Last updated April 2, 2022 at 1:47 pm

Perhaps the most popular and affordable controller in the line of gas equipment from Digitronic[/anchor] is the Digitronic Maxi 2 ECU. The reason for this is its versatility, ease of adjustment and compatibility with most common cars.

We will talk about the capabilities of the unit, its correct connection and configuration in this article.

About the digitronic brand

In 2004, the engineering and management staff of GAZPART 95 began developing the foundation for a new brand. The idea was to use a wide range of high-quality components from various manufacturers.

According to the technical specifications of Digitronic specialists, work is being carried out to manufacture equipment at the Italian plant AEB (Alternative Fuel Electronics). However, there are components from other countries. For example, from the Polish company STAG.

And this is one of the Digitronic policy lines, in which there are no restrictions in the selection of a high-quality assortment.

In many respects, gas cylinder equipment of this brand can be considered universal, because it can be installed on different car models. It is important that these products are applicable to trucks and passenger vehicles.

Products

The company supplies items such as:

- HBO cylinders are cylindrical and toroidal of various capacities;

- Nozzle (Injection) rails;

- Additional components and parts (multi-valves, filters, dispensers, mixers, clamps, tubes, rubber hoses and other consumables);

- Gearboxes;

- Various electronics (injection and traditional gas equipment, CVTs, emulators, sensors and indicators);

- Kits (for four, six and eight cylinders, as well as FSI with direct injection).

In addition, tuning systems, adapters, programming interfaces and much more are provided.

Features of HBO 4th generation Digitronic

The most popular systems are the fourth generation of gas equipment associated with changes in engine production. The Digitronic company has well established itself as a manufacturer with well-thought-out components for 4th generation HBO. The advantages of brand development are:

- Stable and reliable, trouble-free operation;

- Ergonomic installation;

- Easy to set up.

The equipment is designed in such a way that it will function successfully, regardless of the qualifications of the installer. And the ease of installation allows you to set an adequate cost for the work or carry out the installation yourself.

Another plus for the digitronic HBO is that the system is designed in such a way that exhausts as a result of fuel combustion practically do not enter the environment. You can also note some operational characteristics that increase the demand for these systems:

- Increases vehicle range

- Design features reduce maintenance costs

- Engine oil service life increases to forty to fifty percent

- The engine starts quickly

- Engine parts are not exposed to tar deposits, soot or carbon deposits

- Spark plug and engine depreciation is slower

However, with all the advantages, there are also standard disadvantages that cannot yet be improved: cost, cylinder dimensions and an increase in the total weight of the car.

Multivalve

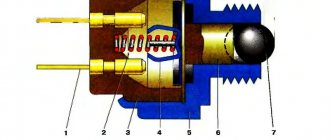

Gas systems of any type must be equipped with shut-off valves. For cars, a multivalve is used, which combines up to ten functions, in addition to shut-off. The device includes several elements: actuator, shut-off, control and safety.

Multivalves can also be divided into two types: without a safety valve with a volume limitation for equipped cylinders and with a valve.

Device functions:

- Possibility of manually shutting off the fuel supply;

- Availability of gas supply speed control;

- Blocking the loss of the gas mixture in the event of a disconnection from the filling column;

- Emergency gas release in case of cylinder depressurization;

- Fuel level sensor.

Digitronic kits

The company supplies both individual components and kits for engines with different numbers of cylinders.

A comprehensive solution involves the selection of each element, which affects the efficiency and stability of the entire system as a whole. The set of gas equipment includes:

- Switch between gas mixture and gasoline (Gas-gasoline button);

- Cylindrical or toroidal gas cylinder with a volume of forty liters or more;

- An electromagnetic valve with a filter, designed to remove impurities from the fuel mixture and performing a shut-off function;

- A ventilation box, which includes shut-off valves and valves, the purpose of which is to reduce the risk of an emergency in the event of a gas leak;

- Reducer - an evaporator through which liquefied gas passes into the gaseous phase;

- Valves for gasoline and gas are electromagnetic type to stop the supply of fuel to the combustion chamber.

Mounted injector rails, gearbox temperature sensors and an electronics kit can also be supplied.

Digitronic control unit MAXI 2

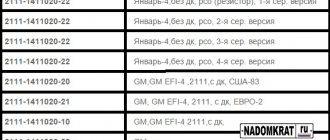

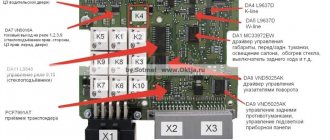

For four cylinder engines, Digitronic has developed the MAXI 2 control unit. This line is designed to reduce installation and calibration time.

The basis of the unit is a thirty-two-bit processor with the possibility of upgrading. Such a unit can be quickly installed thanks to a small number of wires and a sealed compact housing. Calibration is carried out through functions located on two panels, which eliminates the problem of switching between tabs. There is a separate button with a buzzer, which is connected using three wires.

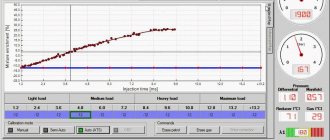

The software capabilities of the unit include displaying engine operating parameters on an oscilloscope, a gasoline injection time map in 2D format, functions for correcting gas pressure and temperature with corresponding maps, heating gas injectors, setting the maximum load on the gas mixture, changing the time for opening and closing injectors, as well as the flow through them, and much more.

The MAXI 2 unit is compatible with almost forty manufacturers of gas injectors, including AEB, Hana, Valtek, Rail, Matrix. Functional and software characteristics have made Digitronic MAXI 2 one of the most popular on the Russian market.

Digitronic control unit IQ series

This line is intended for engines with a number of cylinders other than four. Each IQ block model is installed for its own number of cylinders. The functions of the IQ block include:

- Automatic closing of the solenoid valve if the temperature at the gearbox drops below 10ºC;

- Correction of the volume of injected gas;

- Indication of target OBD corrections depending on engine speed with a map;

- Fuel level emulator (for cars whose gasoline indicator drops when switching to gas fuel);

- Correction of the volume of injected gasoline along with gas;

- An oscilloscope showing the operation of gas and gasoline injectors, as well as engine speed;

- Flow calibration on gas injectors;

- Open Loop adaptation for closed and open loop.

Principle of operation

The 4th generation GBO device provides for operation on gas fuel in automatic mode, i.e. When starting a cold engine, the solenoid valve of the cylinder shut-off device is in the closed position.

After warming up the internal combustion engine, with the gas/gasoline switch activated in advance, the gas system controller (ECU), having received readings from the evaporator temperature sensor, opens the multivalve, where fuel in a liquefied state (or compressed (methane)) begins to flow to the gearbox.

It is also possible to start a cold engine on gas. For this purpose, the fourth generation of gas-cylinder equipment has an emergency start mode. But this creates a risk of damage to the membrane of the evaporator reducer.

The gas, passing through the channels of the gearbox, heated by the engine coolant to the programmed temperature (set when adjusting the gas equipment), begins to evaporate.

Then the computer sends a signal to the gas fuel supply valve, through which the gas, bypassing the liquid/vapor phase filters and the Map sensor, enters the injectors (nozzles). They supply gas in portions to the engine intake system, or, if the internal combustion engine has direct injection, directly into the combustion chamber. In this case, the gasoline injectors are deactivated by the computer or are in after-injection mode.

The quality, quantity, and rate of supply of propane/methane are controlled by the “brains” of the gas equipment, through the obtained readings of the lambda probe, temperature sensors, map sensor, and also the UOZ variator.

The warmed-up engine automatically starts on gas fuel.

4th generation gas equipment from Digitronic

Today there is a large selection of gas equipment on the market from various manufacturers. It differs in quality, price, installation features, and level of availability of service in specialized centers. A worthy place in this series is occupied by Digitronic gas equipment.

Why is this brand so attractive to car enthusiasts, why is it worth paying attention to the 4th generation Digitronic universal gas equipment?

A little about the brand

The Polish company Digitronic for the production of gas equipment was founded in the early 80s of the last century. Many successful companies around the world were involved in the production of gas equipment.

This did not stop the team of proactive specialists from promoting the products. A non-standard approach, the right policy, innovative developments, perseverance, and a focus on success have brought positive results.

The range of products increased every year, the company grew. Gradually, Digitronic gas equipment took a confident position. Today, Polish brand LPG is installed on vehicles in different countries.

The bulk of the Digitronic team’s specialists consisted of experienced car owners who had used gas cylinder systems for many years and knew what to pay attention to. This became the main success factor in promoting the company. Starting a new business with such a team means being doomed to success.

Car owners and car service technicians have the same positive opinion about HBO Digitronic. It is easy to certify the equipment and perform diagnostic procedures.

The connection diagram for the 4th generation digitronic gas system on cars with injectors is not difficult; it comes with clear and detailed instructions. The work of Digital Gas Injection is based on the fact that the gasoline fuel circuit functions separately for each cylinder. Some craftsmen make homemade devices for diagnosing gas equipment.

What is needed for proper installation?

To properly install gas equipment on a car, you will need a certain set of equipment and tools:

- HBO set 4;

- gas hoses with clamps 60-80cm long, Ø4-5mm and Ø12mm 50-100cm (for a 4-cylinder engine); 40-70cm vacuum tube Ø6mm; a cooling system hose with two metal tees corresponding to the size of the inlet/outlet on the gearbox - the length of all lines is selected individually for the car;

- thermoplastic gas tube of the required length (you can use copper or aluminum);

- auto tools;

- drill and/or screwdriver;

- drills (Ø4.8mm, crown 30mm);

- tap 6mm;

- electrical tape, heat shrink tube, hair dryer;

- soldering iron (materials for soldering wiring);

- multimeter;

- metal clamps/brackets with self-tapping screws (for fastening lines under the bottom);

- a can of anti-corrosion treatment or auto enamel;

- engine intake manifold gasket.

You will also need a lift/overpass or inspection hole.

Advantages and disadvantages of HBO Digitronic

Studying numerous reviews from owners of cars with 4th generation digitronic gas equipment, you can find both positive and negative sides.

Of the minuses, it is worth noting only complaints about the impossibility of self-adjustment, as well as premature failure of individual components of the system. But these disadvantages may be only partly true.

In practice, upon detailed analysis, it often turns out that the first and second statements are due to the incompetence of the technician who installed/configured the equipment. Also, untimely or low-quality maintenance of gas equipment or its absence at all.

However, do not forget about fake digital electronics. The advantages are obvious:

- a wide selection of trim levels for both budget small cars and premium cars.

- ease of self-installation, configuration, and maintenance. All instructions/manuals are available

- maintainability (spare parts/repair kits available)

- high quality of system parts and reliability of components (all components undergo multi-level testing)

- manufacturability, it is possible to diagnose and adjust equipment parameters directly from a smartphone through the original application.

Products

The company supplies items such as:

- HBO cylinders are cylindrical and toroidal of various capacities;

- Nozzle (Injection) rails;

- Additional components and parts (multi-valves, filters, dispensers, mixers, clamps, tubes, rubber hoses and other consumables);

- Gearboxes;

- Various electronics (injection and traditional gas equipment, CVTs, emulators, sensors and indicators);

- Kits (for four, six and eight cylinders, as well as FSI with direct injection).

In addition, tuning systems, adapters, programming interfaces and much more are provided.