A couple of months ago I noticed that at the beginning of the rotation of the steering wheel there was a slight knocking sound, at first it was the steering tips, because... The anthers have been torn for a long time, I bought new steering tips, at the same time a set of front and rear silent blocks, bushings and stabilizer links. The other day before replacing the above elements, I decided to check the steering cardan, just in case, and yes, it turned out that it was loose, but everything turned out to be wrong with the steering tips Fine. I bought a new original one and replaced it in an hour or two. It’s inconvenient, of course, to change it, but there were no difficulties, I removed it by hand, and even straightened the steering wheel straight away (before removing it, I made marks everywhere and transferred them to the new part).

Here you can see the difference, on the old one (from below) the grease was squeezed out through the O-rings and wear began to appear.

After the replacement, the knocking sound disappeared when turning the steering wheel, and it also became quieter when driving over uneven surfaces, but I will still change the rubber bands in the chassis, even though they look even worse

The steering crosspiece is the key to the control of the car; it is responsible for transmitting the rotation of the wheel to the rack and pinion assembly through the steering shaft cardan (the crosspiece itself is attached to it). Not just the ease of driving, but the safety and health of all passengers depends on its correct functioning. If the car has been in use for more than 100 thousand kilometers, it most likely needs repairs; it is worth studying in advance the question of when and how to change the crosspiece on the steering cardan.

We remove the knock of the steering shaft on Lada Granta, Kalina and Priora

We noticed that when driving on uneven roads (for example, gravel), vibration is strongly transmitted to the steering wheel.

It is also possible that a knock may occur, but it is not the steering rack that is rattling. The cause of the rattling may be play in the steering shaft. It is proposed to solve the problem with the help of a simple modification, which was used on VAZ 2108-15 cars. Knocking and rattling noises appear due to gaps in the mating parts. To eliminate them, insert a rubber cube (dimensions 22x22x22 mm) into the universal joint of the intermediate steering shaft. It is cut out from the rubber bumper of the rear suspension of the “classic”.

To install the rubber part into the steering shaft, you don’t need to remove anything, just crawl under the panel and look for the connection above the brake pedal. To fit the cube into a narrow space, you will need to lubricate it (for example, WD-40) and use a clamp or jack.

For owners of Lada Granta and Kalina models with ESD, there is an alternative to this modification - install a steering driveshaft without knocking (catalog numbers: 11186-3422092-00, 21230-3401085-00). Let us remind you that in some cases the causes of knocking can be eliminated by tightening the steering rack or steering shaft bolt. Have you encountered such a modification? What effect did you feel after installing the rubber cube?

Photo: theVoL in-flight magazine

Keywords: Lada Granta steering wheel | Lada Kalina steering wheel Lada Priora steering wheel | steering mechanism Lada Granta | steering mechanism Lada Kalina | steering mechanism Lada Priora | soundproofing of Lada Granta | sound insulation of Lada Kalina | sound insulation of Lada Priora

Found an error? Select it and press Ctrl+Enter..

What to do if the hood rattles or knocks on Priora and other Lada models What to do if hydraulic compensators knock on Lada cars. We solve the problem of steering rack knocking on Lada Granta, Kalina or Priora

Lyrical digression

In Lada Kalina, the steering rack never makes a knock when we are talking about a new car. This is also true for the break-in period. Let's say in your case this is not done. Then, do not try to repair anything, but go straight to the dealer. According to reviews, the defect in question is covered under warranty, and most car dealers do this: the steering rack assembly is replaced with a new one.

This is what the replacement unit looks like, the rack assembly

There is a logic here. At the factory, adjustments are made correctly (this is true in 99.9% of cases). If a defect appears, the dealer replaces the assembly without expecting that adjustment will solve the problem. The owner does not need to hope for this either. The choice is yours.

Signs of wear on the crosspiece

How the steering cardan works, a review of faults and instructions for replacing it.

Often, motorists do not pay attention to insignificant signs that it is time to make repairs, and wait until the problem makes itself known publicly and this is fraught with consequences, especially when it comes to loss of vehicle control.

The first signs of wear on the crosspiece appear as:

- the presence of noticeable resistance to the steering wheel when rotating at speeds above 80 km/h;

- delayed wheel turning and loss of sensitivity (delayed response of wheels and steering shaft);

- increased free play angle of the wheels (popularly this symptom is also called “Steering play”);

- uneven rotation of the steering wheel, the steering wheel moves with sharp jerks;

- obvious grinding or knocking noise that occurs when the steering wheel is rotated; the grinding becomes especially noticeable and obvious on an uneven road.

Most often, motorists turn to a car service center to replace the steering shaft crosspiece mechanism only when the last sign of a malfunction appears, but in vain, because in the event of an emergency, the steering control will not be able to adequately respond to the driver’s efforts, and sometimes, the steering control may even fail, this is already fraught with very big troubles.

Repair of the shaft cross is carried out every 50 - 100 thousand, it is better more often, otherwise it will have to be completely replaced with a new one.

To replace, you will need to purchase a crosspiece - on average 150-300 rubles, some car services claim that for the steering to work correctly, you need the entire steering shaft (4 - 7 thousand rubles), but on most cars it is enough to change only the crosspiece.

Replacing the steering cardan — Lada Kalina Sedan, 1.4 l., 2008 on DRIVE2

The electric power steering on the viburnum does not work. Why doesn't the electric power steering work on the Kalina? fixing the problem

A couple of months ago, a nasty rumble appeared in the front when driving over all sorts of irregularities. I started to think that there might be a rattle... I thought and drove along) We examined the ball joints - everything is normal. The steering wheel is normal. The supports and struts are normal. All the rubber bands and not only are also normal. But there is also a nasty noise. It feels like the front end is falling apart. And then I thought about the steering driveshaft, since I read that it can rattle. I went to the mechanic and the verdict was: the driveshaft needs to be replaced. Today we finally managed to find the time and change it. But since it costs a lot in principle, it was decided to buy the lower part first, and then we’ll see.

The lower part costs 1300 rubles, the upper one - 1400 rubles. Of course, you could buy the crosspiece itself for 200 rubles and change it, but we are not looking for easy ways)))

I bought this thing.

Now it’s time to replace the outer CV joints. It started to crunch when the wheels were turned out. I didn’t change them.

Well, while they were changing my steering shaft, I occupied my hands with some useful work. I took it and repainted both grilles black.

Full size

and again like that)

Now I’m thinking... Maybe I should have painted the mesh black, and not the color of the car? What do you think?

Issue price: 1,300 ₽

Removing the electric power steering column

Repair kit for repairing or replacing the Lada Kalina steering rack

We set the wheels to the position of straight-line movement of the car. Disconnect the wire terminal from the negative terminal of the battery. Remove the steering wheel (see “Removing the steering wheel”). We remove the steering column switches (see “Removing the steering column switches”). Disconnect the ignition switch wire connectors from the instrument panel wiring harness connectors. If necessary, remove the ignition switch from the steering column (see “Removing and disassembling the ignition switch”)

Using a Phillips screwdriver, unscrew the three screws.

. and remove the lower cross member of the instrument panel.

By pressing the clamps, disconnect the two wiring harness blocks from the power steering control unit. Disconnect the wiring harness block from the connector of the steering column switches (see “Removing the steering column switches”).

Using a high “13” head, unscrew the four nuts securing the bracket (the fourth nut is not visible in the photo).

. and lower the column to the floor. If necessary, remove the connector for the steering column switches (see “Removing the steering column switches”).

Using a 13mm socket, unscrew the nut of the bolt securing the lower cardan joint to the steering gear shaft. If the bolt turns, hold it with a 13mm wrench.

Using a powerful slotted screwdriver, release the terminal connection of the hinge.

. and remove the intermediate propeller shaft from the steering gear shaft. Before disconnecting the intermediate propeller shaft from the steering shaft, use a marker to mark the relative position of the upper joint of the propeller shaft relative to the steering shaft.

Using a 13mm wrench, unscrew the nut of the hinge coupling bolt. If the bolt turns, hold it with a 13mm wrench. We take out the bolt

Use a screwdriver to loosen the terminal connection of the hinge.

. and remove the intermediate driveshaft from the steering shaft.

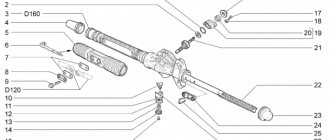

Intermediate cardan shaft

Install the intermediate driveshaft in reverse order. When connecting the upper joint of the intermediate propeller shaft to the steering shaft, it is necessary to align the previously made marks. Install the steering column in the reverse order. Installation this way is best done with an assistant. However, it is more convenient to install the column when the lower hinge of the intermediate propeller shaft is installed on the steering gear shaft in advance. To do this, after connecting the intermediate propeller shaft to the steering shaft...

. Using a 13mm wrench, unscrew the nut of the intermediate shaft coupling bolt. . remove the bolt.

. and disconnect the lower universal joint from the upper one. We install the lower hinge on the steering gear shaft (the bolt securing the hinge to the gear shaft should be located vertically on the right side). We turn the steering shaft so that the hole in the upper hinge for the intermediate shaft pinch bolt is located horizontally at the bottom of the shaft. We connect the upper and lower hinges of the intermediate shaft, insert the coupling bolt and tighten the nut. We carry out further installation in reverse order.

Diagnostics, repair and reassembly

Before determining why there is a knock in the steering, you should completely disassemble the rack and carry out diagnostics for wear, destruction of components and connections. Disassembly is carried out in this order. Secure the steering rack in a vice, having previously installed spacers made of soft metal or other material. Unscrew the nut securing the mechanism crankcase pipe. The crankcase tube is removed. Remove the clamps securing the pipe bushings and remove them.

Unscrew the adjusting nut. Here you need to use a special 24mm wrench, which has external edges for unscrewing. Sequentially remove the rack stop spring, the sealing ring and the rack stop. Remove the crankcase cover. After removing the bearing cage and sealing ring, remove the rack. The second element of the steering mechanism pair - the gear shaft - is dismantled.

Now you can diagnose the condition of the bearings and sealing rings. After thorough cleaning, the wear of the gear sectors and the condition of the surface of the rack and shaft are assessed. After all, this is where the reason lies that causes the knocking that appears. If necessary, select the necessary parts and replace them.

Self-replacement procedure for the steering shaft crosspiece

The replacement takes place in several stages:

- We lift the car off the ground using a lift or by rolling it into a hole, but you can also get by by lifting the front of the car.

- We set the steering wheel at a right angle and fix it, and also fix the steering wheel; during replacement, movement of the wheels and steering wheel is not desirable.

- To access the steering shaft, remove the left (right) wheel. We go into the salon and unscrew the fastening bolt; after a slight effort, the steering shaft should come off the steering wheel.

- Under the car, carefully remove the upper and lower casings, check the amount of dirt on the crosspiece and steering shaft driveshaft; not all cars have them protected by a boot (purchase and installation of such rubber will cost 100-200 rubles).

- We find and unscrew the bolt on the crosspiece; you may have to use a WD tool. Once the bolt is removed, the steering shaft should easily come off the steering rack.

- Pull the shaft down and pull it out. Often the crosspiece mechanism is rusty and dirty; first of all, you will need to wash it.

- For flaring you will need a sprocket of the appropriate diameter; fix the shaft in a vice.

- Using a head (presumably a 8-pointer), we knock out the cross first in one direction (remove the bearing cup), and in the other direction (also remove the cup).

- Then we take a new crosspiece and insert it in the same order - we start one side first, and then the other, press it in using a vice (but not too tightly, the metal may wrinkle).

- We align both cups and roll them with a chisel and hammer.

The final assembly procedure is no different from disassembly - the main thing is to maintain order. So, we have replaced the steering shaft crosspiece; if everything is done correctly, the handling will respond better to your efforts.

I haven’t written anything for a long time, as I was busy with construction and during this time I did almost nothing with the car, I just changed the rear brake cylinder and the handbrake cable, otherwise it completely turned sour and the handbrake disappeared if you didn’t pull it. The driveshaft had been rattling for a long time, but now the noise has become It was completely unbearable, and even the steering play became like that of a Kamaz. I decided to change to a solid one from TAYA (Technology from A to Z)

and not because it’s super duper, but since I didn’t turn the original one, there was still some play in the connection of the two halves of the original one. I set the steering wheel straight, made marks on the rack and on the steering wheel,

I separated the two halves of the original, to do this I unscrewed the bolt that held them and hit them with a hammer until they separated and removed them separately from each other.

Then I removed all the plastic around the steering shaft from the EUR,

then I loosened the fastenings of the steering shaft, did not remove it, but only moved it up, this was praised,

in order to put the new one in place, I moved the clamping parts of the shaft a little to the sides, to do this I inserted a chisel and hit it a couple of times,

and put it in place without any problems, but turning the bolts turned out to be problematic, I had to tighten it with a clamp from the side of the steering rack and then the bolt would turn,

but on the other hand it was not possible to crawl up with a clamp, I had to drill a hole from the side where the thread was

and insert a bolt with a nut from the old cardan (there they are with nuts, but in the new one the threads are cut into the body of the cardan and the bolts are without nuts).

I tightened everything up and put it in place and drove off. What can I say from the sensations, it’s just a thrill, there hasn’t been such silence in this part of the car for a long time, the steering has become very collected, bumps are not felt at all and steering has become much easier and softer, I’m very pleased the work done. I don’t want to say that my native one was completely bad, but there was always a slight play in the connecting part, I even climbed into my father’s viburnum to check, he also had a play, but it didn’t rattle.

Treating the steering shaft driveshaft or replacing the crosspiece

Lada Kalina Universal 11173 Kalina Krasnaya › Logbook › We are treating the steering shaft driveshaft or replacing the crosspiece.

And again Kalina's classic. I was bothered by a knocking sound in the steering when driving over small bumps. Due to my inexperience, I would confuse it with the knock of the steering rack. We are already very familiar with the rack. The steering shaft driveshaft remains. Diagnostics is simple: hold the driveshaft with one hand and turn the steering wheel with the other. The play is noticeable immediately. In my case, there is play in the lower cardan.

For a new cardan in the store they asked for as much as 1.5 thousand rubles! Moreover, you can find its horseradish in stores. Having read Drive here and there, I decided to radically modify the driveshaft with the help of caprolactane. I ordered bushings from a turner according to a drawing made by user livFeniX. who asked not to post the drawing. I'm guessing nanotechnology))). Those who are curious should write to him in a personal message.

Removing the cardan is simple: two nuts with a 13mm wrench. The bottom bolt is simple, the top is figured. Using a screwdriver, we open the spline connection, move the cardan shaft up along the splines, and remove it from the steering rack shaft. This is the most difficult thing. The splines around the bolt hole were partially jammed, and the cardan had to be knocked off the rack shaft. If everything is in order, he should get off on his own.

Further, when pressing out the crosspiece, all the relatives of the VAZ designers were mentioned. The cross bearings did not want to come out of the fork. It turned out to be simple: to knock out the bearings, you need to strike the base of the fork under the bearing.

I lost a lot of time on this. There is nothing on the internet about this, there is only information about how to assemble the crosspiece. Otherwise, you press it with a hammer in the right place and the bearing jumps out on its own.

And then came the most interesting moment

The fact is that when I removed the rack two years ago and installed the rack, I noticed that the cardan, or rather its half with splines, was sticking. Not that it bites, but the jerks are clearly noticeable

The half with the square moves freely. Having turned the new cardan in my hands in the store, I didn’t take it because it jams in the same way. Then I thought it was meant to be. Well, since the new spare part behaves the same way, it means the factory came up with it that way. So, let's return to caprolactane bushings.

Everything is fine, everything is beautiful. The bushings move freely on the crosspiece, but... after pressing into the forks, the crosspiece clamps - you can’t turn it by hand. Either something is not quite right with the tolerances in the drawing, or the turner didn’t get the tolerance right. Although I measured it with a caliper, everything seemed to be as per the drawing. I had to resort to a backup option and do it as here. For 200 rubles. In Exist, in advance (the turner had been making the bushings for a long time and no longer relied on them) a crosspiece ST-1640 was purchased

So, when pressing the bearings, the reason for the jamming of the splined fork of the cross was found out. Holes are misaligned! Moreover, the square fork works perfectly with both bushings and bearings! Here's to grandma and St. George's Day! It turns out that the factory is defective and the stores are also defective! A working crosspiece should move freely in all directions. And here it turns out that the bearings in the fork with splines are initially skewed! There was nowhere to go, I had to put it as is.

It’s reassuring that I drove 50 thousand km with a defective cardan. And the fact that with the repaired driveshaft the knock in the steering wheel disappeared. But for the future it’s worth looking for an alternative to the SS-20 or TAYA. The truth is, again, there are conflicting reviews about them. Or look for a normal factory cardan.

Addition dated 10.28.15. After 1,500 km, the Japanese crosspiece began to knock treacherously... I’m still going to screw it up.

Read the continuation of the story here.

Good luck to everyone on the roads.

a year and a half ago Mileage 50460 km Tags: self-repair

Weak points of the suspension

In wet weather it is not always possible to see a defect in the shock absorber strut

If you carry out independent repairs, for example, replacing a ball joint, then you must carefully tighten the fastening bolts. There are no through holes in the steering knuckle to which the support is attached: the bolt is screwed into the knuckle itself. Excessive tightening force may cause the bolt to break. A knock in the front suspension may also occur for this reason.

For reliable and long-term operation of the suspension, it is necessary to comply with the speed limit of the machine stated in its technical passport. Also, regular maintenance will help eliminate the appearance of noise, knocking and deviation from straight-line movement.

Downloading a book

After successfully completing the payment (by any method) and returning to the KrutilVertel store from the payment system website, you will be taken to the successful payment page:

The book you purchased will be in your personal account, from where you can always download it.

Please note that after making the payment, you need to return back from the payment system website to the KrutilVertel website. If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book

If for some reason you did not return back to the site and closed the payment system tab with a message about the successful completion of the payment, please let us know - we will send you a letter indicating access to download the book.

Steering shaft

The steering shaft provides the connection between the steering wheel and the steering mechanism. Quite often a joint steering shaft is used. Thanks to it, the level of driver injuries in the event of an emergency is reduced.

Positive qualities of the steering shaft:

- Silence. Due to the absence of play in the universal joint with elastic bushings, silent operation occurs;

- There is no jamming and ease of rotation is noticeable, thanks to the presence of high-quality lubrication and the high anti-friction properties of the cardan bushings;

- Excellent elasticity of the cardan bushings, and this guarantees long-term use.

Replace the lower steering shaft driveshaft

Required tool:

- Open-end wrench 12;

- Hammer;

- Ratchet wrench with heads 10 and 12;

- Chisel;

- A slotted screwdriver with a thick and wide blade;

- Mount.

So, how to change the steering shaft driveshaft on a Kalina?

To replace , you need to follow these steps:

- Align the wheels in the direction of straight-line movement of the car;

- Remove the cover from the corrugated air filter;

- Unscrew the 12mm bolt at the pedal assemblies;

- Unscrew the 12mm bolt in the hood area;

- By tapping on the ears of the cardan with a hammer, it is necessary to knock the cardan towards the steering wheel;

- Remove the cardan from the rack shaft;

- Using a 10mm socket, unscrew the engine shield bolts and slide the casing up the cardan;

- Using a pry bar, push the cardan up along the shaft splines;

- Pull the driveshaft down and remove it from the steering shaft;

- Place the boot on the new cardan;

- Insert a new cardan through the engine shield casing into the passenger compartment;

- In the cabin, you should get the universal joint into the upper universal joint of the steering rack;

- Place the steering wheel straight and place the cardan on the rack shaft;

- Tighten the bolts.

Preparatory actions, dismantling unnecessary parts

To remove the crankcase protection, you need to unscrew 4 screws located in one row near the bumper. Also, unscrew two screws having a standard size of M6 × 16. In some configurations, the protection consists of two parts, but in this case they are attached only with self-tapping screws. These words are illustrated by the following photo:

First, unscrew the “10” screws, and then the two “18” screws. In the second case, there will be more screws (eight).

Now let's look at how to remove the battery. First of all, disconnect its terminals. Then, you need to move the additional fuse box to the side. In general, actions are performed according to the photo:

You also need to remove the mounting platform itself, for which you unscrew 4 screws. You will need a 13mm wrench, as well as a 10mm spanner. We will repeat the entire sequence again:

- Unscrew the nuts holding the battery terminals using a wrench 10;

- Remove both terminals;

- Move the fuse box to the side by unscrewing 2 fastening screws;

- Unscrew the nuts with a 10mm wrench and remove the battery;

- Unscrew the screws with a 13mm and remove the metal plate.

Recommendations

Comments 132

Greetings. Why was the crosspiece 1640 chosen and not 1639? Yours seems to be recessed inside?

Doesn't matter. There is no point in installing a crosspiece, just insert it with caprolon. Then the cardan moves without knocking

Thanks to the author for a detailed and intelligible description of this operation; without these instructions, I would not have even tried to modify this unit. Respect! However, below I describe my first impressions of the result.

Well, I finally decided to install 2 steering joint crosspieces. I did it in two stages with a break of several days. After replacing the top one, I didn’t feel any results at all. But after all the work was completed, the first thing I noticed was that the steering wheel began to turn tighter, perhaps it will develop over time. Secondly, squeaks appeared when turning the steering wheel, until the interior warmed up, they did not disappear. Thirdly, the strumming became, of course, less, but nevertheless, they remained in the area of the EUR (?), as well as a small play there. In terms of improving handling, I haven’t realized it yet, I haven’t gone on the highway yet, perhaps a tighter steering wheel will have its effect (like a damper). Something like that.

Interesting topic. Is the knock of the driveshaft critical? I just got it, so far it doesn’t bother me.

Psst, don’t you really notice how it affects the steering? You immediately start to catch the car all the time!

Alternatively, you can change the car and that’s it

I’ll tell you my story about how my original driveshaft rattled on a grant, I bought a new one, supposedly reinforced enough for 3 months, it rattled, I took Ty and drove it through the fall and winter, a backlash gradually appeared, it reached the point of knocking, the ss20 painted head from a hairy hat and didn’t drive for a month rattled, as for me it’s all SS20 product hat (not anti-advertising), I re-tuned the original cardanic twice, one dick, don’t set the tolerance too tight, they start to play, the only thing is that they don’t knock, since I tried everything, I bought two Toyo 1638 crosses, we’ll re-tulit and see what happens.

I don’t know anything better than caprolon bushings yet

The bushings don't knock, but they do play over time, I don't like play in the steering

They play much less than everyone else.

And what kind of caprolon they took, white or black, they say black is stronger and lasts longer, I couldn’t find the black one that was ground from white.

In this case, white or black does not matter.

How are the bushings now? Is it worth betting?

I installed the SS20 on Kalina, drove the knock for up to a year and appeared there. Replaced under warranty! The other set ran without problems. Where can I get such material?

This is a bad cross. I also took GMB, enough for 2000 km. Take TOYO 1638. The quality is awesome, it’s been around for a little over 2 years, the crosspiece is like new, it doesn’t play, doesn’t knock, in short, I forgot about it. and size 1638 so that the edges could be sealed, I took 1640 so it fit along the edge, I had to weld the edges. I took it from the autodoc, this is not an advertisement. In a small auto shop I saw it was a fake and didn’t buy it.

I'll take note. I'll socket all the cardan shafts now. Bushings run better than bearings, tested with taxi drivers.

This is a bad cross. I also took GMB, enough for 2000 km. Take TOYO 1638. The quality is awesome, it’s been around for a little over 2 years, the crosspiece is like new, it doesn’t play, doesn’t knock, in short, I forgot about it. and size 1638 so that the edges could be sealed, I took 1640 so it fit along the edge, I had to weld the edges. I took it from the autodoc, this is not an advertisement. In a small auto shop I saw it was a fake and didn’t buy it.

How long have you driven the TOYO 1638?

It's been about 60 thousand, and it's still there (no play).

Listen, why 1638 and not 1639, these seem to be the dimensions. Or is it not important?

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

If you still have any questions, you can ask them using the feedback form, or write us an email at [email protected]

Similar products (4)

Information

Support

Additionally

Why is it convenient and profitable to buy goods in an online store?

Let's look together at the main advantages of an online store compared to a regular store.

1. Lack of geographical attachment to a retail outlet (you do not need to look for a store, spending your personal time and energy);

2. The ability to visit any online store 24 hours a day without leaving your home or office;

3. Comparing information about products from different manufacturers and sellers (visiting several stores on the Internet, as opposed to tedious trips to traditional “offline” stores, takes only a few minutes.

4. The opportunity to thoroughly familiarize yourself with the characteristics of the product and its consumer properties, as well as reviews of other buyers (you must agree, this is much more convenient to do in a familiar home environment or while sitting in an office chair);

5. Save time. Efficiency is the most important factor;

6. And finally, another important circumstance for domestic Internet users is the low price. Products purchased through an online store are often cheaper than if you purchased them in a regular store.

Cross design

The mechanism of the steering shaft crosspiece performs a transport-guiding function and is designed to transmit the torque of the wheel to the gear of the rack and pinion assembly. The transmission of torque is carried out by the steering shaft cardan, to which the crosspiece is attached. In many models of modern cars, the crosspiece performs the same function and has a similar shape. The cross itself consists of four identical protrusions, each of which is equipped with needle-type bearings. All elements of the cross are made of high-strength steel and must withstand high loads.

How to adjust the rack?

Adjusting the steering rack involves setting the correct gap in the gear connection. We recommend replacing the thrust nut with a new analogue. The rack and pinion assembly must be set to the “zero” position, which corresponds to the straight course of the car. The adjustment is carried out using a clock-type indicator mechanism. We rotate the gear-shaft and at the same time measure the readings of a special indicator. When the value is 0.05 mm, then tighten the adjustment nut to a similar amount. Upon completion of the adjustment manipulations, we check the mechanism for ease of rotation and smooth movement of the rack in the pipe. After making sure that the steering rack adjustment was correct, we fix the nut of the same name in the specified position by punching it with a special punch.

Now we can easily install the assembled unit on the LADA Granta car. Upon completion of installation on an immobilized vehicle, rotate the steering wheel several times, checking the smooth rotation and movement of the elements. It is possible to make sure that there are no knocks only while driving over uneven surfaces. The steering rack is fine.

What is a steering shaft and how to replace it?

One of the largest Russian enterprises involved in the development of passenger cars is AvtoVAZ. During the period when AvtoVAZ existed, many cars have already been produced and released. One of the released models is the VAZ1118, and this is the very first version of the Lada Kalina. The first Lada Kalina model began production in 2004 and ended in 2011. Although the production of this car model ceased a couple of years ago, the car itself did not disappear from Russian roads and they are still found on the roads of many Russian cities.

Prototypes of “Lada Kalina”

Lada Kalina 1119 hatchback

The first generation of the Lada Kalina model is the Lada Kalina 1119 hatchback, produced from 2006 to 2013 inclusive. The presented Lada Kalina prototype, compared to the sedan and station wagon, has an insufficiently large trunk volume, but if you fold the rear seats, you can carry a fairly large load. There are three basic configurations of this model: luxury, normal and standard. The luxury package includes improved velor upholstery of door panels and seats.

The engine has an eight-valve engine with a volume of 1.6 liters and a modern sixteen-valve unit with a volume of 1.4 liters. Its production began in 2007.

Lighter pistons, cylinder heads, steel intake manifold gaskets and extended connecting rods were used here. Thanks to the modern engine, the Lada Kalina has become more dynamic.

Lada Kalina 1118 sedan

Since 2004, the Lada Kalina model with a sedan body began to be produced, and in 2011, production of the four-wheel drive car ceased. The wheelbase and spacious interior of the sedan are no different from the station wagon and hatchback, and in terms of luggage compartment volume the sedan ranks first. In 2007, the car model received an improved sixteen-valve engine with a lightweight connecting rod and piston group.

Steering shaft cardan Lada Kalina

Lada Kalina 1117 station wagon

Mass production of the station wagon began in 2007, and in 2009 the Lada Kalina was improved. The luggage compartment volume of a station wagon is larger compared to a hatchback and smaller compared to a sedan. The engine has an eight-valve engine with a volume of 1.6 liters and a modern sixteen-valve unit with a volume of 1.4 liters. Reducing engine displacement made the Lada Kalina much more economical and dynamic. There are three basic configurations of this model: luxury, normal and standard.

Steering shaft

The steering shaft provides the connection between the steering wheel and the steering mechanism. Quite often a joint steering shaft is used. Thanks to it, the level of driver injuries in the event of an emergency is reduced.

Positive qualities of the steering shaft:

- Silence. Due to the absence of play in the universal joint with elastic bushings, silent operation occurs;

- There is no jamming and ease of rotation is noticeable, thanks to the presence of high-quality lubrication and the high anti-friction properties of the cardan bushings;

- Excellent elasticity of the cardan bushings, and this guarantees long-term use.

Replace the lower steering shaft driveshaft

Required tool:

- Open-end wrench 12;

- Hammer;

- Ratchet wrench with heads 10 and 12;

- Chisel;

- A slotted screwdriver with a thick and wide blade;

- Mount.

So, how to change the steering shaft driveshaft on a Kalina?

To replace the Kalina steering shaft driveshaft, you need to follow these steps:

- Align the wheels in the direction of straight-line movement of the car;

- Remove the cover from the corrugated air filter;

- Unscrew the 12mm bolt at the pedal assemblies;

- Unscrew the 12mm bolt in the hood area;

- By tapping on the ears of the cardan with a hammer, it is necessary to knock the cardan towards the steering wheel;

- Remove the cardan from the rack shaft;

- Using a 10mm socket, unscrew the engine shield bolts and slide the casing up the cardan;

- Using a pry bar, push the cardan up along the shaft splines;

- Pull the driveshaft down and remove it from the steering shaft;

- Place the boot on the new cardan;

- Insert a new cardan through the engine shield casing into the passenger compartment;

- In the cabin, you should get the universal joint into the upper universal joint of the steering rack;

- Place the steering wheel straight and place the cardan on the rack shaft;

- Tighten the bolts.

Rack and pinion mechanism

If you touch on the steering mechanism on the Lada Granta, you need to notice its design aspects and characteristics.

- The steering column can be adjusted to tilt. The steering wheel itself is endowed with the ability to lock due to the presence of a special anti-rotation device, which is structurally connected to the ignition switch.

- The rack and pinion mechanism of the steering unit allows you to change the ratio of gear ratios in different operating modes.

- A mechanism based on the electrical principle of operation is integrated into the system as an amplifier.

- The electric amplifier is equipped with a unit through which self-diagnosis of the entire unit is carried out and, if a deviation from the norm is detected, it directly excludes the amplifier from the overall functionality of the system.

The principle of implementing the steering unit circuit is quite simple. The mechanism, which has a pair of gears and a steering rack, is fixed in the engine compartment using rubber supports on a specially designed shield. The reliability of such fasteners is ensured by bolts attached to the body. The ability to transmit rotational force to the wheels is carried out through a pair of steering rods, which are connected to rotary levers fixed on the bodies of the Lada Granta shock absorber struts.

The interaction of the gear pair is regulated using a gap, the value of which is set at the manufacturer’s factory. The meshing accuracy is controlled and adjusted by means of a spring stop that presses the rack to the gear.

The indicated gap value under standard conditions reaches 0.1 mm. During operation, the gap changes due to the gradual wear of individual elements of the steering unit. This may be one of the main reasons causing the previously mentioned knocking noise. We will also not ignore other factors that can cause this annoying knock for the Lada Grant owner, namely:

- the fastening of the rack itself to the body elements is weakened;

- the appearance of play in the ball joints of the rods or the tips of the steering unit;

- wear or damage to the steering shaft gear teeth.

In the first case, you need to know how to tighten the steering rack, as well as how to replace it.