I ordered REAR DISC BRAKES for sapphire))))) Description: The main brake is implemented in the form of a disc mechanism with a self-adjusting caliper (a Ford Focus caliper is used). The parking (hand) brake is implemented by mechanically bringing the main caliper pads closer to the disc using a standard cable drive through an installed lever. This method of combining two types of brakes in one unit has proven to be the most effective.

Technical characteristics: The rear brake mechanisms are activated simultaneously with the front brake mechanisms, which allows for more efficient use of the braking system during dynamic driving of the VAZ 2110; In the production of kit parts, advanced technologies are used, such as computer modeling, programmable high-precision metal processing, laser cutting; The device is connected to the standard hydraulic system and standard cables of the parking brake system (handbrake) of the VAZ 2110; The standard pressure regulator of the VAZ (Lada) 2110 car performs the function of braking force distribution; Does not require additional adjustments during operation; You can independently install this device on a VAZ (Lada) 2110, carefully following these instructions, provided you have a minimum of conditions and tools; After installing the kit, it is permissible to install rims from R13 and higher;

Contents of the HA kit for VAZ (Lada) 2110: brake caliper (2 pcs. Ford Focus); guide bracket (2 pcs. Ford Focus); mounting bracket (2 pcs); parking brake drive mounting bracket (2 pcs); brake hoses with copper washers (2 pcs); plastic clamp (2 pcs); brake disc (2 pcs); working pads (4 pcs. Brembo P 24 047 (or substitutes)); protective disk cover (2 pcs); Certificate of conformity for rear disc brakes, fastener kit (complete) (1 piece); instructions (1 piece); mittens (1 pair).

Owners of the domestic “ten” know that the standard braking system involves the use of drum brakes at the rear and disc brakes at the front .

In terms of reliability, there are no special complaints about the drums, however, the rear disc brakes on the VAZ 2110 serve better, more efficiently and longer. Replacement is especially relevant in cases where the power of the power plant increases. The brake system must be modernized.

Disadvantages of drum mechanisms

Drum brakes

Despite the fact that drum brakes are correctly designed, mounted and adjusted at the factory, which is why intervention is not required, they have certain disadvantages:

- This is an outdated solution that is practically never found on new cars from leading European manufacturers;

- When compared with disk mechanisms, drums are significantly inferior in efficiency;

- There is no cooling or ventilation on the drums, which leads to overheating under heavy loads on the car;

- The drums have a closed space, so it is not possible to remove dirt and wear products in the form of black dust, leaks of fuel oil and trapped moisture naturally. This is done by cleaning.

Advantages of disk mechanisms

Components

The main advantages of replacing drum brakes with disc brakes include:

- Increased reliability when braking;

- Reduced braking distance;

- Uniform distribution of braking force, which is especially important for a front-wheel drive “ten”;

- The brakes respond faster when you press the brake pedal;

- Unsprung masses are reduced;

- More efficient cooling when driving in mountainous areas and during sudden acceleration or braking;

- Disc mechanisms are easier to replace and dismantle;

- There is no need to adjust the handbrake after each repair. You only need to do this once after installation and that’s it;

- Discs do not freeze in winter after washing, unlike drums;

- Disc mechanisms allow you to detect pad wear in a timely manner.

Selecting disc brakes

Discs

You yourself understand that it is stupid to skimp on brakes, at least from the point of view of your own safety. It is also recommended to purchase ventilated discs. Additionally, it can be equipped with the option of ABS or hydraulic parking brake.

If you have not previously upgraded the brakes on the front wheels, then 13-inch discs are installed at the rear. If the front wheels are larger in size than the standard ones, then choose the rear ones 1 inch smaller.

Don't forget the importance of the caliper, which is available in three versions. It is selected according to the disk. The caliper comes with a brake pad and hose. Plus, each kit includes a faceplate. This is a universal clamp that will fit any type of caliper.

Handbrake diagram for VAZ-2112

For clarity, here is a diagram of a hand brake

1 - button that fixes the handbrake lever; 2 — hand brake lever; 3 — protective cover; 4 — handbrake rod; 5 — cable equalizer; 6 — adjusting nut; 7 - lock nut; 8 - cable; 9 — protective sheath of the cable.

In this scheme we need element number 6. It is he, and only him!

What is required for adjustment?

In order to adjust the handbrake you need a platform or lift. If there are no such devices, then you can simply hang the rear wheels on the “goats”. They can be installed under the car using a jack. It’s also worth taking two “13” keys and pliers.

- The car is installed on an overpass or “goats”.

The lever position is set to the lowest possible position.

We put the handbrake at the very bottom. Do not pay attention to the scuffs of the console; we conducted an experiment with non-standard armrests. The iron fastenings of the armrest are visible. The photo shows the editorial car

Use a wrench to loosen the locknut.

Tighten the adjusting nut

Everything is rusty, we changed the adjustment mechanism

If you cannot tighten the cable, then it should be replaced with a new one.

Adjusting the handbrake after tensioning

After adjusting the brakes, you need to check them again. To do this, the car should be placed on a road with a slope of at least 23%. The car should be in neutral gear in this area and with the handbrake pulled up. If the handbrake brakes hold the car in this area, then the handbrake is adjusted correctly.

What to do when adjustment does not work

There are also cases when the above actions are not enough to adjust the handbrake. This can happen, for example, when the handbrake cable is broken. This happens on the VAZ-2112, although rarely. In such situations, the cable must be replaced. The cable also needs to be replaced when:

- The tips are loose.

- The cable itself begins to stretch, which will lead to its breakage during operation.

HAIKU! The old cable is very worn out! For comparison, old and new handbrake cables

Physical wear (scuffs and cracks) of the handbrake cables.

Heavy wear on the handbrake cable

This replacement procedure does not require contacting a service station. Although this will require some time and skills from the driver, such work can be done independently.

It should also be remembered that when replacing the cable, certain conditions must be observed. To do this, the driver will need an assistant who will pull the cable.

Why do you tighten the handbrake?

The cable acts here as a drive. If the driver pulls the handbrake lever, then at the same time he uses the cable, which spreads the pads in the rear wheel.

If the handbrake is faulty, you just need to tighten the cable or replace it with a new one. On a VAZ-2112 it’s quite easy to do this with your own hands.

Need for adjustment

You can determine that the parking brake needs adjustment when checking. It is recommended to do it every 30,000 kilometers. This procedure should be done even if the handbrake seems to be working well.

The device must also be checked in cases where it does not work. For example, a car moves when the brake lever is applied.

During the operation of the vehicle, due to wear of the rear brake pads and pulling of the drive cables, it periodically becomes necessary to adjust the travel of the parking brake lever (handbrake).

In this article we will talk about how you can tighten the handbrake on a VAZ-2110. This method can also be used when adjusting the handbrake on other front-wheel drive cars of domestic production.

Dismantling and installation

Of course, you will not be able to install new disc brakes on the rear axle of the VAZ 2110 until you remove the drum mechanisms. To dismantle them, do the following:

- The wheel is removed;

- The drum is dismantled;

- The pads are removed;

- The brake pipe is unscrewed;

- The hub is removed from the wheel.

In words it looks simple, that's a fact. But in reality, certain difficulties may arise. First of all, due to sticking of elements and sticking of fastening bolts as a result of corrosion. In order not to suffer with them, treat them in advance with the almighty WD40, which will dissolve rust and “scale”, and remove them without serious effort or harm to the edges of the fasteners.

Fastener drawings

Now we proceed to the installation, in which the old drums are sent to their well-deserved rest, and new disc brakes take their place.

- When you knock off the hub, it needs to be put back in place.

- Install the element through a plate with a caliper built into it.

- Make sure all holes line up and alignment is correct.

- Use a hammer to adjust the angle of the beam. The caliper should not rest against it.

- Place the brake disc on the hub. A spacer is placed between the elements and the disk is fixed with brackets in its new place.

- Now install brake pads selected specifically for the VAZ 2110.

- First, attach the brake hose to the caliper, and then connect it to the pipe.

- The friction material of the pad must be partially worn off. This is necessary so that the braking force on the rear brakes is less than on the front.

How to adjust the handbrake of VAZ 2110 and 2112

1. Place the car on a pit or a lift. The article shows how to remove the right hand brake cable

2. Lower the handbrake all the way down. 3. Remove the handbrake lever from the cable end (Replacing rear brake pads).

4. Using a 10mm wrench, unscrew the nut that secures the cable to the rear beam

5. Remove bracket6. Remove the cable from the holder.7. Using a screwdriver, bend the three brackets that secure the cable to the body

8. Remove the cable from the brake shield.

9. Using a wrench and a long socket “13”, unscrew the lock nut and the adjustment nut 10. Remove the cable end from the equalizer.

11. Remove the cable end from the bracket.

12. Remove the left handbrake cable in the same way. It is more inconvenient to remove it than the right cable, because... the exhaust system interferes with this.13. Remove the cable and equalizer.

15. Remove the cover and body of the floor tunnel (Removing the instrument panel and heater air ducts).16. Using a 10mm socket, unscrew the four bolts securing the lever to the floor.

17. Using a Phillips screwdriver, unscrew the two self-tapping screws of the handbrake warning lamp switch bracket......and remove the bracket and switch

18. Push the lever forward to remove it19. Remove the cotter pin of the adjusting rod shaft.

20. Remove the axle and disconnect the adjusting rod and lever.

Reassemble the handbrake mechanism in reverse order

Adjusting the hand brake

- loosen the locknut of the tensioner; - rotate the adjustment nut, tighten the cable; - the full stroke of the lever should be 3-5 clicks - when the lever is released, the wheels should rotate freely - tighten the locknut.

Similar articles

Installation Quality Check

Ventilated

When you complete the assembly process, be sure to check how airtight the installation was on each of the wheels.

- Press the brake pedal. If you did everything correctly, pressing will be accompanied by tightness and effort;

- You or your assistant press the pedal again, while the second person begins to turn the new disc brakes;

- If you couldn’t move anything, it means the assembly was done efficiently and reliably.

Adjustment

, a leak test procedure and, of course, bleeding are required .

But the work cannot be considered completed at this point, since the braking force needs to be adjusted.

The efficiency of disc brakes is much higher than drum brakes, therefore the braking force regulator must be adjusted.

- This unit is located at the left wheel, fixed to the body and connected to the beam by means of a small traction.

- Loosen the fastening of the rod to the regulator (sorcerer), move it 2-4 millimeters back.

- In this position, the thrust is fixed.

- Such manipulations allow you to deceive the sorcerer. It will distribute less braking force to the rear brakes.

- Drive the car in favorable weather conditions for several days after replacing the brake system, brake carefully, and do not press hard on the pedal.

- Please note that “rolling” can have both a positive and negative effect on the behavior of the car. If the machine behaves well, then you have successfully replaced the drums with discs. If problems arise with the stability and balance of the brakes, it is advisable to entrust the adjustment to specialists from good service stations.

Communities › VAZ: Repair and Modification › Blog › Do-it-yourself HA and hydraulic handbrake

I want to tell you how I installed the HTD and handbrake

Since ready-made kits with a cable are expensive and our cat is crying for money, we decide to do everything ourselves

I just had the standard calipers on the front become free (calipers from 2112 with perforated discs were installed on the front)

plans for washers + camber plates and all sorts of little things were purchased for them

plus you will need a bunch of new brake pipes and 2 tees (in my case)

Some tubes can be selected according to length, while others will have to be cut and re-rolled

(it’s better to ask Google how to do this)

First of all I installed the brakes themselves

combining this procedure with replacing bearings and installing wheel studs

Also, in order to put the brake disc on the rear hub, you need to grind off the step at the hub

I gave the hubs to a turner, but I saw how they did it with a grinder))

the next thing that was done was the handbrake

since there are no cables now, you need a hydraulic handbrake

look at the photo of the finished product and make your own)

for this you will need

pros

Let's look at why disc brakes are better than drum brakes:

- Braking becomes more reliable, braking distance is reduced;

- Braking forces are distributed more evenly, given that the VAZ 2110 is a front-wheel drive car;

- There is an effect of faster response after pressing the pedal;

- Unsprung masses are reduced;

- Heat dissipation occurs better, which is especially important when driving on a mountain road or during active acceleration/braking. For this reason, the brake system is cooled better;

- Disk ones are much easier to dismantle and replace;

- There is no need to adjust the handbrake after each repair of the rear brakes, although this will have to be done the first time;

- They do not freeze in winter after washing, like drum ones;

- Rear disc brakes installed on the VAZ 2110 are much more convenient to control and promptly notice pad wear.

Cost of tuning

Now is the time to draw up a detailed estimate for the spare parts used during tuning of the brake system. The price of all components may vary, depending on whether you are purchasing new or used. Approximate cost:

- Hydraulic brake assembly - cost about 2,700 rubles. You can also find cheap Chinese copies, but decide for yourself whether you should trust them. The quality of such products is very often low.

- Regulator – 400-500 rubles.

- Brake pipes for a Gazelle car – 300-400 rubles.

- Clutch cylinder (main) for classics - about 450-500 rubles.

- And small consumables - copper washers, plastic clamps, VAZ-2101 brake hose, fluid - you will spend about 500-600 rubles on everything.

By conservative standards, the cost of tuning will cost about 5,000 rubles. If this is too much for you, then abandon this idea and simply install a new handbrake cable instead of the stretched old one. Before starting work, it is recommended that you familiarize yourself with the advice of specialists and communicate with those who have already done similar work. They will be able to give you a lot of practical advice regarding improving the brake system on a particular car.

Minuses

Replacing brakes with disc brakes was not without the famous “fly in the ointment,” although it rather concerns precisely those problems that their installation can cause.

Firstly, our law enforcement agencies consider their installation on a VAZ 2110 as a design change.

What might this entail?

- Fine when passing a technical inspection;

- You can be simply wrong in a controversial accident if traffic police officers emphasize that you have “wrong” brakes;

- And the insurance company may also consider this a reason for non-payment of insurance.

Secondly, the handbrake will additionally need to be modified - or replaced with a hydraulic handbrake, although the latter weakens over time.

Thirdly, it is necessary to refine or carefully adjust the sorcerer so that on the VAZ 2110 the rear wheels do not brake more than the front ones, as this will certainly cause a skid, especially on ice or wet asphalt. To do this, sometimes you even have to grind down the pads by a quarter, or even more.

Handbrake device VAZ 2110

Modification of the VAZ 2110 handbrake

Manual control of the stove (heater) damper

If you are tired of understanding the problems of the VAZ 2110 heater, which are associated with algorithms for determining the position of the heater damper, then you can adjust the damper manually. Now it will be possible to install the heater damper in the desired position yourself without an SAUO controller.

How to tighten the handbrake

Design Features

It is better to purchase rear disc brakes as a complete set. The VAZ 2110 fits 13 or 14 inch brake discs (ventilated or non-ventilated). Try to purchase certified discs so that they do not have to be modified.

Rear disc brake kit with necessary components

You also need a caliper, which comes in three types, so you need to select it to match the disc. The caliper comes with a hose and brake pads. The kit includes a universal clamp suitable for all calipers - a faceplate.

Communities › VAZ: Repair and Modification › Blog › Do-it-yourself ZDT.

All the best... I decided to write for the first time in the community.

In this post I will briefly describe the installation of rear disc brakes on a VAZ 2113. Unfortunately, I didn’t have a camera at hand, so I had to take pictures with my phone, as a result of which the photos are not clear

. This week, at work, I was inspecting spare parts left over from alterations of someone’s cars. And I came across front calipers from a fourteenth friend.

At the request of readers, a drawing of the faceplate has been added.

Dismantling

Before installing disc brakes, you need to dismantle the old rear brake mechanisms of the VAZ 2110.

This is done like this:

- Remove the wheel;

- Remove the brake drum;

- Remove the pads;

- Remove the hub from the wheel, having first unscrewed the brake pipe.

You should prepare for the fact that dismantling will not be easy. Not only do the brakes have the unpleasant tendency to stick during operation, but the bolts are also “welded” by corrosion. Therefore, it is advisable to treat the nuts and bolts themselves with a special agent (for example WD 40) so as not to tear off their edges.

It is important to plug the removed pipe with something so that brake fluid does not leak out and air is not sucked into the system. After that, knock down the hub. This works best if you attach a board or lath to the back of the support disk and hit it with a hammer, moving the blows: one from below, the other from above. This will prevent you from causing serious damage to the disk.

Parking brake system drive

The mechanically actuated parking brake system acts on the brake mechanisms of the rear wheels. The parking brake drive consists of lever 2, adjusting rod 4, equalizer 5, cable 8, lever 10 (see Fig. Rear wheel brake mechanism), manual pad drive and expansion bar 8.

1 – protective cap; 2 – sensor housing; 3 – sensor base; 4 – sealing ring; 5 – clamping ring; 6 – reflector; 7 – pusher; 8 – bushing; 9 – float; 10 – fixed contacts; 11 – moving contact

Mechanical brake fluid emergency level sensor. The sensor body 2 with a seal 4 and the base 3 with a reflector 6 are pressed by a clamping ring 5 to the end of the tank neck.

A pusher 7 passes through the hole in the base, connected to the float 9 by means of a sleeve 8. There is a moving contact 11 on the pusher, and fixed contacts 10 are located on the sensor body. The contact cavity is sealed with a protective cap 1. When the level of brake fluid in the reservoir drops to the maximum permissible, the moveable the contact moves down onto the fixed contacts and closes the circuit of the hazard warning lamp on the instrument panel.

Installation

It's time to install disc brakes instead of the removed rear drum brakes.

Having knocked off the hub, we will put it back, but in a different way:

- It should be installed through the plate into which the caliper is already mounted. Carefully ensure that all holes line up. Particular attention to alignment;

- Next, use a hammer to straighten the corner of the beam so that the caliper does not rest against it;

- Now you can put the brake disc on the hub, placing spacers between these parts, and secure the disc with a bracket;

- We install brake pads from VAZ 2110;

- First, carefully and securely attach the brake hose to the caliper, and then to the tube;

- To reduce the braking force of the rear brakes compared to the front, you need to partially grind off the friction material of the pads.

Finalization

As mentioned above, after installing the rear discs, the car will brake much more efficiently. But if you don’t modify a few things, the rear brakes will work before the front ones. As mentioned above, to reduce the braking force, some of the friction material of the pads is ground off. That's all. As you can see, we managed to carry out a difficult operation with our own hands, which makes the car’s brakes more effective. The instructions given above include all the important operations and should be followed carefully. According to the latest data, the price for a set of rear brake discs is not that high, and if the replacement is carried out independently, then a lot of money will not go out of the family budget.

Examination

Having carried out all the above operations - first on one wheel, and then on the second, you also need to check the system for leaks. The first phase is to simply press the pedal.

The fact that everything is done normally is indicated by the fact that the pedal is pressed with force, quite tightly.

But this is not enough. Have someone else press the brake pedal while you try to rotate the parts that make up your new rear disc brakes.

If nothing moves, it means that your VAZ 2110 now has new rear disc brake systems - better and more reliable than the previous ones.

To minimize the braking distance, it is recommended to install a vacuum booster. Details: https://vazweb.ru/desyatka/tormoza/vakuumnyi-usilitel-tormozov.html

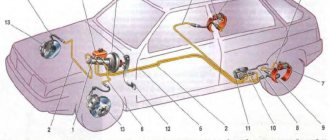

Principle of operation

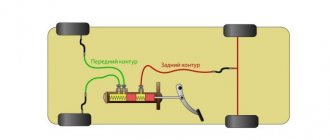

Hydraulic dual-circuit brakes with diagonal distribution are predominantly efficient and reliable. This is due to the fact that if one circuit fails, the second will allow your car to brake.

The circuit system is arranged as follows - one of them is responsible for the left rear and right front wheel, and the second circuit is responsible for the left front and right rear wheel.

This way, you will be able to brake without damaging the brakes or causing other problems with the system.

Bleeding and adjustment

After any manipulations with the brake system (it doesn’t matter whether you repaired the rear, front or parking), on a VAZ 2110 it is vitally important to bleed the brakes so that an air plug does not form anywhere in them, which can negate the ability to brake at the right moment.

It is convenient to do this together, but you can do it yourself, although this requires some additional equipment. Many people know how to bleed the brakes on a VAZ 2110. The main thing is not to forget to do this diagonally, always starting with the front wheels, and pump the right one first.

After bleeding, you still need to check the braking forces. This requires an outside observer. You accelerate and brake sharply, and he watches as the brakes apply. The front ones should work first, then (with a small gap) the rear ones, and the braking force should be greater for the front ones.

The main purpose

You can install and configure a hydraulic handbrake on a VAZ-2109 yourself if you have certain skills and tools. Despite the prohibitions, such designs can be found on sale and can be installed on any make and model of car. It is advisable to carry out all work on an inspection pit or a lift. With the help of a hydraulic handbrake you can greatly increase the efficiency of the braking system. The design provides for a regulator that allows you to distribute the force between the front and rear circuits. The regulator allows you to prevent complete blocking of the rear wheels.