Hi all! Any problems associated with the braking system of vehicles are potentially very dangerous. Therefore, every motorist should know why the brake caliper jams, what can provoke such a situation, how to diagnose and eliminate it. On your own or with the help of specialists, decide for yourself.

Our regular readers remember that we have previously talked about situations when the caliper knocks. Now let's consider a slightly different situation. Moreover, it is even more dangerous and unpredictable in terms of possible consequences if nothing is done after noticing the symptoms.

Let's start with the theory. The caliper on a car is part of the brake system. It is used in the design to press automobile brake pads when the corresponding pedal is pressed against the brake disc. As you understand, the node is extremely important.

But sometimes it can jam and creak because of this.

The pistons of the brake cylinders are jammed, what should I do?

Welcome! Brake cylinders - thanks to them, braking is carried out, and without the pistons that are in them, these cylinders will not work at all, so if a piston fails, then you have to go to a car store and buy a new brake cylinder, because driving without brakes is scary and even more dangerous , but not in all cases the pistons stop working forever, sometimes they can be revived, and we will write in detail about how to do this in this article.

Note! To work, you will need to stock up on: A jack to lift any side of the car, as well as a wheel wrench and you may also have to stock up on bricks, and you may also need a basic set of wrenches and sockets!

Summary:

How to understand that the pistons of the brake cylinder are not working? Let us answer this question before we move on to the repair of pistons, namely inoperative (That is, the pistons do not move in the cylinder), the pistons are recognized if they do not move at all and stand in one place, as a result of which the car, namely the brakes, begins a number of problems occur, that is, the car cannot drive normally because it constantly slows down even though you don’t press the brake pedal at all, or it may be that the car will drive but it will brake much worse than it should, in general, let’s figure it out Why do these cylinder pistons fail?

From time to time, the sealing ring (indicated in the photo below by an arrow) that fits the piston in a circle either wears out, or micro cracks form in it through which dirt begins to get into the piston itself, where the lubricant is located, and as a result the piston becomes unusable.

And also, the piston can simply sour in the brake caliper, and this can happen because of our roads, which in winter are mostly sprinkled with sand and salt, and the brake system is located in the very bottom of the car and therefore is subject to heavy braking. and in general, when moving, all this salt flies which little by little brings the situation to the point where the piston simply rusts, otherwise it simply sours, and therefore it will then be very difficult to move it from its place and thus it stops moving and therefore stops working.

By the way, you can very easily understand if your piston is somehow soured, if your car’s fuel consumption on the highway increases, and also if the car, as already mentioned earlier, starts to drive worse, and also if you notice that In neutral gear, the car began to slow down a little, this can also be understood if the car begins to skid on a winter road from braking, all this indicates that your piston has stopped working.

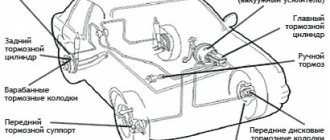

Device

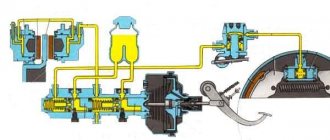

Hydraulic brakes are installed on the machine and operate generally reliably. They are double-circuit and have a diagonal distribution. That is, if one part suddenly fails, then braking by another circuit is possible. For the sake of safety, the VAZ 2110 brakes operate diagonally, one circuit is the right front and left rear wheels, the other is also diagonal.

This device allows you to brake efficiently (without skidding and other troubles) even in the event of a malfunction, if the brakes in one of the circuits are lost.

Let's consider the design of the brake system. The hydraulic drive includes a vacuum booster, as well as a dual-circuit regulator that creates pressure in the rear brakes.

In addition, the hydraulic drive is equipped with pipelines divided into two circuits, hoses and brake mechanisms that provide braking to the front and rear mechanisms.

The hydraulic drive is activated by a pedal located in the cabin (middle). Here are the main components of the hydraulic drive:

- Vacuum booster. It is designed in such a way that it creates pressure on the master cylinder piston, and thus causes braking;

Vacuum brake booster

Brake pressure regulator drive

Master brake cylinder

Front wheel brake

Rear wheel brake

The brakes require attention. Without waiting for the warning light to come on, indicating a critical level of fuel fluid or wear of the linings, and even more so, without allowing the brakes to completely disappear, you need to carry out preventive checks.

Particular attention should be paid to all connections and hoses, since the “escaped” brake fluid will not make it possible to brake, and from here it’s not far from tragedy.

How to turn an inoperative brake cylinder piston into a functional one?

1) At the very beginning of the operation, you will need to remove the wheel from the car.

Note! By the way, when you remove the wheel from the car, try to spin it while it is in the air; if it slows down, then some piston has actually become unusable!

2) After your wheel is removed, immediately remove the caliper from the car after it in order to get out the brake piston that is not working. (For information on how to remove the brake caliper on front-wheel drive cars, see the article: “Replacing the brake caliper on a VAZ 2109”, and for information on how to remove this caliper on a classic, see “this article”)

3) Now, when the caliper is removed from the car, you will need to find a vice, or a very strong compressor, in order to remove the piston from the brake cylinder, so if you have a vice, then go to it and clamp the piston itself and behind the caliper after Once you clamp the piston, pull it, and thereby the piston will be removed from its installation location.

Alarm Signals

The following symptoms are quite unsafe, please note:

- If the brakes are completely gone, then it’s clear that you can’t go any further, even to a service station! If independent repairs on site are beyond your capabilities, or simply impossible, you need to call a tow truck;

- When braking there is a strong vibration, especially felt in the steering column. You press the pedal, and it’s just hard to hold the steering wheel in your hands. There can be several reasons for vibration: • Many argue that vibration can occur due to the fact that there are non-ventilated disks. Their design is such that they really don’t like it when braking occurs in the rain, or even right in a puddle. No repair will help here - you need to replace the disks with ventilated ones; • Vibration may also occur if there is a problem with the rear drums. If upon inspection you find dark spots on the working surface, this indicates uneven wear. The vibration is usually very strong. Such drums need urgent repairs, and possibly replacement with disc brakes; • Check the front brake discs for deformation. At the same time, vibration is also observed.

- The brake pedal is too tight. There may also be several reasons for this: • A clogged air filter for the vacuum booster can cause the pedal to become stiff; • Check the vacuum booster itself. Its possible malfunctions are destruction of the diaphragm, tip, sticking of the check valve, damage to the hose connecting the intake manifold to the amplifier. In all these cases, a stiff pedal syndrome may occur, and repair of any of the indicated faults is necessary; • Also, the pedal may become stiffer as the pads wear, check them too.

- Hisses when you press the brake. If it hisses exactly when you press the pedal, you need to urgently check the vacuum booster, and then decide whether it needs repair or replacement. But if it hisses when you release the brake, then this is a normal phenomenon. Unless, of course, the hiss is too obvious.

Why does the brake caliper squeak and jam?

Secondary causes of jamming:

- the pads are not installed correctly initially, so they begin to creak;

- discs are worn out by 70–80 percent - due to aggressive driving style or natural reasons;

- the lubricant is incorrectly selected or is missing;

- Dirt and moisture got inside the mechanism.

One of the main reasons why a mechanism creaks or jams is overheating. Friction during active braking causes heat production. This causes high loads not only on the pads, but also on the presser itself. Therefore, at least conscientious manufacturers try to make it from the most durable material.

Symptoms of a problem

- oily spots on the visible or inner side of the wheel, which indicates a leak of DOT fluid, a decrease in its level in the expansion tank;

- unexpected, spontaneous pulling of the car to the side after braking - while the wheels are normally inflated and the suspension is fully operational;

- a grinding sound after releasing the brake pedal is the main sign of a situation where the piston is pressed in and does not return to its original position;

- The discs overheat greatly and give off an unpleasant burnt smell - even after driving with relatively infrequent braking.

Diagnostic stages

You need to understand that often, if a car pulls to the right, then the problem in the brakes should be looked for on the left, and if it pulls to the left, vice versa. But in rare cases this is not always the case. We'll talk about this below.

Regardless of what you drive, a Renault Logan, VAZ 2107, VAZ 2114 or another car, as well as the types of brakes installed (disc and drum), the reasons for the car pulling to the side when braking are usually the same.

The first thing you need to pay attention to:

- Air in the brake system;

- The operation of the calipers and the condition of their elements (boots, guide pin, etc.) - touch how hot the caliper is, perhaps it is jammed;

- Operation of working cylinders;

- Oil or other technical fluids getting on brake pads and discs.

What to do if the caliper is stuck on the road

The first thing that is recommended is to give the elements half an hour to cool down. Then identify the problem wheel by conducting an effective test. You need to drive 20–30 meters, stop and touch all four disks with your finger through the provided holes. If the part is hot, it is this particular wheel that jams. It is removed, the car is first placed on a jack.

Cold water will help to quickly cool the elements, but you can water it on a surface that has already partially cooled. Otherwise, the disk will simply blow apart due to strong temperature changes.

If the handbrake cable jams, the inner or outer braid is most likely damaged. It is possible that the return spring has weakened and needs to be replaced with a new one. Also, both return brackets often become dirty. In this case, they must be cleaned of rust and treated with VD-40.

But what to do if sometimes you don’t have time for all this. Then the only way remains is to hit the return bracket with a hammer so that the cable returns to its original position. You can drive further, but just don’t use the handbrake again until it is repaired.

If the piston itself is jammed, a hammer can also quickly solve the problem. You need to tap it carefully, through a wooden spacer, throughout the entire mechanism. If the pads do not wedge, try inserting a screwdriver between the pad and the disc. Finally, the surest, but most dangerous way is to squeeze the hose with a clamp. But you must drive extremely carefully, without brakes.

The process of replacing the VAZ-2110 brake cylinder

If the cause of the non-functioning brakes on one of the rear wheels is determined, then you need to begin the replacement process. First you need to dismantle the old part. It happens like this:

- First you need to remove the rear wheel.

We unscrew the wheel by jacking up the car and placing additional support under the bottom.

It is better to unscrew the tip of the brake pipe with a slotted wrench.

It is more convenient to unscrew the brake cylinder mounting bolts using a ratchet head.

When working with fittings and tubes, the main thing is not to break the threads, otherwise you will have to change them too.

Old brake cylinder.

If the parts are difficult to unscrew, it is better to spray them generously with WD-40 . When rotating the nuts, you need to make sure that they rotate without tubes. If the tube turns together with the nut, it means it is rusty and stuck to the nut. This part is not allowed for use and must be replaced.

The process of installing a new cylinder

Before you begin the cylinder installation procedure, it is imperative to clean the entire rear wheel brake mechanism from dirt. If you really had to climb into the drum, then you need to carefully examine its condition, at the same time inspecting the pads . If worn, they must be replaced .

- If there has been a cylinder leak, then before installing it you need to thoroughly clean the pads from all traces of brake fluid . To do this, you can use a file or sandpaper. Under no circumstances should stripping machines be used, as the pad can be seriously damaged.

- The inside of the rear brake drum also needs to be cleaned of dirt, rust and degreased from traces of brake fluid . If the liquid remains in the drum, the shoe will slide during operation. Only after thorough cleaning of all mechanisms can a new cylinder be installed. The assembly procedure takes place in the reverse order of disassembly.

Consequences

When the bracket wedges, the block remains pressed. This causes the discs to become very hot and the shoes to burn. If the speed of movement is high, and the degree of constriction is maximum, then it’s red-hot. It is obvious that braking efficiency drops sharply, the linings and disc become washed out and lose their properties.

After several heating and cooling procedures, the disks are sure to become deformed. After pressing the pedal, you will feel a beating, and you will not be able to brake at all. You will have to replace the repair kit, but the troubles will not end there, because the cause of the malfunction is in the caliper. If the hub begins to heat up, then the bearing will crumble and the CV joint will be destroyed.

Posts 1 to 20 of 28

1 Topic by OlegD 2015-03-16 20:43:46

- OlegD

- Connoisseur

- Inactive

- From: Moscow

- Registration: 2014-01-15

- Messages: 511 Thanks : 115

- Car: 21114, door 21124 1.6 l., 2007 onwards

Topic: Resolved: Front brakes are pinching the disc

Looks like my summer theme continues. There I had a problem with the rear brakes, and now I have the same problem with the front. The pads do not release the discs completely, which causes the wheel to spin poorly. It seems that this problem began at the same time as with the rear brakes (it was noticeable by the characteristic sound of the pads rubbing, but then I ignored it), only now it has worsened. The car has even become difficult to accelerate, and the hanging wheel can only be turned with difficulty (the right one is more difficult, the left one is easier).

It is clear that in the brake system, malfunctions of various components can have such an effect. But for now it seems to me that it is the brake master cylinder that is sticking. This is supported by the fact that the problem was with the rear, and now with the front brakes. By the way, the rear ones are now in perfect order.

It also happens from time to time that there is a strong beating in the steering wheel and vibration in the car at a speed of about 90 km/h. Then it passes. Looks like these are related problems.

Do you think there could be a problem with VUT? Is it worth buying and installing a brake master cylinder repair kit or is it a waste of time?

Source

Prevention measures

Maintenance of the caliper must be carried out every time the pads are replaced, every two years. It is during this period that the lubricant loses its original properties. In Russian conditions, the timing of the inspection activity must be significantly reduced, and an inspection must be carried out in case of any extraneous sounds, the vehicle slipping and other signs of damage to the mechanism listed above.

The large loads to which the clamp is subjected require the use of special lubricants. Poor-quality compounds quickly harden and are destroyed by water or aggressive brake fluid. You need to use only high-temperature lubricant, with minimal dripping characteristics, moisture-resistant and not susceptible to chemicals. In addition, the correct lubricant must be compatible with plastic and rubber parts. A special type of lubricant is used for the fingers—the elements that guide the mechanism’s brackets.