The gearbox design in the Lada Kalina model has a rather complex design, but it will still be useful for the owner to know the main features of the gearbox design. For the budget “Russian”, the manufacturer has provided the possibility of equipping it with a five-speed transmission.

Many owners pour out complaints about the Lada Kalina gearbox, because when switching, they observe a creaking sound coming from the unit. This is explained by the fact that the developers placed special type synchronizers on the gears of all forward gears. It is these components that “give” themselves away with a characteristic creaking sound. Adjustment or replacement can help here, as a result of which the creaking effect disappears. To perform this repair correctly, you will need a gear shift diagram.

The vast majority of buyers are inclined to purchase Lada Kalina, which have a manual transmission. Note that these boxes are equipped with any of the engines used, be it an 8-valve version or a modification with a 16-valve head.

Gearbox Features

If we talk about the features of the Lada Kalina 2 gearbox, then it is worth mentioning the locking solenoid.

It was installed specifically to prevent the driver from accidentally engaging reverse gear while moving forward. You will not be able to engage reverse gear if the electrical network of the solenoid is interrupted or if it fails. If you find such a malfunction, then repair is needed

But it is important to get to the parking lot

Unscrew the solenoid from the box and install the rod lock plug in its place. You will take it in a special repair kit; every driver should carry it with him. This will help you get to the garage or get to the repair shop. You need to drive carefully. Be careful not to shift into reverse instead of first gear.

How does a manual transmission work?

The mechanical gearbox device in the Lada Kalina 2 consists of several main structural components. These should include:

- unit crankcase with shafts and gears;

- clutch housing;

- back cover.

The plug for draining used lubricating fluid is equipped with a special magnet. It is necessary to collect metal shavings, the formation of which is observed during the natural wear of gears and other crankcase elements.

The system also has two types of bearing designs, both roller products and ball components. The developers placed a special type of oil sump near the front bearing, from which the fluid is directed to the gear shafts and other elements of the system.

At the factory, oil intended for transmission units is poured inside the new box. This fluid must be replaced periodically. This is recommended to be done every 70 thousand km of the distance traveled. The owner should also be inclined to periodically check the lubricant level and, if necessary, top up to the required volume.

To monitor the level in the unit there is a special probe. It allows you to easily verify that there is enough oil inside the box. We act like this. Carefully insert the dipstick into the funnel and then remove it. On the measuring section of the probe there are a pair of marks indicating the maximum and minimum limits of the filled volume. If the amount of lubricant is not enough, then add it without haste.

When there is a need to replace the entire volume of lubricant, it would be better to carry out this procedure in a professional service environment. Alternatively, you can resort to the replacement process yourself. You will need to drain the oil through the hole present on the crankcase, which is closed with a special plug.

What to consider when choosing a box

Technical characteristics of Lada-Kalina (VAZ-1117, 1118, 1119)

When selecting a new transmission, there are a number of nuances that need to be taken into account. These include shape, size, torque and more. But you can pick up almost any of the front-wheel drive Lada.

Shape and dimensions

All front-wheel drive Lada cars are similar to each other. Manual transmission 2108 appeared on models 2108, 2109 and 21099. Subsequently, it migrated to 2110, 2111, 2112, 2113, 2114, 2115 in a slightly modified form for different needs. The Priora received a modified box from the “ten”. “Kalina” and “Granta” are very similar to the “nine” in their design, therefore the dimensions and shape are identical. “Automatic” and “robot” were specially developed for these cars, so it’s the same here. Any will do.

Permissible torque

The Kalina’s torque is about 120-148 Nm, the G8’s is 79-186 Nm. The 2108-2112 transmission was designed for higher torque. Starting from 2113 to “Kalina” and “Grants” the torque dropped and the gearbox became a little weaker.

How to remove the gearbox

The fork fixing bolt and nut must be unscrewed after the input shaft stopper has been removed. The same thing will have to be done if it is necessary to replace the short-throw gearshift link.

The spline must be removed from the secondary shaft. The box assembly diagram assumes the reverse procedure.

https://youtube.com/watch?v=64VfNjK9KKg

One of the popular domestic cars is the Lada Kalina. The second generation became available in 2013. The car has improved its technical qualities. Also, the exterior has improved.

The car may have an engine with a volume of 1.6 liters and a power of 106 horsepower. Lada Kalina VAZ 1118 is equipped with electric power steering. Also, the 2nd generation may have a cable gearbox. Its peculiarity is that it minimizes the occurrence of vibrations that occur on the body.

Design features, gearbox design on the Lada Kalina Lada Kalina VAZ 1118

Light on the road: characteristics and rules for replacing Lada Kalina headlights

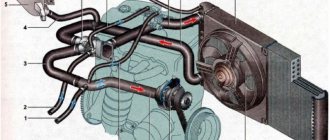

The input shaft 29 (Fig. 5.2) of the gearbox is made in the form of a block of drive gears, which are in constant engagement with the driven gears of all forward gears. The secondary shaft 25 is hollow, with a removable drive gear 3 of the main gear. On the secondary shaft of the gearbox there are driven gears 16, 18, 19, 21, 23 and synchronizers 17, 20, 24 for forward gears. Front bearings 4, 31 roller shafts, rear 22, 28 - ball. Under the front bearing of the secondary shaft of the gearbox there is an oil sump 5, which directs the flow of oil into the secondary shaft and further under the driven gears.

The differential is two-satellite. The preload in the differential bearings is adjusted by selecting the thickness of the ring 13. The driven gear 12 of the main gear is attached to the differential box flange. A master ring 7 of the magnetoelectric speed sensor is installed on one of the axles of the differential box.

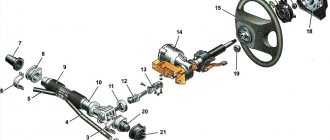

The gearbox control drive consists of gear shift lever 11 (Fig. 5.3), a ball joint, rod 10 and a gear selection mechanism (installed in the gearbox housing).

The reverse gear lock is controlled by a solenoid mounted on the gearbox housing, which, in turn, is controlled by switch 13 mounted on gear shift lever 11.

On a Lada Kalina car, the gear selection mechanism is made as a separate unit and is attached to the plane of the clutch housing inside the gearbox.

In housing 9 (Fig. 5.4) of the gear selection mechanism, two axes are fixed. Axle 3 is equipped with a three-arm gear selector lever 2 and two locking brackets 7 and 11. The other axis 1 passes through the holes of the locking brackets, securing them from turning. Shoulder b

three-arm lever 2 is used to engage forward gears, arm

a

is used to engage reverse gear, and the third arm is affected by the lever of the gear selection rod, connected through a cardan joint to rod 10 (see Fig. 5.3) of the gearbox control drive. On axle 6 (see Fig. 5.4) there is a fork 8 for engaging reverse gear.

Rice. 5.4. Gear selection mechanism:

1 - guide axis of locking brackets; 2 — three-arm lever; 3 — axis of the gear selector lever; 4, 10 - spring; 5 - retaining ring; 6 — reverse fork axis; 7, 11 — locking brackets; 8 — reverse gear fork; 9 — housing of the gear selection mechanism; a - arm of a three-arm lever for engaging reverse gear; b - arm of a three-arm lever for selecting forward gears

Rice. 5.3. Gear shift drive Lada Kalina VAZ 1118:

1 - damper bushing; 2 — spacer sleeve; 3, 16, 20 — nuts; 4, 8, 18 — bolts; 5 — protective cover; 6 — retaining ring; 7 — ball joint housing; 9, 21 — coupling clamps; 10 — transmission control drive rod; 11 — gear shift lever; 12 — clamp for fastening the wiring harness; 13 — reverse gear lock control solenoid switch; 14 — gear lever handle; 15 — washer; 17 — cover of the gear lever handle; 19 — jet thrust

Rice. 5.2. Gearbox Lada Kalina VAZ 1118:

1 — clutch release bearing; 2 — guide sleeve of the clutch release bearing; 3 - main gear drive gear; 4 — roller bearing of the secondary shaft; 5 - oil sump; 6 — satellite axis; 7 — speed sensor master ring; 8 — axle gear; 9 — differential box; 10 — satellite; 11 — clutch housing; 12 — driven gear of the main gear; 13 — adjusting ring; 14 — tapered roller bearing of the differential; 15 — axle shaft seal; 16 — driven gear of the 1st gear of the secondary shaft; 17 — synchronizer of 1st and 3rd gears; 18 — driven gear of the second gear of the secondary shaft; 19 — driven gear of the third gear of the secondary shaft; 20 — synchronizer for 3rd and 4th gears; 21 — driven gear of the fourth gear of the secondary shaft; 22 — ball bearing of the secondary shaft; 23 — driven gear V of the secondary shaft transmission; 24 — 5th gear synchronizer; 25 - secondary shaft; 26 — rear cover of the gearbox housing; 27 — drive gear of the 5th gear; 28 — ball bearing of the input shaft; 29 — input shaft; 30 — gearbox housing; 31 — roller bearing of the input shaft; 32 — input shaft oil seal; 33 - breather

Schemes and design of manual transmission 2181

Main elements of the VAZ-2181 gearbox:

1 – main gear drive gear; 2 – secondary shaft; 3 – input shaft; 4 – fifth gear fork; 5 – fork for selecting third and fourth gears; 6 – reverse light switch; 7 – clutch housing; 8 – gear shift mechanism; 9 – central lock.

Device of synchronizers of VAZ-2110 (A) and -2181 (B) boxes:

1 – first gear gear; 2 – intermediate rings; 3 – blocking ring; 4 – synchronizer clutch; 5 – synchronizer clutch hub; 6 – clamp; 7 – second gear gear.

Gear selection mechanism:

1 – gear selector levers; 2 – selector grid pin; 3 – selector grid; 4 – reverse locking mechanism; 5 – central three-dimensional plate.

Interesting Facts

What is a car pump and why is it needed?

Let's look at the interesting facts that we managed to learn about the new Lada Granta gearbox:

- The VAZ-2181 gearbox will not be installed on the Priora, since the designers considered that it would not be cost-effective to redo the entire design of the power units.

- The cost of Lada Grant and Kalina 2 increased by 5000-7000 rubles. with the introduction of a new gearbox into the car.

- According to reviews from car owners, the first copies of cable-driven gearboxes were not entirely successful and had quite a lot of flaws: vibration became audible after 70-80 thousand mileage, howling of the gearbox, increased wear of parts, etc. Based on this, the manufacturer made adjustments to the design and improved the characteristics, but many car owners had a negative impression of the VAZ-2181 cable-driven gearbox.

- The AVTOVAZ plant continues to develop and modernize a new gearbox, which will become the second generation of cable gearboxes. It is planned to install it on the 2nd generation Lada Granta, which is currently under development. The designers promise to take into account the experience gained during the development of the first generation and not allow such an oversight a second time.

Design and differences of a cable-driven gearbox

Unlike a conventional gearbox, the cable-driven gearbox has received some improvements and upgrades.

VAZ-2181 gearbox with cable drive

In order to understand how everything works, let’s compare a standard gearbox labeled VAZ-2180 and the new VAZ-2181:

- To reduce the vibration generated by the traction drive gearbox, cables from the manufacturer Atsumitec were installed.

- To reduce the effort for shifting 1st and 2nd gears, the manufacturer installed multi-cone synchronizers.

- The clutch size has increased to 215 mm.

- Due to changes in the transmission design, the starter had to be positioned along the engine rather than the gearbox.

- To facilitate gear shifting, it was necessary to reduce the bevel angle of the synchronizer teeth from 125 degrees to 100.

- To eliminate oil leaks, the designers moved the gear selection mechanism to the top. But this nuance gave impetus to the development of a new switching scheme and design changes.

- The volume of lubricant poured has decreased from 3.3 liters to 2.2 liters.

- A selector plate is installed, which allows you to change gears more clearly.

- The transition from mineral oil to semi-synthetic oil has been completed.

- To prevent accidental reverse gear, a special lock was developed.

The main elements and components that go into the design of the new gearbox can be seen in the figures below:

Gearbox diagram and decoding of its main elements

- main drive drive gear;

- secondary shaft;

- input shaft;

- fifth gear shift fork;

- third and fourth gear shift fork;

- reverse light switch;

- clutch housing;

- gear shift mechanism;

- central lock.

VAZ-2181 box synchronizer device

1 – first gear gear; 2 – intermediate rings; 3 – blocking ring; 4 – synchronizer clutch; 5 – synchronizer clutch hub; 6 – clamp; 7 – second gear gear.

Gear selection mechanism

1 – gear selector levers; 2 – selector grid pin; 3 – selector grid; 4 – reverse locking mechanism; 5 – central three-dimensional plate.

Full view of a cable-driven gearbox

Thus, the manufacturer decided to improve and modernize the gearbox, which was unreliable and had a lot of problems. Due to the new improved system, vibration in the body and gear knob has been reduced. The gears switched on, started more clearly, and the huge backlashes disappeared.

Catalog numbers and production

As you know, analogues of gearboxes are rarely produced, and even more so for domestic cars.

Therefore, for the Lada Granta cable-driven gearbox there is one catalog number - 21810-1700012-00.

Repair, features and technical specifications

Inside a VAZ 21118 car, like any other, there is always a gearbox. For a model such as Kalina 1118, this device is a mechanical type design, which is equipped with one reverse stage, as well as 5 forward stages.

Gearbox from Lada Kalina.

In Lada Kalina, the gearbox is structurally combined with a differential, the main gear. Transmission differential repair should also take this into account.

The mechanism body of the VAZ Kalina car is presented in the form of three aluminum copper crankcases:

Special sealants are applied between them when assembling and repairing the gearbox.

Gearbox lever jammed

In any case, it is necessary to remove the last fastener after the bolt nut securing the left suspension arm has been unscrewed to the body bracket.

Repairing a box cushion is not complete without many of the steps described above.

After this, all that remains is to remove the lever. Another rather important element is the gearbox fork; its condition must also be monitored.

You will need to drain all the remaining oil into the container. A complete gearbox repair also involves removing such parts as the wheel drive from the gears of the differential axle shafts. The plugs are placed in the place where the gears used to be. After the gearbox adjustment is completed, they usually proceed to installing the left suspension support and brackets for the rear of the car.

Any such work, including repair of the secondary shaft, must take into account the general design of the gearbox and the basic principle of its operation. It contains a book on repairing the box. The same applies to the functionality of the component elements, otherwise the gearshift lever support cannot be replaced, like other parts.

The features of the repair are fully familiar only to real professionals. It is better to entrust the work to them if you do not have the proper experience or some practical skills.

It is necessary to completely rinse the mechanism with water before disassembling it to identify a gearbox malfunction. Problems during repair may arise if the part itself is not installed on a special stand. The bracket, which is responsible for fixing the clutch cable and engine suspension, is completely dismantled.

Many people give useful advice on replacing a VAZ gearbox. According to them, in any case you will need to remove the rear cover of the crankcase.

Oil

With the introduction of the new box, the amount of oil also changed. Thus, for the VAZ-2181 gearbox, the oil volume decreased by 30%. The requirements for oil have also changed - AvtoVAZ switched from mineral to synthetic gear oils. This applies to both old gearbox models and new ones. The manufacturer pours oil into the gearbox and writes in the instructions that it will last for 5 years or for the entire life of the gearbox. But in reality it needs to be changed.

The oil life of the Kalina gearbox is approximately 30 thousand km. You can choose any of the domestic transmission products as gearbox oil. Thus, domestic car enthusiasts speak well of the products of Lukoil and Rosneft. You can also purchase imported oils - for example from Zic. The box will say “thank you” for this.

Comparison of manual transmission 2180 and manual transmission 2181

The difference between the two boxes is significant:

- Instead of rigid rods, a cable is used (Japanese company Atsumitec). Due to this, vibration on the body and gearshift knob is reduced.

- Multi-cone synchronizers were installed in 1st and 2nd gears. This increases the service life of the components and reduces the effort when engaging gears.

- The clutch diameter was increased to 215 mm. In this regard, it was necessary to use a different crankcase, and place the starter not along the box, but along the engine.

- The bevel angle of the synchronizer teeth was reduced (from 125 to 100º), as well as the preload force (from 150 to 70 N). This made switching easier.

- The gear selection mechanism has been newly developed (Schaeffler Group).

- The gear selection mechanism was moved from bottom to top. This made it possible to eliminate oil leaks and make gear shifting easier in cold weather.

- The design of the gear selection mechanism includes a selector plate, providing a clear gear shift pattern.

- The mechanism includes a lock to prevent accidental reverse gear.

- The oil volume in the gearbox decreased from 3.3 liters to 2.2.

- From the factory, the gearbox is filled with semi-synthetic instead of mineral water.

Replacing a manual transmission

If the circumstances were not the most favorable, and you still had to resort to replacing the Kalina gearbox, you need to know the correct sequence for dismantling the transmission.

Preparation

Before removing the gearbox, read the vehicle's operating instructions or watch a video about replacing the gearbox on a Kalina.

https://youtube.com/watch?v=gi3AALz3998%3F

After this, prepare your work area. Replacing the gearbox on Kalina is carried out only when the car has cooled down. Raise the car on a lift or drive it into a pit. Don't forget about safety requirements. Ask a partner for help to carefully remove the gearbox.

Be sure to drain the transmission oil to prevent it from leaking when you remove it.

Tools

Prepare the necessary tools - wrenches and sockets of various sizes, a wheel wrench, a jack, an empty container.

Removing the box step by step

The first step is to unscrew the engine protection, which is secured with 6 bolts. The next step is to drain the oil from the gearbox - to do this, unscrew the filler and drain plugs of the gearbox.

- Remove the battery for convenience and to avoid spontaneous short circuits. The battery platform will also be in the way, so unscrew the 4 bolts securing it.

- Disconnect the throttle cable. To do this, remove the special bracket that secures it and pull out the cable.

- Remove the air filter. After disconnecting the main pipe, pull out the filter housing towards you. Under it you can see the clutch cable, which is located next to the starter; unscrew it as well.

- The next step is to unscrew and remove the starter, which also makes it difficult to get to the box. Now jack up the car and remove the front wheels.

- After removing the wheels, unhook the left drive. Now you need to hang the engine on a hydraulic jack. Remove the right drive. Be sure to insert the differential lock plug to prevent the planetary gear from flying out. In the case of a cable box, loosen the fastenings slightly so that the cable drives can be disconnected from above.

- Having unhooked the rocker arm from the box (by loosening the clamp), disconnect the torque rod. More precisely, you need to remove the part that is closer to the gearbox driveshaft.

- Hang the box on a hydraulic foot or special support. A “cushion” is screwed next to the cardan - unscrew it from both the body and the transmission, it is secured with bolts from the end side. Then you can easily crawl to the right front drive, which needs to be removed.

- To remove the box from the engine, unscrew the 4 bolts around its perimeter.

- The box is free. All that remains is to carefully lower her to the ground, pulling her out from under the car. If dismantling is carried out in a pit, then ask your partner for help to remove the gearbox without dropping it.

Lada Kalina gearbox mounting bolt

The box can be replaced at a service station. The price for replacing a gearbox on Kalina starts at 5 thousand rubles.

Which box to choose

Replacing the Kalina gearbox involves installing a transmission that was installed on this model by the factory. Mechanical gearboxes are considered the most reliable.

They are easy to repair and maintain and do not require special skills from the car owner during repairs.

When switching from one system to another, significant modifications to the Lada Kalina are required. The price for a gearbox with rigid traction is about 15 thousand rubles. If you have a new Kalina model, and it has a cable-driven gearbox, you will have to pay 25 rubles for a new unit.

Installing the box step by step

The step-by-step installation process is similar to its dismantling, only in reverse order. With the help of a partner, install it in its place, connecting the splines of the gearbox input shaft and the engine crankshaft, connect all attachments and pipes. Pour transmission oil into the box. The replacement of the gearbox on the Lada Kalina is almost complete. Connect and adjust the rocker rod drive.

Installing a gearbox on a car

Start the car, let it warm up, inspect the engine compartment for leaks, try changing gears. The move should be soft and without extraneous sounds. If so, the box is installed correctly. Turn off the car.

After the car has cooled down, install the engine protection.

Identifying and eliminating gearbox problems

Servicing the gearbox involves removing this device from its original location. Especially for this, the car needs to be placed in an inspection hole or use a lift. To remove the box, you need to remove the air filter, starter, mudguard, crankcase protection, wheel drive, suspension mounts, disconnect the jet rod, front wheel drives, mounting bolts and nuts. Transmission repair may also involve replacing the rocker.

During diagnostic work, all components of the gearbox control drive are checked, from the shift lever to the control rod. Attention must be paid to the gearbox fork. This component of the gear shift mechanism is made of durable material. The fork has two branched tines and an axle. If it becomes deformed, the part should be replaced.

Lada Kalina can be repaired with your own hands. In particular, one of the ways to restore the performance of the gearbox is to change the gearbox oil. It is possible to independently determine the oil level using the control marks that are placed on a special indicator. As for the use of transmission fluid, you should choose a fuel that does not lose its properties over a wide temperature range. In particular, it can be 75W-90, 80W-85 oil.

When repairing the Kalina gearbox, special schemes are used. This allows you to get an accurate and complete picture of the vehicle system. Increasing noise and howling may also be a consequence of worn-out gear teeth. In rare cases, this is due to the fact that there is not enough oil in the box.

It is possible to eliminate noise from the gearbox if you replace the bearings. Repairing the Kalina gearbox can involve replacing the internal joint seals. If the seals are worn out, then because of this the owner of the Lada will be faced with such a manifestation as an oil leak.

AVTOVAZ’s developments do not stand still, and in 2013 the company’s management, together with the design department, decided to switch to a new type of cable-driven gearbox. These gearboxes are installed on Lada Granta and Kalina 2 cars.

What automatic transmissions are installed on Kalina?

On second-generation Lada Kalina cars, three types of gearboxes were installed from the factory (unlike Kalina-1, which had only one gearbox): a manual gearbox, an automatic gearbox and an AMT robotic manual transmission.

AMT

AMT was created on the basis of the manual transmission MKPP-2180 and bears the index AMT-2182. Unlike mechanics, control and selection of gears here is carried out not by the driver, but by the system in which the program is embedded. Although AMT is something completely new for the Russian auto industry, at the same time, leading automobile companies in Europe and Japan have long abandoned them in favor of newer preselective robots with two clutches.

AMT-2182

The box contains three driving modes:

- movement in automatic mode, when the automation takes over the entire process of control and gear selection;

- driving in manual mode - in this case, the driver himself will change gears by moving the shift selector knob back and forth, but the clutch will be depressed by the robot;

- Reverse mode - back.

Hydraulic automatic

In addition to manual transmission and AMT, the Lada Kalina has a Jatco gearbox. This is a fairly old hydraulic automatic machine from the manufacturer Jatko. This box has the index JF414E. This automatic transmission contains all the classic modes that are found on 4-speed gearboxes:

- parking;

- reverse gear;

- neutral;

- drive.

There are also two modes in which the car will pick up speed only in second or first gear. The result is six operating modes. To move the selector, you must press the brake pedal and also hold the button on the selector itself.

Automatic Jatco

For the first time, boxes of this type debuted on the Lada Granta, and later the Lada Kalina also received it. Unlike all other gearboxes, the Jatco automatic transmission has nothing to do with the developments of AvtoVAZ; the manufacturer of this gearbox is Japan, a company that is a long-time supplier of gearboxes for Nissan cars. So it happened this time, the automatic transmission that suited the Granta was installed on the Nissan Micra, however, it is worth noting that when installing it on the Granta, the engineers made numerous modifications and calibrations of both the gearbox itself and the car. Since this gearbox is much heavier than a manual transmission, it was necessary to change the car’s engine crankcase, suspension elements and mountings of the power unit. At the same time, the vehicle's ground clearance decreased from 160mm to 145mm. They installed a new type of cooling radiator with a block for cooling the gearbox oil; later, a radiator of this type began to be installed on other Grants, in which the oil cooler block was used for the operation of the air conditioning system. In general, the Jatco automatic transmission is a classic representative of torque converter automatic transmissions. It is based on four full stages and an imitation of the fifth, which is achieved by blocking the torque converter. The distinctive features of this transmission are that it ensures the smooth running of cars at a higher level and is devoid of the signature operating noise of VAZ gearboxes.

The fine-tuning of the software part of the new box was carried out by the Austrian company AVL, whose task was to optimally select operating modes to suit AvtoVAZ’s requirements. And the requirements were simple: the car must retain the dynamic character that the VAZ 21126 engine provides and obtain such smooth gear shifting that the driver will not even notice the transition to a higher gear. Based on reviews from owners of cars with a similar transmission, we can say with confidence that the work was done exactly as required by the car factory.

However, this solution also has disadvantages. Firstly, transmissions of this type, by definition, consume more fuel due to design features. Secondly, the gearbox is dead-end, it digests exactly as much torque as the VAZ 21126 engine produces, and it was not possible to install it on a more powerful VAZ 21127 engine. Thirdly, cars with an automatic transmission of this type are much more expensive than versions with a manual or robotic gearbox.

The gearbox is designed for an inexperienced owner; a large number of protection systems have been introduced into its control program. For example, if, when moving forward in a straight line, you move the gear selector to position R, which implies moving in reverse, the gearbox will ignore this action until the operating conditions change, allowing you to engage reverse.

A pleasant bonus for the owner during the warranty period will also be the approach to servicing such boxes. Due to the lack of component bases that provide high-quality repairs, in the event of problems with the automatic transmission, the car plant will not repair the unit, it will be replaced as an assembly, and the damaged gearbox will be sent to Japan, where it will be disassembled and the cause of the failure will be determined.

Although service statistics at this point in time indicate that Japanese gearboxes are quite reliable and there are minimal complaints about their failure.

Over time, the number of trim levels equipped with such a transmission decreased due to the appreciation of the currency and, as a result, the increase in the cost of an automatic transmission. There was a time when AvtoVAZ completely removed the Lada Granta with a similar gearbox from the line of models. However, now the car plant offers Lada Granta and Lada Kalina with a Jatco gearbox, although in very limited configurations.

Source

Recommendations for the use of transmission oils for Kalina

Adding oil or replacing it in the Kalina gearbox will require an answer to the question of which substance to choose. It is better to build on the manufacturer's recommendations. The machine's operating manual provides a list of different oils. They are classified by:

- brand;

- viscosity grade (SAE);

- API group;

- to the manufacturer.

It is important which substance ensures stable operation of the gearbox in the widest temperature ranges. This is oil with viscosity marking 75W-90

It guarantees lubrication of components at temperatures from -40° to +45°.

Which gear oil has more universal properties? This can be considered a substance whose viscosity is designated 80W-85. If Kalina’s gearbox is filled with this oil, then normal operation of the units is maintained in climatic conditions from -26° to +35°.