Updated: 02/28/2021 12:59:54

Expert: Boris Vladimirovich Filatov

*Review of the best according to the editors of expertology.ru. About the selection criteria. This material is subjective in nature, does not constitute advertising and does not serve as a purchase guide. Before purchasing, consultation with a specialist is required.

In the hydraulic braking system, a special place is given to the brake cylinders. These units ensure the transmission of force from the pedal to the pads through the brake fluid. The slightest leaks in the cylinders make themselves felt by failure of the brake pedal and a decrease in the level of safety. Therefore, you cannot hesitate to replace it. On the domestic market, dozens of brands offer their products for hydraulic brake systems. Recommendations from our experts will help you choose the most reliable and durable unit.

Why is the rear brake mechanism acting up?

The hydraulic drive built into the VAZ-2110 combines in its internal design a booster and a dual-circuit pressure controller designed to control the rear brakes. If the rear cylinder is not working correctly, problems can provoke and create an emergency situation at any time when the vehicle is moving along the roadway. To prevent this from happening, the part should be repaired in a timely manner.

There is nothing surprising in replacing an old type of rear brake cylinder (RBC) with a new one; nothing lasts forever. Auto parts stores offer car enthusiasts the opportunity to purchase parts from the best manufacturers that will last a long time and guarantee safety on the road.

Where can I buy

Popular models and new items can be purchased in showrooms that sell accessories and spare parts for cars. Consultants will tell you what types of devices there are, how to choose, which company is better to buy, how much they cost, and how they differ.

If it is not possible to buy the necessary parts at your place of residence, the best inexpensive budget models can be ordered online from the online store of a manufacturer or auto parts dealer. This is available using the Yandex.Market aggregator or marketplaces that offer to purchase goods by type of vehicle, make or model of car. There are also descriptions, technical specifications, photos, as well as customer reviews. In addition, it is possible to select analogues of original parts.

In Moscow you can buy:

- GTZ at prices from 300 rubles (rear BELMAG 2105 (Bi-Bi)) to 21,992 rubles (VAG 2E0611917E (Autoperts777.ru));

- RTC - from 279 rubles (TTIALLI CF 701 (CARDONE)) to 6,597 rubles (DT SPARE PARTS 461850 (Autoperts777.ru)).

How to check the condition of the VAZ-2110 air conditioning center

Before you begin replacing the brake cylinder located at the rear, you need to inspect the car and establish an accurate “diagnosis”, especially since no special equipment is required for this - just a set of basic knowledge and your desire to understand the breakdown of the VAZ-2110 brake system.

See if the car has malfunctions and problems that are direct symptoms that the rear brake cylinder cannot be restored:

- Poor brake performance. For example, when pressed, the pedal easily falls down, and checking the brake system and adjusting its individual mechanisms did not give a positive effect.

- Brake fluid is coming out of the cylinder and there are marks on the shield. Even disassembling the unit and replacing the cuffs will be unsuccessful; the part will have to be replaced.

General structure of the vehicle

Speaking about the braking system of the VAZ-2109 car, it should be recognized that it would be more correct to use the term “VAZ-2108 braking system”. It was on the G8 that the scheme of the specified vehicle was implemented. The components, parts and assemblies of the new product have been refined and optimized. But the new braking system was not fundamentally different from the braking system of Russian rear-wheel drive cars.

The “nine” vehicle is represented by a working and a parking vehicle.

The structure of the working vehicle includes:

- a brake mechanism, the functions of which include direct braking;

- a brake actuator that serves to convert and deliver the driver’s command to brake and the effort he exerts for this.

The operation scheme of the VAZ-2109 brake mechanism is based on the operation of friction mechanisms that implement the principle of friction of parts.

The brake mechanisms themselves are located in the wheels and are made up of a rotating part (disc or drum) and a stationary part (special pads). Domestic cars of the VAZ family use a disc principle on the front wheels and a drum principle on the rear. The latest VAZ-2109 models began to be equipped with an electronic system for monitoring the wear of the front pads.

How to extend the service life of a new fuel pump

Before installing the part, you need to know the rules that will further extend the service life of the part:

- Choose the best products in the store, created by experienced manufacturers you can trust. By saving on brakes, you won't end up cheap.

- Pay attention to marriage. A defective product is characterized by the pistons coming out of the cylinder structure by a couple of millimeters. However, this is quite enough to cause another breakdown and replacement of the part.

- Buy good brake fluid.

- Ideally, you need to change not one cylinder, but two at once. As practice shows, if one element of the system has already failed, the second one will not be long in coming either.

Rear brake cylinder replacement instructions

Replacing the rear brake cylinder of a VAZ-2110 looks like this:

- Raise the car on the lift.

- To securely secure the VAZ-2110, lock the front wheels.

- Unscrew the fasteners and remove the rear wheels.

- Using a rubber hammer, remove the brake disc.

- Carefully remove the end of the tension spring installed at the top, this spring is located right next to the brake pad.

- Lift the handbrake lever all the way to the top, you will see how the pads have moved apart, now they can be removed without any problems.

- Unscrew the brake pipe from the cylinder.

- Remove the broken cylinder and install a new one in its place.

- Assemble the knot following the reverse order of these instructions (starting from the last point to the first).

- Replacing the rear brake cylinder of a VAZ-2110 involves pumping the brakes at the final stage.

What should you pay attention to during the entire procedure? Maintain a tight fit of the brake system parts; if additional components are found to be faulty, replace them too.

Instructions

So, how to replace the rear brake cylinder yourself? The VAZ needs to be placed on a flat area and the rear part must be jacked up, having first removed the wheel bolts. Next, remove the wheel itself. Getting to the brake cylinder is quite difficult. To do this we need to remove the drum and also remove the pads. In addition, the brake fluid hose is unscrewed.

How to remove the drum? Before dismantling it, you need to thoroughly clean it with a wire brush, removing all rust and dirt. After this, unscrew the 2 guide pins with a wrench. Next, remove the drum from its seat. This is done using a special puller. If this is not available, you can use 2 M8 bolts 6-7 centimeters long. We evenly tighten them with a wrench into the holes. This way the drum is compressed from the hub.

Now we need to remove the rear brake cylinder itself. So, remove the plastic protective cap and unscrew the bleeder fitting itself. To do this we need a key “8”. To remove the tube, you must use a 10mm socket. We break the tightening on the fitting and unscrew the element. Be careful - brake fluid will flow out of the tube. Wear protective rubber gloves when working. Next, unscrew the bolts securing the rear brake cylinder itself.

Is it possible to repair the rear brake cylinder?

This is indeed possible, you just need to have the skills to disassemble the part and know the design features. To properly disassemble the product, repeat the following steps:

- Remove the protective caps.

- Remove the pistons and elements that regulate the automatic gap from the body; this mechanism appears between the drum and the brake pads.

- After turning the piston and fixing it, you can already unscrew the stop screw.

- Slide out the O-ring and spring support cup.

- Disconnect the thrust ring and screw from each other.

Now carefully inspect the details:

- All surfaces must be smooth; scratches and roughness are unacceptable, as this will cause brake fluid to leak.

- If there are defects on the mirror base, use grinding or lapping - the latter method is gentle. The inner diameter of the cylinder must retain its dimension.

- Replace seals and protective caps.

Step-by-step video instructions for replacing the rear brake cylinder are presented below:

Replacing the rear brake cylinder on a VAZ 2110, VAZ 2111, VAZ 2112

Welcome!

Rear brake cylinder - thanks to it, the brake pads come into contact with the brake drum and from this contact, the car slows down, when the cylinder becomes unusable on one side, the wheel either stops braking at all, or it brakes but very poorly, there are still options when the brake fluid pours out through the drum, it is generally recommended to inspect the brake mechanism from time to time, it is thanks to it that the car is braked, and if at the wrong moment the brake mechanism becomes unusable, then with a very high probability an emergency situation will occur that can turn out differently .

Note!

To replace the brake cylinder, you will need: Wrenches, as well as ring wrenches, if you have a special wrench for the fittings of the working cylinders, it will be very useful, but you can still do without it, and by the way, after replacement, you will need to bleed the brake system, and bleeding requires a larger set of tools, in which one of the most important is a clean, empty liter container and a short hose for it and the bleeding fitting!

Where is the rear brake cylinder located?

You will need to remove the brake drum, after which you will be able to see it very easily, but if you don’t understand what it is at all and have never seen it in your life, then look at the photo just below, in which it is indicated by a red arrow and as you can see its ends (indicated by blue arrows) are connected to the brake pads, we have already said that it is he who pushes the brake pads, namely the pistons, which are indicated by blue arrows, extend and press the pads with their pressure.

When should you replace your rear brake cylinder?

When jamming and when a leak is detected from it, jamming of the cylinder is very easy to understand, in this case one wheel stops braking at all or braking, but what is most important is that the wheel brakes without ceasing, all these situations mean that in some position the brake cylinder is jammed , if it is leaking (It means it has worn out and will soon jam) it is much more difficult to understand, the first symptoms that should alert you are that the brake fluid in the reservoir is quickly running out and there is a leak on one of the rear wheels of the car (In the photo, a brake fluid leak is very clearly visible, if it turns out If the cylinder is intact, then most likely the brake hose has burst).

What it is

A brake cylinder is a component of the brake system that converts fluid pressure into mechanical energy that presses the discs or pads against the wheel rim.

Depending on the purpose and design there are:

- main (GTC) - control elements of the brake system in all cars with a hydraulic drive;

- working (wheeled, RTC) – devices for actuating actuators.

Functional

1. Master cylinder:

- converting pedal force into pressure sufficient to operate the brake actuators;

- maintaining the required fluid level;

- maintaining operability in the event of a leak, leakage or other malfunction.

One GTZ is installed in the car.

2. Wheel cylinder:

- startup of actuators during braking;

- partial return to the initial state of the GTZ upon disinhibition.

Usually the number of RTCs corresponds to the number of wheels, but it can be two to three times more when two or three devices are installed on one wheel.

Connection diagrams depend on the car drive:

1. Contours in front-wheel drive:

- first – front right, rear left;

- the second - front left, rear right.

2. Contours in rear-wheel drive:

- first - front;

- the second is the rear.

If two RTCs are installed on each front wheel, the connection can be combined. One will be in the first circuit, and the second - in the second circuit and will operate simultaneously with the rear ones.

How to replace the rear brake cylinder on a VAZ 2110-VAZ 2112?

Removal:

- Removing the cylinder is not difficult, we’ll even say it’s very simple, but getting to it is not an easy task, because you will have to remove the brake drum, brake pads and most importantly, the brake pipe will have to be disconnected, and therefore the brake fluid will immediately flow out of it, by the way, You can close the tube with a cap from the bleeder fitting, thanks to which air will practically not enter the system and all the liquid will remain intact (we will explain to you how to do this a little later), well, let's start replacing, first, as we have already said, remove all the parts that prevent access to it (For information on how to remove the drum and pads, read the article: “Replacing rear brake pads on a VAZ”).

- Let's go further, now remove the same plastic cap from the bleeder fitting (Indicated by a blue arrow), just do not lose it under any circumstances and also check its condition, it should not be cracked or otherwise broken, otherwise replace the cap with a new one , then grab a special wrench or just the most ordinary socket wrench “8” (in general, it depends on what kind of wrench you have, but it’s also convenient to use a socket wrench, but still a special wrench for the bleeder fitting, if you have one, will come in handy) and with its help, completely unscrew the bleeder fitting itself (This is the one that the cap covered, it has edges, in general, you will understand everything right away), then move to the brake pipe (namely, to its edges, they are indicated by a blue arrow) and using special . wrench or a regular “10” wrench, break the tightening of this tube beyond the edges and with a regular wrench, then unscrew this tube and finally disconnect it (When the tube is disconnected, brake fluid will flow out of it, so that it does not leak out, cover the tube itself with a plastic the cap from the bleeder fitting), and finally, unscrew the two bolts indicated by the green arrows and remove the faulty brake cylinder from the car.

Note!

When working with the brake pipe, we recommend that you first soak its nut in WD-40 and when you unscrew the nut, make sure that the brake pipe itself does not rotate (only one nut should rotate), but if you notice that the pipe along with it is walks around, this means only one thing, the tube in the nut is rusty and is already turning along with the nut itself, such a brake tube must be replaced immediately!

Installation:

Installing a new rear brake cylinder is carried out in the reverse order of removal; before installation, we recommend cleaning the brake mechanism with a brush from dirt, this mechanism simply does not like it very much and it is generally destructive for it, in addition, if the brake pads end up in the brake fluid (And if the brake in the cylinder they will turn out to be 100% like that), then clean them of liquid using sandpaper (Do everything carefully and know when to stop), and degrease the surface of the brake drum itself with white alcohol or any solvent and when everything is installed, Be sure to bleed the brake system, otherwise the car will brake very, very badly (How to carry out this operation, read the article: “Bleeding the brake mechanism on a car”).

Components

Master cylinder

Varieties:

1. Number of circuits:

- single-circuit – almost never seen now;

- dual-circuit - placement of two mechanisms in a single housing.

2. Availability of an amplifier:

- absent;

- installed.

Typically, the GTZ is installed on top of the vacuum booster cover. A fairly simple design includes:

- cylindrical body;

- pistons;

- return springs;

- storage tank;

- sealing cuffs.

Two pistons installed one behind the other inside a hollow cast body create the required pressure and form working sections. Their return and retention in the initial position is ensured by springs. The reservoir is designed to store and also add liquid when it is reduced. Usually located on top, connected to the mechanism by bypass and compensation channels.

The liquid level is controlled using marks on the transparent walls. In addition, there is a sensor inside that, when the level drops, turns on a light on the instrument panel.

When braking, the front piston moves, blocking the compensation channel. Due to the resulting tightness, the pressure increases. The rear piston also begins to move, the fluid is compressed, and the compensation channel is closed. The space behind the pistons is filled with liquid through open bypass channels. As a result of the increase in pressure, the RTCs are activated, activating the actuators on the wheels.

When the brakes are released, the pistons return to their initial position under the action of springs. Removing the brakes is performed smoothly due to the fluid remaining in the cavity behind the pistons and leaving there gradually. In the initial state, with the compensation channel open, the pressure is compared with atmospheric pressure.

Working cylinder

Varieties:

- drum system - an autonomous device for expanding the pads. It consists of a hollow body and pistons with a liquid-filled space between them. Connection to the system through the brake pipe fitting (M10x1 or M10x1.25);

- disc mechanisms - a device as part of a brake caliper for pressing the pads. Consists of a cylindrical cavity and an inserted piston. Connection to the brake system through a fitting located behind the piston.

As braking begins, the pressure increases and the incoming fluid moves the piston. In a drum system, the pistons move in different directions and press on the pads. In a disk mechanism, they move out of the cavities with the pads pressed.

When the brakes are released, the pressure decreases and the pistons return to their original position.

Causes of malfunction of the rear braking mechanism

The hydraulic drive consists of a vacuum booster and a dual-circuit pressure regulator for the rear brakes.

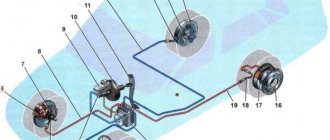

The main elements of the brake mechanism for the rear wheel are:

How effectively the rear brake cylinder of the VAZ 2110 will work will depend on the safety of the vehicle on the roads. The article suggests how to replace a brake cylinder with your own hands.

The brake mechanism, like any other, is subject to wear, which requires its replacement after a certain period of time. Trade organizations offer a large selection of brake cylinders.

When purchasing it, you need to pay attention to the quality of the product and the presence of positive reviews from car owners. So that you don’t have to purchase a new cylinder after the first day of using the car.

To check the condition of the rear brake cylinder on the VAZ 2110, you need to remove the drum.

The presence of a faulty brake cylinder may be indicated by:

- Deterioration in the effectiveness of the brakes (see Repairing brakes at home), his pedal became much “softer”, and bleeding the entire brake system and checking the condition of the brake pads did not eliminate the problem.

- Brake fluid leaks from the brake cylinder, as indicated by traces of its leaks on the brake flap, position 11. In this case, the tightness of the system is broken, and its mechanisms will not ensure stopping the car. The wheel pistons will push the pads apart and the disc will stop spinning. The pedal will fail and if an emergency occurs, the car will not be stopped in time.

After disassembling the unit and replacing the cuffs, the situation does not improve.

How does it work?

The operating principle of the system is to use a hydraulic drive. When the driver presses the pedal, pressure is generated in the system. The rod presses on the piston. This, in turn, transfers forces to the liquid.

Traffic safety depends on the proper operation of this system. Therefore, you need to be able to diagnose a malfunction in a timely manner. How to do it? Let's look further.

Replacement of rear brake cylinders

The best rear brake cylinders on the VAZ 2110 can work for a long time. An example of a defective product would be a brake cylinder in which the pistons extend out of the cylinder only a few millimeters, which is not enough to move the brake pads apart.

The quality of the brake fluid also plays a role in the service life of the brake cylinders. The instructions indicate that the rear brake cylinders are removed with the brake drum removed.

Advice: It is advisable that the replacement of the rear brake cylinders of the VAZ 2110 be carried out simultaneously on both brakes. Wear of one of the elements indicates that the second one will soon fail.

And the price of the work will be reduced by disassembling the car once.

- The machine is installed on an inspection pit or a lift.

- The front wheels are fixed.

- The rear ones are removed.

- Using a rubber hammer, the brake disc is pulled out of its place.

- Carefully remove the end of the upper tension spring, position 7 in the first photo.

- Previously, it was connected to the brake pad.

- The handbrake handle is raised all the way. In this case, the brake pads move apart and are removed without much effort.

- The brake pipe is unscrewed from the cylinder.

- The rear brake cylinder is removed.

Removing the rear brake cylinder of a VAZ 2110

- If necessary, the rear brake cylinder of the VAZ 2110 is replaced with a new one.

- Assembly of the unit is performed in reverse order.

- The job ends with bleeding the brakes.

Tip: Replacing the brake cylinder on a VAZ 2110 car is carried out in strict sequence - both dismantling and installing spare parts. The main condition is serviceability and tightness in the hydraulic system.

How the rear brake cylinder is replaced on a VAZ 2110 car can be seen in the video.

Repair of rear brake cylinders of VAZ 2110

There are times when, to save money, it is enough to replace worn parts of an assembly. In this case, after removal from the vehicle, the rear brake cylinder is disassembled.

Dismantling the rear brake cylinder of a VAZ 2110

- Remove the protective caps, pos. 10 in the picture above.

- Pistons are pressed out of the cylinder body along with parts to automatically regulate the gap formed between the drum and the brake pads.

- After installing the piston pos. 9, turn it onto a special device and remove the thrust screw, pos. 3.

- Remove the sealing ring pos. 8 and support cup pos. 7 with crackers pos. 5 and spring pos. 6 from the screw.

- The thrust ring pos. is disconnected. 4 and a stop screw.

After disassembling the unit, the parts are checked for faults:

- The working surfaces of the pistons, cylinder and thrust rings must be smooth, without scratches or roughness. Otherwise, fluid leakage and premature wear of pistons and seals may occur.

- Defects on the mirror surface can be eliminated by grinding or lapping.

Tip: Care must be taken not to increase the internal diameter of the cylinder.

- The thrust screw, springs, support cup and crackers are visually checked. If they are damaged, parts are replaced.

- Seals pos. 8 are replaced with new ones.

- If necessary, change the protective caps pos. 10.

- The structure is assembled in the reverse order.

In this case, you need to take into account:

- All parts are generously lubricated with brake fluid.

- The thrust screws must be tightened to a torque of 3.9 – 6.9 Nm.

- The slot located on the thrust rings is directed vertically upward, the deviation should not be more than 30 degrees. This ensures that all air is removed from the drive mechanism when bleeding the brake.

- Using the device, the pistons are pressed into the cylinder body.

- After assembly, the movement in the housing of each piston is checked, which should be from 1.25 millimeters to 1.65 millimeters.

- Protective caps are installed.

- Timely repair or replacement of rear brake cylinders is a guarantee of road safety.

Didn't find the information you are looking for? on our forum.