The legendary Niva is an all-wheel drive vehicle. This ensures unprecedented road holding and reliability comparable to expensive high-performance cars. With the exception of updated versions under the Chevrolet brand, the traditional Niva has always had a rather modest design, but this did not prevent it from being the undisputed leader among car owners who prefer high-end car platforms.

What distinguishes the Niva's chassis from other all-wheel drive vehicles is the transmission of torque to two axles at once without disabling the axles, which significantly affects cross-country ability while simultaneously reducing the influence of critical loads on the transmission. This same quality makes this legendary Russian SUV very uneconomical in terms of fuel consumption.

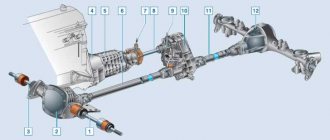

Diagram and description of the Niva 2121 transmission

The legendary Niva is an all-wheel drive vehicle. This ensures unprecedented road holding and reliability comparable to expensive high-performance cars. With the exception of updated versions under the Chevrolet brand, the traditional Niva has always had a rather modest design, but this did not prevent it from being the undisputed leader among car owners who prefer high-end car platforms.

What distinguishes the Niva's chassis from other all-wheel drive vehicles is the transmission of torque to two axles at once without disabling the axles, which significantly affects cross-country ability while simultaneously reducing the influence of critical loads on the transmission. This same quality makes this legendary Russian SUV very uneconomical in terms of fuel consumption.

The legendary Niva is an all-wheel drive vehicle. This ensures unprecedented road holding and reliability comparable to expensive high-performance cars. With the exception of updated versions under the Chevrolet brand, the traditional Niva has always had a rather modest design, but this did not prevent it from being the undisputed leader among car owners who prefer high-end car platforms.

What distinguishes the Niva's chassis from other all-wheel drive vehicles is the transmission of torque to two axles at once without disabling the axles, which significantly affects cross-country ability while simultaneously reducing the influence of critical loads on the transmission. This same quality makes this legendary Russian SUV very uneconomical in terms of fuel consumption.

Tips for owners

To make driving your car comfortable, read some important points:

- The usual, standard arrangement of the front and rear handles is forward and backward, respectively. Movement in this mode can and should be carried out in areas characterized by even and smooth surfaces.

- Locking the differential by switching the front handle to the rear position is best on roads characterized by increased slipperiness. This measure will give Niva stability. It is worth understanding that after overcoming the problem area, the handle will need to be returned to its original position.

- As noted earlier, downshift should be activated before a potential obstacle, but not while the car is already stuck.

- It is worth understanding that activating the lock when the vehicle is stationary is sometimes impossible, even if the clutch is depressed. This may be caused by the clutch teeth hitting the gear teeth. In this case, you can try to activate the lock by starting to drive slowly and make a slight turn. If problems arise with disabling the lock, it is recommended to perform the same procedure with the clutch depressed and the steering wheel slightly rocked.

Design and principle of operation of the Niva 2121 transfer case

The transfer case mechanism includes more than 60 independent parts, which is confirmed by the presented drawing. Therefore, it is quite prudent to name the main elements and their purpose.

- Frame

- Differential housing

- Shafts

- Couplings

- Oil seals

- Satellites

- Gears

- Flanges

- Levers

Also interesting: Niva Chevrolet transfer case: device, connection diagram and how to use?

A pair of gears are tightly seated on the drive shaft, one of them (large) is intended for high gear, the second (small) is responsible for low gear. They have serrations with straight and oblique profiles. The first ones are in contact with the coupling, the second ones - with the intermediate shaft. The inclusion of one or another row causes the coupling to move along the hub in the horizontal direction, after which it is connected to the gear on the transfer case drive shaft.

The intermediate position turns off the gearbox (the gearbox is open), and the vehicle cannot be moved in this mode. The front helical gear on the intermediate shaft is used to control the differential. The locking is engaged, or the rigid coupling of the drive shafts of both axles, is carried out through a clutch. The design is typical for modifications 21213 and 21214, and the latter is additionally equipped with a speed sensor drive.

In the operating state (with the transfer case reduction gear connected), the gear ratio in the first stage changes from 4.4 to 7.83, the second - from 2.52 to 4.58, the third - from 1.63 to 2.9, in the fourth - from 1.2 to 2.14, fifth - from 0.98 to 1.75, which is expressed in an increase in traction on the wheels.

- Housing Differential housing Shafts Couplings Seals Pinions Gears Flanges Levers

- Housing Differential housing Shafts Couplings Seals Pinions Gears Flanges Levers

Eliminate vibration with additional fasteners

The Niva family of cars differs from VAZ passenger cars in permanent all-wheel drive - they have two drive axles.

In total, the VAZ SUV has three differentials in its transmission - one for each axle and another center differential. 1. Oil seal; 2. Thrust ring of the front bearing of the drive shaft; 3. Front bearing cover; 4. Front drive shaft bearing; 5. Transfer case front cover; 6. High gear; 7. Gear clutch hub; 8. Gear clutch; 9. Low gear; 10.

Transfer case housing; 11. Rear drive shaft bearing; 12. Drive shaft; 13. Transfer case rear cover; 14. Intermediate shaft; 15. Rear intermediate shaft bearing; 16. Rear differential housing bearing; 17. Installation ring of the rear axle drive shaft bearing; 18. Rear axle drive shaft bearing; 19.

Differential housing bearing retaining ring; 31. Differential locking clutch; 32. Front axle drive shaft; 33. Front axle drive housing; 34. Retaining ring of the front axle drive shaft bearing; 35. Differential bearing spring washer; 36. Front differential housing bearing; 37.

Speedometer driven gear; 38. Speedometer drive housing; 39. Front intermediate shaft bearing; 40. Gearbox; 41. Elastic coupling; 42. Constant velocity joint; 43. Transfer case; 44. Shims; 45. Transfer case suspension bracket; 46. Rear engine mount bracket.

I. High gear engaged; II. Low gear engaged; III. Low gear is engaged, differential is locked.

The Niva transfer case is designed to distribute traction forces between axles, and operates on the principle of a 2-speed gearbox.

- driveshafts are poorly secured;

- wheels are not balanced;

- there is play in the cardan crosspieces (vibration is especially affected by play in the rear driveshaft crosspieces);

- The vibration comes from the engine itself.

Vibration when starting off on a Niva can also occur for the following reasons:

- the mounting supports of the transfer case have become loose;

- The rubber on the RK supports themselves broke.

Installing the third support of the transfer case on VAZ 21213/21214 vehicles allows you to reduce the level of vibration of the transfer case; with this support it is easier to center the transfer case. The part can be purchased at auto stores or made yourself. The finished product comes with three long studs (for model 2121); to install the third support on this machine, you will need to unscrew the short studs from the transfer case housing and install new studs from the kit. We carry out repairs as follows:

- dismantle the front passenger seat in the cabin;

- remove the floor tunnel lining;

- in the cabin we move aside the carpet covering the body amplifier (in front of the handbrake lever);

- remove the transfer case (alternatively, you can simply hang it up, but removing the third support makes it easier to install);

- We attach the bracket of the new support to the body of the RC;

- we install the transfer case in place, center it in the optimal position, and fasten the side supports;

- we combine the third support with the body, drill two holes in the bottom;

- Using washers, bolts and nuts (from the kit) we attach the support to the bottom of the body.

Vibration is eliminated more effectively by installing a subframe under the transfer case. You can also make such a device yourself or buy a finished product at a car store.

In order to install the subframe, the transfer case must be removed. It is more convenient to carry out such work in a pit; we carry out repairs as follows:

- leave the car in neutral gear;

- disconnect the propeller shaft from the transfer case, it is advisable to mark the driveshaft flange and the drive shaft so that during installation, align the driveshaft according to the marks - this way, the occurrence of unnecessary vibrations is eliminated;

- dismantle the muffler mounting bracket;

- remove the gearbox traverse;

- jack up the transfer case, remove the side fastenings of the transfer case;

- We treat the places where the subframe fits to the body with Movil;

- place the subframe on the gearbox studs;

- we mark the attachment points of the subframe on the side members, drill holes, attach bolts to the body;

- we tighten all fastenings, except for the transfer case supports themselves;

- we perform alignment of the steering wheel;

- Finally tighten the transfer case supports.

It should be noted that installing an additional support or subframe on the steering wheel does not always lead to the desired effect; in some cases, vibration only increases.

The main purpose of the Niva 2121 transfer case

The transfer case (another name is the range multiplier) is connected directly to the gearbox, participates in the distribution of rotation on the axis of the all-terrain vehicle and helps to increase the torque when transmitted to the wheels of the vehicle.

Niva 2121 transfer case cross-sectional diagram

It is necessary to list the main reasons why the RK failed on a Chevrolet. The most common is frequent driving of a given vehicle at high speeds, which negatively affects the working life of the component parts of the box. In particular, the seals may wear out and the fastenings may become loose.

The transfer case is noisy. To solve this problem, you can buy special silent levers for the RK. Thanks to this, the necessary noise insulation is achieved and vibrations will not be noted.

Modified versions

The Niva's standard transmission, for all its advantages, often causes uncomfortable noise in the cabin.

This is generally related to the design, but using engineering developments, you can modernize it and make the car much quieter. This approach has already been applied in the VAZ-21213 model; as a result, even at a speed of 100 km/h you don’t feel any unpleasant noise, you can talk calmly and hear your interlocutor without effort. For these purposes, a number of modernization methods have been used: from unloading the floor near the transfer case and manual transmission mounts, reducing the load on shaft bearings to smoothing out peak torques under conditions of increasing loads on the transmission. The effect is achieved by changing the mounting location of the front axle gearbox, which in the modernized version is suspended at a distance from the engine on rubber supports. This approach makes it possible to reduce to a minimum the reactive torque in the longitudinal-vertical direction and the noise level at speed.

The noise in the modernized Niva transmission is comparable to that of a Zhiguli. It becomes more comfortable to be in the car when driving off-road. Upgrade costs are negligible; modification requires only the master's understanding of the design itself and a little time.

Source

Transfer case control

The Niva 2121 transfer case has manual control with a lever-type mechanical drive. The shift lever swings in the longitudinal direction and is performed on an axis that is installed in the bracket eyes in front of the transfer case. Friction is reduced by pressed plastic bushings into the holes of the lever.

The lower part of the lever is inserted into a groove on the rod, and fixation occurs using a figured spring. The other end of the rod, in turn, is connected to a fork, which moves the shift clutch. The rigidity of this connection is ensured by the bolt. The rod at the outlet of the transfer case is sealed with an oil seal, and dirt and dust are protected with a rubber corrugation. The entire switching drive is fixed in the set position by a spring-loaded ball that fits into special grooves in the rod.

Diagram of a 5-speed gear shift mechanism for VAZ-2123

At the factory, modern Niva cars are equipped with a five-speed gearbox, made according to the three-shaft type.

Gearbox design:

Heat removal from heated rubbing parts is realized by manufacturing a multi-fin structure on the surface of the crankcase and also to protect the speed selection unit from overheating and exceeding excess pressure, a breather is present in the design.

The tightness of body connections is ensured through the use of pressed shaped gaskets. In case of repair of the gear selector assembly, it is also possible to use a liquid gasket former. The lower part of the gearbox housing is covered with a stamped steel protection with a gasket.

In a modern design, the gearbox housing and synchronizer clutches are reliable and adapted to operating conditions on Russian roads.

Over time, any mechanism wears out, sooner or later it will be necessary to carry out maintenance and adjust the gear mechanism. There are quite a lot of companies on the spare parts market that produce any components, parts and related materials for both old and new Chevrolet modifications.

Location of control and drainage holes:

- a control hole is made for ease of oil change in the upper left part of the crankcase housing;

- the technological hole for draining used oil remains unchanged at the bottom of the frame.

It is equipped with a screw-on magnetic plug to collect small metal shavings. Lubrication of rubbing surfaces is carried out by spraying. Domestic oil seals are installed in the housing at the output of the primary and secondary shafts. The axis of the gearbox speed gear is fixed on the rear cover of the gearbox housing.

The rotation of the input shaft is carried out through 2 ball bearings. For the industrial shaft, the design of the unit includes double-row ball roller bearings.

A breather is installed in the upper part of the housing (near the clutch). If the breather malfunctions (cap failure), transmission oil may be squeezed out through the seals and housing connections.

The arrangement of the shaft gears is implemented in the following sequence:

- toothed gear of constant mesh with the input shaft;

- III;

- II;

- I.

Possible problems

During the operation of off-road vehicles, parts and components of the transfer case gradually become unusable due to wear. Most often, the following interruptions in the operation of the mechanism occur:

- The front axle does not engage.

- The transfer case is overheating.

- Leaks and increased oil consumption of the transfer case.

- Unauthorized disabling of the front axle.

Harsh operation and insufficient attention to how to use the transfer case on the Niva 2121 lead to the appearance of:

- Vibrations in the body while moving Vibrations when starting Hum Noise when maneuvering Tight switching on modes

Also interesting: Interior heater valve VAZ 2121 Niva 2131

Experience shows that the culprits are: insufficient oil level, incorrect centering of the steering wheel, loosening of the support fastenings and damage to the rubber bands. An additional influence is exerted by the condition of the cardan and the engine itself.

- Vibrations in the body while driving

- Vibrations at start

- Gula

- Noise when maneuvering

- Tight switching modes

Useful tips

To use the lock installed on the Niva effectively, use the following recommendations from experts:

- When driving on good quality road surfaces, install the front transfer handle at the front and the rear at the rear.

- The front handle is moved back if the road becomes slippery. Once the slippery area has been passed, switch the levers to normal mode.

- If the Niva is stopped, the lock may not engage when the clutch is depressed. This occurs due to the alignment of the teeth with the gear teeth. What should you do in this case? Moving as if on a turn, engage the lock. The differential will turn and the gear teeth will come closer to the teeth. If turning off is difficult, do it while the vehicle is moving, maintaining a minimum speed and squeezing the clutch.

Forced unlock

Sometimes it happens that the lock gets stuck - it cannot be turned off even when the car is completely stopped. The situation is quite common for the Chevrolet Niva. How to solve it? There is a sure way. To do this, engage reverse gear, accelerate a little and turn off the differential lock while driving.

What to do in such a situation? It is necessary to turn on the first speed and try to turn off the unit again. Moving back and forth will solve the problem of a stuck differential. In general, it is recommended to turn on the center lock only in serious off-road conditions. At the intersection of dirt roads and sand dunes, a downshift is sufficient.

Disabling the front axle in the field

Is it necessary to modify the VAZ 4×4 Niva transfer case?

Cheviniva in 4x2 mode (disable all-wheel drive), leaving only.

If the lock does not turn on using the specified method, do not use excessive force. How to disable the immobilizer on a VAZ. Just repeat the entire sequence of actions from the beginning.

Switching to a lower gear is also allowed without stopping the Niva completely, but this can only be done by experienced drivers. The fact is that the transfer case, unlike the gearbox, does not have synchronizers installed. Changing from a lower gear to a higher gear while the car is moving is undesirable, although it is allowed in extreme cases.

It is not recommended to keep the center differential of the wheels in locked mode at all times, especially when driving on asphalt roads, as this will not only lead to increased fuel consumption by the vehicle and poor handling, but also to the breakdown of expensive transmission components.

It is preferable to enable forced blocking in various modifications of the Niva in the following situations:

- The blocking must be turned on in advance if you have to overcome a difficult route.

- On sharp climbs uphill or when driving downhill.

- While crossing terrain with a top layer of sand.

- When you have to drive on snow drifts or an icy road.

Also interesting: How to use the transfer case on a Chevrolet Niva - a couple of tips

Wheel locking is not necessary when driving quietly on a flat road within the city. Grip on asphalt surfaces will be decent, and traction will be distributed evenly by default.

Features of the Nivov design

The features of the Nivov transmission include the presence of a center differential that connects the rear and front axles. As a result, the wheels can rotate not only at different angles, but also at different angular speeds, which significantly affects controllability in impassable roads.

The center differential is located in the transfer case and is similar in design to the cross-axle differential.

The key difference between the Niva’s center differential is the ability to lock when driveshafts rotate with the same characteristics. The center differential is manually locked only in difficult terrain conditions, when you need to overcome a large hole, rut or snow drift without slipping.

In practice, mechanical locking, although somewhat inconvenient, turns out to be better than the modern electromagnetic clutch used for these purposes. For example, the Renault Duster is not so easy to cope with the task in harsh off-road conditions, since the digital control unit can provide limited torque transmission. However, this effect will not be observed in a Niva with a mechanical lock.

Leaving the center differential locked will not only cause increased wear, but will also significantly reduce the vehicle's handling. The activated differential lock mode will be indicated by a lit indicator on the Niva dashboard. Please note that locking will not prevent one wheel from losing traction.

To overcome difficult areas, the transmission allows the use of a low gear with a high gear ratio (2.135); in the highest gear, the parameter is 1.2 and is intended for driving in normal conditions. The transfer case indicates different high and low gear modes. The lower one is turned on before entering a snowy area, unsteady soils, hills, and when a towed load is connected. The low gear compensates for the lack of power of the Niva’s “strong” engine and allows you to overcome difficult areas that only powerful cars can do.

Some drivers master the skill of shifting gears at speeds of 30-35 km/h. Otherwise, you will have to stop the car and perform the operation in the parking lot.

Please note that Niva requires a competent approach to the selection of tires, the quality of which can affect the degree of wear of the transmission in just one season. The tires must be the same in terms of wear and, of course, in size. Different characteristics will lead to increased load on the transmission and slipping in low gear, and during normal driving will increase wear on the differentials.

We help with all our wheels

How to enable all-wheel drive on a Chevrolet Niva? There is an option to block the center differential of the Chevy Niva both when the car is stationary and when it is not moving.

This is done with the clutch pedal depressed using the transfer case control lever, which is located behind the huge gear selector. When the lever is in the neutral position, you need to pull it towards the driver. If you later press in the opposite direction, a lower gear will engage with the center differential locked at a ratio other than 3.5.1. If you pull towards yourself, a lower gear is put into effect (gear ratio 1.5).

When the lever is in this position, the corresponding yellowish pictogram lights up on the dashboard. Disabling the front axle on a Chevrolet Niva. four-wheel drive. How to disable. If you cannot follow these instructions, try repeating the procedure while driving the vehicle.

The correct sequence for activating the lock while driving is given in the instruction manual for this vehicle. Niva permanent all-wheel drive - How it works and. It says here that such blocking should be done in advance, at the time the car is moving along a section of the road with a hard surface. How does all-wheel drive work on a Chevrolet Niva and Niva….

What is the best gear oil to fill?

What year did injection fields 2121 come from?

Lubricants consist of a base (base) and additives. Their chemical and physical properties depend on the composition and origin of these components.

According to the method of manufacturing the base, the transmission is divided into three types:

- Mineral is a product remaining after the distillation of oil in the production of diesel fuel and gasoline. Includes heavy fractions of hydrocarbons and contains large amounts of sulfur. Its properties are determined by naphthenes, aromatics and paraffins. The oil entering oil refineries differs in its composition. This does not allow achieving stable mixture proportions. Therefore, the final parameters are adjusted with additives. Under the influence of temperature, heavy fractions of hydrocarbons disintegrate, and additives oxidize and lose their properties. This oil has to be changed more often. Another disadvantage of “mineral water” is that oxidation products settle on parts.

- The synthetic base is artificially created from the desired hydrocarbons. Thanks to this, it is possible to obtain a product with predictable viscosity values without the use of additives. Additives are used only to improve the lubricating and antioxidant properties of the transmission.

- Semi-synthetic oils are created on the basis of a mixture of mineral and synthetic bases (at least 30% of the latter is used). This approach allows you to reduce the number of additives that change viscosity.

Synthetic gear oil differs from mineral and semi-synthetic oil in that its viscosity changes less with temperature changes. This reduces wear on transmission parts during winter operation of the Chevrolet Niva. But “synthetics”, due to their greater fluidity, seep through worn gearbox seals more easily.

However, the main characteristic of a lubricant is viscosity. This is what is indicated in the operating instructions. The manufacturing company recommends filling in the following types of gear oils (according to SAE):

- Transfer case and gearbox - 75W-90, 80W-85, 80W-90.

- Drive axles (front and rear) - 80W-90, 85W90.

There are dozens of gear oil brands on the market. The most famous imported ones are Castrol, Liqui Moly, Mobile, Shell, and the most famous domestic ones are Lukoil and Rosneft.

Prices for a liter bottle start from 400 rubles.

The Lukoil company is the official partner of AvtoVAZ. It is this brand of semi-synthetics that is poured into the transmission during the production of the Chevy Niva.

Rules for using differential

These include:

- Switching the transfer case should only be done when the car is not moving.

- You can also engage the differential while the vehicle is moving.

- You can switch to a lower gear while the car is moving.

- To ensure long-term and uninterrupted operation of the differential, it is necessary to periodically turn it on, especially in winter. This should be done once every 7 days.

To ensure that the locking mechanism lasts for a long time, use the following rules:

- It is necessary to switch the transfer case when the Niva does not move.

- The differential can also be engaged while the vehicle is moving.

- To ensure efficient and long-term operation of the device, it is advisable for the Niva driver to turn on the lock from time to time. Once a week in winter is enough.

Where is the lever responsible for switching located? Pay attention to the area between the wings located in front, there are 2 levers there. One makes it possible to change gears at the gearbox, the other successfully controls the transfer case.

The basis of the transfer case is a gearbox, which includes 2 stages. The control lever comes directly from it, you can move it forward and backward - this is how the gear is changed on the Niva. The direction of movement of the lever to the left and right allows you to activate the differential lock and vice versa to disable it.

Read news about the new Niva

- Scanner for car diagnostics elm327 OBD2 wi-fi version 1.5, which is better to buy for VAZ, Niva Chevrolet |

- Test drive ZXAuto Grand Tiger - Unfamiliar “Chinese” (Landmark, Grandtiger)

- TOP 5 most reliable Korean crossovers: they are recommended for purchase

- Toyota Hilux - when there is nothing else to drive

- The new Nissan Frontier pickup did not become Navara's twin - Autoreview

- Color spectrum

- Haval H5 2020-2021: characteristics, price, photo and video review

- Review of the standard alarm system Niva Chevrolet

Fuel consumption

Replacing the cuff of the secondary shaft of the VAZ-2107 gearbox

The engine that is equipped in the Chevrolet Niva began to be produced back in the 90s. Since that time, the engine has been frequently updated and gradually it became compliant with Euro 5 specifications. However, each upgrade increases fuel consumption. For the latest version, the figure is over 14 liters.

What will happen in reality? If you remove the front driveshaft, gasoline consumption will become 14.2 liters, and for the “standard version” the figures will become even worse - 14.8 liters per 100 km. According to the manufacturer, the fuel consumption of the Chevrolet Niva is:

| Transmission type | terms of Use | Fuel consumption per 100 km, l |

| Automatic transmission | In the city On the highway at a speed of 90 km/h On the highway at a speed of 120 km/h | 12,0 9,5 12,0 |

| Manual transmission | In the city On the highway at a speed of 90 km/h On the highway at a speed of 120 km/h | 10,8 8,6 11,6 |

However, most owners of this car state other figures, which in reality amount to:

- Automatic transmission: in the city - 16.5 liters, on the highway - 13.0.

- Manual transmission: in the city - 13.5 liters, on the highway - 12.0.

The reason for this fuel consumption is too many auxiliary units. To reduce this indicator, it is necessary to correctly adjust the balancing of the cardans. It should always be remembered that imbalance occurs during deformation.

You should pay attention to the crosspieces, as they should turn easily. It is necessary to avoid play in spline joints, crosspieces and secondary shaft bearings. To avoid unnecessary fuel consumption by car, you must:

To avoid unnecessary fuel consumption by car, you must:

- Do not exceed the speed of 90-100 km/h on the highway.

- Control should not be performed with a sharp increase in speed and an instant transition from one speed to another.

- Be careful about monitoring tire pressure.