Symptoms of a problem

Bearing wear manifests itself as the following symptoms:

- Vibration of the front wheels, which can be reflected in the steering wheel or felt in the cabin.

- Knocking or crackling sounds in the front of the car when driving;

- Heating of the front wheels in the axle area.

If such manifestations occur, you need to check the condition of the wheel bearings. To do this, jack up the car and rock the wheel in different directions. Play and knocking in the bearing area indicates the need for replacement and adjustment. The malfunction may also manifest itself in the form of noise when the wheel rotates.

Separately, it is worth mentioning two problems that arise during the operation of the Chevrolet Niva:

1. The hubs get hot. It is important to understand that when braking, the kinetic energy of the car is converted into thermal energy. As a result, the brake discs and the hubs on which they are attached become very hot. Heating of the part during movement, and not during braking, indicates wear of the bearing or its incorrect adjustment.

The second option is typical for adjustable hubs. The adjusting nut must be tightened with a force of 2 kgf*m. If you tighten it further, the tapered bearings will be too tight.

Their rotation will be difficult. Prolonged operation of the machine in this condition leads to bearing failure and wheel jamming.

2. The adjusting nut is unscrewed while moving. Sometimes this happens literally after 20-50 kilometers. The phenomenon is observed in three cases: the master forgot to tighten the nut, there was a misalignment between the bearing races, or play appeared in the coupling of the CV joint with the hub.

Which bearing to choose?

The best wheel bearings for the Chevrolet Niva and short Niva can be selected from the list below:

- FINWHALE - price 450 rubles;

- AVTOVAZ - price 350 rubles;

- KOYO - price 800 rubles;

Also good companies are SKF and SNR.

Adjustable bearings should not be confused with the new type of double row bearings. They are different in width, price and article number. The catalog number of the wheel bearing on Niva is 2121310302010 . This number is the adjustable bearing.

How to change the wheel bearing on a Chevrolet Niva with your own hands?

For repairs you will need:

- Powerful socket wrench 30.

- Puller for steering rod pin.

- A mandrel for pressing out a bearing or a piece of pipe of suitable diameter.

- A set of spanners or ratchet sockets.

- Balloon wrench.

- Hammer.

- Round nose pliers.

- Jack.

- Wheel chocks.

- Vise.

- Mount.

- Torque wrench.

- Boards or wooden block.

The replacement process is divided into five stages:

- Disconnecting the assembly (brake disc, hub and steering knuckle) from the CV joint strut.

- Pressing out old bearings.

- Installation of new parts.

- Assembling the unit and installing it in place.

- Tightening the adjusting nut.

Work is carried out on a level area. The presence of an inspection hole is not necessary.

Causes and signs of failure of the Chevrolet Niva hub

In addition to all other reasons, a worn hub heats up more when the car is braking, which negatively affects the performance of the car’s brakes. It happens that damage to the hub occurs gradually and, as a rule, this is indicated by an unpleasant sound, accompanied by vibration of the body or weak shocks.

The main reasons for hub failure are :

- careless driving on roads;

- multiple overloading of cars;

- driving on sandy soil or “mud baths”;

- frequent car slipping;

- aggressive driving style with sharp acceleration and braking.

These reasons can have a significant negative impact on the hub housing, outer or inner bearing ring. They are also sources of dirt, moisture and sand getting inside the bearing mechanism, which causes the journal to fail.

Tips for replacing the Niva Chevrolet hub

Before replacing the Chevrolet Niva hub, when disassembling the front suspension, special attention should be paid to damage to the lever mechanism (deformation of parts, breaks and tears in the metal).

The center hub nut is tightened to a significant torque. Therefore, it is recommended to use a socket with sufficient strength.

Inspect the landing channels of the inner and outer rings, the condition of the working surface of the bearing rollers. Metal corrosion in the form of grooves or “pits” on the metal of rollers or rings is unacceptable.

When removing the hub from its seat, extreme care is required so as not to accidentally remove the shank of the internal joint from the gearbox converter, otherwise this may lead to lubricant leakage from the car axle.

In case of serious damage, the front wheel bearing on a Chevrolet Niva is replaced together with the outer rings. After installation, it is necessary to adjust the clearance in the bearing and lock the hub nut.

If you had to change the ball joint, then it is necessary to perform a wheel alignment.

Replacing the Chevrolet Niva hub can be done more conveniently on a lift. However, the work can be carried out using a jack, with all the required safety measures being taken.

To change the hub you will need:

- keys “10”, “13”, “17”, “22”, “30”;

- vice;

- wheel wrench;

- screwdriver;

- puller for steering tip;

- hammer and chisel;

- pliers;

- Litol 24 lubricant;

- new hub.

A new original Chevrolet Niva hub with article number 21230310301400 costs 1,460 rubles. The analogue from Pilenga has catalog number HBP2123, and its price is about 1110 rubles.

Prices are indicated for Moscow and the region for the summer of 2022.

In 2022, the cost has changed slightly. The price of the original hub is 21230310301400 - 2050 rubles. Analogue of Pilenga HBP2123 - from 1040 to 1300 rubles.

Adjustable hydraulic supports (hydraulic compensators).

Old style hydraulic compensators.

Everyone knows what a hydraulic compensator (hereinafter referred to as hydraulic compensator) is and what function it performs. Worse than these g.k. I haven't seen anything, and their price isn't bad. The weakest point of these tensioners is that they tend to constantly unscrew (tightening torque is from 1.7 to 2.5 kg), tighten it harder, it simply will not work. Many people try to install them on various thread clamps, but I think this is not a solution. AvtoVAZ has already stopped producing cars with such cylinder head, but there are a lot of cars with cylinder head, old model, but not everyone has the opportunity to change the cylinder head to a new model. There is a good way, already tested on many cars, to avoid unscrewing the main gearbox. Everything is very simple - tighten them not by 2 kg, but by 4 kg. We did it.

Consequences of an unscrewed g.k.

When starting a cold internal combustion engine, a knocking sound is allowed. for 2 – 4 seconds. If the knocking continues for more than this time or appears on a hot internal combustion engine, it is advisable to contact a service station as soon as possible to eliminate the malfunction of the engine.

And now the most important thing for those who are delaying repairs. An unscrewed cylinder head first breaks the oil drop ramp, wears out the rocker and camshaft cam due to incorrect clearance adjustment and knocks out the threads in the cylinder head, which leads to the replacement of the cylinder head with a new model)))

Timing chain tensioner

Installed on Niva 21214 and 2123. After passing 1 maintenance, I recommend getting rid of this part and replacing it with Pilot 214 (mechanical tensioner). The hydraulic chain tensioner is very unreliable, especially when starting a cold internal combustion engine. The main malfunction of the chain tensioner is that the oil from the tensioner flows back into the system (the tightness of the tensioner is broken), and accordingly, the chain tension has weakened. And what we get: when starting the engine if the tensioner is faulty, the oil needs time to fill the tensioner and bring it into working condition. And then there are only two scenarios: the chain will rattle for 5 seconds and become tense, or the chain will simply fly off, which threatens a very expensive repair of the cylinder head.

Hub replacement

For any type of repair work related to the hub, it must be dismantled. This work may include replacing bearings, the hub itself or the brake disc. For all of the listed types there is a general algorithm for dismantling the hub.

- The wheel nuts are unscrewed. The wheel hangs out.

- Unscrew the hub nut with a 30mm wrench.

- The caliper is dismantled. To do this, use a 17mm wrench to unscrew the two bolts on the rear side of the steering knuckle.

- The steering end nut is unscrewed.

- Using a puller, the tip is removed along with the rod.

- Using a 22mm wrench, unscrew the nut of the upper ball joint, then the lower one. You can tighten the ball joint itself without removing it from the steering knuckle.

- The steering knuckle assembly is dismantled. The drive will easily come out of the hub since the hub nut is unscrewed.

- In order to press the hub out of the inner race of the bearing, you will need a suitable frame. The bearing itself remains in the steering knuckle. It is also knocked out with a frame.

Is there an alternative to permanent repairs?

It must be admitted, but the wheel-bearing unit of the Niva 4x4, being one of the most loaded in the car, has never learned to be reliable. Whether the culprit is bad components or design errors is not easy to figure out. However, the experience of the owners suggests using alternative options, for example, replacing the “stock” with double-row bearings (IVECO, Moskvich, etc.).

- The unit does not require adjustment or lubrication - all settings are made from the factory.

- There is no possibility of rotation;

- Wear of seats is minimal;

- Has an extended service life.

https://www.youtube.com/watch?v=RdXcXbHjaRI

The difficulty of implementation lies in the need to bore the hub for a double-row bearing, as well as the relatively high cost of the components. But there will most likely be no short-term attempts to change the wheel bearing again.

Read news about the new Niva

- Niva Chevrolet front hub repair

- How to check the hydraulic chain tensioner of a Niva Chevrolet - Auto magazine Incam Auto

- Replacing power steering Lada 2131 (VAZ 2131)

- Installation and repair of the VAZ 2121 Niva transfer case

- Replacing the wheel bearing of Niva Chevrolet

- Non-adjustable front hubs Niva and Chevrolet Niva with a reinforced hub, a double-row bearing from an Iveco truck and additional oil seals with ABS

- Niva Chevrolet front hub repair

- Niva Chevrolet front hub repair

Now about the tightening torque

Before fixing the cylinder head, carefully inspect the bolts. Their type is M12×1.25. Be sure to measure the threaded rods - be prepared to replace any element whose length is more than 11.7 centimeters. The fact is that they stretch during use, which means they no longer hold properly.

It is recommended to tighten the bolts in five stages. This will save you from having to tighten them additionally each time during preventive examinations.

In the first step, tighten all ten bolts by hand, and then tighten them in the correct sequence with a torque wrench, with a torque of 20 Nm.

Possible improvements

The Chevrolet Niva hub does not require any maintenance work during operation. In this case, the car owner is obliged to constantly monitor the condition of the wheel bearings. By replacing them, improvements are possible. First of all, this is the installation of non-adjustable, reinforced bearings. Instead of two single-row ones, one double-row bearing is installed, and the landing part of the steering knuckle is bored. The landing part of the hub is also bored. Today you can already buy a non-adjustable hub along with a steering knuckle. You just need to pay attention to the number of splines for the drive. Such bearings are more reliable. In addition, there is no need for constant adjustment.

Purpose and design of a wheel bearing

Bearings serve a dual function. On the one hand, they provide support for an axis, shaft or other element of rotation. On the other hand, they convert sliding friction into rolling friction. The wheel bearing is designed to ensure uniform rotation of the wheel hub. This is the connecting link between the hub and the axle of the car. Note that these elements ensure rotation of not only the front, but also the rear wheels.

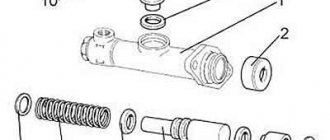

Any bearing has the same basic structure:

Bearings of modern imported cars have a more complex structure. Typically, their inner race is part of the hub, and the design itself contains electronic sensors. They are characterized by an increased service life. Russian manufacturers have not yet reached such technology, so they use simpler devices. On Chevrolet Niva cars, as on previous generations of the VAZ SUV, a pair of tapered bearings are installed on each hub.

Simplifying a unit negatively affects its reliability. Moving elements are especially sensitive to sharp impacts that chassis parts receive when driving over uneven surfaces.

Block plane and gasket penetration

Loosen the fastening clamp and disconnect the hose of the lower thermostat pipe. Loosen the fastening clamp and disconnect the hose of the thermostat side pipe. Loosen the fastening clamp and disconnect the fluid supply hose to the heater radiator from the cylinder head pipe.

Unscrew the nuts of the fuel pipes and disconnect the fuel supply and drain lines. Remove the upper bolt securing the rear intake pipe strut, loosen the lower bolt of the strut and move it to the side.

Torsion bolts (plastically deformable)

Remove the two nuts securing the starter heat shield. Move the shield to the side. Remove the chain from the camshaft sprocket. Carefully place it on the tensioner shoe.

Checking and adjusting the clearance in the front wheel hub bearings of Chevrolet Niva

Tools:

1. We hang and remove the front wheel.

2. Use a chisel to separate the cap from the hub.

3. Remove the brake pads as described here.

4. We attach the dial indicator holder to the steering knuckle. We rest the indicator leg against the wheel hub as close as possible to the adjusting nut. We put ring wrenches on two studs (for example, “17”) and secure them with wheel nuts. Use the keys to turn and move the hub in the axial direction.

5. We measure the amount of axial movement (clearance) of the hub using the indicator.

6. If the gap exceeds 0.15 mm, it must be adjusted. To do this, straighten the jammed nut belt with a beard.

Helpful advice:

Sometimes it is enough to turn the nut with a socket wrench to loosen it.

7. Using a 27mm spanner, unscrew the adjusting nut of the hub bearings.

8. Install a new adjusting nut. We tighten it with a torque wrench to a torque of 19.6 Nm (2.0 kgcm), turning the hub in both directions. Loosen the adjusting nut and tighten it again to a torque of 6.86 Nm (0.7 kgcm). Then loosen the nut 20-25°. We check the clearance in the bearings: it should be within 0.02-0.08 mm. We lock the nut by pressing its collar into the grooves of the shank of the outer drive joint.

The article is missing:

Source: Chevrolet niva device, operation, maintenance and repair. Publishing house “Behind the Wheel”.

Source

Unregulated

As a rule, the Niva has a standard adjustable hub, which requires periodic adjustment. But to get rid of this inconvenience, non-adjustable hubs were developed for Niva Chevrolet , which have such positive qualities as:

- No maintenance required. They don't need to be adjusted

- The bearing in the device does not rotate

- It is filled with special lubricant from the factory, so there is no need to lubricate it.

- Due to the fact that the work occurs thanks to the ball bearing in the unit, friction is reduced

- There is no wear on the seat in the rotary cam

- Not adjustable as it is tightened from the factory

- No need to change the bearing

- Long service life which is equal to 100-120 thousand kilometers

READ Chevrolet Cruze Handbrake Adjustment

Therefore, thanks to all the positive characteristics listed above, many car owners change the standard part to a non-adjustable one.

It is also worth noting that the non-adjustable part can be produced as a reinforced Niva Chevrolet , which solves the problem of wear of the oil seals on the steering knuckle. It is best to choose companies such as VolgaAvtoprom, IVECO, OmegaInterAuto.

The main disadvantage of this unit is its high price, but by installing this part you can forget about the problems that appear in the standard element. By installing a reinforced version of your SUV, the cross-country ability will increase and reliability will increase, and having a standard set of tools, you can make an independent replacement without any problems.