Hydraulic and electric power steering are designed to ease the effort the driver makes when turning the steering wheel. The EUR is a more advanced mechanism compared to the power steering, since it uses an electric drive. The system does not contain oil or other hydraulic components, which increases its reliability. Typically, AvtoVAZ engineers install electric steering systems on passenger cars, and less often - power steering. Both types of power steering are found on the Lada Priora.

Steering diagram

What is the steering rack for front wheel drive cars?

In cars with front-wheel drive, there is no way to install the classic, long-proven front wheel steering control system. The transverse installation of the motor and power drives to the wheels will not allow this to be done. Therefore, the cumbersome system of levers was replaced by a steering rack. Its main task is to transfer force from the steering wheel to the steering arms.

Important! Most Priors are equipped with electric power steering (EPS) and not power steering. This is a feature of this model.

Location and design of the Priora steering rack with EUR

To save space, this element of the Priora control system is located on the wall of the engine compartment. On the bulkhead between the engine and the interior of the Priora. The rack is connected to the steering column located in the cabin.

Steering rack device

This important Priora control unit is assembled from the following components.

- The rack is mobile.

- Frame.

- Splined shaft with bearing.

- Metal case (casing).

- Seals and seals.

- Fasteners and accessories (bolts, nuts).

- Springs.

- Rubber cover for the mechanism.

The basis of this mechanism is a metal pin (rail), so to speak. There are teeth on one part of it. They are mated to the steering wheel drive shaft, located at right angles to the supporting pin. This is, in fact, the well-known worm gear. The rotating shaft moves, engaging the teeth, the rack inside the casing. The protective casing has a special slot for attaching tie rod ends. In the center of the pin (rack) there are special holes for tips, which are connected through special levers to turning wheels.

Malfunctions and their symptoms in the Priora steering rack with ESD

Most often, the rubbing parts of this unit fail. It is quite easy to determine whether the steering mechanism is broken or simply worn out. This will be marked by the following signs:

- The steering wheel is difficult to turn.

- When entering a turn, tapping and grinding noises are heard from the mechanism.

- While driving, when using the steering wheel, sensitive shocks are transmitted from it to the hands.

In general, the handling of the Priora is significantly deteriorating.

During the inspection, the technician will determine the need to replace the Priora steering rack by visual inspection. Usually, he grabs the rod with his hand, and his partner turns the steering wheel. Based on excessive play and extraneous sounds, the technician makes a verdict.

Attention! This device is completely repairable. Ready-made repair kits for the Priora steering rack are available for sale. There are separate articles on this topic.

Possible problems

Some drivers note that in a VAZ 2114 with a hydraulic booster, the control system becomes as if weightless. This can be confusing. When the gain is lost, the steering wheel has to be turned more often.

A fairly common problem caused by the fact that the hydraulic booster operates directly from the power unit. In order to correct the situation, the hydrach is connected not directly to the engine, but using a gain regulator. Another option is to use an amplifier with an electric drive function. Today, such a device is not difficult to find, and it costs relatively little.

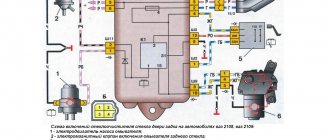

Wiring

As for replacing the hydraulic booster with an electric booster, this is a more than possible option for improving the car. It is considered one of the simplest but most effective types of technical tuning. However, it is strongly not recommended to perform such operations yourself.

Replacement and repair of a faulty steering rack

This not particularly difficult, but extremely important work is best carried out on a repair lift. As a last resort, on a wide inspection hole. But then the car must be positioned so that both wheels can be removed.

So, the car is installed according to the mentioned conditions. The wheels have been removed. We can begin. First of all, set the steering wheel of the Priora car to the position of driving straight ahead. That is, the wheels point straight ahead. After this, it is advisable to secure the steering wheel.

Loosen the electric power steering mount. Remove the cardan connecting the EUR to the splined end of the steering shaft. And go under the car. There are two options. You can unscrew the lugs from the wheel. But most craftsmen prefer to unscrew the bolts securing the steering rods to the rack. The fact is that it is much easier to remove it this way.

This is done as follows: two 17 bots holding the pressure plate are unscrewed. First, 1 is turned out, and the second is weakened. The pull moves to the side. Then the second one is removed, along with the plate, and the other rod is moved back.

Now the fastenings of the steering rack itself are dismantled. These are semicircular brackets with rubber seals. They are mounted on threaded rods in the Priora body and tightened with nuts 13. It is most convenient to unscrew them with a head. After removing the nuts, the staples are removed. The device being removed is pushed slightly towards itself. This is necessary for the worm device to come out of the hole in the passenger compartment. Now you can remove the steering rack. For this purpose, a technological window is provided in the left wing of the Priora. You can carefully push the edge of the knot into it and pull it out. Either for further disassembly and repair, or simply for replacement with a new copy.

Electric power steering

This device increases the force that is transmitted in the steering system. Simply put, you can turn the steering wheel with two fingers. Previously, VAZ models were equipped with hydraulic boosters (power steering), but starting with the Lada Kalina they were abandoned.

The EUR was developed. In terms of force transmission power, power steering is preferable, however, it has many disadvantages:

- Engine power take-off.

- Constant monitoring of the level in the tank is necessary.

- Checking oil lines.

The electric amplifier is devoid of all these disadvantages. And it is even easier to repair than power steering. But it also has its own faults.

EUR device

Main components of an electric amplifier:

- Mechanical part.

- Electrical component.

- Electronic control unit (ECU) with peripherals.

The mechanical part includes the actual steering parts, connecting parts and mounting hardware. That is, the input and output shafts, bracket, nuts, bolts, studs and springs. Well, there’s also an adjustment lever for changing the angle of the steering wheel.

Electric, actually the amplifier motor itself. The most vulnerable is the electronic component. ECU and connectors with sensors.

How to replace the steering rack on a VAZ 2170-VAZ 2172?

Note! The Lada Priora car was equipped with several types of racks, namely: On the first cars, a steering rack with hydro power steering was used, and on the second, with an electric power steering (On new Priors, with a modified appearance, with a different interior, etc.), but the power steering was not I also bypassed the Priora in the old body, it was used on it too, only not on all trim levels, all amplifiers are removed according to the same type, you just need to pump out the fluid from the power steering reservoir in the power steering, and remove the minus terminal from the battery in the power steering before starting work ( After removing the terminal, the rail is removed from the EUR in the same way as a regular rail; how to remove a regular rail is written in another article, which is linked in paragraph 3 below), quite a few words will be said about the first amplifier in this article!

1. Well, let's start, in order to remove the rack from the power steering, you need to do preparatory work, in which you will need to drain the fluid that is needed for the power steering, to carry out this work, pick up a syringe or a rubber bulb and use one of these tools , pump out all the fluid from the power steering reservoir (This reservoir is shown in the photo below), then disconnect the hose going to the pump from the reservoir and lower it into an empty container, and plug the hole in the reservoir with some kind of rag, as soon as this is done, get into the car , turn the key in the ignition so that the steering wheel is not blocked and rotate it from one end to the other until all the fluid has completely drained from the entire system.

Design and operating features of power steering and power steering

To make steering easier to turn and increase comfort, either hydraulic or electric power steering can be used. Both amplifiers have both pros and cons.

Power steering device

Structurally, power steering is a system of high and low pressure hoses containing oil driven by a pump. Power steering fluid must be poured into the reservoir near the pump. It only works when the engine is running. The driver turns the steering wheel, and at this time the fluid flows through the distributor under pressure created by the pump to the steering mechanism. It enters the working cylinder, puts pressure on the piston, which begins to move, and facilitates the rotation of the steering wheel. When moving in a straight line, the liquid flows back into the system reservoir.

Power steering diagram

Advantages and disadvantages of power steering

In the case of a hydraulic booster, the main disadvantage is the bulkiness of the entire system. But it is cheaper to produce and maintain, and this affects the price of the car. At the moment, power steering is found mainly on budget class cars, which include Priora. An amplifier of this type is also installed on expensive, powerful SUVs. This is explained by the fact that the power steering is capable of transmitting greater torque transmission power to the steering. In this regard, it outperforms an electric booster, but there are still more disadvantages:

- In a car equipped with a hydraulic booster, it is not recommended to hold the steering wheel in the extreme right or left position for more than 5 seconds. Otherwise, the oil in the power steering on the Priora begins to heat up, which can lead to system failure.

- The mechanism requires constant monitoring of the oil level, inspection and replacement of drives, hoses, and pump.

- The pump depends on the operation of the engine, which means it takes a certain percentage of power from the power plant. If the power steering does not work when driving in a straight line, this percentage of power is wasted.

- Such a system does not imply setting operating modes depending on the speed of movement or the angle of rotation of the steering wheel.

- At low speeds, the steering mechanism provides good sensitivity, but at high speeds it becomes less pronounced.

Engineers compensate for the last drawback by using a steering rack with a variable gear ratio. Power steering has already become an outdated system; designers are no longer involved in improving it.

Electric amplifier design

The design of the EUR is simpler than that of the power steering. It consists of an ECU, a torque sensor, a steering angle sensor and an electric motor. There are no hoses or fluids here. The electric motor is mounted directly on the steering rack itself, and torque is transmitted to it via a torsion shaft built into the steering mechanism system.

In the case of power steering, the force is facilitated by liquid, and in the electric booster the current is responsible for this. When the driver turns the steering wheel, force is transmitted to the steering rack. At this time, the torque sensor transmits data to the electronic control unit. The controller calculates how much current needs to be sent to the electric motor to optimally facilitate steering rotation. Since the force must be uniform, the speed of movement and the angle of rotation of the steering wheel are taken into account.

If the steering wheel rotates without the vehicle moving or at low speed, as when parking, the electric motor receives maximum current and the steering wheel turns easily. When driving at medium and high speeds, such force is no longer required, and the controller supplies a lower current.

Pros and cons of EUR

The electric booster is a more modern system with high potential for modernization. It is not without its shortcomings, but there are fewer of them than the power steering:

- high price,

- The electric motor cannot provide high power, so it is installed only on passenger cars.

The disadvantages are leveled out, since the design of the electric amplifier is constantly being improved.

The EUR for the Priora has many advantages. The system is easy to maintain due to its simple design. The only part that requires inspection is the rolling bearing. The ESD mechanism has more compact dimensions and can be installed on the steering shaft in the cabin, freeing up space in the engine compartment. Due to this, the durability of the structure increases, since there is no exposure to temperature changes and high humidity.

The electric booster does not take power away from the engine, which saves fuel. The drive only operates when the steering wheel is turned. The ECU is responsible for the operation of the amplifier, with the help of which you can adjust the operating mode of the EUR, taking into account the operating conditions of the vehicle. The electric booster is not afraid of extreme steering positions. Driving at high speed makes the steering wheel with ESD more sensitive.

Lada Priora sedan Priora tsunami › Logbook › DIY steering rack repair

Hi all! Prior has such a disease - a knocking sound from the rack after a certain mileage. For me it started knocking at 100 thousand. Tightening the nut on the mechanism solved the problem, but not forever, and driving with a tight steering wheel is somehow not for me. I didn’t really want to change the rack itself, firstly because of the price, and secondly because of low-quality spare parts - after all, it can last a thousand km. or maybe 100 thousand. After scouring the web, I realized that the shaft bearing was worn out, or the support sleeve, which wears out over time. I was leaning more towards the second option. The solution, it would seem, is obvious - just change it! But this option did not suit me. Everything has to be completed for our engineers! The fact is that when the rack is in the last position, or in the center, one end rests on a fairly powerful gear mechanism, and the other side on a narrow bushing, naturally also worn, as a result, a knock occurs. I decided to fix this jamb using a fairly conventional method. We have the rack itself with an electric booster:

The protective boot has already been removed

Removing the side boot

Inside there is the rack , a deeper support sleeve

Next I take this plastic pipe:

You can find it at any hardware store. Then we cut a piece from it:

I cut it in half approximately

Well, then I begin to push it between the rack and the rack body:

Then we cut off approximately the same piece:

And I begin to push it in again with a second layer. It climbs very hard, which is exactly what I need. In the end, this is the hot dog that came out:

All excess was cut off and trimmed

Well, then I collect everything in the reverse order, having previously filled everything with grease. I also checked the shaft bearing, it turned out to have no free play, but now everything is OK! Well, what else can I add, someone will say - collective farm, it’s better to install the newest one and not worry about it. Yes, I agree - collective farm! Yes, there is a new one - there is a new one (but where are the guarantees that it will not knock) I will say one thing that after this modification I have already driven a couple of thousand kilometers - not a single knock, quiet! Let's see how long it takes! Good luck to everyone!

two years ago Mileage 139,000 km Tags: self- repair

Replacing the steering rack of Lada Priora

Have you noticed a knock in steering rack? Try to pull it up. If the problem arises again, then it will have to be repaired or replaced with a new one. Now we will tell you how to change the steering rack on a Lada Priora with your own hands.

Read

How to remove the steering rack

- remove the front wheels

- prepare the tools (a 13-size head, a 15-size wrench, a 19-size socket wrench, a huge slotted screwdriver, pliers, a mounting blade and a hammer).

Inside, remove the lower part of the intermediate shaft from the splines of the gear shaft:

1. Unscrew the nut of the fastening bolt using a 13mm socket.

3. Release the terminal connection using a large slotted screwdriver.

4. Remove the lower part of the intermediate shaft from the splines of the gear shaft.

Replacing the steering rack repair kit for VAZ 2112

Video about how I repair steering racks

and cardan shafts Kalina, Grant,

Priora

. Having suffered quite a bit from the helm.

To remove the Lada Priora steering rack without tie rods, disconnect the inner tie rod ends from the steering mechanism:

1. Remove the locking plate of the bolts securing the inner tie rod ends by picking it up with a flat-head screwdriver.

2. Unscrew one bolt completely using a 15mm spanner and loosen the other bolt.

3. Turn the connecting plate down.

4. Remove the steering rod. We remove the second steering rod after unscrewing the second bolt.

Let us recall that in the previous article we looked at how to independently install or remove injectors on a Lada Priora . If you do everything yourself, you can save quite a good amount of money.

To remove the Lada Priora steering rack along with the steering rods, you will have to disconnect the outer tie rod ends from the swing arms of the shock absorber struts:

1. Unbend and then pull out the cotter pin using pliers.

2. Unscrew the ball pin fastening nut partly using a 19mm spanner.

3. Press out the finger using a special puller. If it is not there, then insert a mounting blade between the swing arm and the outer tip, and then hit the end of the swing arm with a hammer.

4. Press the ball joint pin all the way out using a large slotted screwdriver.

Read

Now, to pull out the steering rack with or without rods:

1. Unscrew the two nuts securing the steering rack bracket to the front panel using a 13mm socket.

2. Remove two brackets.

3. Remove the steering rack through the window in the left wheel arch, having first moved it forward to remove the gear shaft from the hole in the front panel.

If you remove the Lada Priora steering rack with your own hands, then you will need at least one hour.

Lada Priora steering rack repair

Installing a steering rack on a Priora

Before installation, check that the rail is installed in the middle position. To do this, using sliding pliers, use the flat on the gear shaft to rotate the shaft in any direction until it stops, then turn the shaft in the opposite direction two full turns and turn the shaft so that the flat on the shaft is located vertically on the right side along the direction of the car. Otherwise, the installation of the rack is carried out in the reverse order.

The price of a new rack for a Lada Priora is about 3500-4000 rubles.

How to tighten the steering rack

Before we begin describing this repair, if it can be called such at all, let's look at the main reason why you have to tighten the steering rack on a Priora.

So, I think that many owners know that when a knock appears from the steering rack or its rod, it is necessary to make an adjustment, or rather, tighten the rack using a special nut, which is located on the inside of the case, which is clearly visible in the photo below.

To understand where this nut is located, look at the photo below, everything is shown from above - from the hood side, of course, in this case this nut is located on the reverse side:

To get to this adjusting nut, you will most likely have to remove the battery, since without it there is more free space under the hood. Although the good news is that even the battery in the Priora does not interfere with this repair (unlike cars such as Kalina or Granta).

It is worth noting that you may need the following tools for work:

- 10mm wrench or socket wrench

- key for 13

- the key for tightening the rack is exactly 2110 and not 2108

Now, using a special key from the inside, as shown in the photo below, insert it into the hole:

Please note that the rack clockwise - but taking into account the fact that the nut is in an inverted state (spinning from bottom to top), you will have to follow this rule and turn counterclockwise from above!

It is enough to make less than half a turn, and then try the play on the rods. If it disappears and there is no more knocking, then there is no point in tightening it further, since you can overdo it, and in this case the rail may bite. For a more visual example and description of the entire procedure, watch the video report below.

When tightening doesn’t help and the mechanism needs to be changed

It’s worth thinking about replacing the rack when tightening it does not in any way affect the car’s behavior on the road, and also does not help get rid of the unpleasant knocking noise. A failed steering rack will cause significant play in the steering wheel. Moreover, it may begin to jam (this happens extremely rarely, but similar cases are known). If the rack begins to jam, then it is better to stop using the car, as this can lead to the most dire consequences.

You cannot do without a replacement even if after tightening it you managed to get rid of knocks and vibrations, but they reappeared later.