What is the design of a “robot” that is an automated manual transmission (AMT)? In what ways can AMT be preferred over a conventional automatic? What changed in this unit when it was transferred to Grant from Priora? What was the reason why AMT was chosen for Lada Vesta? Which models are planned to be equipped with it in the future? There are a lot of questions. A meeting with the project manager for the new transmission at AVTOVAZ, Vladimir Petunin, helped to find answers to all these questions.

Before the meeting, I was lucky enough to drive one of the pre-production Grants with a robotic transmission, which had recently been tested.

The impressions from the trip are similar to those left from the test drive of the “robotic” Priora. However, new colors have also appeared. The reason here is most likely that the Granta has a more modern chassis. And the new platform was able to fully reveal all the advantages of the new gearbox that were not so noticeable in the previous model.

In general, for all potential owners of a Lada Granta with a robotic transmission it will be a source of positive emotions. A former follower of the “mechanical” Lada Priora will undoubtedly prefer its “robotic” version. The same can be said about drivers who drove cars with Granta or Kalina chassis, which in the last few years have been equipped with Japanese automatic transmissions from Jatco.

Once behind the wheel of a “robotic” Lada Granta, the driver of a Kalina with an automatic transmission feels at home. He sees familiar ergonomics of a decent level, familiar instruments, similar driving features. Like the Lada Kalina, the car drives composedly, without complaints about the suspension, steering wheel and brakes, although without much brilliance. “Granta” in comparison with “Priora”, which was tested before, is worthy of nothing but praise.

Innovations have also appeared. A new window has appeared above the main window of the on-board computer in the gap between the tachometer and speedometer. It serves to indicate the engine temperature. The main screen of the dashboard has become smaller, and the navigator that used Navitel maps, which was previously located on it, has now moved to the display of the multimedia complex. This arrangement seems more logical. This instrument panel configuration will soon go into production.

The gear selector has also undergone changes. Its handle base is close to Prior’s, therefore it is placed slightly higher than the manual gearbox lever on the Grant. The area where the floor tunnel and the selector base connect is covered with a leatherette casing. This is a temporary solution and is only suitable for a test sample. A more elegant technical solution is expected in the production version.

True, this temporary discrepancy will not interfere with our research into the new product. The internal components of the cars and interaction with the driver are identical to the serial ones. To start the car, you need to put the selector in neutral and press the brake pedal. For the engine to stall, simply turning the key in the ignition is enough. In the standby state, the car can remain “in gear”. We start the car, switch the selector to automatic mode - position “A” and drive off, lightly touching the gas pedal.

Differences between AMT and other types of gearboxes

Unfortunately, there is no “preload” mode, which is available in conventional automatic transmissions, when the car starts to move from idle.

There is no way to overcome small hills by releasing the gas pedal - a car with a robotic transmission must in such situations put on the handbrake or apply gas. During the development of the transmission, foreign analogues equipped with a recoil mode were studied. As a result, we decided not to include this feature in our robotic transmission, since the electronics only notice a steep climb, and a small hill for a momentarily distracted driver can cause a rollback and, in urban conditions, cause an accident. The same danger comes from releasing the brake on a car equipped with a classic automatic transmission with “drive” turned on. At first, the robotic transmission requires the driver to get used to and control his actions. You need to be especially careful in urban environments that require frequent difficult operations: starting, making a U-turn, turning off the engine, parking. But all the required actions are intuitive and logical, so getting used to the new product happens very quickly. By the way, both CVTs and conventional automatic transmissions need to adapt to them. It is much more difficult for a beginner to get used to ordinary mechanics.

The undoubted advantage of the robotic version of the device is the complete elimination of errors and breakdowns caused by subjective factors. At the same time, it will not be possible to engage the wrong gear, for example, reverse while moving forward, in such a gearbox. In addition, the “robot” makes it possible to control the temperature in the gearbox. A special lamp signals critical overheating. This option is not available in either manual or automatic transmissions.

Users of automatic transmissions notice the moments when gears are changed in AMT. Indeed, in the Japanese automatic transmission Jatco, gear shifting occurs very smoothly without obvious power breaks, and the “robot” needs a short time to change speed. AMT is a relatively simple design: in a classic VAZ gearbox, shifting is controlled by two ZF actuators - German-made electrical actuators. One of them helps the driver to depress the clutch, and the second is responsible for engaging a specific gear.

Pre-production tests

However, the Granta, equipped with an automated manual transmission, is now on the agenda; sales begin in February. To approach this date fully armed, a number of tests were carried out. One of the pre-production cars immediately went to Germany so that AvtoVAZ's partners from ZF, for their part, could conduct their own tests and allow the car to be put into production.

Starting with the Priora platform, cars have undergone a huge number of tests in various climatic zones and under a variety of programs. Tests took place in the Alps and Altai mountains with the participation of partners from Germany, at low temperatures reaching -55°C, in the Far North in Surgut. Speed tests were successfully carried out at the Porsche test site with humidity of almost 100 percent and temperatures exceeding +30°C. These tests were followed by accelerated road tests of 80,000 km and 100,000 km. Difficulties that arose during the testing process were resolved promptly, quickly and professionally.

The new gearbox is a product of Russian engineering, since the burden of solving most of the problems fell on VAZ’s shoulders. Engineers from Russia have demonstrated that their level is not inferior to the quality of engineers in the best European companies.

In general, the design of the new box consists of 80% Russian parts, and this says a lot.

Even during the period of joint work with the Germans on adapting the gearbox for the Priora, it was VAZ engineers who managed to quickly achieve smooth switching, which other companies cannot achieve for a long time. It is difficult in foreign boxes and with quick engagement - the transmission resource is insufficient.

An important advantage of the VAZ AMT is the ability of the system to adapt to the driver’s driving style - both calm and aggressive driving is possible. What else distinguishes the box from a traditional automatic transmission: at -40°C outside, the box makes it possible to start moving as soon as the engine is started. But fuel economy is, of course, the biggest plus.

CVT

In fact, it was developed a very long time ago (they talked about the variator in this article ), it allows you to provide excellent acceleration dynamics without unnecessary devices and parts, while combining fuel economy. However, he is something to be afraid of. After all, despite all its simplicity in structure, not every car service center will undertake to repair it. Although now the situation is changing. This type is constantly being improved and modernized. There are more and more specialists in this field. Of course, it’s too early for it to compete with an automatic transmission (more car manufacturers trust automatic transmissions), but many manufacturers are switching to CVTs precisely because of the smoothness of the ride, fuel economy and dynamic characteristics. Even electric car manufacturers prefer this transmission (models with one electric motor installed at the front), so this transmission is the future. Even if he changes to the point of being unrecognizable.

Technical part

The variator, if you look into the structure, is designed quite simply. There are two shafts, certain cones (or pulleys) are put on them, depending on which one hears better. One shaft goes to the engine (now through a torque converter), the other (through various drives) directly to the wheels. Between them there is a connecting link, usually a belt (for example, on NISSAN cars) or a chain (on AUDI).

The cones that are on the shafts can move and move apart, due to this their diameter changes. For example, at start, one shaft has a smaller diameter, the second has a maximum diameter. When the average speed, the diameters are the same, when the maximum, the shafts change in size (one becomes small, the second becomes large). A belt or chain simply ties them together. BUT the maximum load is placed on this connecting link.

Briefly about breakdowns

As I wrote above, a variator is a simple transmission, but quite demanding in terms of its maintenance (especially lubrication). And it’s not so easy to repair it, despite the simplicity of doing them (and even a trivial oil change), not all dealer stations are accepted (I’m already silent about third-party service stations), there are simply no normal craftsmen and knowledge.

- About oil . Here it is special (on NISSAN NS-2, NS-3). Now many can say that this is not oil at all. Calm down, the oil is simply the most technologically advanced, even better than ATF fluid for automatic transmissions. It is expensive, so many save money and do not change it. BUT you shouldn't do that

- Replacement should be every 60-80,000 km. The variator also has a valve body and solenoids, which can become clogged over time. The pressure in the system drops and this will cause the cones to move poorly - move apart. Oil also protects and lubricates the system, but as is clear, it does not last forever, and in order to restore the original characteristics it must be replaced

- Seizure of cones. If you do not change the lubricant and preferably the filter (which is located in the pan), then the cones will not effectively compress the belt, it will begin to slip, and scuffs will appear on the surface. All this will sooner or later lead to jerks and jolts, there will be no normal operation

- Belt failure. Scuffing can also cause the destruction of a belt or chain if it scatters inside. This could ruin the entire box, and there will simply be nothing to restore.

- In general, it’s worth driving a CVT correctly. I have a separate video and article . Have a look, it will be useful.

A few words about the resource

You know, if you drive carefully and don’t tear this transmission, it can last quite a long time, 200 – 250,000 km is not the limit. However, there are also design miscalculations when it doesn’t run even 30,000 km (usually due to a firmware error).

If you change the oil correctly and on time, it can take a long time. However, on runs of 150,000 km (perhaps a little more), it is worth looking at the condition of the chain or belt, and if necessary, it is better to replace

The whole problem with the variator is that it is a difficult-to-predict transmission; some have 209,000 km and no problems, while others have 30,000 km and no problems.

Pros and cons of a variator

| PROS | MINUSES |

| Switching. Almost intangible (because they don't exist) | Service. Expensive consumables. For example, the oil in it is 8 liters and it costs about twice as much as ATF. |

| Dynamics. Excellent, no losses on gear changes | Repair. Not all companies are accepted; there are simply no competent technicians or diagnosticians. |

| Resource. More than your opponent | Torque. Withstands limited torque, cannot be installed on powerful engines and heavy cars. The belt or chain inside simply won’t hold up. |

| Control. Just as easy and intuitive as an automatic transmission | Towing is not allowed. Risky for the belt and cones. |

| Temperature. Practically not dangerous, that is, it does not freeze in winter | It is impossible to skid (for a long time). Again the belt and cones will suffer. |

| Traffic jams. Works great, no excessive overheating | Overheat. You can’t overheat, many different components inside suffer, starting from the valve body with solenoids, ending with the belt and cones |

I think this table will be useful to you. Now let's move on to the opponent.

Impressive result of good work

As a result, we can come to the conclusion that the VAZ team managed to create a good “robot”. What is especially impressive is that the project initially included unification, allowing the design to be quickly adapted to a number of models. The new AvtoVAZ product is in no way inferior to its analogues. From what is known, no unit with a “robot” has such elastic and smooth operation of the power unit.

Therefore, the “traditional” Jatco “automatic” has been replaced by a new product. This happened because VAZ’s “robot” is really quite good and is capable of satisfying the needs of the most demanding drivers. But the partnership with the Japanese continues, because it is necessary to give potential buyers maximum choice.

Today, cars equipped with automatic transmission and automatic transmission practically do not differ in price. But a price increase is coming for currently inexpensive Japanese-made automatic machines. After all, automatic transmissions are imported from Japan complete with a cooling system and require Japanese wheel drives. For AMT, everything was developed at AvtoVAZ. The only exceptions are actuators, control unit and selectors. The difference in price between a manual transmission and a “robot” is only 20,000 rubles. Jatco, even without taking into account drives and cooling, costs more than twice as much as a “robot”.

Design and operating principle of AMT

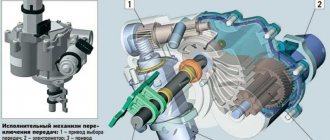

In general terms, AMT is a conventional manual transmission in which two special actuators (servo drives) are responsible for clutch operation and gear shifting. Each actuator installed on the gearbox is an electric motor with a gearbox and an actuator. The entire system is controlled by an electronic unit that selects and engages the required gear.

New LADA Granta on robot

The electronic unit takes into account the vehicle speed and engine operating mode, as well as information received from systems that monitor traffic safety (ABS, BAS, EBD, etc.). Evaluating and analyzing all the information received, the electronics unit issues a command to change gear.

After receiving the corresponding signal, the clutch is depressed using one servo drive, and the second one at this time engages the desired gear. Then the first servo smoothly releases the clutch.

When operating in Tiptronic mode (manual control), the driver independently moves the selector knob towards higher or lower gear and thereby issues the AMT command.

Note: when using a robot, there is no need for a clutch pedal.

Main changes - first impressions of robot 2.0

Let’s say right away that AvtoVAZ this time did not promote itself by updating such an important component in the car; many buyers did not even know that the Vestas being picked up from the showroom already had a completely different unit under the hood. The engine remained the same, but the gearbox received more than 100 small and medium-sized corrections, so it would be hard to call it the same. After a test drive and a comparative ride in a car with an old robot, we can draw the first conclusions:

- AMT 2.0 works much more pleasantly, and this can be seen from the first kilometers of the trip. Soft shifts, no jerking, precise prediction of driver actions and an intelligent control system.

- A creeping mode has appeared. This means that the robot reacts to releasing the brake pedal like a real automatic machine. The car begins to move a little or stands motionless on the hill. Such a system was sorely missed.

- The selector's previous characteristics remained, but it began to feel somehow more reliable and convenient. It was as if I was sitting not behind the wheel of a Lada, but in the cabin of a Toyota or Volkswagen.

- The robot began to work noticeably more quickly, it reduced the time it took to complete the full phase of gear engagement by 30%, and this clearly benefited the dynamics of the car and the sensations of the trip.

- Many of the shortcomings have been corrected, which means that you don’t have to worry about whether the unit will withstand a particular load or cope with certain climatic conditions.

The winter mode remains, but its characteristics have changed slightly. Now the car owner can forcefully engage second gear using the selector. True, you need to do this every time you start. But in the previous version of the robotic gearbox it was not possible to start from second gear to overcome the challenges of winter roads. This makes the box happy; it has become more adapted for Russian operating conditions. So there are practically no disadvantages with the first acquaintance.

AMT for LADA Granta. Design Features

Cars of the LADA Granta family (sedan, liftback) have already received a proven AMT, which has been installed on LADA Priora since September 2014. It was developed by engineers of JSC AVTOVAZ together with specialists from the German concern ZF Friedrichshafen AG, which is the author and owner of many modern technologies and innovative solutions in the field of drive systems.

The design of the basic manual gearbox 2181 (modernization of gearbox 2180) was taken as a basis, on which the following were installed:

- 1. Electromechanical actuators that control gear shifting and clutch operation;

- 2. Input shaft speed sensor;

- 3. Controller.

2180 gearbox and electronic control unit

In addition, the following were completely removed from the gearbox:

- 1. Clutch drive;

- 2. Internal switching mechanism;

- 3. Cable gear shift drive.

Inside the car, the clutch pedal was removed, and instead of a mechanical (cable) gear shift drive, an electronically controlled selector was installed.

In addition to original design solutions, modern software was developed specifically for AMT, with the help of which the vehicle’s transmission is controlled.

All these changes, together with the electronic motor control controller and the on-board power supply network, made it possible to fully automate the processes of controlling the clutch and gear shifting, as well as ensuring high AMT functionality.

Let's sum it up

Modern generation cars from AvtoVAZ have become much better than the previous ones, but buyers want even more progress and pleasant updates from the Russian concern. While buyers complain about high prices, Lada is actively saving on everything it can save on, and is also experiencing constant financial difficulties. It's amazing how you can sell so many cars and still struggle with money. The VAZ plant has always succeeded in this and continues old traditions with pleasure. But irony aside, Robot 2.0 turned out to be one of the concern’s best technical developments.

At least the company is trying to do something with the unit and improve it. Today, this technology provides certain additional capabilities to the driver, drives well, and copes well with difficult Russian travel conditions. Also, the robotic box can be slightly modified for installation on elevated versions of the Cross. Most likely, the robot will get a slightly smoother ride in first gear in crawling mode as an update, which will improve the clutch life and reduce discomfort for the driver in the process of getting used to the car. Did you like the characteristics of the new robot from AvtoVAZ?

Advantages and disadvantages of AMT

Among the many advantages of the “robot” are:

Fuel consumption in a car with an installed robot depends on driving style and is 6...6.5 l/100 km in mixed mode, which allows saving up to 30% of fuel compared to a sedan or liftback LADA Granta AUTOMAT and up to 10% compared to cars , equipped with conventional “mechanics”.

AMT is based on a manual gearbox, which is much less susceptible to breakdowns than an automatic transmission. In addition, the optimal operating modes of the robot are determined electronically (there is no “human factor”), which significantly increases the service life of the engine. Repairing an AMT is practically no different from repairing a manual transmission. In addition, it is much simpler and cheaper than automatic transmission.

- 3. Simplicity of design and unpretentious operation.

Electromechanical structural elements do not require maintenance or adjustment during operation. All connectors and electronic components are reliably protected from dust and dirt. The robot is adapted to difficult operating conditions and ensures operation when exposed to temperatures ranging from -40...+50 degrees Celsius.

There is no mechanical connection between the selector and the gearbox, so there is no vibration of the mode shift handle.

LADA Granta on a robot

Existing disadvantages of AMT:

- When starting to move, LADA Granta with AMT may roll back a little.

- Unlike an automatic transmission, the robot cannot change gears without losing traction torque. This results in barely noticeable jerks during gear changes.