Camshaft location

Modern cars most often use a mechanism with an overhead camshaft, which has reduced the metal consumption of the structure and, as a result, increased reliability.

Since metal expands when heated, and the valves are constantly in a high-temperature zone, to prevent it from being pressed in, as a result of which it does not fit tightly into the seat, a thermal gap is provided between the valve stem and the camshaft cam.

In this case, the thermal gap has a certain value to ensure the maximum possible opening of the valve, eliminating its tightening.

Previously, on engines with an overhead camshaft, the thermal clearance was adjusted by placing shims of a certain thickness between the valve stem and the camshaft cam.

The disadvantage of using these washers was the need to periodically check the gap and adjust it by selecting washers.

Nowadays, to ensure thermal clearance, hydraulic compensators are increasingly being used, popularly known as hydraulic compensators, the use of which eliminated the need to adjust the gap, and all because the gap is adjusted by oil pressure.

Hydraulic compensators, like shims, are located between the valve stem and the camshaft cam.

Externally, the hydraulics look like a small piston, so the head has seats for them.

Reviews

| № | Positive |

| 1. | Vasily: I drove a little more than 50,000 km, there is no knock in the gas distribution mechanism. I regularly fill up with high-octane fuel and fill in Shell 10W-40 semi-synthetic oil. |

| 2. | Konstantin: in two years of active operation of the machine, the valve knocked once. As the service station worker found out, the reason was that the fastening nut was not tightened sufficiently. Half an hour later I was driving the car again. |

| 3. | Vladlen: I recently noticed dark-colored exhaust gases coming from a car, I thought there was a problem with the gas distribution mechanism. During the diagnostics, it turned out that there was a violation in the enrichment of the mixture in the system, as a result of which carbon deposits formed. |

| 4. | Ignat: I heard a lot of complaints about the gas distribution mechanism, I didn’t have any breakdowns in a year and a half of using the car. Perhaps the reason is constant maintenance, careful handling, refueling with high-quality oils and fuel. |

| 5. | Ivan: in two years of using the car, I cleaned the gas distribution mechanism once for preventive purposes. The machine works stably, there are no complaints. |

| Negative | |

| 1. | Vitaly: after 55,000 km, the valves began to knock, I took the car to the service center, and it turned out that the leg was deformed. Replaced with new ones, they gave a guarantee. Dissatisfied with the quality of workmanship. |

| 2. | Kirill: at the first convenient opportunity, re-tighten the valve mechanism on the Lada Granta. Lots of defects, poor quality fitting, loose knots. |

| 3. | Slavik: in the third year of operation of the machine, I replaced the valve mechanism with a new one. The old one has fallen into disrepair. |

Conclusion

The average service life of the gas distribution mechanism of the Lada Granta does not exceed 50 - 60 thousand km. In order not to reduce the resource, periodically carry out preventative maintenance on your car, replace worn parts with new ones.

Refilling with high-quality motor oils and high-octane fuel will only increase the life of the valve mechanism.

Related link:

Replacing the Lada Granta generator bracket

Often, the cause of premature wear of timing elements is an aggressive driving style. Increased load and high temperatures contribute to premature wear of components.

Design and operating principle

The design of the hydraulic compensator itself is simple. It consists of a cylindrical piston, the bottom of which receives the force from the camshaft cam.

Inside this piston, a plunger is installed in its seat, through which force is transmitted through the piston from the cam to the valve stem (see photo above).

The plunger moves freely in its seat, providing a thermal gap.

The hydraulic valve works like this: when the engine is running, the cam runs up against the bottom of the hydraulic compensator piston and moves it down. While moving, the piston presses on the valve through a plunger, and it opens.

The gap is adjusted using oil.

The oil pump supplies working fluid to the head under pressure. In the hydraulics, it enters the space below the plunger and displaces the plunger inside the seat.

The higher the oil pressure, the more it will put pressure on the plunger and the more it will come out of its seat.

When the pressure decreases, the plunger enters the seat again. Thus, the thermal gap between the plunger and the valve stem is independently regulated and depends on the pressure in the lubrication system.

To prevent oil from flowing out of the hydraulic compensator after stopping the engine, ball valves are installed in the oil supply channels in the cylinder head.

Having the advantage of no need for adjustment, the hydraulic compensator also has one significant drawback - high sensitivity to engine oil.

general information

Hydraulic compensators (or hydraulic pushers) are devices that help eliminate gaps in the drive using oil pressure and at the same time transmitting camshaft force to the valves. This device also helps improve the dynamic characteristics of the car and reduce fuel consumption.

Hydraulic compensators consist of a housing, a check valve, a plunger spring and a plunger pair. The device has the shape of a cylinder and is located next to the camshaft and valves.

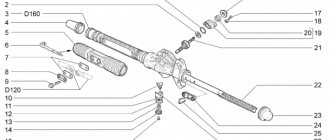

Diagram of operation of the hydraulic pusher in the valve mechanism of the VAZ-21126 engine: 1 – valve; 2 – check valve spring; 3 – check valve; 4 – cylinder head; 5 – camshaft cam; 6 – pusher; 7 – plunger; 8 – plunger spring; 9 – sleeve; 10 – check valve body; A, B – hydraulic pusher cavities; B – oil channel.

As you know, timing elements can heat up and expand due to exposure to heat, resulting in a change in the gaps between them. Adjusting the valve clearance with your own hands is a rather complex procedure, and therefore elements requiring adjustment (like levers and washers) have been replaced by hydraulic compensators that can automatically determine the clearance without any additional settings.

The approximate cost of this device most often varies from 1500 to 3500 rubles. (for example, a hydraulic pusher for a Lada Priora costs approximately 2200-2300 rubles).

Causes of knocking hydraulic compensators

The hydraulic compensator is still not an adjusting washer, which can only decrease in thickness due to constant friction; it may well fail.

Problems with the operation of the hydraulics manifest themselves in the form of a clearly audible knocking sound during operation of the power plant. Moreover, the knocking may occur in some engine operating modes, but in others it disappears.

Also, the knocking of hydraulic compensators can appear when the engine is not warmed up and disappear after reaching the optimal temperature, or vice versa.

The most common cause of hydraulic knocking is engine oil, although there are quite a few other causes.

If, when starting the power plant, a knocking sound is heard from the hydraulic compensators, but it quickly subsides, this is not the reason for their failure.

It’s just that after the next stop of the power unit, some of the valves remain squeezed out due to the location of the camshaft, the oil supply channels also remain open and the working fluid from the hydraulic fluid flows through them.

When starting, the amount of oil in the channels is quickly replenished.

But if knocking on a cold engine continues for a long time or until the engine is completely warmed up, this indicates a malfunction.

The hydraulic compensator knocks when cold.

Knocking when cold may indicate:

- Mechanical wear of the plunger and its seat. In this case, the working fluid does not maintain its pressure and constantly flows out of the sub-plunger space;

- Jamming of the plunger in the seat due to contamination;

- Ball valve jamming in the open position due to contamination;

- Oil supply channel clogged. When warmed up, the blockage is washed out by flowing oil and the hydraulic compensator works normally;

- Use of high viscosity oil in cars. When the engine is running cold, viscous oil simply does not have time to enter the hydraulic compensator;

- Exhausted oil life, as well as significant contamination with friction products;

- Significant clogging of the oil filter, as a result of which its throughput drops, and cold oil is not supplied in full to the cylinder head.

The reasons for the knocking of hydraulic valves on a cold engine are in many ways similar to the reasons for their knocking on a hot one.

Knock of the hydraulic compensator on a hot engine.

The appearance of a knock may be due to mechanical wear, jamming of the plunger or valve.

Regarding the oil, it is worth noting that knocking when hot can be due to highly fluid oil, then the oil pump cannot provide the proper pressure.

Another reason for knocking, both cold and hot, may be wear of the oil pump with a subsequent drop in its performance.

How to fix?

What to do if the hydraulic compensators suddenly start knocking? First of all, the car enthusiast needs to recognize the reason. If the oil is to blame, it is better to replace it. It is worth choosing semi-synthetics. Initially, you can try flushing the engine with a special liquid. Their variety is great. The basis of flushing fluids is mineral oil. Alkaline additives are added to it, which are designed to clean the engine walls of unnecessary dirt. Now there are two types of such liquids on the market: the so-called fifteen-minute liquids and long-term liquids. Flushing is usually carried out before changing the oil. If this procedure does not get rid of the knocking, you need to think about it. In the event of an intake malfunction, it is necessary to replace the oil with oil with a lower viscosity, flush the engine and replace the hydraulic compensators. It is better, if you do, to change everything at once, rather than just one. Even if it's just out of order. If the oil filter is clogged, it can also be replaced. This way the knock can be eliminated.

Consequences of the knocking sound

It is interesting that the breakdown of hydraulic compensators does not lead to any damage to other mechanisms of the power plant.

For knocking hydraulic compensators, the thermal clearance is simply disrupted, which only leads to a decrease in the power and throttle response of the power plant and an increase in fuel consumption.

But a knocking sound may indicate a malfunction in the lubrication system, so it is important to find out why they are knocking and fix the problem.

As for the use of SOHC and DOHC gas distribution systems on cars, the only difference is in the number of installed hydraulic compensators.

Thus, modern cars, including domestic ones, for example, VAZ 2112 and Lada Priora, already use a DOHC gas distribution system, with 4 valves per cylinder, and therefore with 4 hydraulic valves, the total number of which is 16.

The reasons for the knocking sound for all cars, including those mentioned, are the same.

The presence of such a number of hydraulic valves only makes it more difficult to identify a knocking hydraulic compensator if only one or several of the total number is knocking.

Valves knocking on Lada Grant during acceleration

There are modifications: 8 valve and 16 valve Lada Grants Sedan / Liftback. One pair of valves provides the intake of the combustible mixture, the other - the release of the exhaust gas flow.

When the motor reaches operating temperature, the metal parts expand. Incorrectly adjusted cold clearances contribute to the formation of knocking, rapid wear of parts, and a decrease in engine efficiency.

To level out the knocking of valves in the design of the Lada Granta Sedan / Liftback, hydraulic compensators (pushers) are used. They try to maintain permissible valve clearances as accurately as possible.

Identifying faulty hydraulic compensators

In principle, it is not difficult to identify a knocking hydraulic compensator. It is enough to remove the valve cover from the car to gain partial access to them, which will be enough for checking.

To check the hydraulics, it is enough to use a thin wooden block.

The check is carried out by pressing on the bottom of the hydraulic valve. When force is created, it will begin to sink into its seat. When checking, it is important that the camshaft cam does not act on the bottom of the hydraulic valve.

A jammed hydraulic compensator will simply not be recessed into the seat by the created force; human impact will not be enough to overcome the forces of the valve spring.

If there is no oil in it for any of the listed reasons, the hydraulic valve will be recessed into the seat with significantly less force than when working normally.

Using this method, you can calculate broken hydraulic compensators.

Main manufacturers

Of course, original parts and consumables, those installed at the manufacturer, are of higher quality and more reliable. Therefore, we must strive to maintain their performance. However, sometimes analogues are superior to the original.

Hydraulic compensators are manufactured by a variety of companies. But the Germans succeeded most in this. Hydraulic compensators from INA, SWAG, FEBI have proven themselves in reliable and long-term operation of a wide variety of engines. These parts are also produced by AE and AJUSA - they are also European, but, according to reviews, they have low quality workmanship. Elements can start knocking after just a few thousand kilometers. The main problem for all such parts is the danger of defects or low-quality raw materials. As a result, the friction surfaces quickly wear out - the hydraulic compensator knocks on cold and hot. Driving with such a malfunction is highly not recommended.

This is interesting: The cooling radiator is leaking - what to do, how to fix it

Recommendations from experts

Of course, the best option would be cleaning with flushing oil and preliminary preparation of the power unit. If this does not help, it is better to disassemble the cylinder head and identify faulty cylinder head through manual diagnostics. Next, remove them and clean or replace them.

In extreme cases, special additives come to the rescue. They temporarily fix the problem by debugging the inevitable opening of the valve cover. Additive compounds from Liqui Moly and XADO showed their best performance.

Sources

- https://AutoTopik.ru/remont/799-stuchit-gidrokompensator.html

- https://etlib.ru/blog/1233-stuchat-gidrokompensatory-na-goryachuyu

- https://nahybride.ru/dvigatel/stuchat-gidrokompensatory

- https://mashinapro.ru/1786-stuk-gidrokompensatorov-pochemu-voznikaet-i-chto-delat.html

- https://autostuk.ru/pochemu-stuchat-gidrokompensatory.html

- https://autostadt.su/stuk-gidrokompensatorov/

[collapse]