4/5 — (76 votes)

Today we’ll talk about the reasons why the VAZ 2107 fan (injector and carburetor) does not turn on. A little earlier, we figured out how to improve the engine cooling system. The whole procedure is simple and does not require much knowledge. But an equally pressing problem is that the fan refuses to turn on in a timely manner. Let's try to find out why this happens.

Main types of faults

The fan is necessary to cool the radiator at times when there is no oncoming air flow, that is, during slow movement or parking. With its help, a warm air flow from the radiator flows to the engine, which is important during winter warm-up.

There are several options for incorrect operation of the VAZ-2107 electric fan:

- The device does not start under any conditions. In this case, the engine overheats. With this malfunction, it is important to look at the arrow indicating the temperature. If it reaches the red zone and the fan motor does not turn on, then the fault must be found in the power circuit or in the device itself. Most often the fan does not turn on due to:

- wear of brushes, commutator or armature winding of the electric motor;

- electrical circuit break;

- sensor malfunction;

- fuse blown;

- relay failure.

- Full time job. With this failure, the fan does not stop and spins up at any temperature. The following may cause a malfunction:

- sensor failure;

- stuck relay;

- short circuit of the power supply.

- Untimely switching on. This problem occurs when the temperature sensor readings are faulty. It transmits incorrect information to the relay, so it does not activate the device in time.

- Extraneous noise during operation. In the interior of the VAZ-2107, the moment the fan turns on is clearly audible. If this noise is accompanied by a creaking, hum or whistle, then you need to check the bearing or support sleeve of the cover. The appearance of a crackling or knocking sound is characteristic of contact of the impeller with the inner edge of the electric motor frame; this happens when the blades are deformed or misaligned.

If the fan is said to be not working, then most likely it does not start or does not work in a timely manner. Let's look at how to check the devices responsible for running it.

Fan motor

The electric motor is the main component of the device. The VAZ 2107 used two types of engines: ME-271 and ME-272. In terms of characteristics, they are almost identical, but as for the design, it is somewhat different. The ME-271 engine has a stamped housing, i.e., non-separable. It does not require periodic maintenance, but in case of malfunction, it can only be replaced.

Not every fan motor can be disassembled

Design and characteristics of the fan motor

Structurally, the motor consists of:

- housings;

- four permanent magnets glued around the circumference inside the case;

- armatures with winding and collector;

- brush holder with brushes;

- ball bearing;

- support sleeve;

- back cover.

The ME-272 electric motor also does not require maintenance, but unlike the previous model, if necessary, it can be partially disassembled and attempted to be restored. Disassembly is carried out by unscrewing the tightening bolts and removing the back cover.

ME-272 has a collapsible design

In practice, repairing an electric fan is impractical. Firstly, you can only buy used spare parts for it, and secondly, a new device complete with impeller costs no more than 1,500 rubles.

Table: main technical characteristics of the ME-272 electric motor

| Characteristics | Indicators |

| Rated voltage, V | 12 |

| Rated rotation speed, rpm | 2500 |

| Maximum current, A | 14 |

How to check a fuse

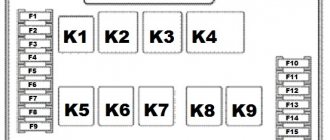

In the mounting block of the engine compartment there is a fuse responsible for the operation of the fan. Its designation on the power supply diagram is F-7, nominal value is 16A. Checking and replacing the fuse is carried out according to the instructions:

- Remove the negative terminal from the battery. Remove the mounting block cover.

- Pull the F-7 fuse out of its seat. Using a multitester, check it by connecting the probes to the contacts.

- If the device is blown, buy a new fuse and replace it with a new one.

This is the simplest repair option, which is carried out when the cooling fan does not work.

Communities › VAZ: Repair and Modification › Blog › A hackneyed topic: Fan and mounting block VAZ 2107

I’m returning to the already well-worn problem with the new type of mounting blocks. The essence of the problem is that when installing a new type of mounting block on a classic carburetor, the cooling fan stops working. This problem is not new and the Internet is full of articles on how to fix it, but it’s still very difficult to find complete information (as they say for dummies) on the Internet, so I decided to post a clear article about solving this problem.

Solution to the problem:

4 relays in the mounting block are responsible for turning on the cooling fan

Usually, when you buy a block, there is a jumper between 30 and 87 contacts instead of a full-fledged relay.

First, you need to unsolder the missing pin, it is marked 7Ш,7 (green) and goes to pin 86 of the relay.

Everything is simple here, we take a pin either from an old block, or simply grind a metal plate to size and solder it in place:

We sorted out contact 86. Now you need to apply + to pin 85 of the relay. There are many ways, the most competent one, in my opinion, is to do everything according to the diagram and instead of the missing track in the block, just throw a wire:

We insert a regular 4-pin relay instead of the jumper and you're done!

With this arrangement, voltage is supplied to the fan through 4 relays and 10 fuse, as required according to the diagram.

I hope this article helps someone

Thank you for your attention

Checking and replacing the electric motor

A more complex option is to check and replace the electric motor. It is performed according to the instructions:

- Disconnect the fan power plug. Connect two wires to the fan connector, of such length that they can be brought to the battery terminals. After connecting to the plug, connect the wires to the battery and watch the fan react. No response means it needs to be replaced.

- If it works, then you need to check whether voltage is supplied. To do this, you need to place the voltmeter probes on the contacts of the second half of the plug. After this, start the engine. If you have a carburetor engine, then you need to additionally close the contacts of the temperature sensor using a screwdriver. Look at the voltmeter readings, the voltage should be from 11.7 to 14.5 V. If you have an injector, then you need to wait until the temperature reaches +85...+95 °C. After this, the on-board computer will send a signal to the relay to turn on the fan. As soon as this happens, look at the readings on the device, they should be within the same limits. Insufficient voltage or its absence indicates problems in the power circuit.

- After checking, when you realize that the fan does not start due to the motor, it is necessary to replace it. To do this, use socket wrenches to remove the two fasteners of the fan casing to the generator.

- Pull the casing towards you and release the wires from the retainer. To do this, use pliers to squeeze the fastening petals and then push them out.

- Remove the fan. While holding the impeller, unscrew the central nut securing it with a 13mm wrench.

- Remove the impeller from the shaft. Unscrew the electric motor mountings with a 10mm wrench.

- Remove the electric motor and replace it with a new one. After this, you need to reassemble the structure.

Temperature sensors rarely fail, so we will not dwell in detail on checking and replacing them. Most often the problem lies in the electric motor or power circuit.

Today we’ll talk about the reasons why the VAZ 2107 fan (injector and carburetor) does not turn on. A little earlier, we figured out how to improve the engine cooling system. The whole procedure is simple and does not require much knowledge. But an equally pressing problem is that the fan refuses to turn on in a timely manner. Let's try to find out why this happens.

Diagnostics and repair

It is recommended to check the fan and elements of its electrical circuit in the following order:

- Fuse.

- Relay.

- Electric motor.

- Temperature sensor.

Checking the functionality of the fuse

The fuse is usually checked first, as this process is the simplest and does not take much time. To carry it out, you only need an autotester or a test lamp. The essence of the diagnosis is to determine whether it passes electric current.

The fan circuit fuse is installed in the vehicle's mounting block, which is located in the engine compartment. In the diagram it is designated as F-7 with a rating of 16 A. To check and replace it, you must perform the following work:

- Disconnect the negative terminal from the battery.

- Remove the mounting block cover.

- Find the F-7 fuse and remove it from the seat.

Relay diagnostics

As we have already said, in the injection “sevens” a relay is provided to unload the electrical circuit of the radiator fan. It is installed in an additional mounting block located under the glove box in the car interior, and is designated R-3.

Checking the relay yourself is quite problematic. It is much easier to take a new device and install it in place of the one being diagnosed. If the electric fan turns on when the refrigerant is heated to the desired temperature, then that was the problem.

Checking and replacing the electric motor

- voltmeter or multifunction autotester;

- two pieces of wire;

- socket wrenches “8”, “10” and “13”;

- pliers.

The work order is as follows:

- Disconnect the fan power connector.

- To the contacts of the half of the connector that comes from the electric motor, we connect two wires, the length of which should be enough to connect them to the battery terminals.

Diagnostics and replacement of temperature sensor

Temperature sensors for carburetor and injection "sevens" differ not only in design, but also in their operating principle. For the former, the sensor simply closes and opens the contacts, while for the latter, it changes the value of its electrical resistance. Let's consider both options.

Carburetor engine

Tools and tools you will need:

- open-end wrench at “30”;

- socket wrench or socket to “13”;

- ohmmeter or autotester;

- liquid thermometer with a measuring range of up to 100 °C;

- a clean container for collecting refrigerant;

- container with water;

- gas (electric) stove or household boiler;

- dry clean rag.

The check and replacement algorithm is as follows:

- We place the container under the plug on the cylinder block of the power plant.

Injection engine

The injection “seven” has two temperature sensors. One of them works in tandem with a device that shows the coolant temperature to the driver, the other with the ECU. We need exactly the second sensor. As already mentioned, it is installed on the pipe next to the thermostat. To check and replace it we will need:

- autotester or multimeter with the ability to measure voltage and resistance;

- open-end or ring wrench set to “19”;

- liquid thermometer with temperature measurement amplitude up to 100 °C;

- heat-resistant container with water;

- boiler or stove (for heating a container of water);

- clean dry cloth.

The order of work is as follows:

- We find the sensor. Disconnect the connector from its contacts.

Carburetor sevens

In these cars, the control system for turning on the electric fan is very simple. It can even be called analog. The entire circuit consists of the simplest form of the following elements:

- Electric fan motor.

- Power sensor.

- Wiring.

That's it, there is nothing else, you need to look for breakdowns only in these parts of the structure. In 70% of cases the sensor fails, in 5% the electric fan fails, in 20% the electrical wiring is to blame.

But some cars use a slightly more advanced circuit, which includes an electromagnetic relay. With its help, it is possible to remove high currents from the sensor. This increases the resource of the device.

Some drivers who are not used to trusting automation install a regular button parallel to the sensor (and sometimes instead of it). Such a scheme has a right to exist, but the driver himself must be extremely careful in order to notice the temperature rise in time and turn on the electric fan.

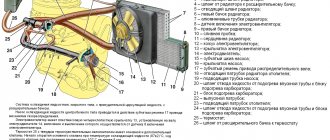

Explanation of symbols

Knowledge of the definitions of the 2107 Lada electrical circuit will help you quickly locate the required wire, diagnose it, identify and fix the malfunction. Of course, when replacing the cabin filter or changing the oil, such information will not be useful, but in specialized matters, deciphering the symbols will significantly simplify the repair process.

- 1 – head lights VAZ 2017;

- 2 – side turn signals;

- 3 – battery;

- 4 – starter activation relay;

- 5 – carburetor electro-pneumatic valve;

- 6 – internal carburetor switch;

- 7 – generator system 37.3701;

- 8 – gearmotors for headlight cleaners*;

- 9 – fan motor activation sensor;

- 10 – electric motor of the engine cooling fan;

- 11 – sound signals;

- 12 – ignition distributor;

- 13 – spark plugs;

- 14 – starter;

- 15 — coolant temperature indicator sensor;

- 16 – engine compartment lighting;

- 17 – critical oil pressure indicator sensor;

- 18 – warning lamp for insufficient brake fluid level;

- 19 – windshield wiper electric motor;

- 20 – power system valve control unit;

- 21 – ignition coil;

- 22 – electric motor of the headlight washer pump*;

- 23 – electric motor of the windshield washer pump;

- 24 – mounting block;

- 25 – windshield wiper relay;

- 26 – hazard warning and direction indicator relay;

- 27 – brake light switch;

- 28 – reverse lamp switch;

- 29 – ignition relay;

- 30 – ignition switch;

- 31 – three-lever switch;

- 32 – alarm switch;

- 33 – plug socket for a portable lamp**;

- 34 – heater heater fan switch;

- 35 – additional switch for the heater electric motor;

- 36 – indicator lamp for turning on the heated rear window;

- 37 – indicator lamp for insufficient brake fluid level VAZ;

- 38 – signaling unit;

- 39 – electric motor of the stove fan;

- 40 – glove compartment lighting lamp;

- 41 – lamp switches on the front door pillars;

- 42 – switches for warning lights of open front doors***;

- 43 – alarm lights for open front doors***;

- 44 – connecting block;

- 45 – cigarette lighter;

- 46 – hours;

- 47 – instrument lighting switch;

- 48 – diode for checking the serviceability of the warning lamp for insufficient oil pressure and brake fluid level;

- 49 – fuel level indicator;

- 50 – indicator lamp for insufficient gasoline level (fuel reserve);

- 51 – speedometer;

- 52 – control lamp for turning on the direction indicators on the dashboard;

- 53 – warning lamp for the carburetor air damper opening;

- 54 – indicator lamp for battery charge indicator;

- 55 – switch for signaling that the carburetor air damper is slightly open;

- 56 – instrument cluster;

- 57 – econometrician;

- 58 – lamp switches on the rear door pillars;

- 59 – coolant temperature indicator;

- 60 – tachometer;

- 61 – handbrake indicator lamp;

- 62 – low oil pressure indicator sensor;

- 63 – indicator lamp for high beam headlights;

- 64 – signaling device for turning on dimensions;

- 65 – voltmeter;

- 66 – parking brake warning switch;

- 67 – external lighting switch;

- 68 – rear window heating switch;

- 69 – rear fog light switch with on indicator*;

- 70 – fog light circuit fuse;

- 71 – interior lighting lamp****;

- 72 – rear lights;

- 73 – fuel level indicator and fuel reserve sensor;

- 74 – pads for connecting to the rear window heating element*;

- 75 – license plate lights.

* Some models have headlight and windshield wipers installed together. **Models up to 2000. ***Cars that came off the assembly line before 1998. ****One lamp in the center of the roof (before 2000) or two lamps located in the body pillars after this date.

Troubleshooting algorithm

If the electric cooling fan does not work on your VAZ 2107 (carburetor), you need to do the following:

- Turn off the engine and turn on the ignition.

- Use a flat-head screwdriver to short-circuit the terminals of the fan switch sensor. Please note that all control is based on mass. If the fan turns on, the sensor is faulty. If it doesn’t work, then the reason lies deeper.

- Disconnect the block from the electric fan and supply power from the battery directly. A rotating rotor indicates that the engine is running. If the electric fan does not work even this way, you will have to think about replacing it.

- If the fan and sensor are working properly, you need to check the electromagnetic relay (if present in the circuit).

- The wires are checked last. Oxidation very often occurs at the joints with the car body. And sometimes a banal break even happens.

The same algorithm can partly be applied to cars on which an injector is installed.

But in order to compare and appreciate the difference, it is worth considering such machines.

Why does the cooling fan turn on when the engine is cold?

The operation of a car's power unit is impossible without a cooling system. If problems arise with it, the motor may overheat, which will lead to its breakdown and costly repairs. One of the main elements in this system is the cooling fan. If any signs indicating a malfunction of this device occur, the cause should be found and eliminated. Since there can be many of them, it is worthwhile to dwell on each of them in more detail.

Lack of fluid in the system

The search for a problem should start directly with the coolant, or, more precisely, by checking its level. If it is below normal, the coolant sensor will operate even on a cold engine, thereby turning on the fan. This is explained by the fact that a small amount of liquid heats up much faster. To fix the problem, you need to check the antifreeze level in the expansion tank and radiator, and, if necessary, bring it up to normal.

Sensor short circuit

If checking the coolant does not produce results, attention should be paid to the sensor itself. There are times when this element “sticks”, which leads to constant rotation of the electric fan

For diagnostics, you will need a multimeter, which measures the resistance at the sensor terminals with the engine running. If the sensor is working, then the device should show infinite resistance. When the multimeter displays some resistance, it means that the contacts of the sensor are closed and it needs to be replaced with a working one.

Video: checking the fan switch sensor

Checking the cooling system fan switch sensor.

Short to ground

Spontaneous turning on of the fan may be caused by problems with the fan itself. The problem is that its contacts are shorted to ground. As a result, the device operates directly from the battery, bypassing the circuit with the sensor. To eliminate the malfunction, you need to check the reliability of the fan connections, insulate the wires if necessary, and tighten the fastening. A constantly running fan can lead to the following consequences:

- short fan life;

- battery discharge (with the ignition on and the engine off);

- spontaneous combustion of wiring if it overheats.

Thermostat sensor

Some modern cars are equipped with a thermostat with a sensor. This design solution allows you to control the cooling system with greater efficiency. However, if there is a problem with the sensor, the fan will run constantly. This behavior is explained by the fact that the signal from the thermostat is not received by the control unit. As a result, the unit goes into emergency mode. Checking the thermostat sensor is similar to the procedure with the coolant sensor.

Additional sensor

Some cars are also equipped with an air temperature sensor. Its main purpose is to regulate the temperature of oncoming air flows. When the ambient temperature is too high, the sensor sends a signal to turn on the fan. This way the motor cools better. If such an element is installed on your car, then during hot periods the fan will work almost constantly, helping to cool the engine. In this case, it is not recommended to disconnect the sensor, since the likelihood of overheating of the power unit increases.

Oxidation or broken contacts

If the car is equipped with a fan that is controlled via an electronic unit, there may be problems with the contacts themselves. Over time, they can oxidize, for example, when exposed to moisture, which is accompanied by constant rotation of the fan.

Air conditioning system

There are cars in the design of which the air conditioning and cooling system of the power unit are interconnected. Therefore, as a result of a clogged air conditioning system radiator, the main radiator fan is activated. In this case, the air conditioner radiator needs to be flushed, and it is better to subject the devices of both systems to this procedure.

Injection engines

Here everything is somewhat more complicated, since the following devices are responsible for the operation of the radiator electric motor:

- Electronic control unit.

- Coolant temperature sensor.

- Electromagnetic relay.

The reason why the electric fan may not work (or often turn on too much) lies in one of these components. Of course, the engine starts too often if the radiator honeycombs, either inside or outside, are very dirty, or if there are air pockets. But it does not turn on due to a breakdown in the control system.

So, you need to find a temperature sensor for diagnostics. It is located in one of the pipes of the VAZ 2107 engine cooling system. If you look at the engine from above, you will find it under the pipe that connects the fuel rail to the throttle valve. To check it, you need to disconnect the terminal and measure the resistance between the central terminal and ground. At a temperature of 20 degrees, the resistance should be about 3.5 kOhm. If the temperature is close to 90 degrees, then the resistance will be about 0.25 kOhm.

If there is no resistance, or it differs significantly from the values given above, then there is clearly a malfunction of the sensor and it cannot be repaired. The price of a new one will be approximately 100-200 rubles (depending on the seller’s appetite). But if the sensor is working, but the electric fan does not work, then you need to check its electric motor and switching relay. If no problems are found, diagnose the electrical wiring.

If this does not work, you will need the help of a competent auto electrician. Most likely, the firmware has gone wrong or part of the electronic control unit circuit has burned out. If there are no other troubles, then instead of an expensive replacement of the ECU it will be easier to install an electric fan switch sensor, since there is space in the radiators for its installation.

Perhaps this is where the troubleshooting can be completed. This algorithm will be enough to repair the cooling system. In the same case, if it is not possible to replace the relay or sensor, for example, simply connect the electric fan to the battery. Only after stopping be sure to turn it off.

The cooling system is designed in such a way that the fan starts only after the engine has warmed up to the set temperature. A malfunctioning fan switch can lead to serious engine problems.

Do not confuse this sensor with the coolant temperature sensor (DTOZH), which displays the engine temperature on the instrument panel and is installed on the right side of the engine.

It is possible to notice its breakdown in time only perhaps only in the summer, and even then in the city or when driving slowly, since the oncoming air flow is quite enough for the normal operation of the cooling system. The cooling system fan on VAZ 2107 cars starts with a characteristic noise, so the moment it starts is clearly audible.

Improving the cooling system with an electric fan

To improve cooling, you can replace the standard VAZ 2107 cooling fan with a more powerful and advanced one. Fans from Viburnum or Priora are suitable for this purpose. The eight-blade fan is especially effective, providing particularly strong air flow.

It is worth considering that the cooling system of the VAZ 2107 was initially designed for efficient operation. If it fails, the reason lies not in an ineffective standard battery, but in clogged radiator cells or a lack of coolant in the system. Therefore, if the engine overheats while the fan is running, it is worth checking the coolant level and cleaning the radiator honeycombs (or replacing it).

Does not work

Therefore, the search for reasons for the fan not turning on begins by removing the connector from the sensor with the ignition on. If the fan itself is working properly, then it should work. By inserting a load in the form of a light bulb into the connector terminals, the fan should stop. Thus, you check the electrical circuit of the fan motor. In this case, it will be fine, but the fan sensor will have to be replaced. However, it should be noted that there are also substandard sensors on sale, which, when installed on the engine, will also not work.

If, after removing the connector from the sensor, the fan does not work, then its functionality must be checked by connecting it directly to the battery. There are only two options for the experiment. If the fan is working, then you will have to check the functionality of the fuse that protects this circuit, the fan relay and the ECU. And if the fan does not work, then you will have to check the condition of its brushes for wear.

On carburetor engines of the VAZ-2107 car, there will be no ECU in the electrical circuit for turning on the fan, and some “sevens” do not even have a fan turn-on relay. Therefore, it is much easier to find the reason why the fan does not turn on, and many drivers of VAZ-2107 cars can cope with this.

Instructions: replacing the radiator grille.

Which thermostat is better to install https://vz07-up.ru/ssh/termostat.html#t2.

Scheme

We present to you a diagram for switching on the electric radiator cooling fan for the VAZ-2107, VAZ-2105 and VAZ-2104. In this circuit, there is a relay in the fuse block; therefore, a low-current sensor can be installed.

Where is the switching temperature located?

The fan switching sensor is located on injection models, on the aluminum outlet pipe of the cylinder head (article - 23.3828, used in VAZ-2107i-2112, 21213, 2123, ALFA ROMEO, DAEWOO, FIAT, LANCIA, OPEL), on carburetor models (TM 108 -02 92/87 C) it is installed on the engine cooling radiator.

For the “classic” fan, the operating temperature is 92 degrees and the shutdown temperature is 87 C 0, so installing a fan that is suitable in size, but with a different number, is not recommended.

On carburetor models the sensor is located on the radiator

Checking the electric fan and its circuits

In order to check the operation of the fan and power circuits on the injection “seven”, you need to disconnect the connector from the sensor, the ECU will give a command to turn on the fan. If this does not happen, then you need to check not the sensor itself, but the serviceability of fuse F7, the electric motor, the fan relay and the power circuits. Below is a diagram of how to turn on the VAZ 2107 injector cooling fan.

Circuit diagram for switching on the VAZ 2107 cooling fan (injector)

The principle of operation of such a device differs from TM 108 and is based on a change in resistance.

As the sensor heats up, it reduces the resistance; the ECU monitors this change and, when the specified parameter is reached (about 195 Ohms), turns on the fan relay.

On the carburetor model, everything is made somewhat simpler; if the fuse and relay are working properly, then in order for the electric motor to start, it is enough to remove the chips from the sensor and close them together.

The operating principle of the fan switch sensor installed on the radiator is this: in a cold state, the bimetallic plate opens the contacts, and when the temperature reaches 92 degrees (ideally), it closes and the relay is activated. In practice, quite often you can buy sensors with some spread in values. You can check the new one by heating it in water, controlling the temperature and switching on.

Possible causes, their search and solution

Why the cooling fan on the VAZ-2114 does not work

There may be several reasons why the cooling fan turns on on a cold VAZ 2114 engine.

The most likely of them are:

- low level of coolant in the system;

- sensor failure;

- fan short circuit;

- thermostat failure.

You should start your search with the first reason, since it is the most probable and at the same time the most quickly resolved. When the coolant level is low, the sensor can operate almost immediately after starting the engine, thus turning on the fan. This is due to the fact that a small amount of liquid heats up very quickly, while the engine itself is still “cold”. In order to solve this problem, you just need to add coolant to the required level.

If it turns out that there is enough antifreeze in the system, and this is not the reason, then you should check the sensor itself. It happens that it “sticks” in the closed position, as a result of which the fan circuit is always on. You can check the functionality of the device using a multimeter.

If you measure the resistance at the sensor contacts with the engine off, the tester should go off scale or show 0, depending on the model of the device (that is, the resistance will tend to infinity). If the multimeter shows very specific numbers, then the sensor is permanently closed, and it should be replaced with a new, similar one.

If the sensor also turns out to be working, then you should check the fan. Sometimes (especially if the housing is poorly screwed on or the wires are poorly insulated), it shorts to ground, as a result of which the fan starts working directly from the battery, without the participation of an electronic circuit with a sensor. This cause can be eliminated by checking and tightening all fasteners, as well as insulating exposed wire sections.

It should be remembered that such a malfunction is quite serious and can cause:

- Rapid fan wear.

- Battery discharge (if you leave the ignition on without the engine running).

- Car fires (due to strong heating of wires).

That is why special attention should be paid to searching for possible faults (exposed sections of wires). The last reason that can lead to the fan turning on spontaneously is a breakdown of the thermostat (or rather the control sensor installed on it)

The bottom line is this: if the thermostat sensor fails, the electronic unit automatically starts a fan to cool the system, since the electronic unit cannot accurately control the temperature of the liquid. A kind of “reinsurance” is performed in case of possible overheating

The last reason that can lead to spontaneous turning on of the fan is a breakdown of the thermostat (or rather the control sensor installed on it). The bottom line is this: if the thermostat sensor fails, the electronic unit automatically starts a fan to cool the system, since the electronic unit cannot accurately control the temperature of the liquid. A kind of “reinsurance” is performed in case of possible overheating.

In order to identify a sensor failure, you will again need a multimeter. When checking, you should measure the resistance between the sensor contacts (with the engine off, of course). Normally, it should be no less than 100 and no more than 500 Ohms. If the values obtained during measurement are outside the limits of this norm, then the sensor should be replaced with a new one. Finishing the conversation about the possible reasons for the fan turning on spontaneously, we should say a few words about how to prevent them.

To do this you will need:

- promptly monitor the coolant level in the system;

- periodically check the condition of the electronic wires of the cooling system;

- clean the sensor contacts from emerging oxides (it is recommended to carry out a similar procedure twice a year - in autumn and spring).

If you notice that the fan begins to turn on on its own, then the search for a breakdown cannot be put off until later, since the consequences (in some cases) can be extremely serious.

- VAZ 2114 on 15 disks 195 55

- Deciding what gasoline to fill the VAZ 2114 with

- Cabin filter VAZ 2114: principle of operation, operation and care

Good afternoon. I have this problem. After starting the engine, about ten minutes later the radiator fan starts working. But the coolant temperature is about 70. At the same time, the check light comes on. The revs start to fluctuate and eventually the engine stalls. When restarted, the engine either starts with difficulty or does not start at all. But the fan works periodically whether the engine starts or not.

Source

Diagnostics

You can check the fan switch sensor by measuring the resistance under different temperature conditions. To do this, use a tester (multimeter) in ohmmeter mode and measure the resistance of the spare part. It should decrease in proportion to the heating of the coolant, as already mentioned, the higher the heating, the lower the resistance.

The resistance can be checked without removing it from the car; to do this, just remove the chip and take measurements on the contacts of the part and warm up the engine by monitoring its heating using the instrument on the panel. See the table with approximate values for the dependence of resistance on temperature below.

Before installing a new controller, you can check the change in resistance in a container of heated water.

You can check the electric motor by applying voltage from the battery, the blue wire is “+”, blue and black or just black is “-“.

It happens that the fan starts at unusually high temperature values, this indicates its malfunction.

If during the check it turns out that the electric motor, fuse, sensor are all working properly, in this case you need to check the serviceability of the relay. It happens that the contacts simply burn out. In the photo below

The fan relay on the VAZ 2107 injector is located on an additional unit under the “glove compartment” (see photo) it is on the leftmost number 23-3787.

Fan relay VAZ 2107 (injector)

If you have nothing to replace this relay with, you can repair it. The contact is attached to the plate and to restore its functionality it is enough to tighten the contact. For this:

- disassemble the relay;

- bend the top stop of the plate;

- lift the plate with the contact for easy access;

- press the contact;

- putting it back together.

It should be noted that over time the breakdown is repeated, verified.

Additional items

Under the hood

Additional headlight wiper fuses (2A rating) protect the motor windings. They are located on the supply wires next to the gearmotors.

The starter activation relay 113.3747 or 90.3747-10 is located in the engine compartment on the right mudguard.

In the cabin

The windshield wiper relay (PC-514) is mounted under the panel on the left under the trim.

The ignition relay and the hazard warning and turn signal relays are installed on the front panel behind the instrument panel. The ignition relay (113.3747-10 or 90.3747-10) and the hazard warning and turn signal relays (23.3747 or 231.3747) have a bracket for direct mounting on the body.

The fog lamp fuse is located in the gear shift compartment, not far from the radio.

Replacing the sensor

Replacing the sensor on an injection model is easier than on a carburetor model, since there is no need to drain the coolant. It is enough to place some rag to absorb the spilled coolant. Using a 19 key, the part is unscrewed, removed and a new one is quickly installed. When installing, it is rational to apply sealant to the threads in advance.

To carry out the replacement procedure on a carburetor car, you must first drain the antifreeze (antifreeze) and only then unscrew the sensor with a 30mm wrench and install a new one.

When purchasing temperature sensors and controllers, try to choose branded parts.

On some vehicles, an electric fan is provided to blow air over the radiator of the cooling system. It turns on when the sensor-switch 37101B, installed in the lower part of the right radiator tank, is activated. Previously, power was supplied to the fan motor through a relay. In this case, a TM-108 temperature sensor was used. Currently, the electric fan circuit has been simplified and the electric motor is powered directly through the sensor-switch contacts. The sensor is non-separable - in case of malfunction it must be replaced.

| rice. 1 |

Fig.1. Circuit diagram for connecting the electric motor of the engine cooling system fan

Technical data of the electric fan and sensor 37101B (TM-108).

Rated shaft speed

electric motor with impeller, min-1

Electric motor current consumption, A

Sensor contact closure temperature, °C

Sensor contact opening temperature, °C

Electric motor ME-272

(or similar) direct current with excitation from permanent magnets. Installed in a casing fixed to the radiator brackets. During operation, the electric motor does not require maintenance; a faulty one must be replaced.

To check the fan motor, we apply 12V voltage from the battery to the motor terminals - a working motor will start working.

To check the electric fan sensor-switch, disconnect the wires from the sensor and connect them to each other with the ignition on. If the fan starts working, the sensor is faulty.

By connecting an ohmmeter to the sensor terminals and lowering it into the water the length of the thread, we use a thermometer to measure the temperature at which the sensor turns on and off. To do this, heat the water almost to a boil, and then control the cooling. For a working sensor, the temperature characteristic should not differ from that given above.

This article will talk in detail about the VAZ 2107 forced-air fan. Two types of this design can be distinguished - electrical and mechanical. Any owner of a 7 begins to regret that in the summer, in a traffic jam, his fan switch suddenly fails. After such an incident, as a rule, they begin to think about improving the design. And modernization can be done in several ways.

Cooling fan VAZ 2107

In the power plants of the first "sevens" the radiator fan was installed directly on the water pump shaft. Like the pump, it was driven by a belt drive from the crankshaft pulley. This design was also used on other cars at that time. It almost never failed, and it was impossible to overheat the engine with it. However, she had one drawback. The constantly cooled power unit warmed up very slowly. That is why AvtoVAZ designers changed the principle of forced airflow, replacing the mechanical fan with an electric one, and with automatic activation.

Early modifications of the VAZ 2107 had a mechanically driven fan

Why do you need an electric fan?

The fan is designed for forced airflow of the cooling radiator. During operation of the power plant, liquid coolant enters the radiator through the opened thermostat. Passing through its tubes equipped with thin plates (lamellas), the refrigerant cools due to the heat exchange process.

Later modifications of the Sevens were equipped with electric cooling fans

When a car moves at speed, heat transfer is facilitated by the oncoming air flow, but if the car sits for a long time or drives slowly, the coolant does not have time to cool. At such moments, it is the electric fan that saves the engine from overheating.

Device design

The radiator fan consists of three main elements:

- DC motor;

- impellers;

- framework.

The fan consists of an electric motor, impeller and frame

The electric motor rotor is equipped with a plastic impeller. It is she who, rotating, creates a directed air flow. The engine of the device is installed in a metal frame, with which it is attached to the radiator housing.

How does an electric fan turn on and work?

The process of turning on the fan for carburetor and injection “sevens” is different. For the former, its activation is controlled by a mechanical temperature sensor mounted in the lower part of the right cooling radiator tank. When the engine is cold, the sensor contacts are open. When the temperature of the refrigerant rises to a certain level, its contacts close and voltage begins to be supplied to the brushes of the electric motor. The fan will continue to operate until the coolant cools down and the sensor contacts open.

The device circuit is closed via a sensor that responds to changes in refrigerant temperature

In injection “sevens” the electric fan switching circuit is different. Everything here is controlled by an electronic control unit. The initial signal for the ECU is information coming from a sensor installed in the pipe leaving the engine (near the thermostat). Having received such a signal, the electronic unit processes it and sends a command to the relay responsible for turning on the fan motor. It completes the circuit and supplies electricity to the electric motor. The device will continue to operate until the refrigerant temperature drops.

In injection "sevens" the fan is turned on by command from the ECU

In both carburetor and injection "sevens", the electric fan circuit is protected using a separate fuse.

Method one - forced mechanical cooling

Perhaps you can call it that. Remember the first VAZ 2101-2107 cars, which did not use electric fans. In them, the radiator was blown through an impeller screwed to the pump rotor. The exact same fan can be installed on a VAZ 2107 injector. The design of the cooling system is not much different.

But we must immediately mention some of the features of this design. The fact is that even in winter the radiator will be blown by air flow. This reduces the engine temperature, so the cabin can be quite cool. It’s good in the summer - the engine is always cooled, the fan is constantly running, the antifreeze does not boil.

But make two more small improvements and summer operation will be just a fairy tale:

- Place a plastic diffuser that will direct the air beam into the radiator honeycombs.

- The upper part of the radiator needs to be installed a little closer to the impeller blades. Fasteners should be made using small strips of hard metal. Try to ensure that the distance from the surface of the radiator to the impeller is in the range of 2-4 cm.

These are the little tricks that will help you improve the cooling of the VAZ 2107 engine. The price of the issue is literally meager - no more than 80 rubles (that’s how much the impeller costs).

How to remove and install a new sensor

After purchasing and checking the controller, you need to do the following:

- Disconnect the negative terminal from the battery;

- Remove the cover of the cooling distribution tank and the cap from the radiator;

- We substitute the container, turn off the tap on the radiator and drain the antifreeze;

- Having removed the wires from the sensor, use a 30mm wrench to unscrew the sensor by the large brass nut;

- Next, the sensor is removed. Be careful not to drop the copper O-ring on the sensor.

After this, the sensor is replaced with a new one. When installing, do not forget to coat the contact areas of the sensor and radiator with a layer of high-temperature sealant before screwing the sensor. This must be done dry. This scheme of action allows you to avoid leakage of antifreeze.

Now you need to tighten the cap on the radiator, fill in the collected antifreeze, and, by connecting the negative terminal to the battery, check the operation of the sensor and fan. Do not forget to push through the air pockets in the cooling lines of the VAZ 2107.

That's it, you can hit the road! The fan will run.

Hello everyone, today I would like to talk about why the fan on a VAZ 2107 car does not work. As you probably already know, two types of engines were installed on VAZ 2107 cars: a carburetor and an injector. Therefore, the voltage supply circuits to the cooling fan motor will be different. On a VAZ 2107 injection engine, a two-contact fan sensor, which is located in the upper pipe, when the coolant temperature rises above that for which it is designed, it should send a signal to the computer. The electronic control unit, having analyzed the signal, turns on the fan through a relay.

Therefore, the first step when troubleshooting is to remove the connector from the sensor. If the fan itself is working, then it should work. By inserting a load in the form of a light bulb into the connector terminals, it should stop. With this technique you check the circuit of the fan motor of a VAZ 2107 car. Therefore, if necessary, the sensor will have to be replaced.

Method two - electric

If you have a new car, an injector and an electric fan are installed, is it worth spoiling it with a forced impeller? It would be somewhat more reasonable to leave the electric fan, but make a backup way to turn it on using a button. Purchase several items and materials from the store:

- New sensor (if the old one has become unusable).

- Electromagnetic relay with normally open contacts.

- Red wire with a cross section of 0.75 square meters. mm.

- A button for installation in the dashboard of a VAZ 2107 (preferably backlit).

- Heat shrink insulation.

- Female connectors and relay socket.

The connection diagram is shown in the photo. First of all, turn off the fan and change the sensor for turning it on. Then you assemble the circuit.

Please note that newer vehicles use sensors that can handle very high currents. But despite this, they still burn out. Sudden loads still quickly damage it. What to do? There is only one way out - to reduce the current at the sensor terminals. To do this, introduce an electromagnetic relay into the circuit. Now the chance of sensor failure is reduced. But the chance of relay failure becomes higher. True, it will be easier to change it.

Install a button to force the fan on in the dashboard and stretch two wires from it - one can be connected directly to ground, and the second to the sensor output. It turns out that your button and sensor contacts are connected in parallel. Therefore, if the sensor fails, you can turn on the electromagnetic relay with a button.

Forced fan activation

Some owners of “classics”, including the VAZ 2107, install a forced fan button in their cars. It allows you to start the electric motor of the device regardless of the coolant temperature. Taking into account the fact that the design of the 7’s cooling system is far from ideal, this option could one day be of great help. It will also be useful for those drivers who often travel along country roads or are forced to stand in traffic jams.

Forced activation of the fan is appropriate only on carburetor cars. In cars with injection engines, it is better to rely on the electronic control unit and not make any changes to its operation.

Video: forcing the fan to turn on

The easiest way to make the fan turn on at the driver's request is to bring two wires from the contacts of the temperature sensor into the passenger compartment and connect them to a regular two-position button. To implement this idea, you only need wires, a button and electrical tape or heat shrink insulation.

If you want to “unload” the button from unnecessary loads, you can install a relay in the circuit according to the diagram below.

The relay allows you to “unload” the fan switch button

In principle, there is nothing complicated either in the design of the fan itself or in its connection circuit. So, in case of any breakdown, you can safely proceed to self-repair.

Method three - perfect fans

To improve the cooling of the VAZ 2107, you can use more modern ones instead of a standard electric fan. Those that are installed on cars of the Kalina and Priora models are perfect. An electric fan with eight blades will work especially well. The air flow from it will be much stronger, therefore, the radiator honeycombs will cool down faster.

Today we’ll talk about the reasons why the VAZ 2107 fan (injector and carburetor) does not turn on. A little earlier, we figured out how to improve the engine cooling system. The whole procedure is simple and does not require much knowledge. But an equally pressing problem is that the fan refuses to turn on in a timely manner. Let's try to find out why this happens.

What to do when turning on the cooling fan on a cold engine

Sometimes car owners are faced with a situation when the cooling system fan turns on and starts working when the engine is cold. Although, under normal operating conditions of this element, it must be activated only when the temperature of the internal combustion engine reaches certain values.

There are many reasons why this situation occurs on modern cars. Some of them can lead to serious negative consequences if measures are not taken in time to eliminate the causes and provoking factors.

To understand the situation, you need to find out the reasons for turning on the fan, understand its operation and find the best methods to solve the problem.

Carburetor sevens

In these cars, the control system for turning on the electric fan is very simple. It can even be called analog. The entire circuit consists of the simplest form of the following elements:

- Electric fan motor.

- Power sensor.

- Wiring.

That's it, there is nothing else, you need to look for breakdowns only in these parts of the structure. In 70% of cases the sensor fails, in 5% the electric fan fails, in 20% the electrical wiring is to blame.

Advice!

To diagnose a car, I recommend using a fairly cheap solution: install it once and use it always.

But some cars use a slightly more advanced circuit, which includes an electromagnetic relay. With its help, it is possible to remove high currents from the sensor. This increases the resource of the device.

Some drivers who are not used to trusting automation install a regular button parallel to the sensor (and sometimes instead of it). Such a scheme has a right to exist, but the driver himself must be extremely careful in order to notice the temperature rise in time and turn on the electric fan.

Troubleshooting algorithm

If the electric cooling fan does not work on your VAZ 2107 (carburetor), you need to do the following:

- Turn off the engine and turn on the ignition.

- Use a flat-head screwdriver to short-circuit the terminals of the fan switch sensor. Please note that all control is based on mass. If the fan turns on, the sensor is faulty. If it doesn’t work, then the reason lies deeper.

- Disconnect the block from the electric fan and supply power from the battery directly. A rotating rotor indicates that the engine is running. If the electric fan does not work even this way, you will have to think about replacing it.

- If the fan and sensor are working properly, you need to check the electromagnetic relay (if present in the circuit).

- The wires are checked last. Oxidation very often occurs at the joints with the car body. And sometimes a banal break even happens.

The same algorithm can partly be applied to cars on which an injector is installed.

But in order to compare and appreciate the difference, it is worth considering such machines.

Cooling fan malfunctions and their symptoms

Taking into account the fact that the fan is an electromechanical unit, the operation of which is ensured by a separate circuit, its malfunctions can manifest themselves in different ways:

- the device does not turn on at all;

- the electric motor starts but runs constantly;

- the fan starts working too early or too late;

- During operation of the unit, extraneous noise and vibration occur.

The fan doesn't turn on at all

The main danger posed by a broken cooling fan is overheating of the power plant. It is important to control the position of the arrow of the temperature indicator sensor and feel the moment the device turns on. If the electric motor does not turn on when the arrow reaches the red sector, most likely there is a malfunction of either the device itself or the elements of its circuit. Such breakdowns include:

- failure of the armature winding, wear of the brushes or commutator of the electric motor;

- sensor malfunction;

- break in the electrical circuit;

- fuse blown;

- relay failure.

Constant fan operation

It also happens that the device’s motor turns on regardless of the temperature of the power plant and runs constantly. In this case, the following may occur:

- short circuit in the fan electrical circuit;

- sensor failure;

- relay stuck in the on position.

The fan turns on early, or, conversely, late

Untimely turning on of the fan indicates that the characteristics of the sensor have changed for some reason, and its working element does not respond correctly to temperature changes. Similar symptoms are typical for both carburetor and injection “sevens”.

Extraneous noise and vibration

The operation of the cooling fan of any car is accompanied by a characteristic noise. It is created by the impeller, cutting the air with its blades. Even merging with the sound of the car’s engine, in the “seven” this noise is clearly audible even from the cabin. This is the norm for our cars.

If the rotation of the fan blades is accompanied by a hum, creaking or whistling, the front bearing or support sleeve in the cover may have become unusable. A cracking or knocking sound indicates contact of the impeller with the inner edge of the frame in which the electric motor is installed. This malfunction is possible due to deformation or misalignment of the fan blades. For the same reasons, vibration occurs.

Injection engines

Here everything is somewhat more complicated, since the following devices are responsible for the operation of the radiator electric motor:

- Electronic control unit.

- Coolant temperature sensor.

- Electromagnetic relay.

The reason why the electric fan may not work (or often turn on too much) lies in one of these components. Of course, the engine starts too often if the radiator honeycombs, either inside or outside, are very dirty, or if there are air pockets. But it does not turn on due to a breakdown in the control system.

So, you need to find a temperature sensor for diagnostics. It is located in one of the pipes of the VAZ 2107 engine cooling system. If you look at the engine from above, you will find it under the pipe that connects the fuel rail to the throttle valve. To check it, you need to disconnect the terminal and measure the resistance between the central terminal and ground. At a temperature of 20 degrees, the resistance should be about 3.5 kOhm. If the temperature is close to 90 degrees, then the resistance will be about 0.25 kOhm.

If there is no resistance, or it differs significantly from the values given above, then there is clearly a malfunction of the sensor and it cannot be repaired. The price of a new one will be approximately 100-200 rubles (depending on the seller’s appetite). But if the sensor is working, but the electric fan does not work, then you need to check its electric motor and switching relay. If no problems are found, diagnose the electrical wiring.

Removal and Replacement Guide

If you do not know how to remove and disassemble the mounting device or safety elements and how to replace the old unit with a new one, then we will consider each instruction in turn.

Changing fuses yourself

Before you begin replacing the safety devices located in the main unit, you must turn off the ignition and battery terminals under the hood.

The replacement procedure is carried out as follows:

- Find the installation location of the device. There are latches on the plastic cover of the block; press them. After removing the cover, you will be able to see a diagram printed on the reverse side, which indicates the location and purpose of all used elements.

- Then you need to identify which device has failed and needs to be replaced. Sometimes a breakdown can be determined visually - the component itself may be burnt out, sometimes a broken thread is clearly visible in it.

- Under the cover of the device you will see tweezers, which can be used to remove the device. If you don't have tweezers, you can use pliers.

- Remove the burnt out element and replace it with a new one, then replace the cover and connect the battery terminals (video filmed and published by the AVTOCLUB_22 channel).

Replacing fog lamp fuses

If the fog optics break down, you should first diagnose the operation of the device. The component is located inside the car.

To check and replace, follow these steps:

- First you will need a Phillips screwdriver, use it to remove the two switches located in the middle of the console, near the audio system.

- Using a screwdriver, you will need to press out two fasteners.

- Then remove the plastic insert.

- You can now remove the fuse housing. Remove the protective cover of the device and replace the part with a new one.

1. Remove the two switches with a screwdriver.

2. Press on the pad fasteners.

3. Remove the insert and remove the device.

Changing the fuse box

Removing and replacing the block with components is done as follows:

- First, open the engine compartment of your car and remove the air filter housing. Unscrew the nuts that secure the housing using a Phillips screwdriver.

- Then under the device you will be able to see a plug with cables connected to the device, you need to unplug it. The product body itself is marked in colors; it corresponds to the color of the connected connectors. By taking these plugs into account, the need to label cables can be avoided.

- After this, you should climb into the vehicle interior and remove the shelf, which is located under the control panel. After this, unscrew the bolts that hold the glove box housing.

- Next, disconnect the plug with cables connected to the connectors directly on the device. Once you do this, you will be able to see the color coding.

- Using a wrench, remove the bolts that secure the block itself. Please note that the outermost screw on the case is hidden, so you will not be able to see it immediately.

- At the end, remove the block with the devices, now the device can be replaced. Installation of a new device, as well as assembly of components, is carried out in the reverse order.

The mounting fuse block contains some electrical control elements of a VAZ car and most fuses that protect electrical circuits from short circuits and overloads. It is located in the engine compartment on the left side, immediately on the metal partition between the engine compartment and the cabin. Here is the photo (top left):