When choosing wheels for a VAZ, you need to look not only at their appearance, but also at the possibility of using them on a particular model. In addition, certain technical characteristics must be taken into account.

The most important of them are:

- bolt pattern;

- diameter;

- departure;

- fastening elements;

- diameter of the centering hole.

Additional information markings on the disc

In addition to the disc width offset and disc diameter, you can often find other information.

The disc may indicate: - Date of manufacture. Usually a year and a week. For example: 0407 means that the disc was released after the 3rd week of 2007, that is, in the 4th week of the year. – SAE, ISO, TUV - the mark of the regulatory body indicating the standard by which the disc is manufactured. The marking indicates that the wheels comply with international rules or standards. – MAX LOAD 2000LB - a very common designation for the maximum load on a wheel (indicated in kilograms or pounds). For example, maximum load 2000 lbs (908kg)

- MAX PSI 50 COLD - means that the tire pressure should not exceed 50 pounds per square inch (3.5 kgf / sq. cm), the word COLD (cold) reminds that the pressure should be measured in a cold tire; - TOYOTA - wheel manufacturer .

How to recognize malfunctions

There are many signs that help identify a breakdown:

- uneven wear of tires;

- increased vibration;

- the appearance of extraneous noise;

- overheating of the disk (this means that the bearing is not working properly);

- the car deviates to the side from a straight path and the body sways (these signs are explained by the fact that a working wheel ensures smooth movement, and when a breakdown occurs, imbalance occurs).

The most characteristic “pattern” is the sound in the rear chassis.

The easiest way

If all of the above is not picked up by the hearing and vestibular apparatus, then there is an optimal method. You need to push the tire with your foot to identify any play.

This method is very effective in the initial stages, when the symptoms are least pronounced.

Syverlovka and bolt pattern of VAZ wheels

Wheel bolt pattern on VAZ 2107

Bolt pattern of wheel rims on the Lada Largus

The design of the seven involves drilling 4×98 wheels, where the number 4 indicates the number of bolts, and 98 indicates the diameter of the holes on the disk structure.

Many foreign cars use a bolt pattern with similar parameters – 4×100. In the first situation, the distance between the centering bolts is 69.3 mm, and in the second case - 70.7 mm. The error is 1.4 mm and does not allow for tight fixation of a non-standard disc.

In addition, installing a car disk with non-standard parameters can lead to deformation of elements, namely mounting holes and bolts.

There are other methods for attaching 100x4 rims to the seven. For example, you can use extended bolts, adapter rings, studs and eccentrics. However, these parts can ultimately complicate or impair the mounting of the wheel product.

Therefore, it is recommended to install standard car wheels and tires so as not to lead to wheel imbalance and vibration while driving.

Wheels on the VAZ 2107 are equipped with 13-inch stamped wheels or analogues with identical parameters. Tires have dimensions 175/70/R13.

| Bus parameters | Disc sizes | Bolt pattern | Width | Departure | Center hole |

| 175/70/R13 | 13” | 4×98 | 5.0J | ET 29 | DIA 60.1 |

The nominal pressure in “seven” tires directly depends on the tire sizes:

175/70/R13 – 1.9 rear, 1.6 front wheels;

165/80/R13 – 2.0 rear, 1.7 front.

Wheel bolt pattern on model 2106

For a six, the wheel bolt pattern is 4×98. As for the factory dimensions of the disks, then:

- standard width is 5.0J,

- centering hole 58.5 mm,

- departure ET

Tire size for the six is 175/70/R13.

As a restyling, you can install wheels 185/60/14, 195/50/R15.

| Tire parameters | Factory bolt pattern | Non-standard disk parameters |

| 155/R13/82Q | 4×98 | 4.5Jx13 ET37 |

| 175/70/R13 82 S | 4×98 | 5Jx13 ET29 |

| 175/70/R13 82T | 4×98 | 5.5Jx13 ET32 |

| 175/65/R14 82S | 4×98 | 5.5Jx14ET29 |

Drilling on the VAZ 2109 model

The VAZ 2109, “nine”, has factory settings for the wheel bolt pattern of 4×98. The factory equipment was equipped with 175/70/R13 tires and 13-inch wheels.

| Tire sizes | Disc sizes | Bolt pattern | Departure | Center hole |

| 175/70/R13 | 13 | 4x98 5Jx13 | ET29 | 58,6 |

| 175/65/R14 | 14 | 4×98 5.5Jx14 | ET29 | 58,6 |

| 195/50/R15 | 15 | 4×98 6.5Jx15 | ET32 | 58,6 |

| 205/45/R16 | 16 | 4x98 7Jx16 | ET34 | 58,6 |

Wheel bolt pattern on VAZ 2110

The tenth VAZ model is equipped with factory stamped 13-inch wheels and 175/70/R13 tires. There were also dozens of configurations with 14-inch casting and 175/65/R14 tires.

As for the dimensions of VAZ factory wheels, the width is 5.0-5.5J, drilling is 4×98, as on other models, the centering hole is 58.5 mm and the offset is ET 37-40.

Drilling on 2111

The Lada station wagon 2111 was equipped with 13 or 14-inch wheels from the factory, depending on the vehicle's configuration. Both options could be used.

Tire sizes: 175/70/R13, 175/65/R14, rims: width 5.0J, drilling 4×98, centering hole 58.6 mm, offset ET40.

Drilling on the VAZ 2114 model

Lada Samara 2113, 2114 cars were equipped with factory stamps with a 4x98 drill bit.

As for the rims, the offset was ET40, width 5.0 J and centering hole 58.5 mm. Wheels 175/70/R13.

Drilling on the VAZ 2115 model

The fifteenth model Lada 2115 is equipped with factory stampings with dimensions of 13 and 14 inches, and a 4 × 98 drill.

| Disk size | Tire parameters | Sverlovka | Departure | Center hole |

| 13 | 175/70/R13 | 5.0J 4×98 | ET40 | 58.5 |

| 14 | 175/65/R13 | 5.5J 4×98 | ET37 | 58.5 |

As a restyling option, you can use car tires:

Drilling on the VAZ 2121 model

The first Russian SUV Niva from VAZ or Lada 4x4 is equipped with 16-inch steel factory wheels and tires with sizes 175/80/R16 and 185/75/R16.

Disc dimensions: offset ET40, drilling 5x139.7, centering hole 98.6 mm and width 6.5J.

Wheel bolt pattern on a Niva Chevrolet car

The Russian Niva Chevrolet SUV is equipped with factory-made 15- and 16-inch rims with drilling parameters of 5×139.7, offset ET40-48, centering 98.6 mm and width 6-6.5J.

Removing the front wheel hub

Now you need to remove the hub. To do this you will need:

- Mark the position of the hub on the strut using a marker. Be sure to clean the surface thoroughly before doing this.

- Using keys “17” and “19”, unscrew the nuts from the bolts securing the hub to the shock absorber strut.

- Using a “17” wrench, you need to unscrew the lower bolts securing the ball joint to the hub. This is a simple option when you do not need to replace the ball. But if you need to change it, then you need to use a “19” key to unscrew the nut from the ball pin and remove it using a puller.

- Completely unscrew the hub nut.

- Carefully push the front wheel hub off the CV joint.

That's all, now you need to completely disassemble the element and remove the front wheel hub bearing of the VAZ-2108.

Information on wheel bolt patterns on domestic VAZ vehicles

How to determine wheel rim bolt pattern, compatibility table

All VAZ cars from the very foundation of the plant to the present day had only 3 main types of bolt patterns, since most modifications were made on a single platform, only their appearance changed. The bolt pattern for most Lada models looked like this:

The smallest representative of the automaker - VAZ 1111, popularly called "Oka", was produced in the Russian Federation for 20 years - from 1987 to 2008. Considering that the weight of this especially small class car was only 975 kg, and the load on the wheel was less than 250 kg, Oka became one of the few representatives in its class for which a bolt pattern of 3 studs was used.

It was quite problematic to find a similar wheel size on the market, so stamped products with a radius of R12 and R13 were often re-drilled in order to successfully fit on the hub.

Bolt pattern VAZ 2107 4x98

The vast majority of models of the AvtoVAZ concern, starting from 2101 and ending with the Lada Priora or Kalina, were produced from the assembly line in the form of sedans, liftbacks, hatchbacks or station wagons of the compact or subcompact class.

Starting from 1966, when the concern released its first “penny”, and ending in 2015, the wheel bolt pattern for these cars was 4x98 mm, the diameter of the central hole was 58.1 mm.

The most popular Lada models today, for which wheels with a 4x98 bolt pattern are still sold, are VAZ 2106, 2107, 2109, 2110, 2112, 2114.

The latest VAZ models, such as Vesta, Granta and X-Ray, produced since 2015, have a wheel pattern as close as possible to the international standard for compact cars. This parameter on the specified modifications is 4x100.

Among all the products of the AvtoVAZ concern, such models as the VAZ 2121, or the classic Niva and all derivatives of this SUV have always stood out: the 5-door Taiga, Chevrolet Niva and other models. Due to increased loads on the hubs and wheels due to unsatisfactory road conditions, for which all parameters of the Niva were designed, these compact all-terrain vehicles traditionally had a disc bolt pattern of 5x139.7, with a central hole diameter of 98.5 mm.

These increased indicators allowed the wheel to freely resist bending moment, absorb large loads when the center of gravity is shifted to one side when moving on an inclined plane or when the wheels are forced to hang, and also allowed the car to transmit more torque to the tire treads when driving uphill without the risk of breaking parts .

Wheels for VAZ 2114

Structure

The part has a fairly simple structure. Essential elements:

- outer rim (used for screwing in bolts);

- internal part (for bearings);

- holes with slots (for CV joint);

- protective caps;

- sensor (it is sometimes included in the design).

CV joints are constant velocity joints; their main task is to transmit torque.

The set of fasteners for this part consists of two nuts and one washer.

Hubs for different purposes have different technical characteristics. Hubs for passenger cars have the form of a hollow, lightweight cylinder, while for “heavyweights” the diameter of the part is larger.

Bolt pattern compatibility table for Zhiguli wheels

Bolt pattern Chevrolet Cruze 1.3i HR51S 2001-2003

This table of correspondence of geometric characteristics to brands and modifications of domestic cars is given below:

| Make and model VAZ | Disc diameter, inches | Rim width, inches | Wheel offset, ET, mm | Bolt pattern, pcs x mm | Central hole diameter, mm |

| VAZ 1111 (“Oka”) | 12, 13 | 4; 4,5; 5 | 35, 40 | 3x98 | 58,1 |

| VAZ 2101…2115, “Kalina”, “Priora” | 13, 14, 15 | 5; 5,5; 6 | 25, 30, 32, 35 | 4x98 | 58,6 |

| "Lada Granta", "Vesta", "X-Ray" | 13, 14, 15, 16 | 5; 5,5; 6; 6,5 | 22, 25, 30, 32, 34, 35 | 4x100 | 58,6 |

| VAZ 2121 (“Niva”), 2123, 2131, Chevrolet Niva | 15, 16, 17 | 5; 5,5; 6; 6,5; 7 | 15, 35, 58 | 5x139.7 | 98,5 |

Interior of rims for VAZ cars

The bolt pattern of VAZ wheel rims is a very important indicator of the model, which significantly limits the range of products offered for sale. If the driver suddenly takes a fancy to a disc that has different characteristics, he will have to completely change the design of the hub and install the studs in a new order. Experts say that such a practice is fraught with unpredictable consequences during the operation of the vehicle.

- Tire sizes from to , width from to and profile from to .

- Minimum tire size: 175/70R13, maximum:

Method of calculations

Based on the tire characteristics of a standard 175/70 wheel with a radius of R13, where:

- values 175 and 70 are the values of the tire width and rubber profile height in percent;

- multiplying 175x0.7 together gives 122.5 mm;

- the actual diameter of the R13 disk is 13x25.39 will be 330 mm.

To find out the total diameter of the wheel, you need to add the two obtained values, but the profile height comes in double size, i.e. (122.5x2) is added to 330 and the result is 575 mm.

Calculations are carried out using the same principle for a more visual perception, for example: for models 175/70R13, 175/65R14 and 185/60R14, it comes out to 575, 583 and 577 mm, respectively.

The last value will be most suitable for the VAZ-2109, since it is 10 mm larger in width. This will reduce the braking distance during operation, add controllability, and reduce tire bending when cornering at high speed. Fuel consumption will increase slightly, but potholes and potholes on the road will become less noticeable.

Features of wheel sizes for the most popular VAZ models

Among several dozen VAZ modifications, the most popular models over the entire 50 years were only 2 of them, as can be judged by the number of copies sold. The wheel sizes for these cars had the following parameters, which varied depending on the year of manufacture, technical equipment and equipment of the car:

VAZ is the latest modification of the “classic”, produced on the plant’s conveyors for 30 years: from 1982 to 2012. During this time, it never changed its appearance, and the disc bolt pattern was the same - 4x98 with a central hole diameter of 58.6 mm.

If in 1982 the plant produced models with tire dimensions ranging from 5J to 5.5J, then at the end of production the concern increased the permissible size to 6J.

The radius of the wheels invariably varied from R13 to R15, which made it possible to alternate them by season, periodically changing the side profile of the tire, or immediately use all-season tires with a diameter of R14.

The VAZ 2107 tire size invariably consisted of only 3 main parameters - 175/70/R13, 185/60/R14 and 185/55/R15. The last of the listed parameters was actively in demand among lovers of fast driving on smooth city roads.

If we look at the concern’s earlier cars, we can see that the wheelbase of the Zhiguli has remained virtually unchanged for more than 40 years. This leads to moral backwardness of the technical equipment of the plant's products. At the same time, the lack of new developments greatly reduces both the speed of release from the assembly line and the cost of engineering equipment, which leads to a very attractive retail price for the vehicle.

VAZ 2114. Produced in a smaller range - from 2001 to 2013. The car was just a restyled modification of the classic “nine”. The legacy of the outdated model did not affect the high popularity of this Lada, and all the wheels that were installed on hubs in the basic version had the same traditional bolt pattern 4x98, DIA 58.6 mm.

European standard bolt pattern 4x100 for Lada X-Ray

Like the bolt pattern of the VAZ 2114, the width of the wheel rims was not much different from the “seven” and fluctuated between 5J – 6J for the entire production period. As for radius, the concern has completely eliminated the 15-inch diameter from the factory equipment, without prohibiting drivers from installing this parameter as an option. The bolt pattern of VAZ 2114 wheels in the current size also made it possible to install standard 4x100 wheels in accordance with the sizes usual for Europe.

Not a single Lada model has ever looked aggressive; the hallmark of the product was practicality and reliability in operation. The concern did not use extreme overhang indicators, and the wheels were always hidden under the body arches. The average ET limit values for both VAZ 2107 and 2114 were ET25...35 mm, and deviations from this characteristic obligated drivers to install additional mudguards on the side parts of the body and change the design of the hubs, making them more durable to avoid deformations.

Bearing removal

To remove the bearing from the seat, you will need a puller. You can even make it yourself, there are no scarce components, the design is very simple. The VAZ-2108 front wheel bearing puller is a long bolt with a coarse thread and a nut. And most importantly - spacers and mandrels with a diameter similar to that of a wheel bearing. If there is no such puller, then all the work can be done with a hammer, but there must still be a mandrel.

First of all, remove the hub itself, in which the holes are made for attaching the wheels. Next, you need to use pliers to remove the retaining rings. If you don’t have such a tool, you can use a flat-head screwdriver, pliers and an awl. After removing the rings, you can begin pressing out the bearing. If you do this with a hammer, then try to hit accurately and sharply, this way the bearing will come out faster.

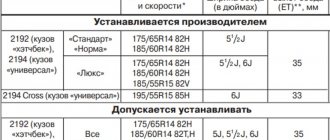

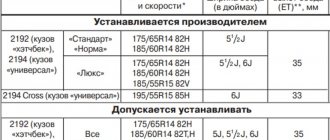

Dimensions of wheels, tires and disks VAZ 2109 1997

The highlighted entries mean factory sizes, the rest are replacement options

VAZ 2109 1997 1.1

Generation: 1987 .. 2006Power: 53 hp | 39.7 kW | 54 PS Engine: I4, petrol Central hole diameter: 58.5 mm Thread: M12 x 1.25 Fastening type: bolt Years of production: 1987–1997

| 165/70R13 | 5Jx13 ET40 | 5×112 | 2 (29) |

| 155/80R13 | 4.5Jx13 ET40 | 5×112 | 1.9 (28) |

| 175/70R13 | 5.5Jx13 ET40 | 5×112 | 1.9 (28) |

| 175/65R14 | 5Jx14ET40 | 5×112 | |

| 185/60R14 | 5.5Jx14ET37 | 5×112 | 1.9 (28) |

| 185/60R14 | 6Jx14 ET35 | 5×112 |

VAZ 2109 1997 1.3

Generation: 1987 .. 2006Power: 63 hp | 47.1 kW | 64 PS Engine: I4, petrol Central hole diameter: 58.5 mm Thread: M12 x 1.25 Fastening type: bolt Years of production: 1987–1997

| 165/70R13 | 5Jx13 ET40 | 5×112 | 2 (29) |

| 155/80R13 | 4.5Jx13 ET40 | 5×112 | 1.9 (28) |

| 175/70R13 | 5.5Jx13 ET40 | 5×112 | 1.9 (28) |

| 175/65R14 | 5Jx14ET40 | 5×112 | |

| 185/60R14 | 5.5Jx14ET37 | 5×112 | 1.9 (28) |

| 185/60R14 | 6Jx14 ET35 | 5×112 |

VAZ 2109 1997 1.5

Generation: 1987 .. 2006Power: 71 hp | 53.0 kW | 72 PS Engine: I4, petrol Central hole diameter: 58.5 mm Thread: M12 x 1.25 Fastening type: bolt Years of production: 1988–2006

| 165/70R13 | 5Jx13 ET40 | 5×112 | 2 (29) |

| 155/80R13 | 4.5Jx13 ET40 | 5×112 | 1.9 (28) |

| 175/70R13 | 5.5Jx13 ET40 | 5×112 | 1.9 (28) |

| 175/65R14 | 5Jx14ET40 | 5×112 | |

| 185/60R14 | 5.5Jx14ET37 | 5×112 | 1.9 (28) |

| 185/60R14 | 6Jx14 ET35 | 5×112 |

VAZ 2109 1997 1.5i

Generation: 1987 .. 2006Power: 77 hp | 57.4 kW | 78 PS Engine: I4, petrol Central hole diameter: 58.5 mm Thread: M12 x 1.25 Fastening type: bolt Years of production: 1994–2006

| 175/70R13 | 5Jx13 ET40 | 5×112 | 1.9 (28) |

| 155/80R13 | 4.5Jx13 ET40 | 5×112 | 1.9 (28) |

| 165/70R13 | 5.5Jx13 ET35 | 5×112 | 2 (29) |

| 175/65R14 | 5Jx14ET40 | 5×112 | |

| 185/60R14 | 5.5Jx14ET37 | 5×112 | 1.9 (28) |

| 185/60R14 | 6Jx14 ET35 | 5×112 |

More details about standard sizes

All over the world it is common to use the European designation system. For example, simple wheels for tubeless on a VAZ-2109 are 4 1/2 J-13H2 ET30.

- J – coded parameters for the rim flange in mm (this includes rounding radii, tilt angles, etc.). This paragraph includes a list of dimensions to obtain a highly specialized conclusion when conducting technical tests. There are other categories - D, E, F, etc.

- H2 – double hump or annular offset of the rim flange HUMP (it keeps the tubeless tire from slipping). There are also such variations of humps - H (simple), A (asymmetrical), CH (combined), FH (flat).

13 – bore diameter in inches.

The drawing below clearly shows the main parameters for the structure of the arrangement of technological holes and protrusions.

- ET30 or ET+30 – wheel offset in mm. The dimensions of the distances between the middle of the width of the disk and the mating plane (where the disk and hub are in contact) are indicated, respectively equal to 30 mm. Based on where the product is manufactured, the marking changes to OFFSET (negative) or DEPORT (positive).

For a minus value, a designation with a similar sign is used, for example “-ET30”.

What is the bolt pattern of wheel rims on a VAZ 2109 diagram?

Any owner of a VAZ-2109 sooner or later has a question: what is the bolt pattern on the rims of their car? It is usually asked at the moment when they begin to think about replacing these important wheel elements that ensure traffic safety and the image appeal of the vehicle.

In general, the concept of “bolt pattern” implies the distance from the center of one disk mounting hole to another. For the most part, this parameter is the same for all products of the Volzhsky Automobile Plant, but in general no standard values have been developed. That’s why the holes for the bolts on the hubs are located differently among different manufacturers.

Bolt pattern - dimensions

This wheel parameter for VAZ cars is marked with the following combination – 4×98. As mentioned before, this is a standard value for all models of domestic manufacturers.

It is deciphered quite simply. So:

- the first number (4) only indicates the number of fasteners provided to secure the disk;

- the second (98) means the gap between the holes (or rather their centers) in millimeters.

Many have noticed that the corresponding markings on foreign vehicles begin with the number 5. As you might guess - this should be understood this way - the disc is attached directly to the hub with exactly the same number of bolts.

If you draw a circle through the holes, you get the total diameter. In particular, the VAZ-2109 leaves the factory assembly line with wheels measuring 13 inches.

They use tires of the following marking – 175/70 R13.

When planning to purchase third-party wheels for your car, it is important to know which ones are suitable for your model. In particular:

- It is best to choose those that have the following dimensions - 5.5 by 13.5 inches;

- 5.5 by 14 is also not bad;

- It will be possible to install 6 to 14.

In theory, it is possible to attach even larger ones, but usually this requires certain changes to the design of the vehicle itself.

In addition to the previously mentioned number of attachment points and the distance between them, designated as PCD, there are also other dimensions:

- the diameter of the central hole (DIA) of the nine is 58.1 millimeters;

- offset (ET) is indicated as +40.

If you purchase discs with a lower ET value, the grip on the road surface will increase significantly, which means:

- controllability will deteriorate;

- fuel consumption will increase;

- wheel bearing wear will accelerate.

Is it possible to install 4x100 disks?

This option can be seen quite often on the VAZ-2109. However, in reality this solution is not correct.

The problem is that the standard bolt pattern of the model in question differs relatively little from the factory one. It seems to many that these couple of millimeters do not matter. However, it is impossible to secure a 4×100 disk properly with ordinary bolts. There is a thickening on them (under the head) - it is this that does not allow the fasteners to be screwed in completely. Moreover, if you try to do this by force, most likely you will break the thread in the hub.

Therefore, they have to be secured with special eccentric bolts, and they have disadvantages that do not have the best effect on reliability. You should not forget about them if your own safety and that of your passengers is important to you.

Signs of a broken wheel bearing

As the vehicle is used, its components and assemblies wear out. Moreover, those that suffer the most are those that are constantly loaded - these are rubbing parts. The weight of the engine and the friction force act on the front hub bearing of the VAZ-2108. That's why its dimensions are so impressive - to cope with the load. But when an element fails, the following symptoms occur:

- In the early stages, a barely noticeable hum appears.

- Minor vibrations may be felt transmitted from the wheels to the body.

- As the bearing wears, the noise and vibration increase.

If you do not replace it in a timely manner, the bearing may jam. During operation, excessive heating of the hub will be observed - there is very little lubricant inside the bearing race, the metal elements rub against each other.

Advantages and disadvantages of stamped wheels for VAZ 2110

Initially, VAZ 2110 cars in the basic configuration are produced with stamped wheels. And many owners prefer not to change them due to a number of advantages that such discs have:

- high strength, which allows you to withstand aggressive driving style;

- high performance characteristics are designed for the condition of domestic roads;

- affordable price;

- ease of restoration of the stamped disk in case of damage.

Their main disadvantage is their outdated design, which spoils the look of the quite stylish and modern VAZ 2110 car. In addition, stamped wheels are heavy and susceptible to corrosion.

Self-adjustment

Next, you need to stand on a level surface and load the machine, as recommended by the manufacturer. That is, about 320 kg in the cabin and 40 kg in the trunk.

The first adjustment is to set the pitch angles of the turning axis. The second is camber, the third is toe.

In this case, the camber angle in the loaded state should be 0°30'+-30'. The toe-in should be within 0°15'+-10', and the pitch angles of the steering axes should be 0°20'+-30'.

Remember that camber and other wheel adjustments are necessary in all cases when you in any way interfere with the operation of the front suspension of the VAZ 2110.

Manufacturers of wheels for VAZ 2110

There is a wide range of wheels for the VAZ 2110 on the market. A huge number of manufacturers can confuse even an experienced car enthusiast. Therefore, when choosing the optimal wheels for your car, you should carefully study information about all manufacturers. To do this, they should be divided by country:

- Russia. Domestic wheels for the VAZ 2110 are a combination of low cost, reliability and durability. Considering that these are the wheels that are installed in the basic version of the car, it would be quite logical to replace them with higher quality wheels from a similar manufacturer. In addition, domestically produced wheels are designed taking into account the low quality of roads, so they will last a long time even under intense load.

- China. Chinese-made disks are affordable and have mixed quality. However, even on the Chinese disk market recently you can find very good quality copies that are practically not inferior to European products. But you should buy wheels made in China only after personal inspection. When ordering such products online, the chance of purchasing low-quality discs is much higher.

- Türkiye. Turkish-made wheels are distinguished by the use of high-quality materials, stylish appearance and durability. They can withstand driving on domestic roads, but their cost will be higher than Chinese or Russian ones.

- Asia. In addition to Chinese, you can buy Asian wheels from South Korea, Taiwan and Japan. Disks from these manufacturers are distinguished by excellent technical characteristics and reliability. They can be installed on a VAZ 2110, guaranteeing a stylish appearance and a comfortable ride. The cost is higher than domestic analogues.

- USA and Europe. The most expensive options. They are distinguished by high technical characteristics, but due to the prohibitive price, their installation on a VAZ 2110 makes almost no sense.

When choosing the optimal model of wheels for a VAZ 2110, you should take into account indicators such as wheel size, center hole diameter, and tire size. In addition, you should make a choice between stamped and alloy wheels.

Parameters of standard nuts

Fastening the cast disk to the hub involves the use of special bolts or nuts. It should be noted that nuts from stamped disks are unacceptable here. Firstly, because in cast specimens the conical or spherical part of the fastener is more pronounced than in stamped ones.

For example, the conical part of a bolt or nut has an angle of 60 degrees. This is done in order to increase the area of their contact with a material softer than steel. Secondly, the stamp is thinner than the casting, and when replacing the disk, the length of the bolt simply will not be enough.

It is better to immediately use the fasteners that correspond to the light-alloy wheel used, otherwise deformation of the holes, crumbling and scratches are possible.

By saving on the necessary nuts or bolts, you can irreversibly damage a more expensive element.

The softness of the metal also means regularly checking the tightness of the fasteners, especially at first and with new discs, when the material has not yet become compacted from work loads. Otherwise, under the influence of cyclic shock and vibration, the nuts may spontaneously unscrew.

Nuts must have conical or spherical washers. It is necessary to ensure that the profile of the washers exactly fits the corresponding recess in the hole of the disk being installed. Some disc models are designed to use cylindrical fasteners with flat washers.

What wheels are suitable for VAZ 2110

Many Lada models have universal basic elements characteristic of a wide variety of modifications of these cars:

VAZ 2110

- device,

- engine volume and power,

- wheelbase,

- pendant,

- braking system,

- wheels and tires.

So, depending on the modification and equipment of the vehicle with different options, the following standard parameters for these products are set at the factory:

- The bolt pattern is 4x98, which is the same for all models of the automobile concern, which means that the wheel is mounted on 4 studs of 98 mm each, as well as the drilling or diameter of the circle along which the holes for the studs are located - 58.6 mm.

- What wheels are suitable for the VAZ 2110? The simplest car configurations, regardless of the year of manufacture, were always equipped with stamped wheels in silver, white or black without decorative overlays with a dimension of 5.0J x 13 ET35, on which summer tires 175/70/R13 were put on.

- Further, all subsequent 3 trim levels with an engine capacity of 1.5 liters were equipped with wheels with dimensions of 5.0J x 14 ET35, 5.5J x 14 ET35 and 6.0J x 14 ET35, and this indicates the capacity of the wheel arches, under which with a constant offset The disk freely accommodated tires 175/65/R14, 175/65/R14 and 175/60/R14, respectively. All of the disks listed were also stamped, but already covered with caps.

- In more expensive versions with an engine capacity of 1.6 liters, wheels with an increased radius in a cast version were installed - 5.0J x 15 ET35 or 6.0J x 15 ET38 with tires 195/60/R15 and 205/55/R15.

- All new models produced by the automaker after 2005 did not use a radius greater than R15. However, in the initial version there were 2 top-end configurations of the brand, which came off the assembly line with wheels that were exclusive at that time. Thus, these cast wheels with designer grilles had parameters of 6.5J x 16 ET33 and 7.0J x 17 ET27, which corresponded to business-class foreign cars, and tires were installed in 205/50/R16 and 215/45/R17, but it could only be safely used in the summer due to its low profile.

R13 wheels on VAZ 2110 Important! The VAZ 2110 has always been a fairly universal car, and the parameters of the wheel arches satisfied radii from R13 to R17 without much difficulty, which allowed car enthusiasts to install original wheel rims from famous manufacturers on their “iron horses” as an option.

Corrosion protection

For reliable operation of the chassis, everything is important: the bolt pattern, the dimensions of all components, the alignment/camber settings, and even the protection of the arches from corrosion. It is the arches that are more susceptible to adverse factors than other parts of the body - from ordinary moisture during rain to reagents on winter roads.

To ensure reliable protection of the arches, it is best to install lockers (fender liners) on the VAZ 2110. Such protection will cost much less than subsequent repairs of rusted arches. It is important to choose the correct size of the lockers and ensure their tight fit in the area of the arches.

We hope that by completing all the repair work yourself, you will provide your VAZ 2110 with many years of trouble-free service on the road.