From the very beginning of sales, AVTOVAZ has been installing a modified VAZ 2182 automated transmission (AMT with version 2.0) on the updated Lada Granta family. “Robot” received a number of improvements and new operating modes, which had a positive impact on user ratings. The article presents reviews from auto experts and owners of these cars.

Which models are equipped with an AMT gearbox?

This robot is installed on Lada cars only with 16-valve power units:

Lada

| Vesta sedan 2180 | 2015 - present |

| Vesta SV 2181 | 2017 - present |

| Vesta Cross 2180 | 2018 - present |

| Vesta SV Cross 2181 | 2017 - present |

| Granta sedan 2190 | 2015 - present |

| Granta hatchback 2192 | 2018 - present |

| Granta liftback 2191 | 2018 - present |

| Grant station wagon 2194 | 2018 - present |

| Granta Cross 2194 | 2019 - present |

| X-ray hatchback | 2016 - present |

| Priora sedan 2170 | 2014 — 2015 |

| Priora hatchback 2172 | 2014 — 2015 |

| Priora station wagon 2171 | 2014 — 2015 |

| Kalina 2 hatchback 2192 | 2015 — 2018 |

| Kalina 2 station wagon 2194 | 2015 — 2018 |

| Kalina 2 Cross 2194 | 2015 — 2018 |

DSG 7 Features and typical faults

The seven-speed DSG 7 robotic gearbox appeared in 2006. It was developed for engines with a torque of 250 Nm. One of the features of the box is the need for a minimum amount when changing oil for maintenance. So, if DSG6 requires 6.4 liters of oil, then only two are enough for DSG 7. Today, tens of thousands of Audi, Volkswagen, Seat and Skoda cars are equipped with this particular gearbox. It is not distinguished by its reliability and wear resistance, but it gives pleasure from driving characteristics in tandem with a turbocharged engine. The majority of car owners use cars with this transmission and have no complaints. In general, the reviews about the dsg 7 are both positive and negative, in a ratio of 50 to 50. Some are not satisfied with its twitchiness, while others enjoy the speed of switching.

Design of a robotic gearbox AMT or VAZ 2182

The idea of creating their own automatic machine was nurtured by AvtoVAZ designers for many years, but they lacked the qualifications. Therefore, we decided to turn to foreign specialists again.

At first, negotiations took quite a long time with the famous Italian company Magneti Marelli, but the offer received later from the German concern ZF turned out to be much more profitable. As a result, AvtoVAZ management decided to equip the currently most modern domestic mechanics, the VAZ 2180, with electromechanical actuators from a German company.

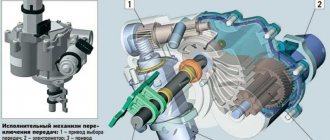

A

— clutch actuator;

B

— gear shift actuator;

B

— clutch fork;

G

— speed sensor on the input shaft;

D

— control knob in the cabin.

1

— gear selector rod;

2

— gear shift drive;

3

— gear selection drive;

4

- electric motors.

1

— drive gear;

2

— clutch fork rod;

3

— wear compensator;

4

- compensation spring;

5

- electric motors.

The result was a typical robot with an electric drive of a single clutch disc. Such models were popular among European or Japanese manufacturers ten years ago. At the moment, almost all the leading automobile concerns in the world have long abandoned them in favor of an even more modern transmission: preselective robots with two clutches.

This issue of Good Mechanics is entirely dedicated to the very first domestic manual transmission.

Similar transmissions from other manufacturers:

Pros and cons of “Grants” with automatic transmission

Both boxes have their advantages and disadvantages. The automatic is more reliable, but more gluttonous. The robot consumes less fuel, but driving the VAZ-2182 is uncomfortable.

Pros and cons of the robot

The outdated single-clutch design has many disadvantages:

- Lack of comfort. Gear shifting is not smooth enough. Owners of Granta with a robot complain about jolts during acceleration.

- Slow operation of the box. Speed changes occur with a delay.

- Unreliable, the service life with careful driving hardly reaches 200 thousand km.

- Afraid of slipping.

- When the movement begins, a rollback occurs.

- No rolling mode. The automatic movement implemented in the automatic transmission was loved by the townspeople. Standing in a traffic jam, the driver just needs to release the brake pedal, and the car begins to roll forward. The robot will not move until the gas is pressed.

The VAZ-2182 has fewer advantages than disadvantages. The electrically controlled robot itself is inexpensive, and the main positive feature is low fuel consumption. Servicing a manual transmission is almost the same as for mechanics. Repairing a robot is cheaper than rebuilding an automatic transmission.

Pros and cons of a hydraulic automatic machine

A positive feature of the JF414E is its reliability and simplicity of design. The automatic feels equally good on the highway and on a dirt road. Another advantage is the relatively small size and weight of the unit. The hydraulic automatic machine is easy to maintain without requiring large expenses. At an official Lada dealer, the automatic transmission cannot be repaired; in case of failure, the entire unit is replaced. A new JF414E box costs about 100 thousand rubles; on Avito and car dismantling sites you can buy a restored unit for 2 times cheaper.

There are few negative reviews about the operation of the hydraulic automatic machine. Some owners complain that the Lada Granta automatic transmission lacks fifth gear. They note higher fuel consumption than the Lada Granta with manual transmission.

Due to its age, a time-tested design also has a negative side - many modern engineering solutions do not fit into an outdated unit. The 4th mortar is thoughtful and leisurely in its work. The weakest component of the JF414E is the ECU board. The part does not tolerate power surges and is very demanding on the quality and temperature of the oil. Lada Granta with hydraulic automatic transmission cannot be skidded.

What operating features does the AMT robot have?

The robot has 4 operating modes, each of them has its own letter designation:

- neutral;

- reverse gear;

- automatic mode;

- manual mode.

In manual mode, the driver himself changes gears by swinging the control lever back and forth, while the automatic takes care of only pressing the clutch. But when the revs reach too high, the transmission will change gears on its own to save itself from damage.

What has been improved in AMT

The AMT upgrades of the new Granta are similar to those on the Lada Vesta with 1.8-liter engines:

- The main gear ratio has been increased from 3.710 to 3.940. This means increased fuel consumption, reduced noise and vibration levels in the transmission, and more dynamic acceleration.

- New AMT operating modes have appeared: creeping, sports and winter.

- AMT gear shift time has been reduced by almost a third.

- In the AMT clutch, the driven disc has increased heat resistance and the friction linings have become thicker, which, coupled with new algorithms, makes field driving more confident.

Disadvantages, breakdowns and problems of AMT

The robot inherited from the mechanics of the 2180 regular oil leaks from the seals. There is nothing much you can do; carefully monitor the lubricant level.

Sometimes the robotic box goes into a stupor and stops responding to commands. In this case, only flashing the control unit will help you.

Sometimes vibrations bother you when the clutch disc wears out at low mileage. Only replacement helps. In 2016, AvtoVAZ changed its supplier and the problem went away.

The following video will tell you in detail about the symptoms of sudden transmission overheating.

Gearbox selection

All types of gearboxes on the Lada have their advantages and disadvantages, but even the domestically assembled Grant gearboxes do not cause very big problems for car owners.

If we do not take into account the slight noise of the mechanical part of the transmission, then we can say that the “robot” and “mechanics” are quite reliable, without pronounced characteristic “diseases”.

For those who like a leisurely drive and comfortable driving, an automatic transmission is best; there is only one drawback - increased gas consumption.

Although the manual transmission whines, the noise does not particularly affect its service life; during normal operation, it can travel about two hundred thousand kilometers without problems.

The electronics in the robotic box sometimes malfunction, and you need to get used to the specifics of driving a car with AMT.

Which transmission to choose for the Lada Granta is a personal matter for each motorist; a lot here depends on the preferences of the driver himself.

Lada cars with AMT reviews from owners

Most often, owners of cars with such a manual transmission complain about delays or jerks when switching. They are especially noticeable when driving in city traffic or when starting up a hill. Sometimes this robot generally behaves inappropriately, sometimes it will drop several gears for no reason, sometimes, on the contrary, it drives for a long time and strainedly at high engine speeds, without even intending to shift.

The second inconvenience is the lack of a rolling mode, as on a hydromechanical automatic transmission, which is so convenient in traffic jams. When a car slowly crawls in automatic mode, after releasing the brake pedal, everyone expects that they will move on, because the gearbox is in gear. But no, you need to press the accelerator. Update: version 21827 received a rolling mode.

The deceased LADA Priora was elevated to cult

AVTOVAZ is preparing for the premiere of the economical LADA Largus.

In the center console there is simple music with a USB connector (alas, even in the top version of this budget car we will not find multimedia with an LCD screen) and a climate control unit in the cabin. If we look even lower, then under the dashboard we will find a niche for all sorts of small things, a cigarette lighter socket and two cup holders.

Although, in all honesty, calling two round recesses cup holders is hard to come by. Objectively, a standard cup of coffee bought at a gas station fits in here with a big stretch, but a half-liter plastic bottle of water fits in without comment. Apparently, such containers inspired the creators of these pseudo-cup holders to perform a feat.

Price of VAZ AMT robotic gearbox

It is very difficult to buy a new or at least used manual transmission 2182 at this point in time, just as there are practically nowhere qualified specialists for repairing such transmissions. Therefore, owners of out-of-warranty cars with a robot are left with a large-unit replacement.

The cost of spare parts for restoring the VAZ 2182 or AMT robotic transmission:

| Box VAZ 2180 | RUB 38,450 |

| ZF gear shift actuator | RUR 56,643 |

| ZF Clutch Actuator | RUB 35,756 |

| Large-unit replacement work (on average) | RUB 9,350 |

The price of parts for just such a box is briefly discussed in this review.

You can contact the site administrator by email: [email protected]

All texts were written by me, are authored by Google, included in the original Yandex texts and notarized. For any borrowing, we immediately write an official letter on company letterhead in support of search networks, your hosting and domain registrar.

Next we go to court. Don’t try your luck, we have more than thirty successful Internet projects and have already won a dozen lawsuits.

Impressive result of good work

As a result, we can come to the conclusion that the VAZ team managed to create a good “robot”. What is especially impressive is that the project initially included unification, allowing the design to be quickly adapted to a number of models. The new AvtoVAZ product is in no way inferior to its analogues. From what is known, no unit with a “robot” has such elastic and smooth operation of the power unit.

Therefore, the “traditional” Jatco “automatic” has been replaced by a new product. This happened because VAZ’s “robot” is really quite good and is capable of satisfying the needs of the most demanding drivers. But the partnership with the Japanese continues, because it is necessary to give potential buyers maximum choice.

Today, cars equipped with automatic transmission and automatic transmission practically do not differ in price. But a price increase is coming for currently inexpensive Japanese-made automatic machines. After all, automatic transmissions are imported from Japan complete with a cooling system and require Japanese wheel drives. For AMT, everything was developed at AvtoVAZ. The only exceptions are actuators, control unit and selectors. The difference in price between a manual transmission and a “robot” is only 20,000 rubles. Jatco, even without taking into account drives and cooling, costs more than twice as much as a “robot”.

Test drive Lada Granta liftback with AMT robot

The other day we took a test drive in a Lada Granta liftback equipped with an AMT robot. Feedback and impressions are in today’s material.

Granta in the liftback body immediately after its appearance caused mixed opinions. Some people didn't like its design, others didn't like it. Indeed, the rear of the car has changed significantly. Compared to the Grant sedan, the liftback looks a little more modern and fresh. In addition, in this body the car does not look as bulky as a sedan.

To be honest, in the modern AVTOVAZ line, this liftback looks very good. Unlike the sedan, many minor “sores” and childhood illnesses were improved on the liftback. For example, doors open and close with much less effort and noise, thanks to new closers. Hooks for attaching bags appeared in the trunk, plastic cables for securing the rear parcel shelf were replaced by elastic laces that do not burst in the cold, etc. The combination of these changes creates a more pleasant perception of the car.

The trunk volume of the Lada Granta liftback is a good 440 liters, and with the rear seats folded it reaches 760 liters. This is where the main advantage of the liftback body manifests itself - the large tailgate opens completely and makes loading and unloading easy.

The interior design is exactly the same as on a sedan - everything is simple and without frills, the usual interior of a budget car. Naturally, the interior also depends on the configuration - the base will not have a large LCD monitor and other goodies.

Under the hood of the test car there is a 106-horsepower 16-valve engine paired with an AMT robot. Behind this abbreviation lies an ordinary robotic gearbox, which is successfully used by many manufacturers. This is a simple and cheap solution, popular in the budget segment. “Robots” with one clutch were installed on some models of Peugeot, Renault, Toyota, etc.

In the cabin, instead of a gearshift lever, an AMT selector is installed, and there is also no clutch pedal. The selector has a neutral, forward, reverse, and manual mode. Unlike a traditional automatic, the AMT does not have a “Parking” mode; the car must be left in neutral when parked or turned off while the gear is engaged. This is one of the disadvantages of the Lada Granta with AMT - in winter, after washing the car, in order to avoid freezing of the pads, you will have to leave it with the gear engaged and without a handbrake, which will not allow you to use the automatic engine start.

Another disadvantage of AMT on the Lada Granta is maneuvering in a parking lot. The fact is that when the brake is released, the car does not start moving, like a classic automatic. In order for the car to move, you need to increase the speed of the gas pedal. Sometimes this causes shocks when maneuvering forward and backward in a parking lot - you need to get used to it.

Oh yes, the robot won’t go without warming up either - when you try to start in winter, immediately after starting the engine, the car does not react in any way to turning on the driving mode and pressing the gas. But a couple of minutes after launch - already please.

On the move, the Lada Granta behaves like a typical car with a robot. Here you won’t be able to just drive and not think about anything, like in a car with a conventional automatic transmission. You need to understand that a robot is the same mechanics that is simply switched not by a person, but by electronics. Therefore, between switching there is a noticeable pause, and sometimes even a noticeable “peck”. However, there is a trick here too. After a while you begin to intuitively feel the moment of gear shifting. If you slightly release the gas pedal before doing this, the switching occurs very smoothly and quickly. Much better than many manual drivers switch.

Another nice feature is that if you press the gas to the floor, the robot in each gear allows the engine to spin up almost to the red zone of the tachometer, and then quickly switches to the next speed. There is also a manual shift mode: if you need to accelerate sharply, you can downshift manually. This is useful, for example, when overtaking on the highway.

In general, Granta and the robot have both disadvantages and advantages. But in terms of price, the robot will cost the buyer significantly less than a classic machine. In principle, it’s a pretty good alternative for those who are tired of working with the clutch and gearshift lever, but don’t want to overpay for an automatic.

Popular rumor is a scary thing. Take robotic gearboxes, for example. The amount of knowledge about them among the population is approximately the same as that of teenagers about intercourse: someone has heard something, someone knows something about how, where, and most importantly - why, but few have seen and understand what it is. actually.

Judging by forum remarks from buyers and even reviews from less experienced colleagues, few people like the VAZ AMT the first time: it doesn’t know how to do it, it doesn’t do that, it’s unlucky... How could it be otherwise if you don’t know what to eat it with?

The “robot” cannot be approached as a classic AT. It's not AT because. In essence, this is the same mechanics, only the closing and opening of the clutch discs is controlled by automation. In classic ATs, instead of a clutch, torque goes to the drive axle through a torque converter. That’s why the operation is a little smoother than that of the RT, but a considerable part of the power is lost in the torque converter fluid. This is especially true for cheap boxes of this type.

Automatic transmission from Renault: torque converter, a bunch of gears, extra weight...

A robot is an intermediate thing. When you want two pedals, but also save money. And not only for the buyer, but also for the manufacturer. And so it happened: the AMT box was made on the basis of the old VAZ mechanics: specialists from the German ZF attached actuators to it (the same ones that control the clutch engagement). Therefore, the work was done very quickly.

Automatic transmission

“Automatic” was installed on the car of the Togliatti Automobile Plant from July 2012 to March 2015 - this is 4 speed. Automatic transmission from Japanese manufacturer Jatco.

Grant's four-speed automatic transmission - model JF414E, classic type, with a torque converter; similar units are equipped in Nissan, Mitsubishi, and Suzuki passenger cars.

This type of transmission on Granta is paired only with the 98-horsepower VAZ-21126 power unit.

The gearbox is highly reliable; with careful operation and timely maintenance, it can run up to 200 thousand km.

It is necessary to replace the transmission fluid every 60 thousand km; the manufacturer recommends filling with Nissan branded ATF EJ-1 or Matic-S oil.

Automatic transmission problems.

The quality of the Lada Granta automatic transmission does not cause any major complaints; if the transmission requires repair, it is mainly due to the fault of the driver:

- as a result of slipping, the clutches burn out;

- after overheating, gaskets and seals begin to leak;

- When you hit an obstacle, the automatic transmission pan breaks through, and then a thorough repair is definitely required.

Car owners have more complaints about the performance characteristics of an automatic transmission - increased fuel consumption, sluggish acceleration of the car, jerking during gear changes during dynamic driving.

Lada Granta AMT: conclusions and performance characteristics

| We like | widespread work on bugs; new rear view mirrors; a domestic robot that is better than Opel’s and Toyota’s. True, mid-2000s. |

| We do not like | nostalgic communal crampedness |

| Data is given for Lada Granta AMTc with 1.6 engine and MT | |

| Engine | petrol |

| Number and arrangement of cylinders | 4 in a row |

| Working volume, cm³ | 1 596 |

| Max. power, hp | 102/5800 |

| Max. torque, Nm | 148/4000 |

| Drive unit | Front |

| Transmission | robotic, 5-speed |

| Front suspension | independent, with McPherson struts and anti-roll bar |

| Rear suspension | semi-independent, lever, spring |

| Front brakes | d claims |

| Rear brakes | drums |

| Maximum speed, km/h | 180 |

| Acceleration time sec. | 12,3 |

| Dimensions, mm | |

| length | 4 260 |

| width | 1 700 |

| height | 1 500 |

| wheelbase | 2 476 |

| ground clearance | 160 |

| Curb weight, kg | 1 075 |

| Tires | 175/65 R14 |

| Trunk volume, l | 520 |

| Fuel consumption, l/100 km | |

| urban cycle | 9 |

| suburban cycle | 5,2 |

| mixed cycle | 6,6 |

| Fuel tank volume, l | 50 |

We thank AMK-Ekaterinburg for the test car. Text: Kirill Zaitsev Photographer: Nikolay Kovalevsky Illustrations, graphics: Jatco, Renault, Lada, archive 66.RU

Roskomnadzor killed the Telegram bot 66.RU. Subscribe to the backup channel.

Pre-production tests

However, the Granta, equipped with an automated manual transmission, is now on the agenda; sales begin in February. To approach this date fully armed, a number of tests were carried out. One of the pre-production cars immediately went to Germany so that AvtoVAZ's partners from ZF, for their part, could conduct their own tests and allow the car to be put into production.

Starting with the Priora platform, cars have undergone a huge number of tests in various climatic zones and under a variety of programs. Tests took place in the Alps and Altai mountains with the participation of partners from Germany, at low temperatures reaching -55°C, in the Far North in Surgut. Speed tests were successfully carried out at the Porsche test site with humidity of almost 100 percent and temperatures exceeding +30°C. These tests were followed by accelerated road tests of 80,000 km and 100,000 km. Difficulties that arose during the testing process were resolved promptly, quickly and professionally.

The new gearbox is a product of Russian engineering, since the burden of solving most of the problems fell on VAZ’s shoulders. Engineers from Russia have demonstrated that their level is not inferior to the quality of engineers in the best European companies.

In general, the design of the new box consists of 80% Russian parts, and this says a lot.

Even during the period of joint work with the Germans on adapting the gearbox for the Priora, it was VAZ engineers who managed to quickly achieve smooth switching, which other companies cannot achieve for a long time. It is difficult in foreign boxes and with quick engagement - the transmission resource is insufficient.

An important advantage of the VAZ AMT is the ability of the system to adapt to the driver’s driving style - both calm and aggressive driving is possible. What else distinguishes the box from a traditional automatic transmission: at -40°C outside, the box makes it possible to start moving as soon as the engine is started. But fuel economy is, of course, the biggest plus.

Description of soil thermometer AMT-5, AMT-5A

The operating principle of AMT-5 thermometers is based on remote measurement of soil temperature using contact temperature sensors (DT). Analog signals from sensors are converted into digital form by measurement and registration units (MUR) and transmitted to the information reading console (PRI) for processing, display and storage. The principle of measuring the temperature of contact sensors is based on the dependence of the resistance of a platinum thermosensitive element on temperature.

Structurally, the AMT-5 thermometer is made according to a modular principle.

Temperature sensors are installed in the soil at the required depths and connected by cables to the measurement and recording units BIR1 (7 contact temperature sensors) and BIR2 (4 contact temperature sensors). Measurement and registration units of IIR are installed at the meteorological site in protective cabinets. Inside their cases there are measuring controller boards with built-in software (software). The measurement and registration units are connected by a communication cable to the information reading console located in the weather station premises. Structurally, the remote control is made in the form of a portable device, on the outer panel of which there is an indicator and a keyboard, and inside the case there is a controller board and backup batteries.

After turning on the power, the AMT-5 thermometer operates in the mode of automatically measuring soil temperature at specified synoptic times. The measured information is stored in the remote control memory, can be displayed on a digital indicator or transferred to the user’s personal computer for further processing.

The AMT-5 thermometer has a modification AMT-5A

, which consists of ten BIR-A measurement and recording units with one temperature sensor each and a PSI information reading panel. BIR-A blocks are attached to a communication cable and form a thermal garland for measuring soil temperature in wells.

Main problems of DSG7 - video

Weak points of mechatronics

The weakest points are the mechatronics and clutch.

DSG 7 - disadvantages

There are car enthusiasts who are not 100% satisfied with the performance of this transmission. What could they not like and what problems arise in the DSG ?

Is the DSG7 gearbox that good?

— The appearance of jerks and vibrations in the DSG when changing gears. This drawback is caused by the fact that DSG clutch begins to wear out. The result is the same effect if you do not depress the clutch pedal when changing gear in a car with a manual transmission. In a word, the vibration spreads throughout the entire body, depending on the state of the clutch, and progresses until the gearbox completely fails.

— Extraneous noises under the hood. Mainly metal parts when driving over speed bumps.

— Reduced traction when accelerating the car. This problem is known to the developers and they promise to fix it soon.