The engineering staff of any automaker carefully calculates the compatibility and ability of the vehicle to withstand the design loads for all systems. A vehicle of the declared weight and dimensions must satisfy its technical characteristics, dynamic and load-carrying parameters. One of the most critical parts is the wheel hub, which bears at least 25% of all permanent, long-term and short-term loads that act on the car. This is how the wheel bolt pattern parameter is created.

Disc radius options

The cars were equipped by the manufacturer with R13 wheels, which combine technical and operational convenience. They were appreciated by owners who value the attractiveness and practicality of driving.

But if you want to update the appearance of the car and make it as solid as possible, it is recommended to pay attention to R14-15 and even R16 wheels, while providing the corresponding technical advantages.

Due to the fact that manufacturers have tried to carefully study the design features, car enthusiasts can count on ease of use in accordance with the established rules. Even a large radius will look perfect and will not cause a violation of the technological features of the vehicle.

But, as practice shows, it will be difficult for an inexperienced driver to drive a car on large rims, so it is recommended to gradually switch to them so as not to encounter operational inconveniences.

This is interesting: What size tires are on Mazda 6

How to choose wheel bolts for alloy wheels? There's an answer!

Some may think that wheel bolts do not play any important role, so you can buy the first ones you come across and install them on your car. However, not everything is so simple, and these bolts are not so unimportant, but quite the opposite. After all, think about it, they fasten the wheel, or rather wheels, and without reliable fastening, as you understand, there can be no talk of any traffic safety. And this is a serious sign of problems on the road.

Technical specifications

The choice of disks is based on technical parameters that are important to consider for safe use in subsequent operation. Experts have formed basic technical standards that are important to adhere to when choosing disks in order to avoid operational inconveniences:

- The number of mounting holes and their circumference diameter is 4*98.

- Hub diameter is 58 mm.

- The most suitable disk size is 13-15, but the 16 radius refers to non-standard variants of a special design.

- Reach – 15-30 mm.

- The most suitable disc width is 5-6 mm.

- M12*1.25 bolts are suitable for fastening the wheels.

These are technical recommendations, but depending on the specifics of the tires and the individual needs of the buyer, wheels are also selected.

Wheel alignment

After replacing wheel rims, the dimensions and bolt patterns of which differ from those provided for by the design of the VAZ 2110, it is necessary to make all the necessary adjustments in order to ensure reliable protection of the entire chassis, as well as tires and arches.

Correct alignment angles are required for each front wheel. There are three parameters that require correct installation: wheel toe, caster angles of the steering axles, and camber angles of each wheel.

Wheel installation options

The rules by which the parameters of the front wheel are set are as follows:

- You won't go far if everything hangs out the way it wants, and the car is pulled to the side when it should be going straight. To ensure the stability of each front wheel, they are installed strictly at the required angles to the body and suspension elements. This is called the longitudinal inclination angles of the turning axis. Installation dimensions are indicated in the instruction manual;

- Camber is the angle between the plane in which the wheel rotates and the vertical. The camber bolt helps install it (it secures the telescopic strut and steering knuckle). If the camber is installed incorrectly, the car “steals” and the tire tread wears out more on one side;

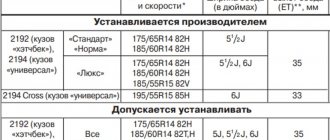

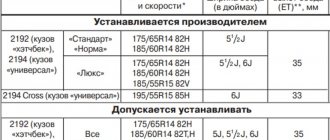

What wheels were installed on different bodies and configurations?

Initially, the VAZ-2106 car was conceived as a modernization of the VAZ-2103, which included getting rid of various “excesses” and bringing some parameters to European standards of that time. In total, since 1976, 7 modifications of the domestic “six” have been produced.

But none of these transformations affected the assembly line equipment with car wheels. The VAZ-2106 was always factory-installed with the most budget-friendly 13-inch stamped steel wheels with the following parameters:

- 4.5JX13ET37;

- 5JX13ET

4.5J and 5J are the width (inches);

13 – diameter (inches);

ET – disc offset size in mm.

Options with wider 13- and 14-inch wheels were considered as an acceptable replacement. Equipping the wheels with only the smallest diameter and most inexpensive steel stampings was caused not by the design features of the car, but by the desire to reduce the financial costs of production.

Stamped steel wheels are durable, repairable and low cost. But this is where the list of their advantages ends. If we compare dies with cast or forged lightweight specimens, then we can only talk about some shortcomings.

The result of replacing with lightweight versions of products is improved handling and reduced fuel consumption. But you shouldn’t make a replacement just for the sake of replacing it. Improper implementation can later turn into a real problem.

General background information

Ranges of possible values for tires and wheels of VAZ 2106 Zhiguli 1990.

Tires

| Diameter | 0″–14″ |

| Width (mm) | 155–185 |

| Profile (%) | 0–70 |

| The smallest size | 155/0 R0 |

| The biggest size | 185/60 R14 |

Wheel disks

| Diameter | 13″–14″ |

| Width (inches) | 4.5–6 |

| Reach (mm) | 29–37 |

| Drills | 4×98 |

Photo

Expert advice

When choosing tires for a car, you must first follow the manufacturer's instructions. Ask yourself a few questions.

- On what roads will the car be primarily used?

- Do you need increased cross-country ability?

- How much of the route will be city roads and how much will be highways?

- Will the vehicle carry heavy loads?

The answers to these and similar questions will help determine which tire parameters you need to pay special attention to.

How to choose the right wheels for a VAZ 2106 Zhiguli 1990?

3 types of rims:

- Stamped (economical price category) - made from a sheet of iron by stamping on a press.

- Light alloy - manufactured by casting (more reliable than stamped ones).

- Forged (the highest quality and more expensive than the previous ones) - made from light alloys by stamping at high temperatures.

The choice depends on financial capabilities. However, it should be borne in mind that the quality of the road surface on which you have to drive every day must also be taken into account.

So, if it gets into a hole, a stamped disk will bend and will not cause harm to the tire, but a forged or cast one can cut it. There is a possibility that the cast disc may burst or crack.

It should also be noted that repairing “stamping” wheels is cheaper than repairing cast or forged wheels. But wheels with high-quality cast and forged disks kill the suspension less, because lighter and have more perfect geometry (better balanced).

The same wheels may or may not rub with tires on the same car - wheel alignment adjustment will help here.

What is the tire pressure?

It is the driver's responsibility to constantly monitor tire pressure. This will avoid standard problems associated with vehicle operation. An abnormal pressure value often causes:

- deterioration of management;

- uneven tread wear.

Often the car owner independently reduces the pressure in the wheels of his own vehicle. This reduces the load on the suspension, and the car “passes” various road irregularities an order of magnitude easier. But it is worth noting: a decrease in pressure even by 0.1 MPa leads to serious problems. The main ones include:

- increased fuel consumption;

- rapid wear of the outer tread segments;

- the car becomes less maneuverable.

An overinflated wheel causes no less problems. The central part of the cylinder begins to wear off quickly. In addition, at ambient temperatures of more than 60 degrees Celsius, the tire may simply explode. Which will lead to driving into the oncoming lane.

If this is your first time on our Forum:

- Please note the list of useful topics in the first message.

- Terms and the most popular models in messages are highlighted with quick tips and links to relevant articles in MagWikipedia and the Catalog.

- There is no need to register to explore the Forum - almost all relevant content, including files, pictures and videos, is open to guests.

Best wishes, Administration of the Car Audio Forum Radio

- 02.04.2007 20:28 #2

VAZ 2101 Lada 2101x 1987 1.3

Generation: 2101xEngine: I4, Gasoline Power: 69 hp (51 kW)

Wheel bolt pattern parameters

| PCD (number of holes x circle diameter) | 4×98 mm |

| Center Hole Diameter (DIA) | 58.1 mm |

| Fasteners | M12 x 1.25 |

| Type of fastener | Bolt |

| Tires | Discs | PCD | Dia | Pressure |

| 155/0 R0 75P Factory kit | 4.5Jx13 ET37 | 4×98 | 58.1 | 1.7 |

| 155/0 R0 75P Factory kit | 5Jx13 ET29 | 4×98 | 58.1 | 1.9 |

| 175/70 R13 75P Tuning | 5Jx13 ET29 | 4×98 | 58.1 | 1.9 |

| 175/70 R13 75Q Tuning | 5.5Jx13 ET29 | 4×98 | 58.1 | 1.9 |

| 175/65 R14 75Q Tuning | 5.5Jx14ET32 | 4×98 | 58.1 | 2 |

| 185/55 R15 77S Tuning | 6Jx15 ET25 | 4×98 | 58.1 | 2.1 |

What wheel sizes does the manufacturer recommend to install?

The VAZ 2101 Zhiguli 2101x 1987 1.3 car is equipped with 4.5Jx13 ET37 rims assembled with 155/0 R0 75P tires as standard. Where:

- 4.5J - rim width in inches;

- 13″ — tire diameter in inches;

- ET37 - disc offset in millimeters.

The vehicle tire marking 155/0 R0 is deciphered as follows:

- 155 — profile width (cross section of the tire) in millimeters;

- 0 — profile height as a percentage of its width;

- R - radial cord winding;

- 0 — tire diameter in inches.

In addition, information about its load capacity and speed parameters can be printed on the rubber - load index and speed index. The load index is a two- or three-digit number; the speed index is indicated in Latin letters, for example 75P:

- 75 - maximum permissible tire load 387 kg;

- P — maximum permissible vehicle speed is 150 km/h.

Using the recommended tire sizes will help you avoid problems with handling, safety and other difficulties. What non-standard sizes can be supplied? Refer to the table; it indicates possible acceptable alternative sizes for tuning. Although there are other options that we have not described in the table. For example, wider discs of the same diameter. Or install wheels of the same width, but with a larger diameter, which is quite popular among car owners. The choice of discs is huge; you can find copies with the same parameters, but with an overhang 1-2 millimeters more or less. It is not possible to list all the options.

At the same time, the bolt pattern for all types of wheels is the same - 4x98. Thus, all disks are mounted on four bolts and the distance between them is exactly ninety-eight millimeters. The car's hub diameter is 58.1 mm.

Standard tire pressure is 1.7 MPa.

Standard disk sizes

All standard wheels on the VAZ-2106 have two constant indicators related to the design of the hub:

The diameter of the central hole is 58.5 mm.

For those wheels that were installed on the VAZ 2106 by the manufacturer, tires with the following dimensional parameters were used:

| Disk options | Tire sizes |

| 4.5JX13ET37 | 155/70R13 |

| 5JX13ET29 | 175/70R13 |

The numbers in the tire parameters mean the width in mm, separated by a fraction - the profile height as a percentage of the width, 13 - the rim diameter in inches. Other wheels and tires that were considered by the manufacturer as standard and acceptable for installation:

| Disk options | Tire sizes |

| 5.5JX13ET35-32 | 175/70R13 |

| 5.5JX14ET29 | 175/65R14 |

| 6JX14ET29 | 185/60R14 |

How to determine bolt pattern

Each make and model of car has individual bolt pattern parameters. There are special tables for this, based on which you can select disks.

If it is not possible to use tables, or if your car is not included in them, you can determine the bolt pattern yourself. To do this, we count the number of holes for mounting the disk. The first parameter is there. Determining the diameter of the circle on which the holes are located is a little more difficult.

For disks with 3 holes, measure the distance between the walls of adjacent holes and multiply it by 1.155. The result obtained will be the desired diameter.

For disks with four-point mounting, measure the gap between the walls of opposite holes and multiply it by 1.414.

For five-bolt wheels, measure the distance between the two farthest holes through one, and multiply by 1.701.

Parameters of standard nuts

In the factory assembly, M12x1.25 bolts were used to fasten the disks. Standard bolts from VAZ-2106 wheels can only be used to fasten stamped steel wheels. When replacing with alloy wheels, the bolts must also be replaced. The diameter and thread pitch will remain the same. The overall length and shape of the cone under the head will change.

The thickness of cast discs is greater than that of stamped ones. Therefore, the fasteners must be longer. The conical thickening under the head is the clamping surface of the bolt. If the bolts are replaced with studs, the standard nuts should have a similar surface.

The pressing surface can be not only conical, but also flat or spherical in configuration. The choice of bolts or nuts according to the profile of the clamping surface depends on the shape of the recesses in the holes of the disks, since their contours must completely coincide. This will ensure reliable clamping density. The most common conical version of the clamping circuit. For cast wheels, the cone is more pronounced than for stamps, and its angle is 60°.

Important! After installing new alloy wheels, the first time you need to regularly check the tightness of the bolts or nuts until the soft metal is finally compacted under the influence of loads. If this is not done, spontaneous loosening of the bolt may occur.

What are these wheel mounts?

Wheels are fastened with both bolts and nuts; the second option is less common among us than among the Americans or Japanese, so today we will talk about wheel bolts, not nuts. Bolts can have different shapes, sizes, configurations and colors; in addition, bolts from different manufacturers can differ in threads and the composition of the metal from which they are made. As a rule, bolts are made of metal, less often titanium or aluminum. As for color, chrome-plated wheel bolts or nickel-plated analogues are most often popular, however, both of them are not particularly resistant to corrosion.

What drives can be installed

With the installation of standard disks everything is very clear. Stamped steel wheels perfectly match the parameters of the hub, and together with the tires, they completely fit into the wheel arch of the car. However, their heavy weight reduces dynamic performance and increases fuel consumption.

To improve these indicators, you can install light alloy wheel options. In addition to optimizing technical characteristics, the appearance of the car is also significantly improved. Today's aftermarket offers aluminum, magnesium and titanium rims. They are much more expensive than stamped ones, but lower fuel costs partially offset such costs.

When choosing replacement options, when purchasing a new rim you need to pay attention to the following aspects:

- Manufacturer reliability. You should not buy products from unknown manufacturers. After all, everyone claims the high quality of their goods, but no one knows how things really are.

- Technical specifications. When choosing a disk, at a minimum, you need to take into account the dimensions and technical parameters of the car's hub and wheel arch. If the product exceeds the standard parameters, then you need to make sure that you can select the appropriate adapters or the right type of tires.

- Material of manufacture. The disc material must be certified and meet all safety requirements

- Place of purchase. It is better to buy new discs at official retail outlets, because not only the product itself, but also the technical passport and quality certificate can be counterfeited.

Standard tires

The original wheels also go with the original tires. Their standard designation is 175/70 R13 82T. Let's go through the decoding again:

- 175 is the width of the tire profile in mm;

- 70 – percentage ratio of tire width and profile height;

- R – rubber type, radial;

- 13 – tire radius in inches (select for the rim);

- 82 – maximum tire load, in this case it is 470 kg;

- T – maximum possible speed, equal to 190 km/h.

The manufacturer also recommends a 165 mm wide tire. The wheel size is 80R13. The load indicators are the same. This rubber is low-profile, single-layer steel cord breaker.

Tires should be selected according to the following criteria:

Low-profile tires have a beneficial effect on vehicle handling, but in the event of impacts, the risk of damage to the chassis increases significantly. A profile that is too large, on the contrary, may not fit into the arch, which is why it will constantly wear out; Also, a non-standard profile height will affect the speedometer readings, because the length of the rim changes. When selecting large rims and tires, it is very important to maintain the correct bolt pattern and fit it all into the wheel arches accurately; If the tire has a low load, it may burst when hitting an obstacle if the vehicle is fully loaded.

Like any other car, the 7 is equipped with summer, winter and all-season tires. All-season tires, in principle, show good results, but they are inferior to summer and winter tires when compared under the conditions of their “native path”.

Therefore, it is recommended for any car owner to have 2 sets of tires for the cold and hot seasons of the year.

Characteristics of winter tires for VAZ 2107

A winter tire is distinguished by the fact that it is made of softer rubber, which does not allow it to harden in the cold. It has a higher tread.

The design includes many small wavy lamellas, which open when in contact with asphalt, as if sticking to the road surface.

This structure allows you to move well on compacted and even icy roads. Due to the shape of the tread and its size, the tire can paddle well on loose snow.

Such tires are divided into “Velcro” and studded.

Studded winter tires

The principle of operation of the former is reminiscent of suction cups, which we described earlier, but the studs help to better cope with acceleration and braking on icy and compacted roads. Metal spikes “bite” into the hard surface, which ensures better contact with it.

Traditionally, studded tires are considered a more reliable solution for driving on snowy roads. This is confirmed by many test drives that are conducted annually by various companies and auto magazines.

However, such rubber also has its disadvantages:

Firstly, not all regions of our country have snow on the roads all winter, especially in the south, where snowfalls occur once or twice a month and most of the time you have to drive on cold asphalt. In braking on such a surface, Velcro will definitely be better.

Secondly, if you ride on spikes on “bare” asphalt, you will constantly hear an annoying noise.

Thirdly, almost all imported rubber is studded at Russian enterprises - only blanks are supplied. For this reason, the studs are often poorly installed and constantly fall out.

And if the loss of a few pieces is not critical, then when the amount approaches 5-7 percent, the effectiveness of such a tire decreases many times over. Again, this is facilitated by driving on such tires on asphalt.

Velcro (friction)

“Velcro” also shows good results in terms of acceleration and braking on different roads. At the same time, it is not so noisy - even in the northern regions of our country, many drivers prefer just such tires.

Winter tires are indicated by the manufacturer either with a painted snowflake or with the M+S marking (Mud+Snow/Mud+Snow). They will also be easy to recognize by their tread type and increased softness.

Summer tires are stiffer, which is explained by the smaller amount of natural rubber in the composition. This tire wears out much more slowly and performs very well at high temperatures, when winter tires would become too soft to handle serious loads.

Protectors are divided into several types - they are symmetrical and asymmetrical, while within each type you can find a directional pattern and a non-directional one.

If the tire tread is directional, then on the side it will indicate the Rotation value and an arrow indicating the correct direction of rotation.

VAZ 2114

Tires of two sizes are relevant for the hatchback: R13, R14. Full details can be found in the technical manual. The optimal size is considered to be R13. In summer, such models are completely safe.

R14 tires are considered more suitable for winter. Tires with dimensions 175/65 can be considered an ideal option for driving on snowy roads, as well as icy tracks.

When choosing, be sure to take into account the width of the tire. It will not allow the car to “drown” in the snow; it will only be pushed to a certain depth.

Factory wheel parameters depend on the vehicle configuration. They can be standard or slightly enlarged:

For such tires, wheels on the VAZ 2114 are suitable 14.4x98. Moreover, their width is selected according to the size of the tire. Usually it is in the range of 5-6.

If R15 are installed, the wheels must be 6.0/6.5x15 4x98. For R16 tires – 6.5x16 4x98.

Secrets

For car owners, the issue of protecting their car from theft or theft of parts has become no less pressing. Along with alarms and anti-theft devices, security bolts are popular. They have a special head for a key, which is included in the kit. Only the owner can open it. Vandals may try to forcefully remove the wheels, but nothing will work. It is no secret that in car services there are similar keys that are easy to pick up.

You may be interested in this Wheel rims R19

For maximum protection, it is advisable to choose the least common product

Types of secrets:

- With a curly profile. Lines of varying curvature are applied to the object. An intricate design is stamped onto the head, the imprint of which is repeated on the hollow key.

- With holes. Asymmetric holes of various sizes are drilled into the rod. The key, in turn, has correspondingly shaped protrusions. Options are possible when the convex parts are located on a metal rod, and the holes are on keys.

Note!

The downside is the likelihood of losing the key. In this case, neither the thief nor the owner himself will be able to remove the secrets. If there is a strong impact, there is a possibility of breaking the knob.

Select modification VAZ 2106

Despite the fact that this information is taken from the websites of auto manufacturers, our catalog is for informational purposes only and does not guarantee full compliance of the proposed sizes with your car.

Source razboltovka.ru

The operation of any car always raises many questions among owners. After all, the driver wants not only to fix all problems in a timely manner, but also to predict them. Especially many questions arise about the correct selection of tires and wheels for your car. Today, a huge number of different products are sold, and few people know how to choose the kit that is ideal for a car.