For the normal functioning of the front suspension and turning mechanism, VAZ-2110 ball joints are used. Every driver should know which ones are best to install. In stores, the assortment is presented by at least three companies, and prices vary significantly.

Therefore, you need to evaluate the quality of products from each manufacturer in order to purchase a good part that will last for several years. Unfortunately, not every ball joint is able to withstand the loads that affect the car and its suspension when driving on roads.

Which ball joints are better for a Priora - Replacing a ball joint on a Priora - faults, analogues, standard part

| Place | Name | Characteristics in the rating |

| The best foreign manufacturers of ball joints |

| 1 | Lemforder | The largest margin of safety |

| 2 | Delphi | Extended service life |

| 3 | CTR | The optimum ratio of price and quality |

| 4 | TRW | The widest range |

| 5 | Sidem | Buyer's Best Choice |

| The best domestic manufacturers of ball joints |

| 1 | Cedar | Best domestic manufacturer |

| 2 | TRACK | Longest service life |

| 3 | BZAK | Best price/quality ratio |

| 4 | BelMag | Affordable price |

Ball joints are one of the most important components of a car, because a sudden failure of the joint can create an emergency situation on the road. This is exactly the detail on which it is completely impractical to save. Our review presents manufacturers who produce balls with the best performance characteristics. All of them are distinguished by their endurance, reliability, and have a longer service life compared to products not included in our rating. Brand positions are based on manufacturer claims and reviews from direct owners who have had the opportunity to personally experience the performance of these ball joints.

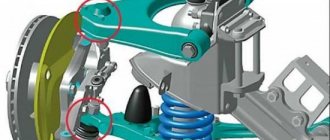

Design

First of all, you need to know the differences between upper and lower ball joints. The first are cast-in-place structures that work in compression - they are subjected to light loads, which results in a long service life. Lower ball joints are most often created on the basis of sintered metal bearings, which allows them to withstand shock and tension. Most experts strongly do not recommend saving on lower ball joints, since they often fail with very serious consequences.

Lower ball joint

To understand how to choose a ball joint, you also need to know about the fundamental differences between the designs of these units. The most common production method is the sunset production method - it allows you to obtain very high strength at a relatively low manufacturing cost. However, it cannot withstand very large shock loads - therefore, if you frequently drive with a heavy load on a bad road, it is worth regularly checking the condition of such front suspension components.

About a third of ball joints produced in China, Russia, Turkey and Poland use a stamped-welded design. It allows you to get by with minimal costs and significantly reduces the weight of the part, but has rather low strength. It is recommended to install such ball joints only on small cars with minimal loads on the chassis, and even in this case they should be replaced every 25–30 thousand kilometers.

The best option used by American and Western European manufacturers is solid forged ball joints. They are very strong and can withstand loads of more than 5 tons without breaking. Despite their high cost, they are popular due to their long service life.

BZAK and FENOX

The design feature of the element produced by BZAK is a forged all-metal body. Due to this, the hinge has high strength; it is almost impossible to tear the finger out of the holder. Ball joints have very high resistance to loads acting in the vertical plane. The VAZ-2110 ball joint race is very strong and does not collapse during long-term use.

FENOX produces various models of ball joints for front-wheel drive VAZ cars - rolled, stamped, solid forged. The body is maximally reinforced, so it can withstand heavy loads when moving. But, according to reviews from car owners, this manufacturer does not shine with quality, despite the fact that the passport indicates such good characteristics.

Most modern cars use ball joints to turn the wheel. Previously, in some models, in particular domestic ones, the task of maintaining the entire suspension was also assigned. Due to the high degree of wear and tear during such operation, leading manufacturers abandoned such designs. Ball joints, even without additional tasks, are subject to very serious strength requirements. In addition, they must have a high coefficient of friction of the liner. This characteristic allows you to significantly increase the service life. The liner must be made of high-strength material and, thanks to the nuances of its design, retain lubricant. Another important element is plain bearings.

The quality of the support depends on its design, manufacturing technology and materials used. The hinges, serially installed on the AvtoVAZ assembly line, most fully meet the technical conditions and GOSTs. Ball joints come in two types: filled and with sintered metal bearings. The first ones work mainly on compression and are installed as upper ones on front-wheel drive cars, as well as on classic models - from “kopek” to “seven”. The second ones work in tension and are used as lower ones. The design also differs accordingly. A characteristic external feature of the lower support is the presence of an oval hole for the finger. This solution (if the required swing angle is provided) allows you to increase the contact area of the bearing with the housing.

How to choose spare parts?

You can use parts designed for installation on all front-wheel drive models of the ninth and tenth VAZ families. Here are the requirements for parts and their features:

- On new supports the pin should be made of hardened steel. The color of the metal is gray, scale may be present. Be sure to make sure there is no paint on it. The thread of these products is rolled.

- The body is made of two halves. Please note that the welding seam is visible only on one side.

- When scrolling, you need to apply a lot of effort. Make sure there is no snacking. This is the first sign that the part is of low quality. It is impossible to manually scroll on new products, so you need to use a crank. This indicates that the product is of good quality.

- It is best if the ball joint comes with a boot and a nut. If it turns out that these components are missing, it is better to choose another option.

- There are a lot of manufacturers of these elements, but, as a rule, there are three on sale - “Trek”, “BelMag” and “Trial-Lux”.

Which ball joints are better for the VAZ-2110 is up to you to decide. But if you have to choose from the above trinity, then they are approximately the same in quality.

The most common causes of failure of VAZ 2114 suspension elements

Before starting repair work, the workshop technicians recommend conducting a comprehensive diagnostic of the car in order to study the general condition, identify faults, and correctly calculate the number of spare parts and consumables. A preliminary inspection will help to accurately determine the location of the fault and identify the defective part.

The self-diagnosis process is not at all complicated; the presence of special equipment and tools is not at all necessary. Standard car key set, enough crab remover. It is extremely difficult to squeeze out a metal tip without a puller.

Step-by-step diagnostic process:

In good condition, there should be no sounds, creaks, or extraneous noises. Otherwise, the disks must be replaced with new ones.

The manufacturer in the operating instructions indicates a maximum free play of the ball pin of 0.8 mm. It is impossible to check the permitted space without special equipment.

In parallel with the diagnosis and replacement of suspension elements, we inspect the steering knuckle, hub, thrust bearing, and brake caliper. We evaluate the general conditions and make a decision to replace worn parts.

Since the work is carried out near the shock absorber and springs, we check for oil leaks and depressurization of the shock absorber cylinder. Finally, we diagnose the support bearing located in the engine compartment.

Check it seven times...

Unfortunately, Russian sellers are not always honest with their customers - there are cases of selling outright defects or fakes in original boxes. Therefore, when purchasing, you need to not only look at the beautiful packaging with a familiar logo, but also check how well the ball joints work.

Take them out of the box and try to spin them - they should rotate with noticeable force, but not lock up or slip in certain areas. If the seller claims that you will receive solid forged parts, pay attention to their body. It should not contain welds or a sloppily rolled flange - otherwise you are looking at cheap ball joints with low strength and short service life.

Which one is better to buy?

When purchasing a new part, the following components are considered mandatory: a protective cover, a retaining ring, fasteners, and lubricant. Reviews from car owners are unanimous that it is better to take a complete set so as not to have to buy additional parts.

It is worth choosing the best ball joint companies that produce certified products that are not inferior in quality to the originals. And you shouldn’t skimp on this issue, as cheap spare parts become unusable faster, becoming a safety hazard.

Required tools and materials for replacement

To replace ball joints on a Priora with your own hands, you will need the tools from the list below.

Table - Tools and materials required to replace the ball joint.

| Name | Note |

| Jack | To lift the car |

| Mount | Can be replaced with a durable rod |

| Hammer | Medium size |

| Spanners | "at 17", "at 19" |

| Socket head | TORX E12 |

| Vorotok | Preferably with a ratchet |

| Balloon wrench | For mounting and removing the wheel |

| Grease | Special for CV joints or graphite |

| Penetrating lubricant | For example, WD-40 |

| Rags and wire brush | To clean dirt |

| prop | It is prohibited to carry out repair work on a vehicle that is only supported by a jack. |

A set of tools needed to replace the ball joint

Source

Lemforder

The products of this company are made from high-strength materials using special technologies, which together reduce the occurrence of defects to zero. There are several factories of the company; manufacturers of ball joints in Germany and the European Union are considered the highest quality. The reason is that factories in other cities use materials with a lower safety margin.

The support, fasteners, nylon liner, retaining ring and boot are included as standard equipment. The kits from some factories do not include fasteners and a ring. These missing items can be purchased at the car market.

Under the manufacturer's warranty, the ball joint will last a year, with a minimum mileage of 60 thousand km. With desire and simple skills, you can extend the life of the hinge up to three years.

Positive features:

- Long service life of parts due to safety margin;

- Possibility of selecting parts similar to the originals;

- Logo and barcode for counterfeit recognition;

- No marriage.

Negative features:

- Lack of a locking ring in some configurations;

- Parts from non-European countries are of low quality and often counterfeit;

- There is an urgent need for special lubricant.

Igor, auto mechanic, 10 years of experience

I have been repairing cars for many years. Replacing ball joints is a common occurrence in our region. I recommend the Lemforder brand to my motorists. This applies to both ball and steering joints. After replacement, rarely does anyone return with repeated complaints. On my car, the mileage is 330 thousand km, at 145 thousand I installed Lemforder, still no knocking or squeaking. The main thing is to buy the original and add lubricant, there is a minimum of it from the factory.

Ball joints for VAZ (Lada) Priora

for repair of VAZ (Lada) Priora

I bought it for a Priora and changed it in September. The creaking on the right started after 3-4 months. Then there is a creaking on the left side, then a knock on the right. In general, I didn’t really start to trust these supports. I called the Lem-er hotline and they said that they do not bear any responsibility, contact the store. It is unlikely that I will order spare parts from this manufacturer from now on. I didn’t perform any additional manipulations, didn’t remove the boot, didn’t add any lubricant.

Comments on the review

After the replacement, less than 10,000 miles passed and the spare part was trash. I will no longer buy parts from this manufacturer.

I just wanted a pair with CEDAR trial fittings. Somehow they looked worse.

Belmag is still ok. And a Chinese thing with a German name like HÖFER or KRAFT is still crap.

When I changed the suspension 4 months ago, I changed the balls to my misfortune, but to my misfortune, I took the untested ones to see, this miracle only lasted for 4 months, SCHAEFFLER, I don’t recommend it at all.

I changed the support bearings separately and took new support bearings assembled (Belmag). They didn't stay with me for long.

I had cedar that was over 80 years old, and it was replaced with a living one, with the same cedar when I changed the stands. No complaints.

Top brands

For domestic equipment

Number one among manufacturers of ball joints for Russian cars is the Kedr company, which focuses on the production of solid forged parts. The declared service life reaches 75 thousand kilometers, depending on the specific model. Customer reviews show that such figures are quite justified. Only a few motorists claim that they changed the Kedr ball joints after 30–45 thousand kilometers. There are also reviews about a service life approaching 100 thousand kilometers.

If you need to find out which ball joints are better for a Chevrolet Niva, it is better to give preference to products from the Magnitogorsk concern BelMag. The main feature of such parts is that they are supplied pressed with anti-friction lubricant, which allows them to be installed without further processing. Ball joints of the budget series last 40–50 thousand kilometers, and reinforced products called Champion last up to 70 thousand kilometers. Customer reviews confirm the correctness of the specified parameters. However, you should be wary of counterfeits - cheap parts that have not undergone basic heat treatment are often sold under the guise of BelMag products.

For fans of extreme driving, ball joints from the Trek production association are offered. The “Champion” model is made from the most durable materials and has a unique design that prevents damage to the part under the highest impact loads. Thanks to this, the manufacturer specifies a service life of the support of 60 thousand kilometers, regardless of operating conditions. Consumers claim that the high price of such components is completely justified - they really do not create any problems during operation. However, the problem with counterfeits is also relevant for ball joints from this manufacturer.

For foreign cars

The rating of ball joints for foreign cars included the most famous world manufacturers - in this case, dealing with unknown brands is dangerous, since the consequences of a breakdown may require repairs costing more than one thousand dollars. The best option for European cars are Febi ball joints, which are manufactured exclusively using solid forged technology.

You can also expect long life when purchasing products from Delphi and Moog. To save money without losing quality and safety, you should give preference to Mapco products. Experts recommend paying attention to ball joints from the following manufacturers:

- TRW;

- Sidem;

- Fenox

Japanese manufacturers recommend purchasing products from other suppliers, although most of the brands mentioned above also produce spare parts for cars from Asia. Nipparts ball joints are considered the best option for Japanese cars. The company’s products with the simple name 555 also earned praise from consumers.

Ball joints manufactured by Nipparts or JapanCars are also in good standing with experts and ordinary motorists. Far Eastern stores offer exclusively high-quality Masuma brand products, but they practically do not reach the European part of Russia.

A fundamentally different approach must be taken with American cars - since Americans prefer large and heavy cars, reinforced components are offered for them, including ball joints. Most manufacturers do not allow the use of third-party parts in the chassis, but sometimes there is simply no other choice. Experts agree that for American-made cars it is better to purchase products made by Ruville.

In second place in terms of reliability were the products of the Hanse company, and only then - the parts of the above-mentioned companies Febi, TRW, Sidem, Delphi. When purchasing ball joints for a fairly large foreign car with a complex chassis design, remember that using products from the same manufacturer that offers parts for Kalina will not work - in this case, greater strength and the ability to withstand enormous loads in any conditions are very important.

How to check a ball joint on a Priora

So, to make sure that the support needs to be replaced, it needs to be checked in several simple ways. Jack up the wheel and, placing your hands on the top and bottom points of the wheel, try to shake it. If you feel play, the ball joint may be faulty. Also, the cause of play may be the tips or stabilizer struts.

Another way to check is to drive into an inspection hole or overpass and use a mount or pry bar to check the ball play. Place the pry bar between the ball and the lever and try to shake it. A faulty ball will play easily, which indicates either high wear or lack of lubrication.

Signs of a bad ball joint

In order to accurately verify the malfunction of the ball joints, you must contact either specialists or independently, according to the instructions indicated above, carry out inspection and diagnostics. If during a visual inspection you find that the boot on the ball joint is torn, this basis is sufficient to replace it. Because dust and dirt get on the ball pin, mix with the lubricant and it fails.

Article number and price for the original ball joint

The original ball joint of the Lada Priora car has article number 21082904185. The price for the product varies from 150 to 420 rubles. The quality of auto parts varies from batch to batch.

Ball joint for Priora

When purchasing an original product, special attention should be paid to the presence of lubricant under the boot. In some cases it is completely absent. Such a ball can last no more than a couple of thousand kilometers.

Which ball joint to choose for Lada Priora

Today, a fairly large selection of balls is offered, from Chinese to conveyor and even reinforced ones. The choice is up to the buyer.

The most expensive conveyor ball joints are from the BELMAG company; also in terms of price, the ball joints from ASOMI, which also produces front and rear struts, as well as support bearings, stand out.

Article number and cost of ball joint analogues

There is a constant debate among car owners about which ball joints are best to install. Some drivers believe that original parts are optimal in terms of price to reliability ratio. Other owners claim that the instability of the quality of their original balls completely eliminates the possibility of purchasing them. They advise buying analogues from third-party manufacturers, especially since the cost of non-original components is quite attractive. According to driver reviews, below is a list of pole brands that they recommend as an alternative to the original.

Table - Good analogues of the Lada Priora ball joint.

| Manufacturer | vendor code | Approximate cost, ruble |

| Delphi | TC583 | 340-400 |

| Denckermann | D110112 | 210-250 |

| Teknorot | L303 | 230-280 |

| Lemforder | 1545602 | 420-500 |

| TRW | JBJ156 | 445-490 |

Detailed manual for replacing ball joints

We will need 17 and 19 mm wrenches, preferably socket wrenches so as not to tear off the nuts, WD40, a ball joint remover, and a hammer.

So, jack up the car, put stops under the rear wheels and remove the wheel.

Next, using WD40, we spray the bolts securing the ball joint to the lever and the ball joint nut itself so that there is no difficulty in unscrewing them. Let’s wait a few minutes until they “dissolve” and get to work.

Using a 19mm wrench, unscrew the ball joint nut and a 17mm wrench to unscrew the nuts securing the ball joint to the lever.

Now we need a ball joint remover, it can be of several types, the principle is the same - remove the ball joint from the lever.

We take a new ball joint and, for our own peace of mind, check the grease under the boot. Carefully remove it and check - if there is no grease, fill the boot with Litol or similar grease. Be careful not to damage the boot.

Now install the new ball in the reverse order. You will have to tinker with the installation when screwing the ball to the lever.

We advise you not to install cheap balls of questionable quality, as they will affect the performance of the suspension and handling in general. A good option for ball conveyor BELMAG or TRACK.