Today we will talk about the causes of hydraulic compensator knocking and ways to solve this problem.

The gas distribution mechanism of a car's power plant is a very important component, since it ensures timely supply of air or a combustible mixture to the cylinders and removes exhaust gases from them.

Modern cars most often use a mechanism with an overhead camshaft, which has reduced the metal consumption of the structure and, as a result, increased reliability.

Since metal expands when heated, and the valves are constantly in a high-temperature zone, to prevent it from being pressed in, as a result of which it does not fit tightly into the seat, a thermal gap is provided between the valve stem and the camshaft cam.

In this case, the thermal gap has a certain value to ensure the maximum possible opening of the valve, eliminating its tightening.

Previously, on engines with an overhead camshaft, the thermal clearance was adjusted by placing shims of a certain thickness between the valve stem and the camshaft cam.

The disadvantage of using these washers was the need to periodically check the gap and adjust it by selecting washers.

Nowadays, to ensure thermal clearance, hydraulic compensators are increasingly being used, popularly known as hydraulic compensators, the use of which eliminated the need to adjust the gap, and all because the gap is adjusted by oil pressure.

Hydraulic compensators, like shims, are located between the valve stem and the camshaft cam.

Where is the hydraulic compensator located?

Externally, the hydraulics look like a small piston, so the head has seats for them.

Device

Design and operating principle

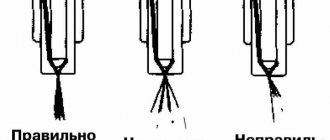

The design of the hydraulic compensator itself is simple. It consists of a cylindrical piston, the bottom of which receives the force from the camshaft cam.

Inside this piston, a plunger is installed in its seat, through which force is transmitted through the piston from the cam to the valve stem (see photo above).

The plunger moves freely in its seat, providing a thermal gap.

The hydraulic valve works like this: when the engine is running, the cam runs up against the bottom of the hydraulic compensator piston and moves it down. While moving, the piston presses on the valve through a plunger, and it opens.

Principle of operation

The gap is adjusted using oil.

The oil pump supplies oil to the head under pressure. In the hydraulics, it enters the space below the plunger and displaces the plunger inside the seat.

The higher the oil pressure, the more it will put pressure on the plunger and the more it will come out of its seat.

When the pressure decreases, the plunger enters the seat again. Thus, the thermal gap between the plunger and the valve stem is independently regulated and depends on the pressure in the lubrication system.

Design and principle of operation

To prevent oil from flowing out of the hydraulic valve after stopping the engine, ball valves are installed in the oil supply channels in the cylinder head.

Having the advantage of no need for adjustment, the hydraulic compensator also has one significant drawback - high sensitivity to engine oil.

Hydraulic compensators and malfunctions in them

Let's immediately determine that the knocking of the hydraulic compensator is a problem that occurs in 90% of cases not on new cars, although exceptions are possible if a low-quality part was installed at the factory. But this is also unlikely, since the hydraulic compensator belongs to the power unit, and factories producing engines have much more stringent requirements regarding the quality of components supplied by suppliers.

Problems with knocking hydraulic compensators can arise over time on a car of any make, year and country of manufacture.

There are a number of ways to eliminate annoying sound, each of which should be used in a specific situation.

But in order to understand why the hydraulic compensator is knocking and the reason for its failure, you first need to understand what kind of mechanism it is, what it consists of, and how it functions. And in general, what can such a knock lead to, and what will happen if it is not eliminated in a timely manner.

Causes of knocking hydraulic compensators

The hydraulic compensator is still not an adjusting washer, which can only decrease in thickness due to constant friction; it may well fail.

Problems with the operation of the hydraulics manifest themselves in the form of a clearly audible knocking sound during operation of the power plant. Moreover, the knocking may occur in some engine operating modes, but in others it disappears.

Also, the knocking of hydraulic compensators can appear when the engine is not warmed up and disappear after reaching the optimal temperature, or vice versa.

The most common cause of hydraulic knocking is engine oil, although there are quite a few other causes.

If, when starting the power plant, a knocking sound is heard from the hydraulic compensators, but it quickly subsides, this is not the reason for their failure.

It’s just that after the next stop of the power unit, some of the valves remain squeezed out due to the location of the camshaft, the oil supply channels also remain open and the oil from the hydraulic fluid flows through them.

When starting, the amount of oil in the channels is quickly replenished.

But if knocking on a cold engine continues for a long time or until the engine is completely warmed up, this indicates a malfunction.

Wear

The hydraulic compensator knocks when cold.

Knocking when cold may indicate:

- Mechanical wear of the plunger and its seat. In this case, the oil does not maintain its pressure and constantly flows out of the sub-plunger space;

- Jamming of the plunger in the seat due to contamination;

- Ball valve jamming in the open position due to contamination;

- Oil supply channel clogged. When warmed up, the blockage is washed out by flowing oil and the hydraulic compensator works normally;

- Use of high viscosity oil in cars. When the engine is running cold, viscous oil simply does not have time to enter the hydraulic compensator;

- Exhausted oil life, as well as significant contamination with friction products;

- Significant clogging of the oil filter, as a result of which its throughput drops, and cold oil is not supplied in full to the cylinder head.

Oily hydraulic compensator

The reasons for the knocking of hydraulic valves on a cold engine are very similar to the reasons for their knocking on a hot one.

Knock of the hydraulic compensator on a hot engine.

The appearance of a knock may be due to mechanical wear, jamming of the plunger or valve.

Regarding the oil, it is worth noting that knocking when hot can be due to highly fluid oil, then the oil pump cannot provide the proper pressure.

Another reason for knocking, both cold and hot, may be wear of the oil pump with a subsequent drop in its performance.

How to solve the problem of knocking hydraulic compensators?

- You can try changing the oil if it has been changed for a long time or looks bad (dark brown color, bad smell, etc.). As a rule, after replacement, the knocking of hydraulic compensators disappears. If the knocking does not disappear, you will have to take out the main battery and see what’s wrong.

- If adding oil did not lead to anything, and washing the engine did not give any result, you can try another way to solve the problem of knocking hydraulic valves. The principle is to remove the main hydraulic valves, perform a visual inspection of them, in case of insignificant wear and normal condition, you can disassemble and wash the hydraulic compensators. When removing, I recommend remembering or writing down where which hydraulic compensator was installed. After washing, everything is assembled and the operation of the engine is checked; if washing the hydraulic compensators does not lead to anything, the only way out is to replace the hydraulic compensators .

Consequences of the knocking sound

It is interesting that the breakdown of hydraulic compensators does not lead to any damage to other mechanisms of the power plant.

For knocking hydraulic compensators, the thermal clearance is simply disrupted, which only leads to a decrease in the power and throttle response of the power plant and an increase in fuel consumption.

But a knocking sound may indicate a malfunction in the lubrication system, so it is important to find out why they are knocking and fix the problem.

As for the use of SOHC and DOHC gas distribution systems on cars, the only difference is in the number of installed hydraulic compensators.

Thus, modern cars, including domestic ones, for example, VAZ 2112 and Lada Priora, already use a DOHC gas distribution system, with 4 valves per cylinder, and therefore with 4 hydraulic valves, the total number of which is 16.

The reasons for the knocking sound for all cars, including those mentioned, are the same.

The presence of such a number of hydraulic valves only makes it more difficult to identify a knocking hydraulic compensator if only one or several of the total number is knocking.

Hydraulic lifters rattled on the Priora, what should I do?

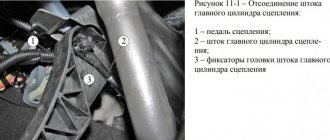

Lada Priora is equipped with a VAZ 21126 engine with an automatic gas distribution mechanism adjustment system. The gap between the camshaft cam and the valve stem is selected by a hydraulic tappet, the successful operation of which is ensured by the engine oil system. The mechanism allows you to avoid making various types of adjustments in the timing belt, reduces fuel consumption and increases the efficiency of the power plant. Fundamentals of the design and operation of a hydraulic compensator

Identifying faulty hydraulic compensators

In principle, it is not difficult to identify a knocking hydraulic compensator. It is enough to remove the valve cover from the car to gain partial access to them, which will be enough for checking.

Remove the valve cover of the VAZ 2112

To check the hydraulics, it is enough to use a thin wooden block.

The check is carried out by pressing on the bottom of the hydraulic valve. When force is created, it will begin to sink into its seat. When checking, it is important that the camshaft cam does not act on the bottom of the hydraulic valve.

A jammed hydraulic compensator will simply not be recessed into the seat by the created force; human impact will not be enough to overcome the forces of the valve spring.

If there is no oil in it for any of the listed reasons, the hydraulic valve will be recessed into the seat with significantly less force than when working normally.

Using this method, you can calculate broken hydraulic compensators.

Replacement

Experienced car enthusiasts advise replacing hydraulic compensators as a set. They wear about the same. Therefore, if one fails, the other will soon fail. To replace the hydraulic valves, you will have to remove the camshafts, as well as some other engine parts. In principle, the work is not difficult and does not take much time. This should only be done on a completely cooled engine.

For greater reliability, you need to change the engine oil at the same time. When you first start the engine, do not be alarmed; you may still hear the same knocking noise. It will end after half a minute, as soon as the required amount of oil is filled into the hydraulic compensator. If replaced correctly, the motor will run quietly for a long time.

Conclusion

. The engine on the “two-wheeler” has a lot of advantages; it is quite resourceful, and at the same time not gluttonous. But it has one drawback, valve knocking. Therefore, novice drivers often ask what to do if valves or hydraulic compensators on a VAZ 2112 16 valves are knocking. Before answering this question, it is necessary to find out the exact reason for this phenomenon. After which, it can be eliminated.

Basics of the design and operation of a hydraulic compensator

Configuration

The idea of automatic regulation of thermal clearances can be implemented in two versions: a conventional hydraulic pusher and a hydraulic support. The latter is used in gas distribution modules with rocker arms. On the Lada Priora in the sixteen-valve version, the intake and exhaust are equipped with individual camshafts. The optimal solution for this arrangement is the use of a hydraulic pusher.

Why do you need hydraulic compensators for the BAZ 2112?

My camshafts didn’t turn, I took everything apart, but I couldn’t get the hydraulics out. You press on them, they stand there dead, what could be the reason?

Thank you! Very necessary information. I'll try to change the oil, I'll write what happens.

When it’s cold, it doesn’t knock, or at least barely audibly, but as it warms up, the knocking intensifies. What should be the pressure when the engine is warmed up?

Thank you very much, I’ll also try to change the oil and filter. I'll see what happens.

I got my head full, completely new headers, but the knocking doesn’t stop

Why do the valves knock? The hydraulic compensator was changed, the oil too, the pressure sensor is on, the car does not pull.

The camshafts could be worn out, if new camshafts don’t help, then throw away the head

If you have a BAZ 2106 and the distributor has failed, then this article is for you. From it you will learn: which distributor to buy, how to check its functionality, how to install and configure it, and also how to adjust the contact gaps of the breaker.

Are you ready to replace the struts on your BAZ 2110? Then hurry up and read the article. Here you will find out which racks from which companies are best to buy, which racks will make the car softer, and which ones will make the car harder. The article also provides a step-by-step guide to replacing all racks.

The article is intended for owners of the VAZ 2109 who have problems with the side member. From it you will learn how much replacement costs, when to change it and when to weld it, the sequence of work when replacing, etc.

Few drivers know what to do if valves or hydraulic compensators on a VAZ 2112 16 valves are knocking. This is a fairly common situation. But most people do not know the reasons for such phenomena and are afraid of them. In fact, this may be quite common and should not be a cause for concern. Depending on the characteristics of the knock, we can draw a conclusion about its nature and danger to the engine. Some types of knocking are quite harmless. You can ride with them, but this problem may lead to others. Therefore, it is still better to eliminate the cause immediately. Moreover, in most cases this does not require any special costs.