Hi all! Any problems associated with the braking system of vehicles are potentially very dangerous. Therefore, every motorist should know why the brake caliper jams, what can provoke such a situation, how to diagnose and eliminate it. On your own or with the help of specialists, decide for yourself.

Our regular readers remember that we have previously talked about situations when the caliper knocks. Now let's consider a slightly different situation. Moreover, it is even more dangerous and unpredictable in terms of possible consequences if nothing is done after noticing the symptoms.

Let's start with the theory. The caliper on a car is part of the brake system. It is used in the design to press automobile brake pads when the corresponding pedal is pressed against the brake disc. As you understand, the node is extremely important.

But sometimes it can jam and creak because of this.

Choosing a DVR with Internet access

- VAZ 2110;

- VAZ 2109;

- Lada Kalina;

- Chevrolet Lanos;

- Lada Priora;

- VAZ 2114;

- Chevrolet Niva;

- Lada Kalina;

- VAZ 2112;

- Daewoo Nexia;

- Volkswagen Polo Sedan;

- Skoda Octavia;

- Mercedes E class, etc.

Regardless of whether it is installed on a Niva or a BMW, the caliper must be in constant working order.

This is the direct task of the car owner himself. Or persons responsible for maintaining the machine and maintaining it in proper technical condition.

Before determining why it does not press out and what to do to prevent the car caliper from jamming, you need to understand the principle of its operation.

In optimal condition, when the brake assembly is working properly, the operating diagram looks like this:

- the driver presses the brake pedal;

- pressure is built up inside the braking system;

- this pressure is transmitted to the piston group of the auto calipers;

- the calipers, being under high pressure, bring the brake pads to the disc;

- the braking disc is attached to the car wheel;

- friction force arises;

- wheel rotation slows down;

- the car stops;

- or reduces the speed to the required values.

As you can see, in theory there is nothing complicated. But in fact, the caliper is rightly called an extremely complex element.

For the brakes to work effectively, it is important to ensure that the pad is parallel to the disc.

Friction during active braking causes heat production. This heats up the pad, brake fluid and our caliper.

Therefore, it is extremely necessary that the car caliper be made on the basis of a material that does not change its properties and characteristics during the process of strong heating. Plus, there are increased requirements for strength.

How does the GTZ function?

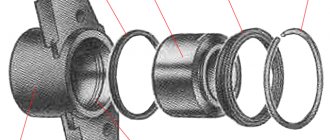

The unit consists of the following parts:

- metal housing with holes for supplying brake fluid, pedal rod and connecting the expansion tank;

- 2 pistons with rubber seals;

- 2 return springs;

- guide bushings;

- end plug with gasket.

An expansion tank is attached to the top of the main distributor body, where excess fluid goes through compensation holes. Inside, the element is divided into 2 cylinders with separate pistons standing on the same axis.

The blind end of the housing is closed with a threaded plug; on the other side there is a flange for attaching to the vacuum booster. The brake pedal rod is attached to the first piston. The brake circuit pipes are connected to the lower holes - separately for the front and rear wheels.

The operating principle of the master brake cylinder looks like this:

- When you press the pedal, both pistons simultaneously move forward and push fluid into the circuit tubes. Under its pressure, the wheel cylinders are activated, compressing the pads on the discs.

- Part of the liquid that does not have time to pass into the tubes flows into the expansion tank through special bypass holes.

- When the driver releases the pedal, the springs push the pistons back, returning them to their original position. Liquid from the tubes and reservoir refills the cylinders.

- To compensate for the expansion of the liquid (for example, from heating), another pair of holes is provided leading to the expansion tank.

Note. The GTZ acts in conjunction with a vacuum booster (not shown in the diagram), which helps put pressure on the pistons. This allows the system to respond faster and make the driver's actions easier.

Do-it-yourself front wheel bearing replacement: when necessary

It is the creaking that indicates that the element is seriously worn out. In the near future, the unit must be replaced without fail, which the car literally and figuratively screams about. It is extremely difficult not to hear such a creak. But for some reason, thousands of motorists still stubbornly ignore it. As a result, they pay a rather high price. Sometimes even to the point of road accidents resulting from brake failure while driving. To prevent this, you need to understand the issue and understand the essence of what is happening.

The first step is to look at the possible causes. In fact, there are several potential problems to look for. Some of them arise due to the fault of the motorist, others are caused by the natural process of wear and tear.

In any case, the appearance of a squeak as a symptom is a harbinger that at the most inopportune moment the caliper may simply jam.

If you know the reasons, you can prevent them and troubleshoot them by contacting a car service center or solving the problem yourself.

The reasons are:

- The brake pads were initially installed incorrectly. As a result, they are not strictly parallel to the response drives. Because of this, creaking often appears;

- The brake discs are seriously worn out. The reasons are natural wear and tear and aggressive use of the car;

- There is no lubrication in the unit. Initially there was little of it, or it was used up;

- The lubricant was selected incorrectly. Many people skimp on lubricant intended for calipers, hence the consequences.

The most undesirable and dangerous situation is rightly considered when the piston does not return and the unit begins to jam during operation.

Imagine that you are driving a car, press the brake, and then accelerate again. But at the same time, the calipers do not release the front brakes. Additional resistance arises, the car tries to move, but cannot. The result is uncontrolled braking, extremely intense wear and serious overheating of the entire system.

Kalina front wheel brake cylinder jams

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

The first step is to adjust the gap between the VUT rod and the GTZ piston.

It is easy to check - the next time it jams, you need to release the pressure in the wheel cylinders (through the bleeder fittings) of the front wheels. If the brakes are released, adjust the gap between the GTZ and VUT. It happens with similar symptoms that the hoses “flap”, but so that they are synchronized on both wheels

I forgot to describe my method of treatment: I remove the battery, unscrew the GTZ from the VUT, a hiss is heard, and the tommosis is “unwedged”.

I unscrew the GTZ from the VUT, a hissing sound is heard, the tommosis is “unclipped”.

here either the gap is incorrectly adjusted, as described above, or the brake pedal gets stuck and does not return to its original position.[/quote]

The “gap” or length of the rod is set at the factory, I don’t want to change it, it’s difficult to return it to its original state. I tried it on VUT1, reduced it, only the free play of the pedal increased, the jamming did not stop. The length of the rod is still a “static” value, i.e. does not change over time, and the jamming of the front wheels ranges from a slightly noticeable deterioration in rolling to complete blocking of the wheels.

Added after 4 minutes 18 seconds:

The tubes are difficult to confuse; they are rigid and of different lengths. I'll check.

Yes, in the evening I will try to disconnect the hose from the VUT, I read that you can plug it with an old spark plug. I'll post the results!

and the jamming of the front wheels ranges from a slightly noticeable deterioration in rolling to complete blocking of the wheels.

Here the operating principle of VUT is explained. There, look at the picture to see if the hole in the VUT through which the pusher No. 18 from the pedal passes is blocked. Shumka, for example, or something else.

the “gap” or rod length is set at the factory,

Blessed is he who believes! But the factories producing VUT and GTZ are different

, especially since you bought them at random.

Here is an example of a “factory adjustment” - an oil painting! https://www.tatauto.ru/news/2004/02/03/205.html

Kalina station wagon 1.6; 8-valve, 2010, mileage 120,000.

I have a Kalina station wagon 1.6; 8-valve, 2010, mileage 120,000. In the summer of 2022, I changed the front brake discs and pads on the advice of a relative who works at a service station. The reason is wear and tear. Then I noticed that the rolling had disappeared, the wheel rims began to get very hot (the rear ones were a little less), and at 80-90 km/h a strong beating of the steering wheel appeared. There was heating when driving around the city; on the highway there was only a slight vibration of the steering wheel. I thought about the caliper pistons, carried out maintenance on my own, the left piston moved very poorly, the right one was noticeably better. I changed the left one along with the guides and brake hose (TB), lubricated it, the right one just lubricated it. The beating is gone, there is no heating. Contacted the service. Master1 suggested adjusting the vacuum booster rod. Having disconnected the main brake cylinder from the VUT, we found brake fluid in the VUT (100-150 ml), which had gotten there from the GTZ (wear of the “working mirror”, I’m not sure I’m naming it correctly). Indeed, I periodically added brake fluid, there were no obvious leaks. Diagnosis from the master of GTZ and VUT for replacement. In his opinion, the presence of brake fluid in the VUT was what caused the jamming + the rear sorcerer was changed, the old one had gone sour. I bought new GTZ and VUT (not assembled), changed it myself, according to Murzilka, bled the brakes. During a test drive after 8-10 km. The roll began to abruptly disappear, it was difficult to move away from a traffic light, and the brakes jammed. I called the foreman1 and advised him to “reduce”, i.e. tighten the VUT rod. I tightened it 1.5-2 turns and the problem went away. A month later everything happened again. I began to blame the defective GTZ; there are many messages on the Internet about their marriage. I exchanged it in a store (kept by a friend), on the condition that the “defective” one would be checked, and if there was no defect, I would pay for it, and that’s what happened. To avoid confusion, I will further denote factory parts without numbers, spare parts purchased as replacements by number 1, etc. (“defective” GTZ - GTZ1; VUT1). I have in my hands a “defective” GTZ1, a new GTZ2. GTZ1 was disassembled for testing and self-development, no obvious defects were found, assembled, installed on the car, GTZ2 was kept as a “spare”. For about a month I drove only in case of urgent need, I cleared the jams by disconnecting the GTZ1 from the VUT1, while the sound of (most likely) air entering the VUT1 was heard, the brakes “died.” After 3 or 4 times of repeated jamming, the brake pedal gave way and the brakes were lost. Having opened the hood, I saw an empty brake fluid reservoir; I managed to unscrew the cap with great effort, and the float was “sucked in” so much that I had to use pliers. At home, it turned out that the retaining ring of the GRTs1 was torn off (probably installed poorly during assembly), the entire fuel fluid was inside the VUT1. Realizing that I couldn’t identify and solve the problem on my own, I decided to contact the official VAZ service. I arrived at the reception without a vehicle (I was standing at home), began to describe the problem to the receptionist, who, without listening enough, and demonstrating extrasensory abilities, one by one. coupon, made a diagnosis - replacement of the GTZ and VUT assembly, purchase only from them, price 4700 rubles. To my proposal to at least inspect the vehicle, he stated that this was not necessary, his knowledge and experience are undeniable, and to the proposal to issue a written conclusion, he also refused. This was followed by advice to buy a new car from them, and forget about trying to repair the old one. He was sent, but he is probably not used to it. Then there were calls to a number of services, where everyone unanimously spoke about the entry of a large amount of fuel fluid into VUT1 as the reason for the failure of the “diaphragm” of VUT1, which, as at VUT, led to jamming. The solution was seen in replacing GTZ1 and VUT1, and “then we’ll look and change something else...”. I was aware of the need to replace GTs1 and VUT1; I had the appropriate skills, but I had no desire to “feed” such masters. Having removed GTZ2 from the bins and purchased VUT2, I made another replacement. Today there is a problem: when driving in the city (I didn’t go on the highway) after 15-20 km. (affects the number of times the brake pedal is pressed) the front wheel brakes jam. This was determined by the fact that the front wheels get very hot, but the rear wheel rims remain cold. With a diagonal 2-circuit braking system, I cannot find an explanation for this fact. I realize that all the actions described above were a fight against the consequences. I ask you to help identify the cause and your reasoned advice on how to eliminate this problem. Thank you!

What to do in such a situation

If you were able to diagnose creaking and signs of wedging in this unit, you need to perform a number of measures.

And here it is not necessary to contact a car service. You need:

- put the car on a jack;

- remove the wheel;

- unscrew the caliper;

- remove it;

- unscrew the problematic piston;

- remove the piston from the cylinder;

- visually inspect the element;

- check for chips, damage, corrosion;

- if there is rust, clean it;

- if severely damaged, replace;

- drain the working fluid from the element;

- remove the sealing ring;

- clean all surfaces;

- dry;

- fill in new hydraulics;

- assemble in reverse order.

When putting the assembly back together, pay special attention to not accidentally damage the old boot. If you notice cracks on it, then no restoration will help. Replacement only.