESP9.1 mini

- F26 15A K30S Power supply for mini fuel pump module

- F27 5A K15S Power supply for parking sensors mini

- F28 5A K15S EURU controller (electric power steering) mini

- F29 10A *1 /5A *2 K30S Power supply for mini trailer lighting

- F30 5A K15S Controller ERA GLONASS mini

- F31 5A K30S Controller ERA GLONASS mini

- F32 10A K15S Bus power supply K15M (engine compartment) mini

- F33 5A BTP Window control mini

- F34 5A VTR Power supply for steering angle sensor, mini steering wheel button block

- F35 5A BTP Switch block in the driver's door mini

- F36 15A K30S Radio, mini diagnostic connector

- F37 7.5A K30S Stop lamps right mini

- F38 7.5A K30S Stop lamps left mini

- F39 10A *1 K15R DRL (daytime running lights) not luxury mini

- F40 10A *1 K15R High beam headlight right (not luxury) mini

- F41 20A ACC 12V socket (power supply for additional devices), cigarette lighter JCase

- F42 20A K30S BCM controller (BTP bus power supply) JCase

- F43 20A K30S BCM controller (door locks) JCase

- F44 30A K30S Electric windows (ESP) JCase

- F45 30A K30S Interior heater fan (heater) JCase

- F46 30A *1 K15R Power supply for windshield wipers JCase

- F47 25A *2 K30S EMM controller (PDS, LBS, LGO)

- F48 30A *2 K30S EMM controller (windshield wiper)

- F49 25A *2 K30S EMM controller (PTF, ZPTO, license plate)

- F50 25A *1 K30S EMM controller (LDS, PBS, PGO)

Replacing the standard sound signal on a Lada Vesta

Replacing the sound signal on a Lada Vesta is a simple procedure that any owner should be able to perform. After all, driving without a properly working horn is a priori unsafe, and taking a car to a service station due to such a breakdown is an unreasonably large amount of time. However, replacement in the event of a malfunction is not the only need. Many people are simply not satisfied with the volume or tone of the sound signal, and they replace the standard Vesta components with alternative ones. Therefore, both of these paths need to be considered in more detail.

TO-1

Once the car has reached a mileage of 15 thousand km or is 1 year old, it is necessary to undergo a TO-1 in the service centers of official dealers with mandatory subsequent marks in the service book, which contains a list of all the work required to be performed, and the car owner only needs to control their actual completion and , depending on the degree of competence, quality. As mentioned above, the car owner first performs work according to the “zero maintenance” list.

The cost of TO-1 Lada Vesta, according to the manufacturer’s official website, is 5,200 rubles.

To assess the cost of this procedure, let’s compare this amount with the cost of servicing some foreign-made cars:

The acceptability of the cost of performing maintenance 1 on Lada Vesta is obvious. To get an idea of the scope of work, here is a brief description of it:

It is easy to see that the list of TO-1 works, taking into account the preliminary “zero” maintenance, includes all the necessary measures to identify a malfunction in a car approximately one year old.

Replacing the standard sound signal in case of breakdown

First you need to prepare the car for work by putting the parking brake on and turning off the ignition. Then you need to lift the hood and, armed with a “10” key, disconnect the negative terminal from the battery. Then you should dismantle the front bumper, which is best done with an assistant, so as not to damage the paintwork on the bumper itself and on the wings of Vesta.

The figure shows the mounting location of the Vesta signal, its plug and the signal itself.

Once this is completed, all that remains is to disconnect the plug with the wires from the signal horn. Then you can dismantle the signal itself, the bracket of which is attached to the body with one nut. For dismantling you will need an extension, a wrench and a 13mm socket.

Removing and installing the front bumper requires an assistant.

Assembly is carried out in the reverse order - you need to secure the signal, inspect its operation, install the bumper with an assistant and tighten the terminal on the Vesta battery.

Manufacturers and prices of analogues

- Changing the signal on the West is easy. For convenience, it is recommended to remove the bumper. This way it will not interfere with connecting the wires. It is better to remove the bumper with the radiator.

- Remove the numbers and air receiver. The bumper is attached to the body with bolts in tens, twenties and thirty from below (four self-tapping screws). The bumper is secured at the edges with 20 screws (next to the wheels). Unscrew the remaining screws on top while holding the lid.

- Place the part on the floor, first laying it with a soft cloth. Do not place the bumper on the ground: small pebbles can scratch the paint.

It is not necessary to remove the standard Vesta horn. It can work together with the new one. This will increase energy consumption, so most car owners turn it off and leave it inactive in case the replacement breaks down. To connect it, it will be enough to connect the block.

Remove the negative terminal from the battery. Choose a location for new horns. They can be hung on old brackets from original Vesta parts. If the fasteners do not fit, buy new ones. It is better to inspect the fastenings before actual installation. Do not place the horn too close to the body. This will cause resonance: the wear of the part will increase, and the bell will be clearly audible in the cabin. Mark future holes for the brackets. Drill them. Screw the horns tightly. They should not dangle or shake when driving. Place the signal further from the bumper: moisture trapped in the membranes can short-circuit the contacts. If the installation is done correctly, you will not need to remove the bumper to remove the horns in the future.

The disk signal setting is different from the standard one. They can be mounted under the hood or placed next to the headlights. Connecting the signal to the wiring will be noticeably more difficult: it is important to insulate the wires well. They should not get wet. The horns located near the edge of the hood run the risk of burning out during rain.

Alternative options

In this case, the possibilities are limited solely by the imagination of the Vesta owner. Most often, sound signals from the Volga are installed on the Lada, since their sound is much louder. But there are other ways. The most common options for such “modernization” are:

- installation of signals from the Volga - in this case, different installation methods are possible (with connecting a relay in the cabin or under the hood)

— installation of other signals;

— installation of a signal with an integrated compressor;

— a combination of signal and high beam.

Setting other signals is just one of many options.

Installation of signals from Volga

It involves not only installing “shells” directly on Vesta, but also various options for connecting them. It is worth remembering that the sound signal from the Volga can be either old or new. However, they have no differences, except for a slight difference in tonality:

— sound signals Volga-3110 (22.3721/221.3721) – low and high tone;

- sound signals Volga, RAF S302/303D - low and high tone.

Sound pressure – 105-118 dB.

The signal from the Volga is perfect for the Lada Vesta.

It is necessary to take into account that simply replacing the signals on Vesta will not work, because their current consumption is different. For Vesta this figure is 5A (passport data), although in reality it usually does not exceed 3.5A. Signals from the Volga consume 8A each, which gives a total of 16A. Therefore, for their installation it is necessary to use a 4-pin type relay. In particular, you can use relay 904.3747-10.

In addition, on Vesta, only one plug is supplied to the factory signal - “Plus” is permanent, since it supplies power to the fan, and “Minus” comes from the button on the steering wheel. Regarding the Volga signals, they only need “Plus”, because “Minus” goes directly through the metal mount to the body.

This mounting option will lead to vibration and ringing during signal operation. Brackets must be used.

It is also necessary to take into account the dimensions of the sound signals - the Volgov ones are larger than the standard ones on Vesta. Therefore, installation in factory locations is excluded. In addition, it is not advisable to mount them directly to the body, as this will lead to vibration, and the sound of resonating metal will be mixed with the horn. So the best solution would be to use a bracket. The advantage of this option is its low cost - a set of “Volgov” signals will cost about 1,000 rubles.

Installation of relays in the interior of Lada Vesta

This is done directly in the fuse box. To carry out the work you will need the following components:

— sound signals from the Volga;

— 4-pin type relay;

— terminals – wide (6 units) and narrow (1 unit).

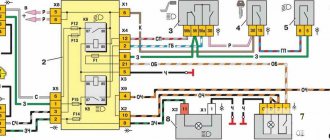

For installation, it is best to use the free space in the fuse box, to which the wires from the contact relay, which is responsible for activating the signal on the steering wheel, are transferred. In the place that has become vacant, a wire from relay contact “87” is placed. Next, you will need to remove the wire from the 13th contact block and insert it into the 13th connector “87” of the relay contact.

Connection diagram for Volga signals on Lada Vesta.

To supply “Plus”, you will need to feed the wire to relay contact “30” from connector “Ш5-6”, using a jumper of contact “86”. In this case, you will have to insulate the wire in red-white or black-white color, since “Plus” always goes to it.

Pneumatic signal

Initially, an electromagnetic horn is installed in the car. Such pipes consist of an electromagnet, a membrane and a core. The sound occurs when the core rod presses on the membrane. This type of horn is most often chosen by manufacturers: they have a simple design. They are divided into:

- Horns. Average sound quality. Outwardly they resemble a forge.

- Snails. Installed with the pipe facing forward. The design is not comfortable for installation; it is used in the production of Lada Vesta cars.

- Disks. Occupies minimal space. Easy to install.

- Pneumatic horns are louder than electromagnetic ones. Their volume reaches one hundred twenty-five decibels. The tonality of the pipe covers more frequencies. In order for the pneumatic signal to work stably, you will need a powerful compressor.

- Klaxons can consist of a large number of horns: up to five pieces. A programmable relay provides detailed melody customization. The resulting tone will be unique in its content.

- The music relay is used for entertainment vehicles only. Installing such a horn for driving around the city is prohibited by Russian law.