- Home /

- Blog /

- Chassis LADA Largus /

- Largus rear wheel bearing with ABS - features

The wheel hub spare part for Lada Largus requires replacement from time to time. You will find Largus rear wheel bearings with ABS for Lada on the website by spare part number or article number, you can order from a warehouse in Moscow and replace the part. The catalog presents auto parts for suspension and steering, which are made on the basis of innovative composite materials. The hub bearing is made of special grades of steel and new generation plastic materials, so it is not afraid of serious loads. All spare parts for the rear of Largus have been tested by an independent expert, which confirms the conformity of quality. Advantages of bearings for cars with ABS:

- Belongs to category “A”, is not afraid of heavy loads.

- The accuracy class according to the standard gap group GOST 520-2002 is sixth.

- The ideal geometry and the highest precision processing of rollers and balls allows the system to operate as quietly as possible.

- The rubber element of the oil seal contains special additives that increase elasticity and resistance to the influence of temperature conditions.

- The seals create the highest tightness.

- Modern lubricant is used.

If the Largus rear wheel bearing with ABS is installed correctly, with tightening and the rules for operating the parts are followed, then the part will not need to be replaced for many kilometers. Includes: 1 rear wheel bearing. For more information about the terms of payment and delivery, please call in Moscow.

Main functions

For free and correct rotation of wheels on the Lada Largus, special hub bearings are used. The devices are made of durable metals and have a cast form. This is necessary because during use they take on enormous mechanical loads. As the mileage progresses, this element, one way or another, begins to wear out naturally. This inevitably leads to the fact that the part needs to be replaced. The need for replacement can be accelerated by incorrect operation of the vehicle or unqualified repairs.

The bearing is located on the axis of the wheel hub. Every motorist must be attentive and be able to recognize malfunctions of this mechanism, since the safety of driving the car and all the people in it depends on it. If this element is destroyed, the wheel may jam and the car will become uncontrollable. And at high speed this may provoke an emergency situation, so you shouldn’t bother with replacement. With all this, wheel bearings are very strong, wear-resistant and durable parts (given high-quality products) that can withstand severe loads.

Double-row conical roller-type devices are installed on the front axis. The use of more complex units is justified by the introduction of a front drive, where during braking, acceleration, etc., several forces act on the bearings at once. At the rear, single-row roller hubs are installed, since the load on the rear axle is even less.

With proper operation and timely maintenance, these elements can last up to 130,000 km or more.

- Replacement of the rear brake pads in a LADA Largus car should be carried out at least once within 2 years, because the ingress of water into the circuit leads to a decrease in the boiling point, and, consequently, the efficiency of the system.

- Monitor the fluid level in the reservoir regularly. It has to be replenished.

- If the level is actively decreasing, then take measures to find the source of the leak. There may be a depressurization of the system, and this is very unsafe due to the “loss” of brakes on the road.

- We recommend replacing pads with or without ABS when the degree of wear has reached or begun to exceed the 70 percent limit.

- After winter, don’t be lazy to clean the brake calipers and lubricate the guides (in the front mechanisms). This will prevent these nodes from turning sour.

- Do not skimp on pads, because safety depends on the properties of these consumables.

Replacing rear brake pads is not an easy, but responsible procedure.

Timing belt roller engine 1.6 16V Lada Largus (parasitic) Quartz analogue QZ0107150

- Manufacturer: Germany

- Quartz: QZ0107150 — 500rub

- Availability: yes

- Applicability: Logan Phase1, Logan Phase2, Sandero, Lada Largus

The AUTO COURIER company has been operating on the market since 2005 and has extensive experience in the selection of spare parts for Renault and other brands. In the process of productive work with manufacturers and suppliers, we managed to establish uninterrupted supplies of spare parts to the Saratov region and other regions of the country. The company focuses on auto parts for Renault Logan, Lada Largus, Renault Duster, Renault Sandero, Renault Megane.

Renault spare parts and accessories from different manufacturers are available: original and third-party manufacturers. The specialists of our online store are highly qualified and have extensive practical experience. By contacting us, you will receive the necessary advice and we will select the necessary spare part for you from the large assortment of our warehouse. You can use any communication method convenient for you and receive the necessary goods at a time convenient for you by ordering delivery. Delivery is carried out both in the Saratov region and throughout Russia in any way convenient for you.

AUTO COURIER is developing a huge warehouse of used automatic transmission units, manual transmission parts, body parts and chassis. We do not ignore oils, lubricants and special chemicals, therefore we purchase very high-quality products from such manufacturers as Pentosin, SRS, ARAL, Petro Canada, Chevron, ELF, Total. The AUTO COURIER company is chosen for its individual approach, speed of work and special attitude towards work and clients. The main goal of the company is mutually beneficial cooperation. Good luck on the road!

Operations for removing the wheel bearing LADA Largus

We recommend replacing the bearings of both front wheel hubs at once.

Remove the steering knuckle (see Removing and installing the LADA Largus ). 2. Clamp the steering knuckle in a vice and knock out the hub with a hammer using a mandrel of suitable diameter (for example, a socket head).

Remove the hub. Most likely, the outer half of the inner race of the bearing will remain on it. After removing the hub, the bearing is not suitable for reuse.4. Install the puller.

...and remove the outer half of the inner bearing race from the hub.

Install the bearing puller and press the outer bearing race out of the knuckle. 7. If a puller is not available, knock out the bearing using a mandrel of a suitable diameter, since the pressed out bearing is not suitable for reuse. 8. Clean the parts and lubricate the inner surface of the knuckle seat and the outer surface of the hub with a thin layer of grease.9. Press the new bearing all the way into the steering knuckle. When pressing the bearing into the steering knuckle housing, force should only be applied to the outer ring of the bearing, otherwise the bearing may be damaged. 10. Press the hub into the bearing until it stops, supporting the inner ring of the bearing with a support. If you do not secure the inner ring of the bearing with a support when pressing the hub, it can be damaged. 11. Install the steering knuckle on the vehicle in the reverse order of removal. 12. Check and, if necessary, adjust the wheel alignment angles in workshops with special equipment.

Faulty wheel bearings

External manifestation of a malfunction/breakage/problem: Damage to the raceway Probable cause: Impact on the inner ring during bearing installation.

External indication of malfunction/breakage/problem: Damage to the raceway Probable cause: Incorrect tightening torque when installing the bearing, resulting in too little clearance, causing damage to the raceway.

External manifestation of a malfunction/breakage/problem: Damage to the raceway Probable cause: Foreign body entering the bearing

External manifestation of a malfunction/breakage/problem: Darkening of the surface of the outer ring of the bearing. Probable cause: Incorrect installation of the bearing in the knuckle, which led to fretting corrosion of the surface of the outer ring and its darkening. For components of this type, anti-fretting paste LGAF 3 should be used.

External manifestation of a malfunction/breakdown/problem: Damage to the raceway Probable cause: A foreign body entering the bearing, causing wear and subsequent spalling of the ring surface.

New Lada: Luggage systems – Largus Shop

External manifestation of a malfunction/breakdown/problem

Breakage, chipping of the outer ring Probable cause: Impact on the housing/outer ring when installing the bearing.

External manifestation of a malfunction/breakdown/problem

Water Entry Probable Cause: Water intrusion through the seal causing corrosion on the inner surface of the outer ring.

External manifestation of a malfunction/breakdown/problem

Peeling of raceway surface

Probable cause: Violation of installation technology: inappropriate installation force, which caused the preload in the bearing to be exceeded.

External manifestation of a malfunction/breakdown/problem

Seal Dents Probable Cause: Seal damage is most likely caused by impact during bearing installation.

External manifestation of a malfunction/breakdown/problem

Peeling of raceway surface

Probable Cause: Bearing installation misalignment caused raceway damage that progressed to surface peeling.

External manifestation of a malfunction/breakdown/problem

Seal Displacement Probable Cause: Impact to the bearing during installation damaged the inner ring edges, race surface and caused the seal to move from its original position.

External manifestation of a malfunction/breakdown/problem

Plastic deformation of the track surface

Probable Cause: Plastic deformation occurs under loads exceeding the tensile strength of the material. Static or shock overloads cause plastic deformations with the formation of dents on the surfaces of the bearing raceways, located according to the pitch of the rolling elements.

External manifestation of a malfunction/breakdown/problem

An increased width trace of a characteristic color on the track from the rolling elements towards the shoulder

Probable reason: During operation, the clearance in the bearing increases, which causes a significant change in the width of the mark on the track from the rolling elements.

External manifestation of a malfunction/breakdown/problem

Plastic deformation of the inner ring surface Probable cause: This type of deformation on the raceway indicates increased vibration of the shaft.

External manifestation of a malfunction/breakdown/problem

Damage to the seal Probable cause: Violation of installation technology, most likely impact on the bearing during installation.

External manifestation of a malfunction/breakdown/problem

Seal Damage Probable Cause: The damage is most likely caused by misalignment during bearing installation, causing the seal to come into contact with the threaded part of the shaft.

External manifestation of a malfunction/breakdown/problem

Surface spalling Probable cause: Misalignment during bearing installation, resulting in spalling of the raceway and outer ring surfaces.

External manifestation of a malfunction/breakdown/problem

Water ingress/rust Probable cause: Damage to the seal, most likely due to poor installation technology.

Algorithm of actions

We first carry out the entire list of necessary actions, which we do not focus on here. Using a press, press the hub out of the steering axle

If there is no press, then we use a mandrel paired with a hammer. With this action, the bearing in most cases is destroyed and its inner race remains on the hub shaft. A puller will help you remove it. If it is missing, you will have to cut it off, although this is dangerous due to damage to the hub shaft. We remove the outer race of the product from the cavity of the fist. We install the new bearing and secure it with a retaining ring. We press in the hub. We check that it is seated correctly. We install the assembly assembly on the LADA Largus car.

Changing the front bearing

When replacing a unit from the front, keep in mind that front-wheel drive complicates the process. In addition, in addition to standard tools (a set of socket heads, a 30mm socket is required, wrenches, screwdrivers, a hammer, etc.), you will need a special puller to remove the bearing. Before starting work, be sure to secure the machine, turn on first gear, place chocks under the wheels and lift the hand brake lever.

The further replacement process is as follows.

- Using a screwdriver, you need to remove the protective cap of the hub covering the nut, after which you should unlock it and, using a 30mm socket with a powerful amplifier, loosen the nut.

- Now you can hang the wheel with a jack and remove it by unscrewing the nuts.

- It is recommended to tie the brake caliper to the strut spring in advance to prevent it from sagging on the brake hose alone. After this, the caliper can be removed from the steering knuckle. First you need to unscrew the two bolts and remove the brake pads.

- Next, the brake disc nuts are unscrewed, after which it can be dismantled.

- Use a flat-head screwdriver to remove the retaining ring.

- Using a special puller, you can press the bearing out of its seat.

- After removing the part, this socket must be thoroughly cleaned of dirt, grease residues and corrosion, then filled with fresh lubricant.

- Using the same puller, the new bearing is pressed into the seat, but the device must not be skewed.

- The retaining ring is installed in its place, after which the bearing is secured with a thrust washer and a hub nut. The same nut adjusts the play when the wheel rotates.

After reassembly, you should do a test run to make sure there is no vibration, crunching, etc. To be sure, you need to check the play in the steering again. If there is no special puller, other, more labor-intensive methods are used. For example, knocking out using a suitable piece of metal pipe or heating the landing socket.

Take off1111111111111111ok

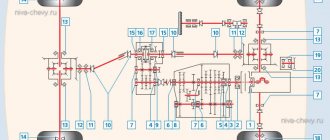

Diagram of the drive of auxiliary units of a car with air conditioning: 1 - drive pulley of auxiliary units;

2 - tension roller; 3 — power steering pump pulley; 4 — generator pulley; 5 — support roller; 6 — belt; 7 — air conditioner compressor pulley Diagram of the drive of auxiliary units of a car with air conditioning: 1 — drive pulley of the auxiliary units; 2 - tension roller; 3 — power steering pump pulley; 4 — generator pulley; 5 — support roller; 6 — belt; 7 - air conditioning compressor pulley

Diagram of the drive of auxiliary units of a car with air conditioning: 1 - drive pulley of auxiliary units; 2 - tension roller; 3 — power steering pump pulley; 4 — generator pulley; 5 — support roller; 6 — belt; 7 - air conditioning compressor pulley

The belt tension is adjusted automatically by a tensioner. To replace the belt, remove the right mudguard of the engine compartment. To loosen the belt tension, from below the car we put a spanner or a “15” socket on the tension roller mounting bolt.

Replacing a wheel bearing yourself

If such malfunctions occur, you must understand that the procedure with the front element is somewhat different from removing and installing the rear device.

Dismantling the wheel bearing of a LADA Largus car

To press out the hub, you need a head or other metal object of suitable diameter.

READ Replacing Niva Front Wheel Bearing

REPLACEMENT AND REVISION OF REAR PADS ALMERA G15, LARGUS, DASTER 2×4 D=228mm. IS THE DRUM OR WHEEL STILL?

After removing the ring, press out the bearing. We will press on the inner race. Before inserting the mandrel, you need to tear off the bearing so as not to bend the fist. Any metal plane will do for this. Having torn off the bearing, you can use mandrels to completely remove it. After pressing out the bearing, we move on to the hub. Here you need to remove the inner race from the hub. First, we take a chisel and a hammer, use them to knock down the boot and clean the hub. Now you need to remove the inner race of the old bearing. There are special tools for removal. But if you don’t have such a puller, you can use a grinder to make a cut. You can finally split the clip with a hammer and chisel. Having removed the clip, we look at the surface of the hub. It should be even and smooth. The inner race of the bearing sits on it. If the surface is not level, the hub should be replaced.

Dismantling the suspension of the LADA Largus car

Then remove the wheel and disconnect the ABS sensor. We take the sensor out of the bracket; for convenience, it can be bent to the side. Now unscrew the steering tip. The original nut is 16 mm, if the tip was changed, then the size will be 17 mm. We tighten the nut, having previously cleaned and lubricated it with a wedge. To remove the tip from the fist, it is better to use a puller so as not to damage the boot and threads.

When the tip comes out of the fist, remove the caliper. To do this, we separate the block and unscrew the 2 18 mm bolts from the back. After dismantling, the caliper is suspended on a spring.

Next, remove the brake disc. Before unscrewing the disc, be sure to tap it around with a hammer, especially the parts of the part with fastening bolts. This operation will make it easier to unscrew the hardware.

At the next stage of work, we unscrew or loosen the nuts securing the fist to the stand. It is better not to remove the bolts immediately.

It's time for the ball joint. It is fastened with a 16 mm through bolt, passing through the fist and compressing the assembly. Unscrew the nut and pull out the bolt. To make it easier for the ball pin to come out, you need to unclench your fist. We drive a wedge into the place where the fist is clenched.

We take a hammer in our hand and hit the counter. You cannot hit it too hard, as the stand may become deformed. Then remove the fist and take out the bolts. After removing the steering knuckle, it is advisable to unscrew the protective casing. If you press out the hub correctly, you don’t have to remove it.

Operations for removing the wheel bearing LADA Largus

We recommend replacing the bearings of both front wheel hubs at the same time.

Remove the steering knuckle (see Removing and installing the LADA Largus steering knuckle). 2. Clamp the steering knuckle in a vice and knock out the hub with a hammer using a mandrel of suitable diameter (for example, a socket head).

Remove the hub. Most likely, the outer half of the inner race of the bearing will remain on it. After removing the hub, the bearing is not suitable for reuse.4. Install the puller.

5 and remove the outer half of the bearing inner race from the hub.

Install the bearing puller and press the outer bearing race out of the knuckle. 7. If a puller is not available, knock out the bearing using a mandrel of a suitable diameter, since the pressed out bearing is not suitable for reuse. 8. Clean the parts and lubricate the inner surface of the knuckle seat and the outer surface of the hub with a thin layer of grease.9. Press the new bearing all the way into the steering knuckle. When pressing the bearing into the steering knuckle housing, force should only be applied to the outer ring of the bearing, otherwise the bearing may be damaged. 10. Press the hub into the bearing until it stops, supporting the inner ring of the bearing with a support. If you do not secure the inner ring of the bearing with a support when pressing the hub, it can be damaged. 11. Install the steering knuckle on the vehicle in the reverse order of removal. 12. Check and, if necessary, adjust the wheel alignment angles in workshops with special equipment.

Front wheel hub bearing LADA Largus (removal, replacement)

Bearing failure is accompanied by howling, whistling, and extraneous sounds when driving. As a rule, the noise and its volume depend on the wheel speed. In addition, the wheel develops excessive play when it moves vertically. In order to check it, you need to hang the wheel and swing the wheel with your hands by its edges. The movement and play, compared to a normal wheel, will be much more noticeable. To replace the bearing, it is convenient to use a commercially available puller for pressing out and pressing in wheel bearings.

2271-3-8-05-04

Remove the accessory drive belt from the pulleys.

Remove the accessory drive belt from the pulleys.

Remove the accessory drive belt from the pulleys.

The marking of the drive belt for auxiliary units with air conditioning is 6РК 1822 (six-strand, 1822 mm long). When replacing the belt, the support and tension rollers must also be replaced.

sequence of work with and without ABS

The main purpose of any bearing is to support and fix the shaft. This ensures free rotation of the shaft in space. In addition, the bearing takes on the mechanical load and transfers energy to other elements. bearings are a type of rolling bearings. Without it, it is impossible to ensure that the wheel rotates smoothly around its axis without displacement and runout. These devices are used in all trucks and cars, including the Lada Largus . In this case, the front wheel hub element has a number of differences from the wheel bearing on the rear axle of the car.

How to replace the front wheel bearing of LADA Largus

the hub bearing when play appears. Bearing wear can be determined by increased noise when the vehicle is moving.

The operations for replacing a wheel bearing with and without ABS are similar. The only difference is the installed speed sensor in the steering knuckle.

We prepare the car for the job.

We install the car on a viewing hole or lift.

In order to unscrew the hub nut, we install stops under the wheels.

Usually the hub nut is tightened with great force, so you need an assistant to press the brake while unscrewing the nut.

Using a 32 socket (Fig. 1), unscrew the wheel hub bearing nut.

Remove the front wheel speed sensor (if installed).

We remove the ball joint pin from the steering knuckle hole

Disconnect the shock absorber strut from the steering knuckle

Remove the steering knuckle (Figure 2) assembled with the hub from the splined shank of the outer wheel drive joint housing.

When removing the steering knuckle from the drive, you must try not to pull the drive shaft out of the CV joint or gearbox.

We rest the steering knuckle on the jaws of the vice (Figure 3).

By striking the end of the hub through a mandrel or head of a suitable size

We press out the hub. In this case, the inner bearing ring, located closer to the hub flange, remains on the hub.

Use a screwdriver to pry off the protective washer covering the bearing seal.

We insert the chisel between the ends of the inner ring of the bearing and the hub shoulder.

By striking the chisel with a hammer, we move the inner bearing ring along the hub.

Then, into the resulting gap, we insert the puller's grips and finally press the inner bearing ring from the hub.

Signs of Problems

To correctly determine the malfunction of LADA Largus wheel bearings, there are several simple but guaranteed symptoms of problems with this device. Firstly, there is a dry crunch coming from the wheel. This sound always appears when the hub bearings fail. The noise is caused by destroyed rotating elements of the product; their cage is already broken and a crunching sound occurs due to uneven placement. It is impossible to miss this moment, because the sound is clearly audible not only outside, but also inside the car when driving. If such noise occurs, the bearing must be replaced immediately.

The second symptom is the occurrence of strong vibration. When the wheel bearing wears out, vibration is transmitted to the body and is clearly felt on the steering wheel. This sign indicates complete wear of the holder: the destruction of the spherical elements has begun, which can at any time lead to the wheel jamming. It should be changed immediately.

READ Replacement Front Shock Absorbers Peugeot 206

The third, but at the same time indirect sign, is the car pulling to the side when driving. Of course, this could be incorrect wheel alignment, imbalance, etc. But it happens that such a sign also indicates that the lubrication in the bearing is not working and there is a slight force when the spherical elements rotate, which causes some kind of stopper.

Many motorists say in all seriousness that they can continue to drive with a faulty wheel bearing, and moreover, drive at high speeds. You can’t do something like this, it’s simply life-threatening. If a wheel gets stuck while moving, it will stop abruptly. It is not difficult to guess what will happen when, at high speed, one of the four wheels suddenly becomes motionless. In the best case, the car will suddenly be thrown onto the side of the road, and in the worst, into the oncoming lane under moving traffic, hence the accident. There are cases where a wheel jam caused the car to overturn.

If the bearing is about to fall apart, then you can drive to the nearest service station or garage, but at a speed of no more than 40 km/h, otherwise you risk getting into a serious accident.

How to replace the rear wheel hub bearing Lada Largus

If, when driving, extraneous noise occurs in the area of the rear wheel (usually a whistle or howl, which increases with increasing speed, strong heating of the hub), then the bearing has failed and needs to be replaced

By tightening the hub nut, the play of this bearing cannot be eliminated (if tightening this nut will cause progressive wear, the axial play should not exceed 0.03 mm).

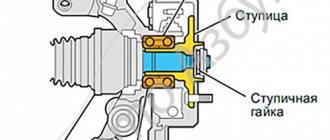

Figure 1 shows details of the rear wheel hub.

We replace the bearing in an inspection pit or a lift.

Release the brakes on the rear wheels.

Fully lower the parking brake lever.

Use a chisel to knock down and remove the protective cap of the hub bearing.

Unscrew the hub nut.

Removing the brake drum

After removing the brake drum, do not press the brake pedal as the pistons may come completely out of the wheel cylinder.

Mounting the bearing in the hub (Fig. 5)

From the outside of the drum, use special snap ring pliers to remove the bearing snap ring.

Press the bearing to be replaced out of the drum seat using a cup puller

You can knock out the bearing using a suitable mandrel by placing two wooden blocks under the brake drum.

Before installing a new bearing, clean the seating surface under it in the brake drum.

Insert the bearing into the drum socket.

We press in the new bearing with a puller until it stops, applying force through the mandrel to the outer ring of the bearing.

In this case, you can use the outer ring of the old bearing as a mandrel.

By supporting the puller cup on the other side of the drum when pressing the bearing on a car with ABS, do not damage the rear wheel speed sensor master ring.

Install a retaining ring into the groove of the drum.

We check the condition of the trunnion.

If its seating surface for the wheel bearing or the thread for the nut is damaged, we replace the rear wheel hub axle.

To do this, use the E-16 head to unscrew the four screws securing the rear wheel axle to the flange of the rear suspension beam, remove it and install a new axle.

We mount the brake drum on the axle. Bolt tightening torque 80 Nm.

Tighten the rear wheel hub bearing nut to 175 Nm.

Source

Purpose of the wheel bearing

The front wheel bearing is used to allow the wheels of the LADA Largus to rotate freely. Manufacturers use high-strength metal as the basis for this product. This allows the hinge to withstand increased loads. Over time, this part experiences natural wear and tear, resulting in the need for replacement. Also, improper operation can contribute to the damage of the hinge, then the bearing needs to be replaced .

Vigilance should be exercised in terms of timely diagnosis of the condition of this important component of the chassis, which has a significant impact on ensuring the overall safety of people present in the vehicle. To avoid emergency situations, timely replacement of the bearing will be a truly effective measure. It is important to carry out this repair measure when the first signs of damage appear.

Largus chassis .

How to identify a faulty Largus wheel bearing

To understand what signs of failure look like, you need to know how bearing wear occurs. Between both the outer and inner races of the bearing are balls that use the rolling effect to reduce friction. To avoid wear of the balls, the entire cavity is filled with thick lubricant.

Driving through puddles washes away the lubricant, as a result of which the bearing begins to run dry. The situation can be aggravated by dust and dirt getting inside, which acts on the parts like an abrasive.

Driving for a long time on such parts leads to displacement of the inner race, and the lack of lubrication causes a hum when driving. Also, driving for a long time on a faulty wheel bearing can lead to a wheel wedge while driving! This can cause an accident, especially on slippery roads.

Common symptoms of a worn wheel bearing

Symptoms of a hub malfunction on Largus appear in the form of stages:

- Noise when driving when there is a load on the wheel.

- Clicking noise when starting.

- Metal scraping.

- Wedge.

Clicks appear when one of the balls begins to fall apart; its rolls along the inside of the cage will be reflected in the form of clicks when starting to move or stop.

If you continue to ignore this, a metallic grinding sound appears - when the remaining balls begin to jam. Most likely, all the parts are already covered with rust.

Driving with a grinding noise will not take long to occur. At one “wonderful” moment, the wheel jams, which leads to the car stopping. It is no longer possible to move further.

How to determine which side the Lada Largus bearing is humming from

The easiest way to diagnose is the front wheel bearings. This can be done while on the move. To do this, follow these steps:

- Drive at a speed where the noise will be most pronounced.

- Turn the steering wheel first in one direction, then in the other, simulating a long “snake”. Observe the noise as you go.

- If, for example, when moving to the right the hum stops, but when moving to the left it intensifies, then the right wheel bearing is faulty.

Why the right one? Because when we turn to the right, the wheel is unloaded, and when we turn to the left, it is loaded more. The hum only manifests itself under load, therefore, it is the right bearing that requires replacement.

Rear wheel hubs on Lada Largus are more difficult to diagnose, since their load is distributed more evenly. Therefore, you need to hang the wheels and try to swing them in the vertical and horizontal planes; there should be no play!

A bad sign is also noise when turning the wheel, as well as its rapid stop during rotation. The same rule applies to the front wheel.

How to replace the front wheel bearing of LADA Largus

We replace the hub bearing when play appears. Bearing wear can be determined by increased noise when the vehicle is moving.

The operations for replacing a wheel bearing with and without ABS are similar. The only difference is the installed speed sensor in the steering knuckle.

We prepare the car for the job.

We install the car on a viewing hole or lift.

In order to unscrew the hub nut, we install stops under the wheels.

Usually the hub nut is tightened with great force, so you need an assistant to press the brake while unscrewing the nut.

Using a 32 socket (Fig. 1), unscrew the wheel hub bearing nut.

Remove the front wheel speed sensor (if installed).

Using a TorxT-30 wrench, unscrew the three screws securing the brake shield to the steering knuckle and remove the shield.

Disconnect the tie rod end from the steering knuckle

We remove the ball joint pin from the steering knuckle hole

Disconnect the shock absorber strut from the steering knuckle

Remove the steering knuckle (Figure 2) assembled with the hub from the splined shank of the outer wheel drive joint housing.

When removing the steering knuckle from the drive, you must try not to pull the drive shaft out of the CV joint or gearbox.

We rest the steering knuckle on the jaws of the vice (Figure 3).

By striking the end of the hub through a mandrel or head of a suitable size

We press out the hub. In this case, the inner bearing ring, located closer to the hub flange, remains on the hub.

Use a screwdriver to pry off the protective washer covering the bearing seal.

We insert the chisel between the ends of the inner ring of the bearing and the hub shoulder.

By striking the chisel with a hammer, we move the inner bearing ring along the hub.

Then, into the resulting gap, we insert the puller's grips and finally press the inner bearing ring from the hub.

Replacing the rear wheel bearing on Renault Logan

Lada Largus. Replacing the rear wheel bearing

We replace the bearing when it fails - noise, howling in the area of the rear wheel or its noticeable play. We carry out the work on an inspection ditch or overpass.

Fully lower the parking brake lever. We remove the rear wheel and dismantle the brake drum (see “Replacing the brake pads of the rear wheels,” p. 187).

We press in the new bearing with a puller until it stops, applying force through the mandrel to the outer ring of the bearing.

In this case, you can use the outer ring of the old bearing as a mandrel.

By supporting the puller cup on the inside of the drum when pressing the bearing on a car with ABS, do not damage the rear wheel speed sensor master ring.

Install a retaining ring into the groove of the drum. We check the condition of the trunnion. If its seating surface for the wheel bearing or the thread for the nut is damaged, we replace the axle.

. Using the E-16 head, unscrew the four screws securing the rear wheel axle to the flange of the rear suspension beam.

How to diagnose?

In practice, there are a number of signs that make it possible to indicate with sufficient confidence that a bearing is failing. Among them:

- A crunching sound that can be clearly heard in the cabin.

- A characteristic vibration on the steering wheel, which increases with speed.

- The car pulls to the sides, reminiscent of a lack of proper wheel alignment.

The bearing should be replaced as soon as the first symptoms of a malfunction occur. When a breakdown is identified, you need to head to the repair site at a speed not exceeding 40 km per hour.

Malfunctions and their diagnosis

Car owners remember about these parts hidden from view in the hub only when problems begin and the wheel makes extraneous sounds when moving. If the issue is not natural wear and tear, then the cause may be errors during replacement or the use of parts of questionable manufacture. Such bearings are not so easy to deform or break. To achieve their destruction, you need to try hard. Typically, this element rarely gives a car enthusiast a reason to visit special service stations.

Unskilled replacement work can also cause an early breakdown. If the car owner incorrectly installs the wheel bearing or if incompetent car service technicians do it, you should not hope for a long service life of this part.

Even a high-quality model, if installed incorrectly, will not work correctly and will not perform its functions, and will fail very quickly.

Causes of malfunction

The front wheel bearing is a fairly strong part in its structure, and in order to prematurely fail it requires the application of truly significant efforts. With adequate operation, this suspension component exhibits enviable survivability, without annoying the owner with hints of its malfunction. Only natural wear and tear over a long run can affect the condition of this component.

If we touch on the reasons for the failure of the bearing we are considering, we can highlight several aspects:

- Increased mileage. Bearing failure in LADA Largus can make itself felt after a mileage of 60 to 110 thousand km. This parameter is individual for each model. It is also directly influenced by operating conditions. The occurrence of a breakdown will be indicated by a specific crunching sound coming from the front wheel area. Almost every driver knows about this sound accompaniment of a malfunction.

- Loss of tightness. The separator part of the bearing is covered with plastic casings. They allow the lubricant to be retained and reduce the amount of friction that occurs when the internal race of the product rotates together with the hub. Over time, these protective elements become unusable, after which dirt penetrates into the working area, washing away the lubricant. Soon a hum appears, which hints to the owner that the node needs to be diagnosed.

- Extreme riding. Broken roads are not the ally of wheel bearings. Regular driving of the LADA Largus over potholes mercilessly damages these seemingly reliable suspension elements.

- Incorrect installation. An incorrectly replaced bearing will not perform its functions and will soon require another replacement.

Signs of Problems

To correctly determine the malfunction of LADA Largus wheel bearings, there are several simple but guaranteed symptoms of problems with this device. Firstly, there is a dry crunch coming from the wheel. This sound always appears when the hub bearings fail. The noise is caused by destroyed rotating elements of the product; their cage is already broken and a crunching sound occurs due to uneven placement. It is impossible to miss this moment, because the sound is clearly audible not only outside, but also inside the car when driving. If such noise occurs, the bearing must be replaced immediately.

The second symptom is the occurrence of strong vibration. When the wheel bearing wears out, vibration is transmitted to the body and is clearly felt on the steering wheel. This sign indicates complete wear of the holder: the destruction of the spherical elements has begun, which can at any time lead to the wheel jamming. It should be changed immediately.

READ How to Adjust Headlights on Volkswagen Jetta 6

The third, but at the same time indirect sign, is the car pulling to the side when driving. Of course, this could be incorrect wheel alignment, imbalance, etc. But it happens that such a sign also indicates that the lubrication in the bearing is not working and there is a slight force when the spherical elements rotate, which causes some kind of stopper.

Replacing the rear wheel bearing on LADA Largus

Many motorists say in all seriousness that they can continue to drive with a faulty wheel bearing, and moreover, drive at high speeds. You can’t do something like this, it’s simply life-threatening. If a wheel gets stuck while moving, it will stop abruptly. It is not difficult to guess what will happen when, at high speed, one of the four wheels suddenly becomes motionless. In the best case, the car will suddenly be thrown onto the side of the road, and in the worst, into the oncoming lane under moving traffic, hence the accident. There are cases where a wheel jam caused the car to overturn.

If the bearing is about to fall apart, then you can drive to the nearest service station or garage, but at a speed of no more than 40 km/h, otherwise you risk getting into a serious accident.

Troubleshooting

In addition to the above symptoms indicating a faulty wheel bearing, you can carry out a number of checks to ensure the accuracy of the diagnosis. This is very easy to do and can even be done in a parking lot.

- The car is placed on a flat asphalt surface.

- With both hands you need to grab the top of the wheel and try to swing the wheel from side to side as much as possible. A broken hub will be indicated by play and characteristic clicks.

- To be more convincing, you need to hang the wheel with a jack and spin it as quickly as possible. If a crunching noise occurs, the part should be replaced.

There is also another method for diagnosing a wheel bearing, but this will require a lift. The LADA Largus car is front-wheel drive, so this method is suitable for it. The car is raised on a lift, the engine is started and the gear is engaged. You need to speed up the wheels and listen. If noise and vibration appear on one wheel or another, it means the part is failing.

Malfunctions and their diagnosis

Car owners remember about these parts hidden from view in the hub only when problems begin and the wheel makes extraneous sounds when moving. If the issue is not natural wear and tear, then the cause may be errors during replacement or the use of parts of questionable manufacture. Such bearings are not so easy to deform or break. To achieve their destruction, you need to try hard. Typically, this element rarely gives a car enthusiast a reason to visit special service stations.

Unskilled replacement work can also cause an early breakdown. If the car owner incorrectly installs the wheel bearing or if incompetent car service technicians do it, you should not hope for a long service life of this part.

Even a high-quality model, if installed incorrectly, will not work correctly and will not perform its functions, and will fail very quickly.

Replacing a wheel bearing yourself

If such malfunctions occur, you must understand that the procedure with the front element is somewhat different from removing and installing the rear device.

Changing the front bearing

When replacing a unit from the front, keep in mind that front-wheel drive complicates the process. In addition, in addition to standard tools (a set of socket heads, a 30mm socket is required, wrenches, screwdrivers, a hammer, etc.), you will need a special puller to remove the bearing. Before starting work, be sure to secure the machine, turn on first gear, place chocks under the wheels and lift the hand brake lever.

The further replacement process is as follows.

- Using a screwdriver, you need to remove the protective cap of the hub covering the nut, after which you should unlock it and, using a 30mm socket with a powerful amplifier, loosen the nut.

- Now you can hang the wheel with a jack and remove it by unscrewing the nuts.

- It is recommended to tie the brake caliper to the strut spring in advance to prevent it from sagging on the brake hose alone. After this, the caliper can be removed from the steering knuckle. First you need to unscrew the two bolts and remove the brake pads.

- Next, the brake disc nuts are unscrewed, after which it can be dismantled.

- Use a flat-head screwdriver to remove the retaining ring.

- Using a special puller, you can press the bearing out of its seat.

- After removing the part, this socket must be thoroughly cleaned of dirt, grease residues and corrosion, then filled with fresh lubricant.

- Using the same puller, the new bearing is pressed into the seat, but the device must not be skewed.

- The retaining ring is installed in its place, after which the bearing is secured with a thrust washer and a hub nut. The same nut adjusts the play when the wheel rotates.

After reassembly, you should do a test run to make sure there is no vibration, crunching, etc. To be sure, you need to check the play in the steering again. If there is no special puller, other, more labor-intensive methods are used. For example, knocking out using a suitable piece of metal pipe or heating the landing socket.

Replacing the rear wheel bearing

With the Largus rear bearing everything is much simpler. The car owner can replace the drum assembly, thereby solving the problem with the brakes, if any, or change the bearing separately.

By choosing the second option, you can save a lot of money, but you will have to look for the bearing itself.

To replace you need:

- Remove the rear wheel.

- Unscrew the hub nut.

- Remove the drum from the axle.

- Remove the bearing retaining ring.

- Repress the bearing in the drum.

Use a 27 socket as a mandrel for repressing. The bearing must be dismantled on the outer part of the drum. And press it into the inner one. In addition, it is necessary to check the condition of the trunnion. If there are obvious signs of wear, such as scuffing, then it must be replaced.

Next, reassemble in reverse order. This completes the bearing replacement.

LADA Largus wheel bearings and their replacement

The main purpose of any bearing is to support and fix the shaft. This ensures free rotation of the shaft in space. In addition, the bearing takes on the mechanical load and transfers energy to other elements. bearings are a type of rolling bearings. Without it, it is impossible to ensure that the wheel rotates smoothly around its axis without displacement and runout. These devices are used in all trucks and cars, including the Lada Largus. In this case, the front wheel hub element has a number of differences from the wheel bearing on the rear axle of the car.

Main functions

For free and correct rotation of wheels on the Lada Largus , special hub bearings are used. The devices are made of high-strength metals and have a cast form. This is necessary because during operation they take on large mechanical loads. As you drive, this element, one way or another, begins to wear out naturally. This inevitably leads to the fact that the part needs to be changed. The need for replacement can be accelerated by improper operation of the vehicle or unqualified repairs.

The bearing is located on the axis of the wheel hub. Every car owner must be vigilant and be able to recognize malfunctions of this mechanism, since the safety of driving the car and all the people in it depends on it. If this element is destroyed, the wheel may jam and the car will become uncontrollable. And at high speed this will likely provoke an emergency, so you should not neglect replacement. With all this, wheel bearings are very strong, wear-resistant and durable parts (given high-quality products) that can withstand heavy loads.

Double-row conical roller-type devices are installed on the front axle. The use of more complex units is due to the use of front-wheel drive, where during braking, acceleration, etc., several forces act on the bearings simultaneously. At the rear, single-row roller hubs are installed, since the load on the rear axle is much less.

With proper operation and timely maintenance, these elements can last up to 130,000 kilometers or more.

Sources:

https://xn80aaajvii0auesmd7d.xnp1ai/raznoe/zamena-stupichnogo-podshipnika-lada-largus-lada-largus-zamena-podshipnika-perednej-stupicy-s-abs.html https://vesali.ru/otslezhivanie/podshipnik-perednej -stupitsy-kolesa-snyatie-i-ustanovka https://expertvaz.ru/lada-largus/zamena-podshipnika-stupicy.html