On carburetor engines of VAZ 2108, 2109, 21099 cars, the recommended idle speed is 750-800 rpm. At the same time, they must be stable (without frequent misfires and “triples”). It is recommended to adjust the idle speed of engines with carburetors 2108, 21081, 21083 Solex once every six months or if problems arise with engine operation.

Preparatory work

Before carrying out the adjustment, at a minimum, it is necessary to make sure that the spark plugs, high-voltage wires, the distributor cap, the “slider” are in good condition, that the ignition timing is set correctly, that no foreign air is being sucked into the carburetor, and that the fuel pump is in good working order.

In addition, you should warm up the engine to operating temperature (80-90 degrees) and fully open the carburetor air damper, pushing the “choke” handle all the way.

It is not necessary to disconnect and plug the vacuum supply tube from the carburetor to the vacuum ignition timing regulator. Although, after adjusting the idle speed, you can remove it from the fitting on the vacuum regulator housing and check whether there is a vacuum in it when the engine is idling. At correctly adjusted speeds, there should be no vacuum there or it should feel very light.

Tools required for adjusting idle speed

Fine-tuning the idle speed is carried out using a gas analyzer, but not everyone has one. Therefore, it is advisable to have a separate device - a tachometer. If it is not available, you can use the tachometer built into the instrument panel (available on all VAZ 2108, 2109, 21099). You will also need a thin slotted screwdriver.

Adjusting the engine idle speed

Let's start the engine. We turn on the high beam headlights and the heater.

— The simplest way to adjust the idle speed of an engine with a Solex carburetor (2108, 21081, 21083) is to rotate the fuel mixture “amount” screw.

Counterclockwise the revolutions decrease, clockwise they increase. When the screw rotates, its tip acts on the lever of the throttle valve axis of the first chamber of the carburetor and thereby either opens the throttle valve of the first chamber of the carburetor, or, conversely, closes it. Because of this, the air flow passing through the first chamber and the vacuum in the CXX channel increases or, conversely, decreases. Thus, the “quantity” screw regulates the volume of fuel entering the engine cylinders. Accordingly, the engine idle speed will either increase or decrease.

The image shows the screw for adjusting the “quantity” of the fuel mixture of Solex carburetors (2108, 21081, 21083). The carburetor choke lever has been removed for clarity.

More precise tuning involves additional adjustment of the composition of the fuel mixture entering the engine cylinders.

The “quality” screw of the fuel mixture is responsible for this in the 2108, 21081, 21083 Solex carburetors.

To begin with, you can set the initial position of the “quality” and “quantity” screws of the carburetor. This is 3 full turns from the stop of the “quality” screw; the “quantity” screw should be set to the minimum crankshaft speed - 600-700 rpm.

— At the next stage, it is necessary to set the maximum idle speed, using only the “quality” screw of the fuel mixture.

Using a slotted screwdriver, gradually unscrew it from its socket until the idle speed reaches its maximum. It can be 1000 rpm or slightly higher.

— Next, use the “quantity” screw to set the speed to 900 rpm.

We achieve this by slowly rotating it counterclockwise.

— Using the “quality” screw, we set the idle speed at the required level of 750-800 rpm.

To do this, again slowly, wrap it clockwise.

If it is not possible to immediately achieve the desired crankshaft speed, we carry out the adjustment again.

The idle speed of the engine with a Solex carburetor has been adjusted.

— A second, more precise adjustment using both carburetor trim screws will lead not only to a stable and stable engine idle, but also to a decrease in the toxicity of exhaust gases.

— If “dips” occur when you press the gas pedal after adjusting the idle speed in this way, you should slightly turn the “amount” screw of the fuel mixture clockwise, thereby adding a little of the fuel mixture entering the engine cylinders from the idle system. After this, the engine speed will increase slightly, the limit value for engines of VAZ 2108, 2109, 21099 cars is 900 rpm.

— In some cases, it makes sense to modify the carburetor idle system. See “Modification of the idle system of Solex and Ozone carburetors.”

Five more articles on adjusting and tuning the Solex carburetor

Comparative car repair test

On all cars of the “ninth” family, the engines were equipped with domestically produced Solex carburetors. The only exceptions are later modifications, on which the manufacturer installed injection power units. Although far from being the most technically advanced vehicle, the Nine is still popular among car enthusiasts. This is largely due to the car’s maintainability and the relatively low cost of spare parts. In addition, a significant part of the restoration and adjustment work can be carried out by the owner himself, including adjusting the VAZ-2109 and 21099 carburetor, tuning it and cleaning it.

This article will consider only those operations that every car enthusiast can perform with his own hands. Don’t be intimidated by the large number of manipulations - follow the instructions, be careful, and setting up the VAZ carburetor will go no worse than in a service station. This way you can save time and reduce machine maintenance costs.

You can clean and adjust the carburetor for the VAZ nine yourself, in the garage

Preparing the carburetor for tuning

Before you begin adjusting the VAZ-2109 carburetor and other modifications of the model, you should ensure unimpeded access to its parts by removing contamination. If the car is used regularly, then the carburetor needs external flushing only in the case of adjustment procedures or to clean the moving mechanisms if they are heavily contaminated. External washing is carried out using a brush, a clean rag and a liquid that can dissolve oil (gasoline, kerosene or a special cleaning composition). This procedure does not involve removing the carburetor and consists of the following operations:

Solex design

The carburetor mechanism of all modifications on the VAZ 2108/2109 is emulsion and consists of two internal combustion chambers. At the top of the carburetor there is a cover that prevents dirt from entering the cavity of the device, and fittings - fuel lines are supplied to them. The middle part is the body itself, into which diffusers and cameras are mounted. At the bottom of the carburetor are the float chamber and throttle valves.

The key elements of the system are:

- accelerator pump;

- float;

- throttle thrust;

- forced idle economizer;

- main dosing system;

- trigger mechanism;

- econostat;

- vehicle idle system.

The principle of operation of the Solex carburetor is that gasoline is supplied through the inlet valve in the fitting. The fuel is directed directly into the float chamber. The fuel level in the cavity must always be at a certain level to avoid dips and jerks in engine operation. Level control is carried out through the movements of a needle valve mechanism.

After the chamber, gasoline is sent to emulsion wells, where it is supplied in strictly limited quantities through fuel nozzles. It is in the wells that air flows break up large drops of gasoline, forming a single air-fuel mixture with it.

The mixture is supplied to diffusers, and through them to the power unit device. Thus, the main task of the carburetor is to form the air-fuel mixture in the desired consistency and direct it to the engine.

The interaction of many elements ensures smooth operation of the motor

This is interesting: Air filter VAZ-2114 - what are they and how to change them?

How to set up a VAZ-2109 and 21099 carburetor in a garage

According to the recommendations of experts, adjustment of the VAZ-21099 carburetor should begin with the float chamber. Using this procedure, it is possible to check and establish the optimal fuel level. You need to configure it by following the steps below step by step:

- Start the engine and turn it off after 2-3 minutes;

- After the air filter has been removed and the fuel hose has been disconnected, remove the carburetor cover (to do this, you need to unscrew five bolts). Place the lid on a clean surface with the floats facing up, being careful;

After removing the air filter, disconnect the fuel supply and remove the carburetor cap

- Using a caliper, determine the fuel level in the float chambers: the distance between the edge of the housing and the upper level should be 25.5 mm. If it turns out that the measurements do not comply with the standard, you will have to make an adjustment by bending the tongue of the float bracket and re-measuring the fuel level;

Additionally, you can check how the edges of the floats are located relative to the mating surface of the cover and, if they are not parallel, adjust by acting on the float brackets.

How to adjust the throttle valve actuator

Before you begin adjusting the damper itself, you should check the degree of cable tension. If it turns out that the cable is slack or its tension is too strong, then adjusting the VAZ-21099 carburetor involves starting to adjust the drive in such a way as to prevent the damper from completely closing. To do this, use a wrench set to “13” and tighten the end nut on the cable sheath. Next, use the same key to gradually loosen the locknut.

Now you can set the optimal distance between the carburetor and the tip of the nut. It should be taken into account that in the free position of the accelerator pedal, the damper must be completely closed. All that remains is to tighten the nut and the setting can be considered complete.

How to adjust the air damper actuator

First, the free movement of the thrust must be checked - this will require dismantling the air filter cover. The drive settings can be considered correct only if the air damper is fully opened in the “recessed” position of its handle. If deviations from the norm are detected, read the instructions on how to adjust the carburetor on a VAZ-2109 by performing a series of adjustments.

Throttle adjustment is an important part of the carburetor tuning procedure.

The drive setup process looks like this:

- Loosen the bolt that secures the rod to the lever. After this, you need to recess the drive handle and fully open the air damper, acting on its lever;

- Using pliers, pull the cable out of the sheath and tighten the fixing bolt;

- Next, you need to check how the damper closes when the handle of its drive is extended. Closing must occur completely, otherwise the adjustment operations will have to be repeated.

- The adjustment should be made until you achieve complete opening and closing of the damper in the extreme positions of the drive handle. Make sure that the lever does not come into contact with the cable jacket in any position.

So, at this stage, you have learned how to adjust the carburetor on a VAZ-2109 by setting the optimal operating position of its throttle and air dampers. Now let's move on to adjusting the starting device and idle speed.

Self-adjustment of the starting device

The most precise adjustment of the starting device by setting the values of the starting gaps requires removing the carburetor from the car. But first you need to make sure the integrity of the trigger device diaphragm. To do this, unscrew the four bolts, remove the cover and inspect the diaphragm. If it is suitable for further use, you can continue to make adjustments, otherwise the part will have to be replaced.

Below is a list of operations performed one by one, which describes how to adjust the VAZ-21099 carburetor by adjusting the starting device:

- First you need to close the air damper by turning its lever;

- Using a screwdriver, press down the starter rod;

- The gap formed between the chamber wall and the damper must be measured, and then its value must be compared with the calibration data (indicated by the manufacturer individually for each carburetor model and car);

- If the received data does not correspond to the nominal value, adjustment should be made. The locknut, which is located on the accelerator pump housing, should be loosened and the adjusting screw should be turned with a screwdriver until the required clearance is established;

- Now, having closed the air damper, it is necessary to measure the clearance of the throttle valve of the first chamber. Check the obtained data with the calibration table. If necessary, set the desired gap value by turning the damper adjusting screw.

It is likely that at this stage the adjustment of the VAZ-2109 carburetor can be completed. If you need to adjust idle speed or improve fuel consumption, you can read the relevant guide below.

The secret of 99 - how is people's love justified?

The car, whose history goes back almost four decades, is still considered one of the most successful VAZ assemblies. Until 2004, all VAZ 21099 models had a carburetor engine type, and only after 2004 did manufacturers replace this device with an injector. So the carburetor 99, a symbol of the dashing 90s, is today found on the roads of post-Soviet countries no less often than modern cars.

The car has front-wheel drive, a 1.5 liter 4-cylinder engine. A VAZ car can accelerate to 160 km/h with its 70 hp. Some models have a 1.5i engine with 76 hp, although not many of these cars were produced. The carburetor of model 21099 is very economical, the average consumption of the VAZ 21099 reaches 7–7.5 l/100 km. Fuel consumption on the highway with high-quality fuel and average speed is 5.5 liters.

Signs of a Solex carburetor malfunction

Before adjusting the carburetor on a VAZ 2109, you need to familiarize yourself with the associated faults so as not to repair the unit just like that.

So, the reason after which the VAZ 2109 carburetor is adjusted is considered:

Fuel mixture too rich. Experienced auto mechanics know that for an ideal ratio of fuel and air, a value of 1 to 15 is required. This means that for the combustion of 1 kg of fuel, 15 kg of air are needed. If the mixture is called rich, it means that the fuel level is higher than the nominal level.

Symptoms: the engine is difficult to start, black smoke from the exhaust pipe, spark plugs with black soot and lumbago in the exhaust system. The fuel supply system quickly becomes clogged.

The following signs can be called a consequence of the previous ones and this is:

- Unstable idle speed;

- Increased fuel consumption;

- Deterioration of starting properties;

- Reduced engine response.

The operating principle of the carburetor and fuel supply system forces car owners to perform such a procedure as adjusting the VAZ 2109 carburetor at least once every six months. The mechanism on a car with a carb needs to be lubricated once a month, unlike a car with injection, which has injectors. Everything is extremely easy to adjust.

Causes of failure - we make a diagnosis

Very often, owners of 99 VAZ are faced with the problem of poor engine performance, which can occur in both warm and cold seasons. One of the main reasons for this problem is malfunctions of the carburetor. The symptoms that arise during malfunctions are very easy to notice - the car does not start well, the speed on the tachometer fluctuates, unusual sounds in the form of pops can be heard from the exhaust pipe.

While driving, the VAZ 21099 may stall when changing gears. During acceleration or releasing the gas pedal, jerking and failures in operation are possible. Fuel consumption increases noticeably.

If you find problems with the operation of the VAZ 21099 carburetor, then in case of minor damage it can be repaired or replaced with a new one, if the problems are more serious. Repairing a carburetor is a delicate matter and requires experience in the work. For self-repair, you will need a standard set of tools and, preferably, a book on the maintenance and repair of this type of device.

Reasons for failure of the VAZ 2109 carburetor

The Solex carburetor is a very sensitive device, which contains a large number of small channels. When a huge amount of low-quality fuel passes through them, you may encounter the fact that they become clogged with impurities and stop functioning.

The first thing that may immediately become noticeable is a decrease in idle speed. In the future, the car does not start well and needs carburetor adjustment.

This procedure is divided into several stages:

- Removing the unit

- Disassembly and cleaning

- Assembly and installation

- Carb idle adjustment

↑

How to flush a carburetor assembly without disassembling it

Flushing the Solex carburetor is recommended by the manufacturer in cases where there are clearly any problems with its operation: increased gasoline consumption, jerks and jolts when driving, unstable idle speed, problems with starting.

The traditional method of washing carburetors is to completely disassemble them into individual components, which is not always possible for an inexperienced VAZ owner to do. To simplify the procedure, a technique was created for washing and cleaning the carburetor without disassembling it into components. This technique is based on the use of special aerosols in cans. The most affordable carburetor cleaners are considered to be aerosols produced by ABRO and Mannol - they can be bought at any auto store for 100–150 rubles.

These cleaners do an excellent job of cleaning carburetor mechanisms, and they are also very easy to use. To flush the Solex carburetor, it is recommended to turn off the engine, let it cool and begin the procedure:

- Remove the air filter box from the car and place it to the side.

- Unscrew the solenoid valve from the carburetor body.

- Place a special narrow nozzle on the aerosol can and spray the liquid on the nozzle channels, the first and second chambers, dampers and all visible elements of the carburetor.

- After this, spray the aerosol on the external parts of the mechanism.

- Wait 5–8 minutes (depending on the aerosol manufacturer’s recommendations). During this time, the liquid will be able to corrode accumulations of soot and dirt.

- Next, you can start the engine so that it removes all remaining dirt.

- If during one procedure the carburetor did not have time to be properly cleaned, then you can treat it again with the same aerosol.

After such cleaning, the VAZ 2108/2109 will significantly increase its dynamic characteristics, since the accumulation of dirt will not interfere with the normal operation of all parts of the carburetor.

Video: how to clean the carburetor on a VAZ with your own hands and without removing it from the car

How to replace carburetor parts

Replacing the float, accelerator pump diaphragm, and seals is not particularly difficult. Most often, during repairs, repair kits selected for the type of carburetor are used, which include everything necessary to replace the elements.

The replacement procedure is not regulated in any way: it is enough to remove the damaged part and install a new one in its place. The main criterion: the identity of the elements when replaced.

Removing, disassembling and cleaning the carburetor VAZ 2109

If all of the above symptoms are detected, you can begin to remove and disassemble the carburetor. On a VAZ 2109, repairing a Solex carburetor is possible using a repair kit. It is recommended to purchase a repair kit in advance to immediately replace all gaskets, jets and valves. The table contains data on jets and all necessary valves. The machine must be stationary. When sorting out the parts, the most important thing is not to lose anything.

To remove and configure the device, you need to open the hood and disconnect all the hoses from it. They are mounted on clamps, so it is recommended to stock up on a screwdriver in advance. The next stage is the cable for driving the gas pedal and air damper. Both elements can be removed quite easily. After this, remove the chip from the idle speed economizer. Dismantling is carried out extremely carefully so as not to damage the contacts. Taking everything apart is even easier.

Recommended flow rates of pneumatic economizer jets for various operating conditions

| Operating conditions | Flow capacity cm³/min | Operating conditions | Flow capacity cm³/min |

| Light road conditions with heavy loads (economical adjustment) | 60 | Average road conditions |

You can now remove the four housing nuts that hold the carburetor to the intake manifold. If it is difficult to remove, you can pry it out with a thick screwdriver. Clog the manifold with a rag to prevent foreign particles from getting inside and clean the seating area of any remnants of the old carburetor gasket.

The carburetor itself consists of several elements:

- Top cover

- Bottom cover and float chamber

- Throttle valve block

First of all, the top cover is removed. At the same time, the condition of the needle valve and the condition of the float are checked. The valve should move without jamming and also easily return to its original position. You can immediately check the operation of the accelerator pump drive. All connections should turn easily. The operating principle of many mechanisms is very simple, and they must stand level. It is configured after assembly.

Now you need to separate the throttle body from the bottom cover. Everything is held in place with bolts, so a screwdriver will suffice. Once all components are completely disassembled, they need to be treated with throttle body cleaner or regular gasoline. Parts should be wiped with dry rags.

Removing a faulty device

Carburetor repair is a simple procedure. When removing it, there is no need to replace the pump, fuel pump or battery. The device of the VAZ 21099 car allows you to quickly remove the faulty device. To do this, all you need is a standard set of keys and a little patience.

- First, remove the air filter along with the filter element.

- Then we disconnect the air damper rod. It is located on the right side of the carburetor, in the direction of travel of the car.

- There we also remove the return spring of the gas pedal drive.

- Use a screwdriver to pry up the spring clamp on the gas drive sector and remove it.

- Then we remove the throttle cable from the drive sector.

- We disconnect all the wiring connectors from the carburetor, having previously marked their connection points so as not to confuse them during assembly.

- Loosen the clamps and remove the fuel hoses.

- Unscrew the screw and remove the heating block of chamber 1.

- We remove the crankcase ventilation hose, and then the vacuum tube going to the breaker - the ignition distributor.

- Unscrew the 4 fastening nuts and carefully remove the carburetor.

- To top it off, cover the outlet hole with a clean rag to prevent dirt from getting into it.

Main unit VAZ 21099

Installation is carried out in the reverse order of removal. Now you can begin disassembling and cleaning the carburetor.

Return to contents

This is interesting: What is poured into a car radiator - antifreeze, antifreeze or water?

Installation and assembly of the VAZ 2109 carburetor

After cleaning all the elements, you can assemble it. Check the clearances in the throttle valve block in advance and set them to the nominal values. For each type of unit, you can find all calibration data in reference books. Instead of old gaskets, it is recommended to immediately install new ones to avoid repeated disassembly after two weeks of operation. Installation of parts is done carefully.

Replace the needle valve if necessary. A faulty valve can negatively affect fuel consumption, as it backs up and allows a huge amount of gasoline to pass through the channel cross-section.

It is recommended to lubricate the damper drives, levers and rods with Seledol or Litol 24. It is not recommended to use this lubricant in an environment that comes into contact with gasoline. The grease is suitable only for external parts, such as the plastic joints for the carburetor rods. They may not stand.

The top cover is installed last and only after adjusting the level in the float chamber.

Disassembling the device

Maintenance of the VAZ 21099 carburetor involves removing, cleaning and adjusting this device after every 60,000 kilometers. When disassembling the carburetor, it is highly recommended not to unscrew the screws securing the air and throttle valves, as this can lead to jamming of the mechanism. In addition, it is prohibited to press out brass tubes that cannot be twisted out.

- First, unscrew the solenoid valve and remove the fuel nozzle from it.

- Then remove the carburetor cover by unscrewing 5 screws.

- After this, use a thin screwdriver to push the float axis out of the holders, take it out and remove the floats.

- Carefully, so as not to damage, remove the cover gaskets.

- Unscrew the needle valve.

- Unscrew the 4 screws of the starter cover and remove it.

- Carefully separate the diaphragm from the cover and remove the spring.

Adjustment in progress

Then unscrew the fuel filter plug and remove it along with the filter element.

- Carefully pry up the accelerator pump nozzles with a screwdriver and remove them.

- Unscrew the 4 screws of the accelerator pump cover and remove it.

- Carefully remove the accelerator pump diaphragm and spring.

- Unscrew the screws of the economizer cover and remove it along with the spring and diaphragm.

- We take out the plastic plug using a screwdriver or a corkscrew and unscrew the mixture quality screw.

- We unscrew 2 emulsion tubes combined with air jets.

- Then we unscrew the fuel jets 1 and 2 of the chamber, located under the emulsion tubes, and, turning the body over, shake them out.

- We unscrew the screw securing the wire and, carefully bending the tabs of the tip, remove the wire from the tip of the mixture quantity screw sensor.

- Unscrew the screw for the amount of mixture.

Return to contents

Do-it-yourself carburetor float chamber level adjustment

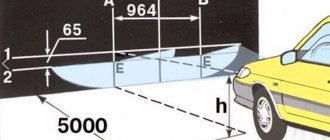

Diagram of the float chamber with installation parameters: 1 - float; 2 - tongue; 3 - gasket; 4 - cover.

The level in the float chamber is necessary for smooth operation of the carburetor. A level that is too high will increase the fuel supply, while an insufficient level will reduce the throttle response of a carburetor engine, since the level will not be able to rise in time.

To adjust the level in the chamber, you need to turn the top cover over and bend the float as far as the antennae allow. The distance between the bottom corner and the cover should be 20 mm. If not, bend the tabs and install the top cover. This do-it-yourself adjustment of the VAZ 2109 carburetor is considered nominal. The principle of action here is simple.

Basic faults

Any malfunctions of the 2109 carburetor affect the performance of the engine: the engine may stall when the speed is reduced, run intermittently, not develop power, and consume gasoline beyond the norm. There are many reasons for problems with this unit, but the most typical of them are:

- clogging of the HDS and idle jets, both air and fuel, and in the solenoid valve (EMV);

- rupture (defect) of the accelerator pump diaphragm;

- failure of the EMG itself;

- loose fit of the locking mechanism needle to the seat;

- air leakage through the junction of the body and the cover;

- leakage of the float in the float chamber;

- clogging of the accelerator pump nozzle with dirt;

- misadjustment of screws XX.

Of course, various types of malfunctions can occur not only due to the carburetor, the engine itself is often faulty, and the ignition may also be set incorrectly, especially if the installation was carried out by an inexperienced technician without a strobe light. Problems with idle speed can occur due to a lack of power to the solenoid valve, so before disassembling the HRV, you should first check for voltage on this wiring.

Adjusting the choke or trigger

Install the carb, but do not install the air filter. Pull the choke out completely and close the valve. In this position, you need to adjust the air damper cable.

Try pulling out and removing the choke several times. The damper should open and close completely without jamming. If everything is done correctly, you can install the air filter in place, connect all the hoses and carburetor drives. It's time to start adjusting the idle speed of the VAZ 2109. Don't forget about connecting the EPHH.

Design and principle of fuel supply

The VAZ 21099 (Solex) two-chamber carburetor consists of 2 parts: the main body and the cover. The cover contains an electromagnetic valve with an idle jet and a cold start system, which was sometimes equipped with a heating device. A float with a needle or ball valve is attached to the bottom of the lid, and 2 brass tubes with jets at the ends come out from there.

The main body of the carburetor is equipped with the following devices:

The idle speed adjusting screw supports the primary chamber damper and is equipped with a plastic handle. The screw that controls the enrichment of the fuel mixture is hidden in a deep well made in the “sole” of the housing. A diagram of the lower part of the unit is shown in Figure 1.

Now about the functions performed by each system:

- The spring-loaded cold start flap in the closed position ensures the supply of a rich mixture. If there is a bimetallic spiral, it opens automatically as it warms up; without it, it opens manually.

How to set up the carburetor correctly on a VAZ 2109?

The nominal speed of the VAZ 2109 engine should correspond to 750-800 rpm. Adjusting the XX carburetor is necessary to economically maintain engine operation while parked and to warm up as quickly as possible before driving. Without this, the device will not work. Table from those. carburetor characteristics does not have such data. This must be done according to the following instructions, which contain the XX norm. The results and adjustment scheme are stable speeds.

This procedure is carried out if there are problems with the engine or once every six months in accordance with the regulations on technical maintenance of the VAZ 2109. You only need to spend 3-4 minutes on it. The engine warms up to operating temperature using choke or using the accelerator pedal. Next, remove the choke and fully tighten the quality screw. Most likely, the engine will stall. Now the screw is unscrewed exactly three turns and the engine starts again.

Using the quantity adjusting screw, the speed is set to 650-700 rpm. Now turn the quality screw until you get the highest possible idle speed. Again we set the number of revolutions equal to the nominal one. Now we need to rotate the quality again until we get maximum speed. You can regulate this way for a long time.

Now turn the quantity up to 800 rpm. This adjustment is considered correct. If this was not achieved the first time, you need to repeat the procedure again. It is worth recalling that the entire procedure is performed with the headlights on low beam and the stove operating at maximum mode. This is due to the fact that when the voltage drops, the speed drops, so when using these consumers, the speed should be nominal, and when turned off it should increase slightly.

The quality and quantity screw on the carburetor of the Lada 2109 car is located at the rear of the unit. In this regard, adjustment becomes more complicated. Although, it becomes more difficult to regulate, but not as often as on a Zhiguli.

Excellent video on fine-tuning the Solex carburetor on a VAZ 2109

What to do if there is no idle speed on the carburetor nine

Adjusting the ignition angle

Sluggish acceleration of the car and instability of the idle speed are also often associated with incorrectly set ignition; this procedure is mainly carried out in car repair shops using special equipment. But if you wish, it’s easy to make the adjustment yourself, and without a strobe, and quite accurately:

- with the engine stopped, loosen the three nuts securing the distributor (the third fastening is located at the bottom, it is not visible from above);

- we start the car, turn the distributor-distributor clockwise (to “+”), and if the ignition was late, the idle speed will increase noticeably;

- we select the optimal position of the distributor (the operation of the internal combustion engine should be smooth, without failures), reduce the speed using the quantity screw, turn off the engine, fix the distributor-distributor with one nut for now, and check the results of the ignition adjustment on the fly.

We recommend: How to replace a VAZ-2114 pump with your own hands

If, under heavy load and sharp acceleration, your fingers begin to noticeably “knock” (engine detonation appears), you should move the distributor a little to “minus”, then check the car again while driving. This way you can set the ignition quite accurately, and sometimes even better than with a strobe light.

Idle speed adjustment

Stroke adjustment is performed on a fully assembled system. The engine needs to be warmed up well before adjusting the idle speed. It is better to use a tachometer and a gas analyzer when making adjustments, but you can do without the latter. Setting up without a gas analyzer is carried out according to the following scheme.

Additionally, we recommend reading the article by our specialist, in which he talks about how to check and clean the idle air sensor.

We also recommend that you carefully study our expert’s article, which talks about why idle speed fluctuates.

- With the engine turned off, it is necessary to screw the air-fuel mixture quality hardware all the way.

- Next you need to make 3 - 4 turns in the opposite direction.

- The engine must be started, the choke removed, the fan and high beams turned on.

- Using the fuel quantity screw, it is necessary to bring the engine speed to 750 - 800 rpm.

- The quality screw must be set to maximum speed.

- The quantity screw must be set to 900 rpm.

- Next, using the quality screw, the speed must be reduced to 800.

- The quality screw must be tightened until the motor begins to operate unstably. After the speed starts to float, you need to turn the screw one or half a turn back.

- The quantity screw must be set to the required speed. For summer, the indicator is in the range of 800 - 900 rpm, for winter 900 - 1000 rpm.

Adjusting the carburetor is a fairly simple task that requires scrupulousness and consistency. If necessary, minor repairs can be carried out along the way. It is better to fix serious breakdowns in a car service center.