Topic in the “Audi Repair” section, created by daer, Dec 18, 2006.

You are using an outdated browser. This and other sites may not display correctly. You need to update your browser or try using a different one.

A manual transmission has its advantages over an automatic transmission, and many drivers still prefer it when buying a car. One of the advantages of mechanics is its unpretentiousness, as well as the low cost of repairs in case of damage to the elements of the box, compared to an automatic variation.

A common symptom indicating that there is some problem with the transmission is that it makes a crunching noise when changing gears. If you hear a crackling or crunching sound when moving the gearshift lever and engaging gears, you need to contact a service center as soon as possible.

Important: You should contact a service center not only because of the likelihood of causing more serious damage to the gearbox and other mechanisms, but also because of the risk of an accident if the gearbox fails.

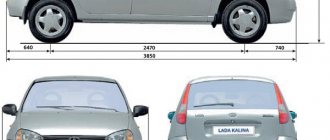

Why does noise appear in the gearbox on a Lada Kalina - when you squeeze the clutch, the noise disappears

Car : Lada Kalina. Asks : Makar. The essence of the question : the problem is noise in the clutch, what should I do?

When starting the car when it is cold, a noise is noticeable. As it warms up the noise disappears. But if you immediately depress the clutch pedal, the noise disappears. What is this? I'm afraid that I might get in the way. They told me it was a release.

This is especially noticeable on a cold engine.

The problem is relevant not only for Kalin, but also for the tenth family, Prior, Grant.

Crunching sound when engaging reverse gear

Reposted from Wikipedia again:

To silently engage unsynchronized gears (including reverse), a special technique is used - by squeezing the clutch, first move the gearshift lever to the position corresponding to one of the synchronized gears, and then, without releasing the clutch pedal, engage the desired unsynchronized gear.

At the same time, the speeds of the gearbox shafts are aligned, which gives an effect similar to the presence of synchronizers in this gear. The use of this technique allows you not only to avoid an unpleasant grinding noise when engaging an unsynchronized gear, but also to significantly increase the life of its gears. Most cars have reverse gears that do not have a synchronizer. It should be turned on with a double squeeze or by analogy with the transition to an unsynchronized transmission described above using a synchronized transmission.

Causes of noise in the gearbox

A damaged release bearing with traces of rust and no traces of lubricant.

The gearbox input shaft bearing can be replaced only after dismantling the gearbox itself.

To avoid unnecessary problems, you should get into the habit of checking the oil level in the gearbox a couple of times a year. When inspecting the dipstick, pay attention to its integrity. The trouble is that when you engage second gear, an incorrectly inserted dipstick (inserted crookedly) may rub.

A typical breakdown of the clutch fork at the point where the lever attaches to the shaft.

The release bearing is usually replaced along with the clutch disc and basket.

The resource depends on the initial quality of the part and the operating characteristics of the vehicle. If you have to drive frequently in traffic jams, the risk of bearing failure is high.

You can drive with a buzzing release for quite a long time, but eventually the bearing will still crumble or jam.

The hum appears because the bearing rotates when the engine is running . But no effort affects it. Therefore, even a slight play can cause extraneous sound. It is not possible to lubricate the bearing - it is a closed type and access to it is problematic. Only a complete replacement will help.

When the clutch is depressed, a load is applied to the bearing, therefore, the backlash decreases. For this reason, the sound may disappear.

- But this can be observed only in the early stages of the destruction of the part. Subsequently, a metallic crunch appears. Often the bearing falls apart into several parts.

All that's left of the release. By the way, these fragments can seriously damage the clutch basket.

Replacing the release bearing

To replace the release bearing, at a minimum, you will have to be patient and drive the car into the inspection hole.

To replace the release bearing, you will need to remove the gearbox.

The work is complicated - it is necessary to disconnect the rocker, dismantle the clutch drive, starter, and attachment to the body.

The drives are disconnected one by one, and the differential mechanism is fixed using any guide. After this, the gearbox fastenings to the engine block are unscrewed and the box is removed.

Other

A humming sound due to a broken bearing on the input shaft can only be eliminated after removing the box and replacing the element . Adjustment will be required. But in practice, extraneous sound rarely appears for this reason; more often it is the fault of the release valve . Also, a hum can be observed from the gearbox due to low oil level or quality. In this case, it must either be topped up or replaced .

Source

Crunching noise when shifting gears: causes and methods of eliminating them

The causes of a crunching, crackling or grinding noise when the gearshift lever is engaged may be different. It all depends on the specific case.

In the event of a minor breakdown, without interfering with the box mechanism itself, the problem can be eliminated by replacing the damaged part. In another case, more serious, the problem is solved by overhauling the manual transmission itself.

The main breakdowns that cause crunching or crackling when changing gears:

- Failure of synchronizers. Synchronizers are responsible for smooth gear shifting. Over time, they wear out and cease to perform their functions. This leads to a crunching or crackling sound when changing gears. The problem is solved by replacing damaged synchronizers with new ones.

Why is the manual transmission noisy in Kalina, Priora, Granta cars, how to eliminate the hum and subsequently prevent it from

Hello, dear friends!

Often on our Lada cars, such as Priora, Granta, Kalina, you can hear the noise of a manual transmission. Below I will show what exactly is making noise. The fact is that in these boxes, most often the problem is the same.

As well as rapid wear of synchronizers, which primarily leads to a crunching sound when engaging second speed and reverse gear.

And now a few words about how to prevent noise from occurring if the box is currently working.

1. Shifting gears in afterburner mode. Many young people like to quickly pick up speed and jump into the next gear.

Often, this happens with a characteristic crunch, since due to the high speeds, the synchronizers have not yet had time to take the desired position.

Do this several times and the gears, especially the second one, will always turn on with a crunch. The gearboxes of these cars are weak and cannot withstand such treatment!

2. Do not suddenly engage in a lower gear. That is, this must be done without jumping from 5 to 2, for example.

If you want to slow down the engine, change gears sequentially so that the characteristic shock does not occur. This has a bad effect primarily on the gearbox!

3. Do not keep your hand on the gearshift knob. Pressure on the lever leads to wear of the fork and clutch, after which play appears and the gears no longer engage clearly.

4. Many car enthusiasts hear noise from the release bearing. Unfortunately, this is a problem with these machines. And to replace it, you need to remove the gearbox.

To ensure your bearing lasts as long as possible, it's worth remembering that it works when you depress the clutch!

Accordingly, you should not keep it depressed for a long time, as many drivers like to do.

You need to engage the gear immediately before you want to start moving.

Okay, we remembered the common truths. Now I will show you the main culprit of noise from manual transmissions on our Kalina, Priora, Grant. He's in the photo:

Source

Reverse does not engage - reasons

- Before you start drastic actions and disassemble “anything and everything”, check the gear shift lever itself, this may be the reason. The linkage and cardan are quite often the cause of this breakdown. The splines could also be worn out or the clamp loosened. In this case, you will need an inspection hole.

- A faulty release bearing is an option. Although it is unlikely, since in this case all gears without exception would be engaged with a characteristic crunch and with great effort.

- Reverse gear may stop engaging due to problems in the reverse gear locking mechanism; in order to confirm or refute this, remove the gear shift knob along with the dashboard between the seats and perform a visual inspection.

In my case, the problem was precisely the faulty wiring of the transmission lock solenoids (break or fracture), how I solved this issue, read on.

How to check and repair the reverse gear locking mechanism of a Lada Kalina with your own hands?

Theory:

Power comes to the solenoid through a switch ring located on the gearshift knob. It works like this: you lift the ring, thereby turning on the solenoid, the rod is pulled into the solenoid, which leads to unlocking the reverse gear. You can then engage reverse gear by moving the gear shift knob. Next, the “limit switch” located on the box is turned on, and the rear stops are turned on, and an intermittent sound signal is turned on in the cabin.

Here is the solenoid control circuit:

Through fuse F21, +12 Volts are supplied to solenoid L1, using switch S1 on the handle, the circuit is closed to ground, after which the solenoid coil is activated.

1. The 10A fuse we need, F21, is located 8th on the left in the fuse block. Take it out and check it with a tester. If the fuse is defective, replace it with a new one of the same rating.

2. Now it's time to check the switch, to do this, lift the cover on the handle, after which you will see the connector connected to the switch. Carefully turn it off.

3. Using a paper clip, you need to close the contacts of the connector from which the wires go down under the Kalina floor. Now try to engage reverse gear; if it does, the switch is faulty. If not, continue troubleshooting.

4. Remove the connector from the solenoid, install two pins in it, then use a tester to measure the voltage, the device should show 12 volts. In addition, you need to load it with a light bulb. A 5-Watt 12 V is suitable for this; if the light bulb does not light up, you have an open circuit, and the voltage is explained by the resistance formed due to copper oxide. As practice shows, 99% of breaks and fractures occur in the harness, in the place where the clamp is installed on the pallet.

5. Remove the clamp by squeezing its fasteners from below.

6. Disconnect the connector from the stop switch and remove the entire harness. Remove the electrical tape from the corrugation and remove the wires. If the wire is broken or broken, you will notice characteristic signs.

7. Using wire cutters, pinch off the wires and connect others of similar cross-section and diameter. It is better to solder the twist itself and insulate it or use heat shrink. If desired, you can put on another corrugation, the main thing is that moisture does not penetrate, otherwise the problem will very soon recur. I personally threw away the clamp, if you need it you can leave it. Secure the harness with a plastic clamp.

8. Connect the connectors and check the operation of the solenoid. Failure of the solenoid itself is a fairly rare phenomenon; to check it, connect a tester; the resistance should be 2.2 Ohms. If there is still a problem, you will have to drain the oil from the box. There is a way. in which it is fashionable not to drain, but here a certain skill is required, the main thing is to sharply plug the hole with something, and then screw in a new one. A little oil will, of course, spill out, but you can add it back. When installing a new solenoid, do not forget to lubricate the threads with sealant, if this is not done over time, oil will begin to ooze along the threads.

If previous checks did not lead to anything, there are several options left, namely:

- The mechanism for fastening the gear selection mechanism has failed;

- The fixing bolt has been cut off;

- The spring in the gearbox has broken.

The worst thing is that each of these three points requires mandatory dismantling of the gearbox, and this is already in the category of “serious repairs”, which is not always within the power of an ordinary driver, and it will take much more time than in the case of a rocker or lock transfers.

That's all I wanted to say! I hope I helped solve the problem. If after all the above manipulations and checks you still do not engage reverse gear, seek help from a specialist or go to a service station.

Lada Kalina noise in the transmission when releasing the clutch

Maybe it's the cable adjustment mechanism, it's under the air filter. It's rattling for me

this is a problem with the input shaft bearing and the problem cannot be fixed, I just ignored it, it’s just that if it starts to rattle a lot, then I just pressed the clutch and caught a quiet crack and that’s it