Lada Priora

Lada Priora with robotic gearbox: from RUB 428,000.

Lada Priora with robotic gearbox: from RUB 428,000.

Lada Priora with robotic gearbox: from RUB 428,000.

The idea to automate a manual transmission was born about five years ago. In the project for modernizing units for front-wheel drive models, including the introduction of cable-driven gearboxes VAZ-2180 and -2181, the fifth point was the task of developing a robotic version.

Robotic gearbox on the Lada Priora: advantages and disadvantages, reviews from owners

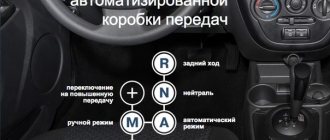

The robotic gearbox on the Lada Priora is a kind of hybrid, an intermediate option between a manual transmission and an automatic transmission. Accordingly, advantages and disadvantages arise from its design. The unit implements the “foolproof” concept, which completely eliminates accidental gear shifting, which can lead to sudden overload of the engine. Switching to manual mode allows the gear to be reduced by one speed, which protects the transmission and power unit from overload.

If you intend to purchase a Vesta, Grant or Priora robot car, reviews from the owners will help you better understand the operation and ease of use of this type of transmission.

Lada Priora

The first real steps were taken together with Magneti Marelli, but preference was given to the more flexible system of the German company ZF. It consists of two separate electromechanical devices (actuators): one depresses the clutch, and the other shifts gears. We have developed three layout options - respectively, for Priora, Kalina/Granta and the promising Vesta. They decided to launch it on Priora. And here it is - a production sample! I’ll say right away: I expected the worst. The automated gearbox of the Priora does not cause irritation at all. Delays during switching are inevitable, but they are tolerable. And the box moves smoothly from step to step. You can, of course, change the firmware and add speed to the box, but the ride will become jerky and the synchronizers will not last long.

Feedback from prior leaders about AMT

In reviews of the Priora robot car, owners say that AMT reacts less sensitively than automatic transmission to the need to change gears. In automatic mode, intensive acceleration, according to reviews, is unattainable. A switch to manual downshift followed by a return to automatic mode is required. Actively driving a robot is difficult because its adaptation is carried out in a static mode, which does not take into account the reduction in reaction time in a dynamic mode. In a word, the robot is poorly trained to suit an individual driving style; on the contrary, the driver needs to get used to the robot’s operating algorithm.

As for maintenance, reviews from owners about the Lada Priora with a robotic gearbox indicate that the adaptation procedure, which is mandatory after repair work and clutch replacement, is not always carried out at a service station during scheduled maintenance. Although it does not require any costs in the form of spare parts and takes a few minutes.

The reason for the malfunction of the robot box is most often the failure of the mechanics or actuators.

Convenience and comfort

Compared to a manual transmission, a robotic gearbox provides a greater level of driving comfort by relieving the driver of constant work with the gear selector lever and clutch pedal. Thanks to the electronic control system, which is not mechanically connected to the transmission, the noise from the operation of the box almost does not penetrate into the cabin. If necessary, you can switch to manual gear shifting. In general, the Lada robot box, according to reviews, does not like a harsh driving style and the concept is optimized for maximum comfort and smoothness when driving the car.

Reliability

The operation of the actuators is not satisfactory; reviews of the Priora robot box are consistent with the service life of the unit, according to the manufacturer, up to 10 years. They are designed for the entire life of the box. However, due to the absence of a mechanical connecting unit that controls gear shifting and disengaging the clutch, the overall reliability of the transmission has not increased. Its operation can be blocked by a broken unit, severe overheating or hypothermia. In the latter case, an insufficient battery charge signal may be triggered when energy consumers are turned on. Reviews of the Priora robotic box agree that cold regions require increased battery capacity and regular checking for loss of capacity.

"Lada Priora" robot

Reviews of the Priora on the robot confirm the reliability factor of the unit if you use a high-quality clutch (VALEO, SACHS, LUK, etc.) and regularly lubricate the actuators (after about 50,000 km).

Lada Priora

In manual mode, the gearbox shifts a little faster. But I prefer the smooth automatic mode - after playing with the switches a little, I return the selector to position A again. The box understands commands well. When you press the gas sharply, it quickly downshifts and holds the gear longer, allowing the engine to rev to maximum power. I tried to drive off on a hill, but it was easy, since on a slight slope you don’t have to hold the car with the handbrake. When you press the gas, the clutch closes quickly, but without jerking, and the car does not have time to roll away. For comparison, I drove a Citroen DS3. It was his box that was taken as a model when setting up the Priora “robot”. I didn't feel any difference.

ROBOT VS JATCO

The first of the VAZs to acquire automatic transmissions were the Granta and Kalina - a four-speed hydromechanical automatic transmission from Jatko. And the robot began to be installed on the Priora in September, and, apparently, for some time these two directions will develop in parallel. Both the robot and the machine have both advantages and disadvantages. Despite the modern control system and well-chosen settings, robotic mechanics with one clutch are difficult to compete with a classic automatic transmission in ride comfort. But the robot also has a trump card - it is more economical. And this is important for the buyer of a budget car. Let's see whose will take it.

Andrey Kochetov

Andrey Kochetov , head of the test group: - It’s no secret that all kinds of automatic and automated transmissions in passenger cars today are already noticeably more popular than “mechanics”. The issue of price, which is especially acute in the most affordable segment of the market. In our case, we found almost a panacea - a “robot” for an additional payment of only 20,000 rubles. Of course, active drivers who are already accustomed to pulling the manual transmission handle and, playing with the clutch, almost starting from a traffic light in their “swallows” with smoke from under the wheels, are not buyers for this “robot,” but others will be happy to give rest your left leg...

The main advantages and disadvantages of AMT on Priora

The robotic gearbox on the Lada Priora is a kind of hybrid, an intermediate option between a manual transmission and an automatic transmission. Accordingly, advantages and disadvantages arise from its design. The unit implements the “foolproof” concept, which completely eliminates accidental gear shifting, which can lead to sudden overload of the engine. Switching to manual mode allows the gear to be reduced by one speed, which protects the transmission and power unit from overload.

Compared to mechanics

Comparison with a manual transmission stems from differences in the gear shift and clutch drive mechanism. The disadvantages are associated with the imperfection of the actuating mechanisms of the switching unit. Reviews from owners of Priora with a robotic gearbox revealed the following advantages compared to a manual transmission:

- efficiency;

- reduction of noise in the cabin;

- reduction of vibrations of the gearshift lever;

- freedom of hands from constantly changing gears.

- limited service life of expensive imported actuators;

- jerks and slowness of gear shifting;

- failures when shifting gears.

Compared to hydraulic automatic

By comparing reviews of Priora owners about the robot and automatic transmission, one can identify the most obvious differences between them. Among the advantages of manual transmission are the following:

- efficiency;

- endurance to increased loads (bad roads, rough terrain);

- the cost of the unit and its maintenance is lower than that of an automatic transmission.

Gearbox comparison

- uneven shifting of 1st and 2nd gears;

- the need for periodic adjustment;

- problematic repair of actuators (replacement only);

- increased noise in high gears.

Design of a robotic gearbox AMT or VAZ 2182

The idea of creating their own automatic machine was nurtured by AvtoVAZ designers for many years, but they lacked the qualifications. Therefore, we decided to turn to foreign specialists again.

At first, negotiations took quite a long time with the famous Italian company Magneti Marelli, but the offer received later from the German concern ZF turned out to be much more profitable. As a result, AvtoVAZ management decided to equip the currently most modern domestic mechanics, the VAZ 2180, with electromechanical actuators from a German company.

A

— clutch actuator;

B

— gear shift actuator;

B

— clutch fork;

G

— speed sensor on the input shaft;

D

— control knob in the cabin.

1

— gear selector rod;

2

— gear shift drive;

3

— gear selection drive;

4

- electric motors.

1

— drive gear;

2

— clutch fork rod;

3

— wear compensator;

4

- compensation spring;

5

- electric motors.

The result was a typical robot with an electric drive of a single clutch disc. Such models were popular among European or Japanese manufacturers ten years ago. At the moment, almost all the leading automobile concerns in the world have long abandoned them in favor of an even more modern transmission: preselective robots with two clutches.

This issue of Good Mechanics is entirely dedicated to the very first domestic manual transmission.

Similar transmissions from other manufacturers:

WORD TO THE EXPERT

Vladimir PETUNIN, project manager for automated transmissions

An automated transmission is a budget design that is best suited for a low-cost car. Despite this, the main goal we set when creating the robot was to achieve maximum driving comfort and get closer in performance to more expensive and complex units. In my opinion, the team coped with the task perfectly.

PLUS A simple and inexpensive way to get rid of the third pedal and still maintain manual fuel consumption

MINUS Inferior to more expensive units in comfort and performance