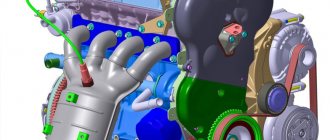

The VAZ 2106 engine is used in small class passenger cars.

It has been produced by the Volzhsky Automobile Plant since 1976. The VAZ 2106 engine cools the system in a closed container using a specially designed liquid. It is located at the very top of the camshaft.

This engine is considered a four-stroke, has a carburetor system and an in-line engine. The liquid inside the motor has forced circulation to quickly cool the container.

The engine has a combined lubrication system. That is, this process occurs under a certain pressure and in the form of splashing. These engines are subject to major overhaul and additional tuning. When the design completely fails, you need to ask how much a new engine for a VAZ 2106 costs and replace it.

In what models was the VAZ used?

Improved engine characteristics made it possible to equip VAZ cars of the following models with it:

- 2103 Zhiguli sedan;

- 21054 Zhiguli sedan (only for the FSB, the Ministry of Internal Affairs and the State Traffic Safety Inspectorate);

- 2106 Lada sedan;

- 21074 Lada sedan;

- 2121 Niva carrying a 5-door station wagon or 3-door hatchback.

VAZ 21054 for special services

Due to the following difficulties in manufacturing some parts, management considered the 2106 motor to be economically unprofitable and it was discontinued.

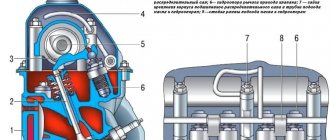

Constructive decisions

- major repairs were required more often due to burnout of valves;

- Unstable operating modes on low-quality domestic fuel.

Valves burnout

The engine was equipped with pistons from a VAZ 21011, there was no need to reconfigure the equipment, and the cost price was not affected.

Disadvantages and advantages

The 2106 engine has significant disadvantages:

- excess heat is transferred to the well of the piston bottom and fins by steel control plates inside the bosses;

- dynamic loads are reduced due to the displacement of the finger from the axis of symmetry to the right;

- When assembled into an engine, the pistons are mounted with markings in one direction, which increases labor costs and the human factor.

Piston 2106

The internal combustion engine uses a cylinder head from model 2103, a starter 35.3708 and a G221 generator for an engine with a current of 42A. Oil consumption does not exceed 700 g/1000 km. The instruction manual states that it is recommended to add 200 ml less lubricant than the volume of the system as a whole. The markings for which oil to pour are given in the upper table.

Reliability, weaknesses, maintainability

Reliability

The reliability of the VAZ-2106 is beyond doubt. The engine is truly durable and reliable. Numerous positive reviews from car owners confirm this.

For example, Andrey from Stavropol states: “... according to the technician, this is the first repair on a VAZ 2106 engine in 27 years of operation with a mileage of 200 thousand km...”.

Dmitry from Smolensk completely agrees with him: “... 195 thousand cars have already been driven on it. I use semi-synthetics. No one climbed into the engine, and the technicians said that it was not necessary. The car is good in winter, when the guys in the yard couldn’t start their jeeps at -30 in -35, my VAZ 2106 started 1-2 times…”.

There are, of course, negative reviews. But in them, the authors themselves agree that on their part there was no proper care of the engine or there was aggressive operation of the machine.

The reliability of the internal combustion engine is stubbornly indicated by the fact that the engine's mileage has exceeded its service life. With timely and high-quality maintenance, the engine can last up to 400 thousand km without major repairs.

The concept of safety factor plays an important role in reliability. VAZ-2106 can be boosted to 200 hp. With.

It must be remembered that such tuning negates the durability of the unit. Mileage is reduced tenfold. And the costs of remaking the engine are also not cheap. For lovers of powerful engines, an engine swap would be the most suitable option.

Another indicator of the reliability of the unit is its modernization. Based on the VAZ-2106, several versions of this engine were created, which were used on various models of VAZ cars.

Weak spots

The VAZ-2106 has weaknesses inherent in all VAZ engines. It should be noted that many of them are provoked by the car owners themselves.

Maslozhor. Occurs when using cheap types of oil. The consequences of this phenomenon are quite serious, resulting in significant material costs. Malfunctions caused by increased oil consumption - sticking of rings, increased wear of the ShPG. The only solution is to overhaul the engine.

Overheat. Causes could be a faulty thermostat, water pump, or stuck cooling fan. The issue is resolved by replacing them.

Floating speed. This malfunction is mainly caused by clogged carburetor jets or fuel filter. Maintaining the power system and using clean fuel eliminates this problem.

Extraneous noise when the engine is running. Here the culprits in most cases are unadjusted valves. Depending on the mileage and “age” of the engine, knocking noises can be caused by worn camshaft cams or piston pins. In any case, to identify the cause of unauthorized noise, the engine requires careful diagnostics.

Vibration when the motor is running. It can occur due to wear or destruction of engine mounts, incorrectly set ignition, carbon deposits in the combustion chambers and for a number of other reasons. In this case, it is also impossible to do without diagnostics.

Timely detection and elimination of identified faults allows you to significantly reduce or completely eliminate their negative impact on the engine.

Maintenance Procedure

The classic design of the internal combustion engine allows you to get by with simple steps when servicing the engine:

| Maintenance object | Time or mileage (whichever comes first) |

| Timing belt | replacement after 100,000 km |

| Battery | 1 year/20000 |

| Valve clearance | 2 years/20000 |

| Crankcase ventilation | 2 years/20000 |

| Belts that drive attachments | 2 years/20000 |

| Fuel line and tank cap | 2 years/40000 |

| Engine oil | 1 year/10000 |

| Oil filter | 1 year/10000 |

| Air filter | 1 – 2 years/40000 |

| Fuel filter | 4 years/40000 |

| Heating/Cooling Fittings and Hoses | 2 years/40000 |

| Coolant | 2 years/40000 |

| Oxygen sensor | 100000 |

| Spark plug | 1 – 2 years/20000 |

| Exhaust manifold | 1 year |

As the actual life of the internal combustion engine increases, consumables may be replaced more frequently than specified, or operations for cleaning the carburetor, engine, jets, and other attachments may be added.

Motor maintenance

Frequent malfunctions

In addition to the fact that when the timing chain breaks, the piston bends the valve, the classic engine circuit has characteristic malfunctions:

| Defect | Cause | Elimination |

| Knock | 1) the main bearings knock dully, the frequency coincides with the crankshaft speed 2) the sound of connecting rod bearings is sharper, present at XX 3) the sound of the pistons is dull, observed at low speeds 4) the valves knock less intensely, the shaft rotation is half as frequent | 1) adjusting the ignition, checking the oil level, replacing bearings, tightening the flywheel bolts 2) replacing bearings, checking lubricant pressure 3) replacement of rings, pistons, cylinder boring 4) replacing springs, adjusting gaps |

| Low oil pressure on a warm engine | 1) wear of oil pump gears 2) increased clearances of liners and bearings | 1) repair of the unit 2) replacement of bearing shells or housings |

| Increased lubricant consumption | 1) leaking seals 2) clogging of the ventilation system 3) wear of cylinders/rings | 1) replacement of consumables 2) cleaning channels 3) installation of repair kit |

| Increased gas mileage | 1) the damper opening angle is off 2) high resistance to movement 3) ignition timing is off 4) breakdown of the vacuum distributor | 1) damper adjustment 2) tire inflation 3) ignition adjustment 4) replacing the regulator |

| Reduced throttle response and power | 1) pump failure 2) ignition fault 3) the fuel filter is clogged 4) the damper is not fully open | 1) pump repair 2) ignition check 3) filter replacement 4) damper adjustment |

Engine overhaul includes boring cylinders, replacing shafts, piston and crank groups in any combination.

Do-it-yourself engine tuning 2106

Increasing the engine capacity of the VAZ 2106

For all owners, sooner or later, the standard 75 power ceases to be enough, the car begins to seem sluggish, unresponsive, and the question arises of how to increase the power of the 2106 engine. The most economical and simple tuning is to bore the VAZ 2106 engine by 3 mm for an 82 mm piston. Sharpening will no longer be possible, the walls of the block become very thin, only the sleeve of the block remains. To obtain a more torquey engine and further increase the volume to 1.8 liters. you need to increase the piston stroke to 84 mm. Otherwise, the modernization, modification and boost of the 2106 1:1 engine repeats the modification of the 2103; we read about installing shafts HERE.

Engine from Priora to VAZ 2106

Do you have an extra prioromotor lying around in the garage? Don’t rush to send it to the landfill, there is a better idea. Installing a 16 valve engine on a VAZ 2106 is one of the best ways to get reliable 100 hp, but at the same time the procedure is quite difficult, you will have to saw the engine shield with a grinder, digest the pan, install the crankshaft bearing 2101 on the eight-wheel, the original gearbox remains, the clutch is changed to Priorovskoe. In addition, the flywheel, exhaust system, cooling system and accelerator drive will require improvements. Doesn't it scare you? Then it's worth a try. Materials with step-by-step photo reports are widely available and will not be difficult to find. The situation is similar with the 2112 engine on the VAZ 2106; in any case, such a swap is better than squeezing the juices out of an old classic engine. All this can be done with Niva 1.7 and 1.8

Injection modification

The first in the line of internal combustion engines of the AvtoVAZ manufacturer, the 2106 engine received tuning in the form of distributed injection. At the same time, the owners received a headache:

- intense heating, since the mixture is lean, the manufacturer’s cooling system cannot cope with temperature loads;

- increased fuel consumption up to 13 l/100 km in winter.

Injection 2106

A positive feature is the low budget for major repairs within 10,000 rubles.

Features of the VAZ-21067, VAZ-21067-10, VAZ-214067-20 engine

The VAZ-21067 engine is an improved version of the VAZ-2106. The main difference from the base model is the replacement of the carburetor with an injector.

Installed on Lada 2105 and 2107 cars of the last years of production.

The engine almost completely repeated the design of the VAZ-2106. Improving the fuel supply system has given motorists not only advantages, but also disadvantages.

Torque is increased to 116 Nm. Thanks to this, the engine has become more responsive. Other technical characteristics are similar to those of the base model.

The injector made the operation of the engine much easier. There is no need for multiple carburetor adjustments or ignition settings, and engine starting at low temperatures is easier. The operation of the unit has become more stable. The exhaust now complies with Euro 2 environmental standards.

At the same time, the likelihood of overheating has increased. The engine cooling system remained unchanged, which turned out to be a design flaw. An internal combustion engine with distributed fuel injection requires more intensive cooling compared to a carburetor.

Car owners feel this when the fan turns on frequently. It is in this unit that failure can occur, because the fan bearing is a rather weak link.

Another serious drawback of the motor is the low service life of some components and parts. For example, the service life of a water pump drive belt is in the range of 40-70 thousand km. The bearings of the pump itself can withstand about the same amount of time.

In general, the VAZ-21067 turned out to be not a bad engine, but with significant shortcomings due to the low quality of components.

The VAZ-21067-10 engine was installed on the modification of the VAZ 21074-20 car. Fundamental differences from the base model consisted of a reduced displacement to 1451 cm³ and torque to 112 Nm. At the same time, the power of the unit was 71 liters. With.

Engine VAZ-21067-20 with a volume of 1568 cm³ and a power of 74 hp. s and a torque of 120 Nm was installed on a VAZ 21074-30 car. Cylinder diameter 82 mm, piston stroke 75 mm.

The VAZ-21067-20 engine differed from the VAZ-21067-10 in cleaner exhaust that complied with the Euro 3 standard.