A carburetor is a component that prepares the fuel mixture for the engine. Its task is to ensure the correct proportions of mixing air with gasoline. The ideal ratio is: 1 portion of gasoline per 15 portions of air. During operation, the adjustment of the VAZ 2106 carburetor gradually gets lost, which leads to excessive enrichment or depletion of the fuel mixture with gasoline. On the VAZ 2106, the manufacturer installed an “Ozone” carburetor produced by the Dimitrovgrad Automotive Assembly Plant (DAAZ). The operation of the device is based on the principle of jet propulsion. A powerful jet of air through the jets located in the diffuser carries fuel from the float chamber. As a result, a fuel-air mixture is formed in the proportions necessary for its ignition in the combustion chamber.

Table: calibration data for the Ozone carburetor

| Parameter | First camera | Second camera |

| Diameter, mm | ||

| diffuser | 22 | 25 |

| mixing chamber | 28 | 36 |

| main fuel jet | 1,12 | 1,5 |

| main air jet | 1,5 | 1,5 |

| idle fuel jet | 0,5 | 0,6 |

| idle air jet | 1,7 | 0,7 |

| econostat fuel jet | — | 1,5 |

| econostat air jet | — | 1,2 |

| econostat emulsion jet | — | 1,5 |

| air jet of the starting device | 0,7 | — |

| throttle valve pneumatic drive jet | 1,5 | 1,2 |

| accelerator pump nozzle holes | 0,4 | — |

| accelerator pump bypass jet | 0,4 | — |

| Accelerator pump flow for 10 full strokes, cm3 | 7 ± 25% | — |

| Calibration number of the mixture sprayer | 3,5 | 4,5 |

| Emulsion tube calibration number | F15 | F15 |

Any deviation in the composition of the fuel-air mixture from the optimal one affects engine performance. It becomes difficult to start a cold and warm engine, its operation at idle and in operating mode is disrupted, and acceleration dynamics deteriorate.

If not the valve, then what?

Dirt, low-quality fuel, malfunction of the ignition system - all this separately and in the compartment can affect the idle speed disappearing or becoming unstable. If you have already decided to carry out a full diagnosis, then start with the filters - air and fuel.

If they are heavily clogged, then gasoline or air (these are the main components of the air-fuel mixture) will not enter the carburetor normally. To be more precise, they will hit, but only after overcoming great resistance. And don't forget about the thimble-shaped filter that is installed at the inlet of the carburetor.

Signs of malfunction of the VAZ 2106 carburetor

The main symptoms of a non-optimal mixture composition are: • difficulty starting a cold engine; • unstable operation of the engine at idle; • dips when pressing the accelerator pedal; If the carburetor begins to produce a rich mixture, you will understand this by the following signs: • Fuel consumption increases • Loud exhaust is heard in the muffler and the smoke turns black If the engine receives a lean mixture, you will understand it by the following sign: • Loud pops are heard from under the hood . In both cases, the engine heats up noticeably more, and its power is also lost.

If you encounter a similar problem, remember that it is a natural consequence of using the carburetor. Any element of the car requires care, regular inspection and maintenance. Therefore, the VAZ 2106 carburetor must be adjusted from time to time. Before proceeding with the adjustment, you need to make sure that the cause of the breakdown is not the failure of any element inside the device. You need to disassemble it, wash it and clean it. And only after you are convinced that all components of the structure are in full working order, you can begin adjustment. The easiest option is to send the car to a specialist. Carburetor technicians have a special tool - a gas analyzer. Using this device, you can achieve the most efficient system setup. However, the services of specialists in this profile are not cheap. You may want to do all the work yourself, using available materials. Next we will look at how to set up a carburetor step by step.

Cleaning the jets

Before adjusting the carburetor, it is necessary to clean the channels and jets of dirt and deposits. To do this you need:

- unscrew the fuel and air jets;

- soak them in acetone or some other carburetor cleaner for ten minutes;

- blow out the jets with compressed air;

- Install cleaned and dried jets into the carburetor.

Before adjusting the carburetor, it is necessary to remove and wash all air and fuel jets.

Working with a carburetor is associated with an increased fire hazard. All precautions should be taken before starting work.

The VAZ 2106 carburetor is a rather complex device consisting of many small elements. Nevertheless, any car owner can wash the jets and strainer, as well as adjust the supply of the fuel-air mixture. To do this, you just need to consistently follow the instructions of the specialists.

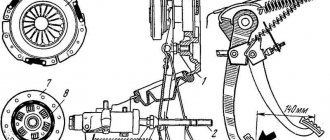

Adjusting the carburetor drive of the VAZ 2106

1. Check the length between the tips. The required size is 80 millimeters. 2. If you deviate from this size, remove one tip.

3. Loosen its lock nut and by rotating adjust the distance to the desired size.

4. Tighten the nut and return the rod.

5. You need to check the adjustment. To do this, our assistant presses the gas pedal. We observe the throttle valve to see if it has opened completely.

6. If not, then you need to remove the tip from the lever and reduce the length of the rod.

7. Now you need to see what position the damper is in when the gas pedal is released: does it close completely. If not, the pull needs to be lengthened a little. 8. Next we work with the air damper. We weaken its drive. In the cabin, we completely recess the damper. 9. Press the three-arm lever so that the damper opens completely. In this position, tighten the locking screw.

10. Check the adjustment. To do this, we completely close and open the door from the passenger compartment again. If the damper has not opened completely, we carry out the adjustment again. If the outcome is positive, fully tighten the screw.

Adjusting the carburetor damper OZONE VAZ 2106

The following step-by-step photo instructions will help you understand the adjustment process:

We adjust the VAZ 2106 carburetor starter

These works can be performed directly in the car. But you will have to first remove the filter cover. 1. Turn out the plug. Underneath we find the adjustment screw.

2. If you carry out the work without removing the carburetor from the car, pull out the choke. If you have the device in your hands, press the three-arm lever. After the damper is completely closed, push the rod down until it stops.

3. We look at the gap between the camera and the air damper. A 5.5 mm drill will help us with this.

4. If necessary, make adjustments by turning the adjusting screw using a screwdriver.

5. Return the cork back. 6. Now you need to check the distance between the camera and the throttle valve. The required size is 1 millimeter. A drill with a similar diameter is suitable for this. The gap is adjusted using a rod, which is either rearranged into a different hole or bent.

What do we have after proper adjustment of the carburetor unit of the “six”?

Checking the adjustments of the fuel mixture preparation unit is the same important maintenance step as monitoring the condition of the car battery. An integrated approach to setting up the carburetor guarantees not only a comfortable mode of movement, but also a lot of useful points:

- An increase in power and a confident increase in speed.

- No failures in the operation of the internal combustion engine in the low and medium speed sector.

- Improved dynamic characteristics - the car picks up speed faster and accelerates in a short time.

- Optimal engine response, which is expressed in the responsiveness of the gas pedal.

The listed qualities make it possible to effectively use the combustible mixture, which is necessary both in urban traffic jams and on country roads. Therefore, proper adjustment of the carburetor unit will help the car gain speed in a timely manner and complete the planned maneuver.

Adjusting the carburetor float OZONE VAZ 2106

Before you begin this work, you need to make sure that the needle valve is working reliably. 1. Take a measurement between the float and the gasket. This distance should be 6.5 millimeters. A slight deviation of 0.25 millimeters is allowed. You can also simply use a suitable drill bit to measure.

2. The clearance is adjusted by changing the angle of the float tongue.

3. Turn the float all the way. We measure the distance to the gasket in this position. It should be equal to 8 millimeters. Using the tongue we achieve the desired value.

Setting the gasoline level in the float chamber

To adjust the float in the DAAZ carburetor, the entire assembly itself does not need to be removed, but partial disassembly is necessary. To carry out adjustment work, perform the following steps:

- turn off the engine, open the hood;

- dismantle the air filter cover (unscrew three nuts);

- remove the filter housing itself (four more nuts);

- disconnect the choke cable;

- remove the telescopic rod of the starting device;

- unscrew the five screws securing the carburetor cover (they need to be carefully removed and reassembled, it is important not to drop the fasteners into the manifold);

- for ease of operation, disconnect the fuel supply hose;

- turn the lid over and determine the gap between the float and the cardboard spacer, it should be within 6-6.5 mm;

- if the gap differs from the required value, we make the adjustment by bending the tongue;

- It will also be necessary to align the float itself on a plane; it may be beveled relative to the surface of the cover.

When adjusted correctly, immediately after removing the cap, the gasoline in the float chamber is approximately at the level of the middle of the beveled surface of the carburetor body, and the float stroke is about 14 mm.

Adjusting idle speed on a VAZ 2106

First you need to prepare the car. We warm up the engine to a temperature of 90 degrees. We ensure that the engine operates stably at idle speed.

1. Using the quantity screw, we achieve a crankshaft speed of 820 to 900 rpm. 2. Using the quality screw, we bring the unit into stable and uniform operation. Then, by tightening the screw, we destabilize the operation of the motor and unscrew it again to restore it. Our task is thus to achieve the most stable operation of the engine with the leanest possible mixture. 3. Using the quantity screw, we again bring the speed to the desired value. 4. It is best to carry out the operation two or three times.

Carburetor diagnostics after adjustment

Now you need to make sure that all settings are set correctly. To do this, you need to start the engine and watch it idle. Is he starting to triple? Next, press the accelerator sharply and also sharply release it. Can you hear any dips? If yes, the fuel quality adjustment screw needs to be unscrewed a little. During heavy braking, the engine should continue to operate stably. If it stalls, you need to slightly unscrew the quality screw. Thus, you now know how to adjust the carburetor on a VAZ 2106 on your own without special tools. Experienced carburetor technicians! If you find inaccuracies in the article and want to share your experience, write your comments. Your opinion will be very useful to all readers of the site. Sixes are often equipped with DaAZ and Solex carburetors. Is there a fundamental difference in adjustment between them? Also interested in your opinion.

OZONE carburetor. Secrets. Diagnostics. Setup. Video

Let's sum it up

Taking into account the above information, it becomes clear that the carburetor of the VAZ 2106 car must be properly and promptly serviced. The quality of internal combustion engine operation, carburetor service life, fuel consumption, acceleration dynamics and a number of other indicators and characteristics depend on this.

If any malfunction occurs, do not delay repairs. Moreover, even if there are no malfunctions in the operation of the engine and dosing system, the carburetor should be adjusted every 20-25 thousand km. mileage

We also recommend reading the article on how to clean the carburetor yourself. From this article you will learn about the features of cleaning a car carburetor, as well as what you need to consider when performing this procedure.

It is also recommended to periodically clean the carburetor. Cleaning the carburetor is quite simple and quick; all work can be done independently, without resorting to the services of a service station.

As a result, the owner receives not only a fully functional, but also a “correctly” functioning dosing device, which will allow him to operate the car with complete comfort and maximum efficiency from the power unit.

VAZ 2106 carburetor maintenance

During the operation of the carburetor, the narrow channels of the jets become clogged. This usually happens when using low-quality fuel, untimely replacement of the air filter, etc. The composition of the fuel-air mixture is disrupted and its flow into the engine is difficult. As a result, the power unit begins to operate intermittently, and its dynamic characteristics decrease. In such cases, it is necessary to flush the contaminated jets with a special cleaning compound and then blow them with air.

If the carburetor jets become clogged, they should be washed with a special agent and blown out with air.

In addition, it is recommended to periodically adjust the composition of the fuel-air mixture to the optimum using special adjusting screws. Otherwise, the engine will run unstably.

VAZ 2106 stalls at idle

In idle mode the valves are closed. A vacuum is formed under them, ensuring the flow of fuel through the hole under the damper of the first chamber. The cause of a situation in which the engine starts but runs unstably is most often the carburetor. Depressurization of its housing may occur. This will lead to excess air entering the carburetor, leaning the fuel-air mixture. The settings of the quality and quantity screws that regulate the composition and quantity of the combustible mixture may also fail. In addition, the lack or absence of fuel in the float chamber leads to a lean mixture entering the engine. The current situation will require the car owner to perform the following actions. 1. To eliminate depressurization of the housing, replace the sealing gaskets between its individual parts.

The Ozone carburetor uses a heat-insulating gasket as a sealing element

2. Tighten all bolted connections.

During operation, to prevent depressurization, the screw connections of the carburetor parts should be periodically tightened.

3. To prevent depressurization, replace the rubber ring of the solenoid valve and quality screw. 4. Check the condition of the vacuum ignition timing regulator hose for wear and mechanical damage.

A loose connection in the vacuum ignition timing regulator hose allows excess air to enter the carburetor.

Dips when pressing the gas pedal VAZ 2106

When you press the accelerator pedal, the throttle valve opens. Next, the accelerator pump comes into operation through an articulated lever. If it is faulty, then pressing the pedal will lead to interruptions and engine stop. This most often manifests itself when starting from a stop and suddenly accelerating. When you sharply press the accelerator lever, a powerful jet of fuel should be observed from the nozzle channel into the emulsion chamber. A weak stream may be the result of: • clogged supply channels, spray nozzle and discharge valve; • depressurization of the housing; • a broken tube of the vacuum ignition timing regulator. To eliminate this malfunction you must:

1. Replace the carburetor sealing elements. 2. Tighten bolted connections. 3. Replace the rubber o-ring of the solenoid valve. 4. Check the vacuum ignition timing regulator tube for wear and mechanical damage. 5. Repair the accelerator pump (rinse the supply channels, clean the spray nozzle of deposits, replace the diaphragm).

The causes of interruptions when pressing the accelerator pedal are often faulty elements of the accelerator pump.

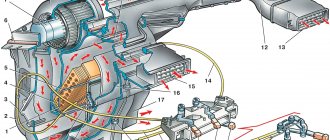

How it works

In the carburetor body (under its top cover) there is a float chamber into which fuel is pumped. Its function is to constantly maintain the fuel level. The chamber has a float that is connected to a needle valve. When the fuel level in the chamber drops, the float will move down, thereby opening the needle valve. Due to this, fuel can again enter the float chamber.

Next, gasoline is fed through a sprayer into the mixing chambers, where it is mixed with air coming from the pipe through the air filter located above the unit. In order for fuel to enter the mixing chamber in strictly defined proportions, gasoline flows through nozzles - these are plugs with small holes of various diameters. By selecting jets, you can change the operating characteristics of the engine.

When the engine is running, a vacuum occurs. To make it quite high, and also to increase the air flow speed, the carburetor device has a diffuser. Using the throttle valve system, the driver can regulate the amount of fuel mixture.