Any car has those aspects without which it is impossible to talk about the complete safety of the driver and people inside the car. A working brake system will be named one of the priorities in this regard. In order to have an idea of its work, you need to know the main components and their functionality. Each of the elements has its own purpose.

On the VAZ 2114, the braking system, like on any other car, is designed to change the speed of movement. Another of its tasks will be to hold the vehicle in place; this occurs due to the fact that the braking force that occurs during the interaction of the wheel and the road is used. It is called upon to create appropriate mechanisms. The brake system in each car is presented in working, parking and spare versions.

Operating principle

The brake in the VAZ 2114 will work on the hydraulic principle: when pressed, the liquid pressure will increase and the brake mechanisms will operate. As a result, the wheels begin to rotate more slowly and force appears at the point of contact of the tire with the road surface. And the harder the pedal is pressed, the faster the process will go. The forced-up pressure in this case will reach from 10 to 15 MPa. It will also increase in the drive itself: this will move the pads to the wheel rims.

Front brake mechanism

The design of the front brake mechanism on the VAZ 2114

The front brake mechanism consists of the following components:

- Brake disk. Directly connected to the wheel hub and rotates with it. Slowing down the rotation and stopping the disk leads to the slowing down and stopping of the wheel.

- Pad guide. Serves as a holder for the pads and a base for the guide pins.

- Caliper. It combines the pads, cylinder, and piston into a single unit and ensures uniform transmission of force from both pads to the disc.

- Brake pads. They directly act on the disc, squeezing it on both sides and slowing down the movement.

- Cylinder. A sealed cavity in which the piston moves.

- Piston. Under the influence of hydraulic fluid pressure, the pad is pressed against the disc. Thanks to the “floating clamp” system, the second block is pressed simultaneously. This ensures uniform wear of their linings and discs and guarantees effective braking.

- Seal ring. Prevents fluid leakage and ensures system tightness

- A cover to protect the guide pin from dirt, allowing for unhindered movement of the pads.

- Guide finger. Allows the pads to move evenly and adhere to the disc with their entire plane.

- Protective cover. Protects the disc from road dirt.

The front wheels are equipped with disc brakes. They automatically adjust the clearance from the pad to the disc. The caliper and cylinder form a floating caliper, which creates the same even force on both pads. This ensures uniform wear of the linings. To monitor their wear, there is an indicator on the inner block.

Features of work

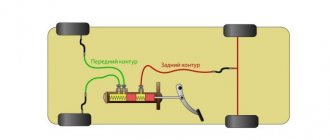

Both the VAZ 2114 and the AZ 2115 models use a braking system that has diagonal separation of circuits. Each of them is responsible for their own area of work: one is responsible for the activities of diagonal systems.

In the event that one of the circuits fails, the other is designed to ensure effective stopping of the vehicle. It should also be noted here that the parking brake system of the VAZ 2113, 2114, 2115 will be driven by mechanisms for the rear wheels.

Brakes VAZ 2114

The braking system of the VAZ 2114 has disc brakes at the front and drum brakes at the rear. As you can see, drum brakes are already outdated, but if you look at the cost of the car, it becomes clear that this is a move to reduce the cost of the car.

If you think soberly, then the light body of the VAZ 2114 is quite sufficient for the efficiency of drum brakes. The front brakes bear the brunt of stopping the car, but here they are disc brakes and are very effective.

The brakes of the VAZ 2114 are completely identical to all front-wheel drive VAZ cars, the only difference can only occur in cars with ABS. In Ladas with an ABS system, slightly different brake pads are installed with special holes for a sensor that reads wheel rotation.

Front brakes

The front brake, as mentioned above, has a disc system. The disc, 14 inches in radius, is made of cast iron with a polished surface to accommodate the brake pads. The disc is also ventilated for more efficient cooling during intensive brake use.

The VAZ 2114 front brake caliper is installed on the steering knuckle and has one piston, which is enough to effectively stop the car.

Rear brakes

The rear brake system is made of drums with two shoes per drum. The pads are shaped like a banana and are spread using a double-sided piston that pushes them apart. The pads are also set mechanically using the handbrake cable.

System elements

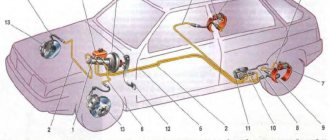

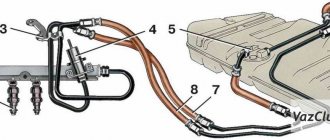

The hydraulic brake drive of the VAZ 2114, 2115 will include the following components:

- brake mechanism from the front right wheel;

- pipeline from the brake circuit, front left-rear right;

- a pair diagonal to them;

- hydraulic main cylinder;

- tank from it;

- vacuum booster;

- brake mechanism for rear wheels;

- elastic lever that regulates pressure;

- pressure regulator;

- a simple lever to drive the pressure regulator;

- pedal;

- hoses for front and rear brakes.

When to change?

Brake pads must be replaced after reaching a certain number of kilometers, but these numbers are not always standards, it all depends on driving style. Brake pads wear out much more often when driving around the city; when driving on the highway, the pads will last much longer.

Also, the front pads will have to be replaced much more often than the rear ones. This is explained by the fact that the front brakes take on most of the load.

On average, rear brake pads can travel almost 80 thousand kilometers without replacement.

The front pads must be inspected every 10-15 thousand km, and if the brake pad lining is worn down to 1.5 mm, it must be replaced without fail.

Features of pedal settings

The driver controls this entire complex assembly using a single pedal. That is why it is very important to monitor the condition of these mechanisms and correct errors in a timely manner. It is necessary to pay attention to the following features:

- Each owner of this vehicle must remember that when the engine is not running, the pedal must have free play. The adjustment can be made with the vehicle turned off. This can be done by moving the brake light switch and lowering its nuts.

- When the switch at the brake light is very close to the pedal itself, this risks the fact that it will not return to its original state. But even here there is a possibility of only partial release of the wheels when the pedal is released.

- When it was not possible to correct errors using a brake light and eliminate incomplete release of the brakes, you can simply disconnect the master cylinder at the brake drive and double-check that the adjusting bolt is not too far from the plane to which the flange of this cylinder is attached (the difference can be from 0.2 to 0.25 mm). This size will be optimal for adjusting the pedal.

DEVICE OF BRAKE MECHANISMS

Many people wonder what is the difference between the brake mechanisms of the front wheels and the rear ones. The fact is that when braking, they are subject to different loads, and they do not operate synchronously. But this is not the main reason for the differences.

The front mechanisms consist of:

- Brake disc of classic design;

- Direction pads;

- Calipers;

- Directly the pads themselves;

- Cylinder;

- Piston;

- Seal rings;

- Protection casing;

- Direction finger;

- And its cover, which performs a protective function.

The design of the front brakes is a little simpler than the rear, however, this does not mean that they play a lesser role in braking. After all, these are the mechanisms that work first.

- Nuts that secure the hub;

- Actually, the hub itself;

- Tension springs (lower and upper);

- Brake pads;

- Directional springs;

- Wheel cylinder;

- Expansion bar;

- Handbrake lever finger;

- Handbrake lever;

- Mechanism casing.

Brake bleeding sequence

It is possible to solve the problem of brake squeezing in the VAZ 2114 by bleeding the system. Before starting the pumping procedure, you should read the instruction manual for this vehicle, which shows the exact algorithm of actions.

To prepare for bleeding the brake system, a number of works should be performed. To begin, put the vehicle on the handbrake, disconnect the fluid sensor from the reservoir and fix it; when bleeding the brakes on the rear wheels, insert a slotted screwdriver into the rear adjuster between the rod and the bracket. There is no need to insert a screwdriver when bleeding the front brakes.

The procedure for pumping brakes on a VAZ 2114

- First, open the hood and remove the cap from the container containing the brake fluid. It is necessary to ensure that the container is completely filled. Otherwise, the liquid should be added to the “max” position.

- You should inspect the rear right wheel and find the cap covering the fitting. You need to unscrew it and remove all dirt from it.

- Fill the prepared glass or plastic container with brake fluid.

- One end of the hose is fixed to the fitting, and the other is lowered into a container with liquid.

- The assistant should sit in the driver's seat and gently press the brake pedal. Seven presses with 2-second breaks are enough. Now he must press the pedal again all the way and leave it in that position.

- While the pedal is pressed all the way, using a wrench, you should unscrew the fitting a couple of turns.

After completing the entire specified sequence of actions, you can observe how the brake fluid flows through the hose into the container. In it you can see air bubbles that should be removed. Why should you drain the liquid until they disappear completely?

After the liquid stops draining, screw the fitting back to its original position. Now the partner must release the pedal. As the liquid flows out, you should monitor how much is left in the tank. If the need arises, the missing liquid should be added. If, while bleeding the brake system of the VAZ 2114, it all leaked out, then the procedure will have to be repeated.

The procedure should be repeated for all wheels. This procedure can be applied not only to the VAZ-2114, but also to the 2113, 2115.

What is needed to bleed the brakes?

When bleeding the brakes on a VAZ 2014 with your own hands, you need to keep in mind that to carry out the process you should use brake fluid identical to that found in the cylinder.

It is not permissible to use any other liquid. Before pumping, it is imperative to check whether the system has become depressurized. The procedure should be carried out together with an assistant. First prepare a hose, the size of which will be optimal for the bleeder fitting, a glass or plastic container, a wrench, and rags to clean the caps. It is important to have an idea of how to properly remove air from the brake system.

A similar process should be carried out diagonally, alternating front and rear brakes in the following sequence:

- First of all, located on the rear wheel on the right.

- Now the one on the left front wheel.

- Rear left.

- Front right.

HOW TO ADJUST HYDRAULICS PRESSURE

As you know, hydraulic drives use fluids and pressure in the system instead of conventional mechanics, where any force is applied either directly or through transmission mechanisms. The key to clear hydraulic responsiveness is the presence of the required amount of brake fluid in the system and, of course, correctly adjusted pressure.

To properly adjust the pressure in the drive, you need to find an assistant. Doing this work alone is extremely inconvenient, and for the final test you will need an outside perspective.

The VAZ 2114 brake pressure regulator allows you to adjust the operation of the brakes to the required level. To do this you just need to do certain things:

- First you need to drive the car into the pit and rock its rear end. This will bring the suspension to the middle position, and this is exactly what needs to be achieved;

- Then slightly unscrew the front bolt on the VAZ brake pressure regulator mount;

- Using a screwdriver, make a small gap (2 mm) between the lever and the spring. For convenience, insert wire or whatever is at hand. A special protrusion on the lever allows you to move it to achieve the desired clearance;

- Tighten the previously loose bolt.

Now you need to check whether everything was done correctly. Accelerate to 35-40 km/h and brake. If the car does not drive away, then everything is done perfectly. In addition, you need to check the wheel locking sequence. Here you need a second person who will see how smoothly the brakes of the VAZ 2114 work. The whole point is that when working correctly, the front wheels should lock a little earlier than the rear ones. If this happens, then the system is set up with a bang.

If the front wheels lock later, the clearance must be increased. It is also possible that the rear wheels will be very late, in this case we reduce the gap. After completing all the work, securely tighten the regulator mount.

It is important to consider that all tests should not be carried out with flat tires. The result depends on this, and accordingly the brake system can be adjusted incorrectly. The tire pressure of the VAZ 2114 must meet the requirements specified in the vehicle documentation.

Operation diagram of the VAZ 2114 brake system

Examination

You should make sure that the master cylinder is the culprit for the malfunction of the brake system. This is easy to do; you don’t even have to go to a service center and spend money on it.

Unit location

- Press the brake pedal with the power unit off.

- Start the engine without taking your foot off the gas pedal.

- During normal operation, the gas turbine engine fails under the influence of vacuum.

- If the pedal does not fail, you will need to conduct more thorough diagnostics and restore the device to functionality.

How to bleed brakes on a VAZ 2114

Bleeding the brakes is a procedure during which air is removed from the hydraulic drive group. Thus, by bleeding the brakes, we remove accumulated air in the brake hoses. In most cases, bleeding the brakes on a VAZ 2114 is done after changing the fluid in the brake cylinder. It happens that when changing a separate mechanism, air enters the brake system, which does not allow it to work correctly, and this is very dangerous. A characteristic feature of the presence of air in the brake cylinder is that the pedal presses when pressing on it. If you press the pedal several times, it returns to its original state. If such a case arises, you should know how to bleed the brakes on a VAZ 2114. If you do everything correctly, then the whole process can be done quickly and without any difficulties.