A car generator is a mandatory element of the on-board network of any modern car, regardless of the type of engine and the fuel it consumes. It is he who provides energy to all systems and mechanisms that consume electric current.

In this article we will look at the design, technical characteristics and operating principle of the VAZ-2110 generator. In addition, we will talk about its malfunctions, diagnostic methods and troubleshooting methods.

Design Features

The stator core has a cylindrical shape. A three-phase winding is wound on it according to a star circuit, the ends of which are brought out to the rectifier block. The stator is protected from above by a housing consisting of two covers fastened together with four bolts. There is an anchor inside it. It is mounted on two ball bearings. Their purpose is to ensure uniform rotation of the shaft.

At the rear of the generator there is a rectifier module consisting of six diodes, as well as a voltage regulator with a brush holder and brushes. For protection purposes, these elements are covered with a steel casing.

Add a comment Cancel reply

You must be logged in to post a comment.

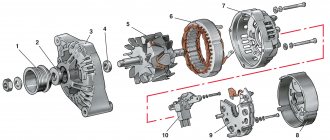

1 — casing 2 — “B+” terminal for connecting consumers 3 — interference suppression capacitor 2.2 μF 4 — common terminal of additional diodes (connected to the “D+” terminal of the voltage regulator) 5 — holder of positive diodes of the rectifier unit 6 —- holder of negative diodes of the rectifier unit 7—- positive diode 8—- negative diode 9 —— voltage regulator 10 —— back cover 11 —— coupling screw 12 —— front cover 13 —— stator winding 14 —— spacer ring 15 —- front rotor shaft bearing 16 — pulley

17 - nut 18 - rotor shaft 19 - cone washer 20 - washer 21 - beak-shaped rotor pole pieces 22 - stator core 23 - bushing 24 - rotor winding 25 - rear rotor bearing 26 - bearing bushing 27 — slip rings 28 — brush holder 29 — stator winding terminals 30 — additional diode 31 — terminal “D” (common terminal of additional diodes)

The generator is a synchronous AC electrical machine with electromagnetic excitation and a built-in rectifier using silicon diodes. The generator rotor is driven into rotation from the engine crankshaft pulley (damper) by a poly-V belt.

Technical characteristics of generator 94.3701

Maximum output current (at 13 V and 6000 rpm), A

Voltage, V

Engine-generator gear ratio

Direction of rotation (drive side)

The stator and generator covers are secured with four screws. The rotor shaft rotates in bearings installed in the covers. The lubricant placed in the bearings at the factory is designed to last the entire service life of the generator. The rear bearing is pressed onto the rotor shaft and is pressed by the rear cover through a plastic sleeve. The front bearing is pressed and rolled into the front cover and can only be replaced together with it. Its inner race, together with the spacer ring and washer, is clamped by a nut between the pulley and the step on the rotor shaft. The back of the generator is closed with a plastic casing with latches.

Principle of operation

In order for the generator to supply current to the load, the field winding must be energized. This, in fact, happens when we turn on the ignition. Next, the crankshaft of a running engine causes the armature to rotate. At this time, electricity begins to be generated in the stator winding, which is sent to the on-board network.

In VAZ-2110 cars, the generator produces alternating current, and all consumers are designed for direct current. To convert it, a rectifying diode unit is used.

But that's not all. The fact is that the voltage produced by the generator constantly changes depending on the number of crankshaft revolutions. To stabilize it, a voltage regulator relay is used.

As a result, at the terminals of the device we have a constant electric current of stable voltage.

Generator device

The design of a car generator implies the presence of its own rectifier and control circuit. The generating part of the generator, using a stationary winding (stator), generates three-phase alternating current, which is then rectified by a series of six large diodes and the direct current charges the battery. Alternating current is induced by the rotating magnetic field of the winding (around the field winding or rotor). Next, the current is supplied to the electronic circuit through the brushes and slip rings.

Generator structure: 1.Nut. 2. Washer. 3.Pulley 4.Front cover. 5. Distance ring. 6.Rotor. 7.Stator. 8.Back cover. 9.Casing. 10. Gasket. 11.Protective sleeve. 12. Rectifier unit with capacitor. 13.Latch holder with voltage regulator.

The generator is located at the front of the car engine and is started using the crankshaft. The connection diagram and operating principle of a car generator are the same for any car. There are, of course, some differences, but they are usually associated with the quality of the manufactured product, the power and the layout of the components in the motor. All modern cars are equipped with alternating current generator sets, which include not only the generator itself, but also a voltage regulator. The regulator equally distributes the current in the excitation winding, and it is due to this that the power of the generator set itself fluctuates at a time when the voltage at the power output terminals remains unchanged.

The principle of operation of a car generator

Connection diagram for the VAZ 2110-2115 generator

The alternator connection diagram includes the following components:

- Battery.

- Generator.

- Fuse block.

- Ignition.

- Dashboard.

- Rectifier block and additional diodes.

The principle of operation is quite simple: when the ignition is turned on plus through the lock, the ignition goes through the fuse box, light bulb, diode bridge and goes through a resistor to minus. When the light on the dashboard lights up, then the plus goes to the generator (to the excitation winding), then during the process of starting the engine, the pulley begins to rotate, the armature also rotates, due to electromagnetic induction, electromotive force is generated and alternating current appears.

Next, the diode passes plus into the rectifier block through a sine wave into the left arm, and minus into the right arm. Additional diodes on the light bulb cut off the negatives and only positives are obtained, then it goes to the dashboard assembly, and the diode that is there allows only the negative to pass through, as a result the light goes out and the positive then goes through the resistor and goes to the negative.

The principle of operation of a car DC generator can be explained as follows: a small direct current begins to flow through the excitation winding, which is regulated by the control unit and is maintained by it at a level of slightly more than 14 V. Most generators in a car are capable of generating at least 45 amperes. The generator operates at 3000 rpm and above - if you look at the ratio of the size of the fan belts for the pulleys, it will be two or three to one in relation to the engine frequency.

To avoid this, the plates and other parts of the generator rectifier are partially or completely covered with an insulating layer. The heat sinks are combined into a monolithic design of the rectifier unit mainly by mounting plates made of insulating material, reinforced with connecting bars.

Malfunctions of the VAZ-2110 generator

Now let’s look at the breakdowns of the “tens” generator, which car owners have to deal with most often. These include:

- incorrect tension of the drive belt;

- bearing wear;

- failure of the rectifier unit;

- malfunction of the voltage regulator relay;

- break (short circuit) of the rotor or stator windings.

Let's look at each of the faults in detail separately.

Dismantling and disassembling the generator (in detail)

Work order:

- Disconnect the negative terminal of the battery.

- Next, unscrew the terminals of the device itself, having previously unscrewed the fastenings of these terminals.

- We study the diagram of the generator fasteners in order to begin removing the unit.

- Then remove the crankcase guard and get under the car.

- Next, unscrew the fasteners securing the generator to the frame (positions 5 and 2 in the diagram).

- While unscrewing the last fastener, hold the mechanism with your hand.

- Remove the unit, remove dirt and wipe with a rag. Lubricate the threaded connections with WD-40.

- Use a screwdriver to remove the rear plastic cover on the generator.

- Using a Phillips screwdriver, unscrew the voltage regulator and brush holder fastenings.

- Remove the pulley from the axle and clamp the product in a vice.

- Using an adjustable wrench or other wrench, unscrew the nut on the pulley. To prevent the shaft from spinning, insert the hexagon into a special recess at the end.

- Remove the washer and, having unscrewed the corresponding bolts, disassemble the unit body.

- Remove the plastic cover and then the front ball bearing to access the armature.

What's wrong with the belt

The VAZ-2110 generator belt serves as a drive for the rotor of the device. It transmits torque from the engine crankshaft to the armature pulley. The operation of the generator directly depends on its condition. An important point is belt tension. If it is loose, the pulley may slip. Because of this, the device will not be able to generate the current required parameters.

A sign of a loose belt is a characteristic “whistle”, which is more likely to occur in wet weather. The same symptoms indicate its wear and tear. Over-tensioning the belt distorts the rotor shaft. This contributes to accelerated wear of the device bearings.

The optimal belt tension is such that each of its fields in the middle between the pulleys can be shifted to the opposite side by a maximum of 15 mm.

Step-by-step instructions for installing and assembling the tens generator

Guide to dismantling the VAZ 2110 generator:

- The tensioner nut is unscrewed.

- The generator unit moves slightly back towards the vehicle interior. The drive belt is removed from the pulleys. Then the electrical power circuits of the device are turned off. One block with wires is fixed with a nut and a stud; they must be unscrewed and disconnected. The second connector is attached using a regular block, which is detached.

- After this, the lower nut securing the assembly is unscrewed. This action is performed from under the bottom of the car. To complete the task, it is necessary to dismantle the power unit protection, if any.

- The screw that needs to be removed is usually fastened tightly. When unscrewing it, you need to treat the part with WD-40 if it is stuck and cannot be removed. You can use a hammer to remove the retainer.

- Then, from the reverse side, this element is removed completely.

- At the final stage, the nut that secures the tensioning device is completely unscrewed. The generator unit is moved to the side, this will allow it to be completely dismantled.

Bearings

A faulty bearing in a VAZ-2110 generator is easy to recognize by the sound it makes. Usually it hums or rustles. This sound is a clear sign of wear on the device.

The front bearing of the VAZ-2110 generator is pressed into the “seat” of the cover. It is impossible to remove it from there, since it is rolled up. It changes along with the front cover. The rear bearing is packed onto the armature shaft and supported by a cover. Its replacement is possible if you have a special puller.

When replacement is required

If you hear creaking and howling while the generator is running, then you have discovered the main sign of bearing failure. The only correct solution is replacement.

Creaking and howling occur due to the fact that the bearing separators lose lubrication, they wear out, and are destroyed as a result of prolonged use under heavy loads.

Sometimes a thin creaking sound can be heard from the generator, which is often confused with bearing failure. In fact, it could be the timing belt pulley or the water pump. Because to make sure, just remove the belt. If the sound remains, then the culprit is the bearing.

What to use

Before you start replacing the bearings on the generator, you need to determine what elements are on your car, as well as what they can be replaced with.

| Bearing | Number | |

| Old generators | New generators | |

| Front | 6302 | 6303 |

| Rear | 6202 | 6203 |

When choosing bearings, pay attention to the hub manufacturers. For VAZ 2110, bearing hubs are produced in the city of Samara and are marked SPZ-4. But there are also Vologda and Saratov hubs marked 23 GPZ and 3 GPZ, respectively. It is not recommended to purchase bearings with unmarked hubs, much less use Chinese generator elements.

Dimensions

It will not be superfluous to know what dimensions the standard front and rear generator bearings for your “ten” should have in order to make sure that the spare parts are selected correctly.

The rear bearings of the new type, marked 6203, have the following dimensions:

- Inner diameter - 17 millimeters

- External diameter - 40 millimeters

- Width - 12 millimeters.

We recommend: Repair of power windows on VAZ 2110

The front bearings marked 6303 have the following dimensions:

- Inner diameter - 17 millimeters

- External diameter - 47 millimeters

- Width - 14 millimeters.

Based on the dimensions, you can understand why rear and front bearings are often called small and large, respectively. It’s easy to visually distinguish them from each other, so you definitely won’t confuse the elements when replacing them.

Disassembled device

Rectifier module

The rectifier module is designed to convert alternating current into direct current. It is based on six silicon diodes (gates): three positive and three negative. They are located on two horseshoe-shaped plates. To smooth out voltage surges, the terminals of the positive and negative diodes are connected through a 2.2 μF capacitor.

How to check the generator on a VAZ-2110 for the functionality of the rectifier unit with your own hands? To do this, you will need a regular car tester or test lamp. The essence of the test is based on the ability of diodes to pass current in only one direction. A faulty valve either does not pass current at all, or passes in both directions.

So, first you need to remove the casing of the rectifier unit. Next, connect the first wire of the test lamp to the “B+” terminal of the generator, and the second to the ground of the device. If the unit is working properly, the lamp should not light up. If it lights up, there is a short circuit in the rectifier and it needs to be replaced.

Don't be lazy to check the capacitor as well. Turn the tester into ohmmeter mode (1-10 MOhm) and measure its resistance. For a working capacitor, it should first take a minimum value and then gradually increase. If this does not happen, replace the capacitor.

Technical specifications

If the old generator fails, many motorists wonder which generator they should now replace the old one with.

There is no need to invent anything here. The most correct solution is to install the same generator as before, or a more powerful one.

Today, the VAZ 2110 provides for the use of three types of power supply devices:

- Katek 5102.3771. The generator produces 80 Ampere power and its voltage is approximately 14V.

- Katek 94.3701. This is a device with the same parameters. They are not seriously different.

- Catek 120 amp. A generator that is more adapted to modern realities, when in addition to standard electrical equipment, motorists install many additional devices.

If you have a powerful audio system in your car, you use an electric pump powered by the car, as well as a number of other additional consumers, it is recommended to install a 120-amp unit instead of a standard 80-amp generator.

If we take into account the size of the devices, then we can distinguish between ordinary and compact ones. They have a certain difference in design. To be specific, the differences are in the following components:

- Brackets;

- Anchor;

- Excitation wire;

- Drive pulley;

- Number of mounting bolts.

But in reality this does not play a special role. After all, the structure of all generators used for the VAZ 2110 is the same. Therefore, let's look at the circuit and structure of this unit.

He's an anchor. It is a rotating element of the generator, which creates a magnetic field due to the excitation winding located on the shaft. The field wire receives power from the slip rings. They are mounted on the same shaft. There was also room for a drive pulley, field winding wire, bearing assembly and fan impeller. There may be 1-2 last ones

This is a stationary three-phase element that includes three windings. They provide the creation of alternating current. The windings are connected to each other using a triangle or star

A lightweight non-magnetic aluminum alloy is most often used to make the generator housing. The body looks like a pair of covers connected by a bolt. The front cover is located near the drive pulley, and the rear cover is located on the side of the slip rings. Each connecting bolt must be tightened. To disassemble the housing, simply unscrew the mounting bolts.

The upper mounting bracket for the generator uses two bolts, while the lower bracket is predominantly mounted on one bolt. In some cases there are two. It is not recommended to modify the brackets, since the factory one performs important functions. The purpose of the brackets is to hold the generator. It is recommended to monitor the condition of the brackets as they are subject to wear and breakage

Voltage regulator

The regulator performs the function of a kind of stabilizer. Thanks to it, the voltage of the vehicle’s on-board network is the same, regardless of the number of revolutions of the running engine.

Essentially, a regulator is a relay that closes and opens a circuit. It happens like this. The voltage dropped below the required value, or rose above the norm - the relay disconnected the generator from the network. The voltage has reached the desired range - the regulator connected the device.

There are no electromechanical elements in the VAZ-2110 generator relay. It is built on semiconductors. In addition, its design also includes a brush holder with brushes. It is almost impossible to repair the regulator on your own. It's easier to replace it with a new one.

Checking the functionality of the relay takes no more than five minutes. Yes, and there is no need to disassemble anything here. The diagnostic procedure is as follows.

- We start the engine and warm it up to operating temperature.

- Turn on the low beam headlights and the heater fan.

- Using a tester turned on in voltmeter mode, we measure the voltage at the battery terminals.

The voltage should not go beyond 13.2 - 14.7 V. If it is higher or lower, the relay is faulty.

A regulator is considered faulty if its brushes are damaged or excessively worn. The minimum length of brushes is 5 mm.

What do you need to know when choosing new parts?

Initially, in the design of the 2110 generator, as mentioned above, two bearing devices are usually installed. In older versions of the car, parts marked 6302 or 6303 (these are front units), or 6202 (rear units) are used; in more modern versions, 6203 bearings are installed at the rear.

As for the sizes, they are as follows:

- for 6303 (or the domestic analogue under number 180302) the dimensions are 17*47*14;

- for marking 6302 (or domestic analogue 180303) - 15*42*13;

- for marking 6202 (Russian parts are marked as 180202) the dimensions are 15*35*11;

- for 6203 (domestic equivalent - 180203) dimensions - 17*40*12.

Open circuit (short circuit) in the windings

In a VAZ-2110, the generator may also fail due to a break (short circuit) in the rotor or stator windings. Such a malfunction does not bode well, since it is almost impossible to eliminate it on your own. Here you will need to either rewind the windings or replace the faulty element (rotor or stator).

Before checking the generator on the VAZ-2110, it will need to be removed from the car and disassembled. Let's start with the stator. We take the tester, turn it on in ohmmeter mode and measure the resistance between each winding terminal and the housing. For a working stator it should tend to infinity. If the device shows less than 50 kOhm, there is a short circuit in the winding.

Let's move on to the rotor. Here it is necessary to measure the resistance between the slip rings. It should be within a few ohms. If the resistance is close to zero, the winding turns are closed. If the device produces too high readings, a break may occur.

How to make modifications?

A VAZ 2110 car can have many consumers installed. For example, owners of 2110 often install air conditioning from Priora in the cabin. And if you start all the devices, the voltage can drop to 11.2 volts. The modification allows you to keep the voltage within normal limits, while the generator will provide power to all devices. The modification involves installing a diode. You can take this element from another diode bridge. As an alternative, a diode from KD202V is suitable. To work you will need a standard circuit.

The modification is carried out in circuit D, where a new diode is installed (an option with a current of at least 5A, a voltage drop of 0.6-0.7V and a breakdown of 20V is suitable). As the experience of VAZ 2110 owners shows, the 2D219B diode would be an excellent option. To work you will need 50 cm of 2x0.75 mm wire. Its ends must be sawn to fit the female and male terminals. Now you can put the wire in heat shrink. Armed with a soldering iron, you need to solder the diode on the other side. Next, the “mother” is connected to the anode, and the “father” is connected to the cathode.

The diode must be insulated - a container from photographic film is perfect for this. The next step is to remove the negative terminal of the battery, then unscrew the “plus” from the generator and the “D” wire. After this, there will be open access to the generator cover. Having reached the regulator, you need to run the wires and connect the “male” to the standard wire, and the female to the LV. The modification is completed, assembly is carried out in the reverse order.

Generators that can be installed to replace 9402

9402.3701 ATE – 1 (China LKD)

0124 325 089 BOSCH 90 A

ELD-A-2110-14V-135A with obg. coupling

3747.3771-93 Electrom. Cheboksary.

2110 START – VOLT Ukraine 135A

Operating principle of the generator

Cars use a three-phase synchronous generator. The operating principle of the generator is based on the law of electromagnetic induction. “Electromotive force in a winding occurs when the magnetic field changes.”

The emf of the generator arises in the winding. The rotor serves to create a changing magnetic field. To magnetize the rotor, an excitation winding is built into it. Current is supplied to it through brushes.

The stator winding is three-phase, connected in a star. There is an alternating voltage at the output of the winding, but a constant voltage is required in the car network and for charging the battery, so the output of the winding is connected to a diode bridge (rectifier).

Diode bridge for generator 9402.3701 BPVO 76-105/11, (Electromodule), BVO 3 -105- 01 (Orbit)

Diode bridge for generator 5102.3771 MP 13.80.3.2 (Orbit)

Do-it-yourself replacement of a VAZ-2110 generator

In some cases, it is not practical to repair the generator. The service life of the device declared by the manufacturer is 140 thousand km. If you are faced with a serious malfunction of the current-generating device in your "ten", estimate how much it will cost you to repair it, and compare it with the cost of a new generator. And it’s not that expensive – about five thousand rubles. But for this five thousand you will receive a new device with a guarantee, if used correctly, your car will drive for several years without any problems.

Replacing the VAZ-2110 generator can be done by hand. All that is required for this is an inspection hole, keys to “10” and “13”. The hole is needed to make it easier to get to the device mount. The replacement procedure is as follows.

- We place the car on the inspection hole, fix it, and remove the engine protection.

- Disconnect the negative terminal from the battery. Disconnect the wire from the generator that powers the rotor field winding (at the connector).

- Using a “10” wrench, unscrew the nut securing the “B+” output wires. We remove the wires.

- Loosen the adjusting screw and unscrew the fixing nut.

- Remove the drive belt.

- Loosen the lower fastening of the VAZ-2110 generator (from the pit) by unscrewing the nut with a key set to “13”. We take out the fastening bolt.

- Remove the device (more convenient from below).

Installation of the VAZ-2110 generator is carried out in the reverse order. After replacement, be sure to properly tension the belt and connect the wires.

Which generator to choose for the “ten”

The choice of motorists is not limited to Katek generators. Therefore, if the old device fails, you should think about who will take its place.

There are several main options.

- Katek. A standard, fairly reliable and very efficient generator. AvtoVAZ’s choice in its favor is due precisely to this. Plus it is a domestic manufacturer.

- Chinese products. The attitude of motorists towards Chinese generators is quite skeptical. There are explanations for this. Compared to them, Katek is simply an ideal solution. Although in fairness, we note that you can find some pretty good Chinese-assembled options. But this is the exception rather than the rule.

- Imported analogues. Here, first of all, you should pay attention to Bosch companies. Denso and Delphi. High build quality, impressive service life, efficient operation. They cost more than their Russian counterparts in the form of Katek, but for such a thing it makes sense to spend a little more.

Among imported devices, the following are considered good options:

- Dynamo - manufacturer Bulgaria;

- Eldix - also produced in Bulgaria;

- BATE - produced in the city of Borisov, in Belarus.

When choosing a new generator for your car, pay attention to its technical characteristics and safety margin. Then think about the manufacturer. We do not recommend looking towards China if you are doing repairs for yourself and want to achieve high quality work.

Some useful tips to extend the life of your generator

To ensure that your “ten” generator serves for a long time and does not present unpleasant surprises, use the following tips.

- At least once a month, check the condition of the device’s drive belt and its tension. If it is damaged, immediately take measures to replace it.

- Pay attention to the sound of the generator. If you hear a hum characteristic of failed bearings, replace them yourself, or contact a service center for this.

- Do not connect electrical appliances to the vehicle's on-board network that consume a current greater than the current generated by the generator.

- If the warning light on the instrument panel is constantly on, indicating that the battery is not charging, check the voltage regulator. If it fails, replace it.

- Do not expose the generator to water. It can cause a short circuit.

Charging diagram for VAZ with injection engines

This scheme is identical to the schemes on other VAZ models. It differs from the previous ones in the method of exciting and monitoring the serviceability of the generator. It can be carried out using a special control lamp and a voltmeter on the instrument panel. Also, through the charge lamp, the generator is initially excited at the moment it starts working. During operation, the generator operates “anonymously,” that is, excitation comes directly from pin 30. When the ignition is turned on, power through fuse No. 10 goes to the charging lamp in the instrument panel. Then it goes through the mounting block to pin 61. Three additional diodes provide power to the voltage regulator, which in turn transmits it to the excitation winding of the generator. In this case, the indicator lamp will light up. It is at that moment when the generator operates on the plates of the rectifier bridge that the voltage will be much higher than that of the battery. In this case, the control lamp will not light up, because the voltage on its side on the additional diodes will be lower than on the side of the stator winding and the diodes will close. If the control lamp lights up while the generator is running, this may mean that additional diodes are broken.

How does he work

First, let's figure out how this device functions. His work scheme is as follows:

- The key is inserted into the ignition switch;

- The current goes to the excitation wires;

- The magnetic field created by the armature passes through the stator windings, and voltage appears at its terminals;

- When the armature rotation frequency becomes high enough, the self-excitation mode begins;

- The rectifier unit provided by the car design converts alternating current into direct current;

- The voltage regulator starts working when the crankshaft rotation speed changes, and the time for which the excitation wire is activated is adjusted.

The presented video will allow you to clearly get acquainted with the principle of operation of the generator.

Functions

Beginners are very interested in the most important question, without which there is no point in trying to fix something on their own - what is the generator used for.

First of all, the generator’s task is to provide energy to all electrically dependent equipment.

The mistake many people make is that the equipment is powered by a battery. The battery is needed to maintain the functionality of the devices when the engine is turned off. It powers the audio system, alarm system, etc.

When the engine is started with the help of the battery, all the reins of power pass to the generator. He is now responsible for the operation of the audio system, air conditioning, power windows, etc.

The second, but no less important task of the battery is to recharge the battery. This happens when the engine is running. If it were not for the generator, the battery would not be able to provide power to all consumers for a long time; it would have to be charged regularly in the garage.

Scheme

Trouble-shooting

Repairing a generator on a VAZ 2110 is not a complex process and can be done with your own hands. In extreme cases, the entire unit can be replaced. It all depends on the nature of the malfunction. If you follow the technical regulations, the VAZ 2110 carries out a scheduled check of the generator’s performance every 50,000 km. But this rule only applies to a device that is in good condition.

Examination

Before you begin troubleshooting the generator on the VAZ 2110, you need to make sure that this particular unit is the cause of the problem. The sequence of actions during verification is as follows.

- Start the engine and let it warm up to operating temperature.

- Press the accelerator pedal, raising the engine speed to 3 thousand rpm.

- Turn on the maximum number of electrical consumers of the vehicle's on-board network (high beams, heater fan, interior lighting, hazard warning lights, heated seats and rear window, wipers at maximum speed).

- Measure the voltage on the battery with a tester.

- If, under these conditions, the multimeter shows a voltage of about 13 V or less, then the cause of the problem is guaranteed to be related to a faulty generator unit.

A sign may be a short circuit in the stator windings or a short to ground, a faulty voltage regulator, oxidation of the ring output contacts, etc. To check all the parts for damage, you cannot do without removing the generator from the car and then disassembling the unit. If you have no idea how the generator unit works, and you have never encountered it before, then it is better not to risk it and give it to professionals for repair or replace it with a working device.

Dismantling

To remove from the car and then disassemble the generator on the VAZ 2110 and replace failed parts, you will need to perform a number of standard operations.

- It is advisable to carry out work in an inspection hole or overpass in order to gain access to the engine compartment from below.

- Remove the battery (without this it is impossible to get to one of the nuts holding the device).

- Unscrew this nut and remove the adjusting bar. A wrench or a 17mm socket with an extension is suitable for this, as this will make it easier to unscrew the nut.

- The steel shield should be removed from below, which protects the engine compartment from dust and dirt.

- Disconnect all wires from the generator and remove the belt from the pulley.

- Remove the protective cover and use a 10 mm wrench to unscrew the nut of the tip that secures the “+” wire from the battery.

- Unscrew another retaining nut from the bracket.

- Remove the long bolt from the mount and pull out the generator. When doing this, care must be taken not to lose the buffer sleeve.

This completes the work of removing the device from the car. The procedure is not difficult and can be done with your own hands. After removal, you can begin repair work.

Adjusting belt tension

Often one of the causes of generator malfunctions is the belt and its insufficient or excessive tension. You can easily check the optimal tension yourself by pressing on the belt installed on the pulleys. It should bend no more than 10 mm.

To adjust, simply loosen the generator on the bracket and move it towards the engine.

There is a special long bolt on the adjustment bar. By unscrewing or tightening it, you can change the belt tension. If the reason is not in this part, then you can move on to the brush assembly and the voltage regulating unit.

Brush repair and regulator replacement

In most cases, neither the brush assembly nor a device such as a voltage regulator is subject to repair. And not because it is difficult, but because it is impractical. It's easier to replace these parts with new ones. By purchasing assembled units, everyone can replace them themselves in a few minutes. But many motorists prefer to change the brushes themselves, especially since this is allowed and allows you to save some money.

The process of replacing a generator on a VAZ 2110 is simple. It consists of removing the battery from the machine and disassembling the back cover, after which you can remove the old worn brushes and install new ones in their place. The voltage regulator is even easier to change. It is enough to unscrew the two mounting screws and remove the unit, replacing it with a working one.

Relay repair

Often the cause of the malfunction lies not in the generator, but in problems with the relay. The most common reasons include the following, which lead to the need to replace it.

- The graphite brushes are worn out (the worn-out brushes cannot provide reliable contact, and the generator does not receive power).

- Breakdown in the electrical circuit (associated with an increase in voltage).

- Broken fasteners, broken wiring, etc.

The relay, by the nature of its malfunctions, occupies an honorable first place in problems associated with the generator. Many people, out of ignorance, look for the cause in the generator, although it is worth checking the relay and, if possible, quickly replacing it. To make sure of this, you need to hang one of the front wheels and start the engine, then turn on second or third speed. Next, you need to remove the terminal from the negative terminal of the battery. If the engine does not stall, the cause of the malfunction is in the relay. The car stalls, which means the voltage regulator needs to be replaced.

To replace it, you do not need to dismantle the generator; a simple modification is enough. You need to remove the power wire and unscrew the fastening screws, and then replace the part. It cannot be repaired, and besides, it is pointless. At best, the repair will do nothing, and at worst, the electrical equipment of the VAZ 2110 will be damaged due to a faulty regulator.

Replacing bearings

Removal and installation of the rear and front units differ from each other in some ways. The fact is that the front bearing is rolled into the cover seat. And it is impossible to remove it from there without damaging it. Accordingly, the part changes along with the cover. The rear bearing is located on the armature shaft. To dismantle it you will need a suitable puller. Afterwards, a serviceable bearing is installed in place.

In a practical sense, any repair of generator parts is temporary and sooner or later other problems will begin. This circumstance should be taken into account and, if possible, immediately install new equipment, which, depending on the quality, will last for many years.