When is it necessary to replace rear struts?

For shock absorbers there is no replacement period or service life between repairs. The condition of the Kalina's rear pillars is largely determined by the conditions and intensity of use. In the vast majority of cases, they fail after 30-50 thousand kilometers. Sometimes this happens much earlier, and in some cases the car can travel 70,000 kilometers. Therefore, the racks must be periodically monitored. Sometimes their malfunction can be determined visually.

Analogs of front shock absorbers Lada Kalina 1117, 1118, 1119

Original shock absorbers are in demand when replacing front struts, but increasingly, spare parts from other manufacturers are being supplied to the Russian market, which are not inferior, and in some cases, superior to original products. A list of the most popular shock absorbers is presented in the table.

| Manufacturer | vendor code | price, rub. |

| Front shock absorbers for Lada Kalina (1117, 1118) first modifications | ||

| At program | Right AT5002118SA Left AT5003118SA | 5000 (set, 2 pcs.) |

| At program | Right AT5002118SAG Left AT5003118SAG | 1800 |

| Pilenga | Right SHP2718O Left SHP2728O | 2200 |

| Front shock absorber struts for VAZ 1119 (entire model range) and 1117, 1118 later modifications | ||

| Kroner | Right K350319 Left K350419 | 5000 (set, 2 pcs.) |

| QML | Right SA1011 Left SA1010 | 1500 |

| QML | Right SA1013 Left SA1012 | 1500 |

Shock absorber VAZ 1118

Shock absorber Pilenga SHP2718O(right)

Symptoms of a problem

Damage to shock absorbers, unlike many other components of the car, is relatively easy to determine. It is worth thinking about the malfunction of the rear struts of the Kalina in the following cases:

- oil smudges on the shock absorber housing;

- rocking of the car when overcoming bumps;

- knocking in the rear suspension;

- strong lean when turning.

In any case, when doubts arise about the maneuverability of the car, its handling, or any discomfort is felt while driving, you should first of all pay attention to the rear pillars of the Kalina.

Features of Kalina 2013

VAZ released the modernized Kalina for sale in 2013, having previously widely covered the upcoming event in the media. The debut took place on a grand scale. The car has really become more interesting in every sense. Now completely new power units have appeared, eight- and sixteen-valve, with a volume of 1.6 liters, with a capacity of 98 to 106 hp. with front-wheel drive, five-speed manual or four-speed automatic transmission. The simplest engine accelerates Kalina to a speed of 167 km/h, the most powerful - up to 190 km/h.

Kalina is stable, but the chassis should be carefully monitored

The model now has unprecedented options: a good security system, an increased degree of comfort. But what about the car's dynamics? The 2013 Lada Kalina turned out to be much more powerful and durable than previous developments. The car has many undeniable advantages, good engineering and design solutions.

Racks are one of the issues that require special attention. At the beginning of using the car, the driver notices that knocking noises appear on steep climbs and turns. As a rule, motorists hope that after traveling a certain number of kilometers this will go away, because lapping and rolling are needed. But over time, the knocking not only does not go away, but also becomes even stronger. In addition, they are accompanied by other troubles related to the vehicle’s handling and stability.

There is excessive rigidity of movement; it seems that the suspension does not want to perform its functions and filter out road irregularities. If there is a speed bump along the way, Kalina howls, informing the driver about the unpleasant impact. If suddenly the car gets into an off-road zone, it even starts to skid. To understand this issue, it is necessary to study the features of different types of struts as the most important parts responsible for driving quality.

How to make sure the rack is working properly?

Sometimes it is impossible to visually determine the cause of extraneous noise when the car is moving. For example, the rear pillars of the Lada Kalina are clean, without any oil stains. Rocking also does not allow one to unambiguously diagnose a malfunction. However, the knocking noise in the rear suspension area does not disappear.

In this case, you will have to drive the car onto a vibration stand. It simulates road irregularities, and special sensors monitor how various suspension elements perform. The data is transmitted to a computer, which draws conclusions about the serviceability of the racks. This pleasure, of course, is not free, but it won’t hit your wallet very hard either. The cost of computer diagnostics depends on the region and is within a couple of thousand rubles. But for this money, the owner will receive data not only on the condition of the shock absorbers, but also all components of the front and rear suspension, which is especially important if there is a long trip ahead.

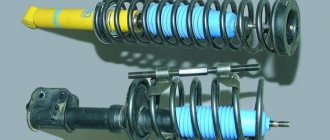

Purpose and design features of racks

The front struts are designed to reduce the impact of the road surface on the car while driving. If the road is full of uneven surfaces, then the operation of the struts in this driving mode is especially important. The front struts, as well as the rear ones, of the Lada Kalina allow you to smooth out the vibrations that occur in the body under the influence of inertia when driving on an uneven road surface. Even if the road has a smooth surface, the shock absorbers are still endowed with the function of holding the car steadily on a given trajectory.

Over time, the front struts become unusable, and then the owner, while driving, notices the appearance of difficulties in driving the car. He also begins to feel the smallest irregularities in the road surface, during which the body tends to sway and move from the set course. Efficient shock absorbers are designed to prevent this development of events.

Before starting repair procedures, you need to familiarize yourself in detail with the design aspects of these elements of the Lada Kalina chassis.

- The front oil struts have a two-pipe mechanism, the functioning of which is possible due to the internal movement of liquid, that is, oil. This design of the shock absorber is quite simple, but in operation a tendency to overheating has been revealed, which provokes the supports to deform. Selecting and replacing these product options is also easy.

- The front gas-oil struts operate under the influence of gas pressure. They are very effective and allow the Lada Kalina car to gain reliable protection from shock and rocking influences.

- Single-pipe structures. In most models, manufacturers use such versions of products in the stern suspension. Shock absorbers can please you with good heat transfer and fairly high efficiency. Disadvantages include low reliability and high sensitivity to shock loads.

The choice of product option is significantly influenced by the operating features. Primary replacement of struts in Lada Kalina is recommended after 100,000 mileage. Subsequent replacements must be carried out after approximately 80 thousand km, but we must not forget about the influence of the operational factor.

What racks should I install?

This point needs to be decided in advance. It should be said right away that the rear pillars of the Kalina in a hatchback, sedan or station wagon are absolutely identical. Therefore, the choice is limited only by the manufacturer and spring stiffness. As for the manufacturer, experts do not recommend installing original racks due to their short service life. The most positive reviews and recommendations come from SS-20 brand products.

As for the stiffness of the springs, much depends on the driving style of the owner. Softer ones are suitable for leisurely drivers who prefer comfort to speed. If the car owner prefers an aggressive driving style, and the main use of the vehicle is on roads with good surfaces, then it is worth choosing stiff springs. This will improve the car's handling, although at the expense of comfort.

Very often, owners strengthen the suspension in the hope of giving the car some imaginary advantages. For example, they install stiffer rear struts on the Kalina. In this case, the station wagon body, according to repairmen, is capable of withstanding increased load capacity. Manufacturers are wary of such experiments. Increasing the spring stiffness creates additional stress on the car body. This is especially unacceptable for machines that have been in operation for a long time.

Front shock absorbers for Kalina 1117, 1118, 1119

According to their technical parameters, front shock absorbers for Kalina are divided into right-hand and left-hand, and for VAZ 1119 models the cup width will be smaller than for VAZ 1117 and 1118. Shock absorbers with the article number right. 11182905002 / lion 11182905003 were installed on the VAZ 1117 and 1118 of the first modifications. And the details with art. number 11192905002 (right), 11192905003 (left) were installed on VAZ 1119 of all model series and VAZ 1117 and 1118 latest versions. Front shock absorbers 1118 and 1119 are interchangeable with each other, but the difference is in the springs.

On cars with an eight-valve engine (the exception is the VAZ 1117 station wagon), conical springs art. 11182902712 or shaped barrel springs art. 11192902712. For cars with a 16-valve engine and for the VAZ 1117, springs with higher stiffness and load rating are installed - article numbers 111862902712 and 111962902712.

The shock absorber parameters are shown in the table:

| Rod diameter, mm | Case diameter, mm | Rod stroke, mm | Rack pipe height, mm |

| Dimensions of front shock absorbers for Lada Kalina 1117, 1118, 1119 | |||

| 22 | 52 | 177 | 360 |

Replacement procedure

First of all, you need to prepare the necessary tools. To carry out the work you will need:

- two spanners 19;

- open-end wrench 6;

- hammer;

- curved socket wrench 17;

- mount;

- WD-40 or other penetrating liquid;

- spring ties;

- flat screwdriver;

- jack.

Replacing the rear struts of the Kalina can be done with or without removing the wheels. The second method is somewhat simpler and much safer, but is only possible if there is an inspection hole or overpass. Therefore, it is recommended to take care of this in advance.

Replacement is carried out in the following sequence:

- Drive the car into the inspection hole and set the parking brake.

- Remove the rear seat along with the backrest.

- Using a screwdriver, remove the decorative plugs from the top mounting of the racks.

- Holding the shock absorber rod with a wrench (No. 6), unscrew the nut that secures the strut with a spanner wrench (No. 17). Sometimes this is not easy to do, especially if the replacement is being made for the first time. You will have to worry about finding a special device. If the nut is unscrewed, the work in the interior is finished for now.

- Using a jack, the rear wheel is hung from the side of the rack being dismantled. Now you need to go down into the inspection hole.

- From below, the stand is attached to the bracket with a long bolt and nut, which should be treated with WD-40.

- Use a union nut (No. 19) to unscrew the nut, holding the bolt itself with another wrench. Sometimes such manipulations do not help; you have to use a special tool to remove the stand.

- We take it out of the bracket. It is pressed from above by a spring, so care must be taken.

- We inspect all rubber parts. If possible, it is better to replace them with new ones. Assembly is carried out in reverse order.

- When installing a rubber buffer on the top of the spring, you need to ensure that the last turn rests on a special protrusion. Now you need to secure it with electrical tape or nylon ties.

- The lower coil of the spring should rest against the protrusion on the cup.

- We install the stand in place, fix it using the lower fastening.

- Now you need to compress the spring, gradually lowering the jack. The complexity of this operation is that at the same time the shock absorber rod must be directed into the hole in the upper mounting. It's better to use a friend's help.

- As soon as the rod gets into the hole, you need to attach a nut to it. This will help pull it out to its maximum length, after which it can be unscrewed.

- Place the support washer and rubber cushion on the rod. Now you can tighten the nut.

Rear suspension: design and features

The rear suspension beam consists of 2 longitudinal arms 13 and a connector 12, connected by means of amplifiers to each other.

Rear suspension parts: 1 – rubber-metal hinge, 2 – bracket for mounting the suspension arm, 3 – hydraulic shock absorber protection casing, 4 – buffer for the compression stroke, 5 – casing cover, 6 – support washer, 7 – shock absorber pads, 8 – spacer bushing, 9 – hydraulic shock absorber, 10 – insulating gasket, 11 – shock absorber strut spring, 12 – connector for levers, 13 – lever for the front suspension beam, 14 – bracket for fastening the shock absorber strut, 15 – flange, 16 – bushing from the lever .

Rear wheel hub and shock absorber strut mount: 1 – hydraulic shock absorber protection casing, 2 – buffer for compression stroke, 3 – support washer, 4 – insulating gasket for the spring, 5 – upper support spring cup, 6 – cushions for attaching the shock absorber rod, 10 – bolt for fastening the rear wheel hub axle, 11 – brake drum, 12 – hub bearing, 13 – hub from the rear wheel, 14 – hub axle, 15 – hub nut from the rear suspension, 16 – retaining ring, 17 – locating pin.

Location of parts from the rear suspension on the car: 1 - bracket for attaching the lever to the body itself, 2 - lever, 3 - shock absorber from the strut, 4 - lower hinge from the strut, 6 - connector for the levers, 6 - rubber-metal hinge of the lever.

In the rear part, brackets 14 with eyes are welded to the suspension arms, thanks to which you can attach shock absorber struts and flanges 15, to which the axles from the rear wheels are bolted together with the shields of the braking mechanisms. In front of the suspension arms, bushings 16 are welded into which rubber-metal hinges 1 are pressed. Bolts pass through these hinges that connect the suspension arms to brackets 2, which, in turn, are attached with studs to the power elements of the body.

The suspension springs 11 rest with one end on the shock absorber strut cup 9, and with the other, through the insulating rubber gasket 10, in the support, which is welded to the rear wheel arch of the body.

The shock absorber from the rear underseed is a telescopic hydraulic double-acting one that is attached with bolt 9 to the bracket from the suspension arm. The rod is attached to the upper support 5 from the cushion suspension spring 6 and the support washer 3.

A 2-row angular contact bearing 12 is installed in the hub 13, similar to the hub bearing in the front wheel, but with smaller dimensions. Unlike the hub in the front wheel, on which the inner ring from the bearing is installed with guaranteed interference, on the hub from the rear wheel, bearing 12 on axle 14 has a transitional fit.

Selection of auto parts

The most important thing: choose the type of racks. Some people prefer to install gas shock absorbers, which are much more expensive, but will also last longer. Other car enthusiasts prefer oil options, which are softer to use. The obvious disadvantage of the latter is the increase in hardness in winter.

Let's highlight several of the most popular options for purchase to help you make your choice. Next, we will move on to the direct replacement of faulty components.

Original spare parts

Most vehicle owners prefer to install only original parts from the manufacturer that were originally supplied with the car. Factory spare parts for Lada Kalina Universal are marked with article number 2110-290540203. Their cost varies from 2200 to 2500 rubles. The racks are produced by the Skopinsky Automotive Aggregate Plant, that is, they are domestic.

Owners of Lada cars note that it is better to immediately replace the original parts with foreign-made analogues immediately after purchasing the vehicle, as they are of much better quality. However, it all depends on you. Some people, on the contrary, only like racks from SAZ.

Parts are often counterfeited. In order not to stumble upon non-original spare parts, make sure of the quality of the product. Ask for accompanying sales certificates and carefully inspect the packaging.

All barcodes and names must be printed clearly. The presence of extraneous logos is unacceptable. The parts should be free of burrs, chips and cracks of paint, and other external defects. Unless, of course, you purchase used parts.

In general, models of the category “Standard 1118 (1119)”, “Sport 1119” and “Highway 1118”, “Optima 1119” are considered the standard choice. Highway and Sport are narrowly focused struts, so they are not practical for city driving. The most common option is the Optima category racks. Note: they are good both off-road and on high-quality trails.

Original parts are covered by a warranty; the kit must contain a coupon. Therefore, it is advisable to purchase them from an official dealer or trusted reseller.

How to change silent blocks

On Lada Kalina, replacing the rear pillar silent block is quite simple. Here you will need a special puller. Standard large yews will also work. The next steps look something like this.

- Remove the shock absorber itself from the car.

- Clean the part from dirt and bitumen stains.

- There is no need to spare the old silent block - the insert is knocked out with a spacer using a sledgehammer or hammer. The main thing is not to damage the seat.

- Next, the mounting sleeve is cleaned and lubricated. Consistent ointments are used here in small quantities, the goal is to ensure ease of installation.

- Then the bushing and rubber insert are installed in the yew so that they are on the same axis.

- The collar is clamped and the insert slides into place.

Part Description

The racks (they are most often called telescopic) absorb shocks and impacts that are directed at the car body. For example, when you are driving on a rough road or off-road.

The part includes a shock absorber, spring and several other parts. Since struts are considered an important element of the entire suspension system, their malfunction leads to emergency situations on the road.

Thanks to the stabilizer struts, comfort is maintained, maneuverability and control are ensured, regardless of how fast the vehicle is moving. In addition, they firmly connect the wheel mechanism and the body itself.