The main brake cylinder of the VAZ-2109 is necessary to ensure the normal operation of the cylinders and calipers, which clamp the pads and stop the car. The design of the entire system is quite simple - there are no frills like a traction control system, and you won’t even find sensors signaling excessive pad wear.

The condition of the elements must be monitored by the driver. To help him, there is only a level sensor on the expansion tank. When the brake fluid level drops below a critical level, a warning light on the dashboard will light up.

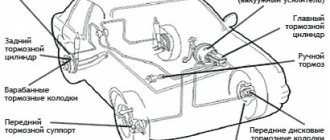

General system diagram

The brake drive system here is of a hydraulic type, functioning using two circuits, they work independently of each other. The use of a dual-circuit system is justified by safety. If one of the calipers leaks or a hose breaks, you can still stop the car. Even directly on the main brake cylinder of the VAZ-2109 there may be a leak. But the car can still be stopped.

True, if the braking system operates on only one circuit, you will feel discomfort. The car will pull to one side when braking. Braking efficiency is also reduced. For these reasons, continuing to drive a vehicle that has a faulty brake system is strictly prohibited. Using the VAZ-2109 master brake cylinder, pressure is created inside the system. When the driver presses the brake pedal, it moves the rod and piston inside the cylinder. This increases the pressure inside the hoses and tubes.

Actuators are installed on each of the wheels. These are the working cylinders that are located on the rear wheels. As well as calipers on the front wheel mechanisms. With the help of these elements, the rear pads are unclenched and the front pads are compressed. In this case, under the influence of friction between the discs, drums and pads, the car is braked.

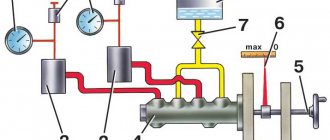

Pressure regulator

This device is responsible for increasing the efficiency of the braking system. Probably every car enthusiast knows that during the braking process, the main part of the braking force is transmitted to the front wheels and the remaining small part to the rear wheels. The degree of distribution may depend on several factors, the main ones being the level of vehicle load and the intensity of braking. However, the design of the brake system of the nine includes a pressure regulator, which is responsible for the rational distribution of braking forces between the front and rear calipers.

Thus, thanks to this unit, there is a significant reduction in pressure in the pipes of the rear axle system. The pressure regulator is located on the rear beam, and is mounted using a special bracket. It is worth noting that when taking preventive measures or replacing this unit, you will need a special key that does not grind the edges of the fixing elements.

Front brake

A metal disc is rigidly fixed directly to the hub. The brake disc is secured using:

- Small conical studs that serve as guides for the wheels.

- The bolts that secure the wheel to the hub.

The rotation speed of the disk and wheel will always be the same. Therefore, in order to brake a car, it is necessary to stop all its wheels. To do this, you need to clamp the disc using pads and brake calipers.

The calipers have two parts - external and internal. On the inside there is a cylinder, a steel piston is installed in it. Under the influence of the pressure created by the main brake cylinder of the VAZ-2109, this piston moves and acts on the block located from the inside. At the same time, the outer part of the caliper moves towards. When the pressure in the system decreases, the pads return to their original position under the action of springs.

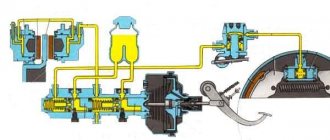

The operating principle of the GTZ in simple words

The process is activated by pressing the brake pedal. The result of mechanical force is a load inside the cylinder, carried out using a rod. It directs the pistons along the desired path, overcoming the force of the return spring. The movement of the pistons is accompanied by the closure of the compensation channels, which causes the opening of the bypass channel and sealing of the entire circuit.

At the same time, pressure is created that drives the caliper. Part of the liquid flows into the pipelines, activating the vehicle, the other pushes the second piston, which, when moving, performs the same functions.

The calipers compress the brake discs with the help of the pads, and the car stops. The pistons return through the compensation hole to the initial position after depressing the brake pedal. The initial mode of the pistons inside the circuits is established by the action of springs. Having returned to their original position, the pistons again open the compensation channels, thereby equalizing the pressure in the vehicle. The waste liquid slowly flows back into its reservoir.

Rear brakes

The brake design, which is located on the rear wheels, has approximately the same design. Only instead of a disk a drum is used. It is made of aluminum alloy, inside of which there is a steel cage. The pads are made of metal, the outer part of which is in contact with the drum, and special linings are glued on. They are made from various friction materials. The pads are driven by brake cylinders.

This element allows, under the influence of pressure created by the main brake cylinder of the VAZ-2109, to release the pads. The service life of the rear drums and pads is much higher than that of similar elements of the front brakes. The reason lies in the fact that the rear wheels account for no more than 30% of the load during braking. The service life of the rear elements of the braking system is approximately two to three times higher than that of the front ones.

Vacuum booster

This element of the nine's brake system is located between the passenger compartment and the engine compartment. It has a cylindrical shape and is connected via hoses to the carburetor and the brake master cylinder. The main purpose of this unit is to improve vehicle controllability. It is thanks to the vacuum booster that the brake pedal has a very soft stroke, and stopping the car becomes very easy. To truly appreciate the importance of this detail, it is necessary to compare the braking process of the Nine with that of older VAZ models, stopping which took more effort and the braking distance was much longer.

Master brake cylinder

The design of this element is quite simple. The main cylinder is made of special aluminum alloys. A one-piece body to which the expansion tank and tubes are attached, through which the liquid is supplied to the actuators.

The design of the VAZ-2109 master brake cylinder is somewhat similar to an internal combustion engine. There is a cavity inside, it is perfectly flat, and two pistons move in it under the action of the pedal. These pistons have rubber seals on the outside. They are necessary to improve tightness. The repair kit for the VAZ-2109 master brake cylinder necessarily contains these cuffs.

An expansion tank is installed on top of the cylinder; it is made of plastic. There is a plug on it, inside of which a float level sensor is built. It does not show intermediate values, but allows you to simply turn on the lamp power circuit when the liquid level in the system decreases.

Repair and preventive measures of the brake system

Operating a car involves a lot of wear and tear on the tubes and hoses through which the brake fluid is supplied, as a result of which cracks may appear on them, through which the brake fluid leaks out. Therefore, it is extremely important to identify such faults in a timely manner and promptly replace these elements. To do this, you will need an eight-inch crimp wrench, as well as a set of new gaskets.

It is worth noting that when replacing the hose, the brake fluid must be completely drained from the system. A special fitting located on each caliper is designed for this purpose. At the intersection of the tube and hose, it is necessary to use metal brackets, with which they are attached to a special bracket.

As already mentioned in the article, it is periodically necessary to completely replace the brake fluid, since over time it loses its properties. In addition, this procedure must also be performed when replacing hoses and tubes, since during the work it becomes airborne, as a result of which further use of the hose becomes impossible. To do this, add fluid to the expansion tank to the maximum level and pump the brakes of each wheel in a strictly defined sequence. If you have not previously performed a similar procedure, then it is recommended to seek help from more experienced motorists in order to avoid making the basic mistakes that all beginners most often encounter. Nevertheless, the procedure for bleeding the brake system itself is not complicated; the only thing that is required is a large container into which the aired fuel fluid will be drained. It is worth noting that it is necessary to drain until liquid with air bubbles stops flowing.

For stable operation of the vehicle's brakes, it is necessary to replace worn out brake pads, since it is thanks to them that the car stops. This is one of the most common types of repairs that car enthusiasts regularly encounter. To replace the braking elements on a VAZ 2109, you need to place the vehicle on a jack and remove the wheel. Next, the caliper fixing bolt is unscrewed, which then simply moves to the side. After this, we press the piston into the housing so that it does not interfere with the removal of used pads and installation of new ones, and we directly replace the spare part.

How to service the master cylinder

The design of the brake system on nines is approximately the same as on classic models. The only difference is that the parts of the VAZ-2109 brake system are much stronger and more powerful, since the car is capable of developing higher speeds, therefore, it needs to be stopped faster.

There is no need to service the master cylinder if it is functioning properly. But try to change the brake fluid, top up if necessary and make sure that there is no leakage in the system. If a leak appears from the master cylinder, it must be repaired or completely replaced.

Causes of malfunction in the GTZ device

If there is a leak in one of the circuits, the pressure between the primary and secondary cylinders is lost. This leads to the fact that the GTZ functions as if it had only one circuit. The pusher will begin to move both pistons in the good circuit until the piston of the faulty one reaches the end of the cylinder body. Accordingly, the required pressure will be ensured in the depressurized chamber. If the idle mechanism is properly adjusted, the vehicle will effectively slow down the vehicle even in conditions of its inferiority.

Here are some signs of a malfunction in the GTZ device:

- depressurization of the cylinder is determined by the presence of a leak in the body and a specific smell;

- brake pad wear is characterized by a characteristic squeak and leakage of brake fluid;

- jamming of the regulator, which distributes the brake force. In this case, it is necessary to clean the cylinder body. There is a low threshold of sensitivity of the brake pedal; it has to be literally “sunk” into the floor;

- the pedal falls to the floor - this damage occurs due to non-working pistons. If they are not able to generate the required pressure, then the pads cannot compress normally;

- An increase in the brake pedal travel is a sign that the vehicle has become airy. Operating a car in this condition is dangerous, since there is a high risk of overheating the vehicle to the point of boiling. Pumping will help eliminate this problem.

Replacement or repair?

The price of the VAZ-2109 master brake cylinder is about 1000 rubles. The repair kit will cost half as much. But the feasibility of its installation is highly controversial. When repairing, you will need to do the following:

- Drain the liquid from the expansion tank.

- Remove the expansion tank.

- Unscrew the pipes that are located on the brake cylinder.

- Remove the two nuts that secure the master cylinder body to the vacuum booster.

- Loosen the locking bolt that holds the first piston in place.

- Pull the piston out of the cylinder. This must be done carefully so that the spring does not jump out. Try not to lose all the elements.

- Loosen the locking bolt holding the second piston and remove the element from the cylinder.

Choice

We will give some recommendations regarding the choice of a new vacuum amplifier.

| Selection criterion | Required parameters |

| Price | The cost of a good vacuum cleaner is now about 2.5 thousand rubles. These are not the most expensive, but not the cheapest Chinese options. Optimal for VAZ 2109 |

| Package | This packaging, used by a genuine manufacturer, is made of corrugated cardboard |

| Label | The label should be clearly legible - the production batch number, the production date of the part and the name of the manufacturer itself |

| vendor code | The vacuum unit corresponding to the technical parameters of the VAZ 2109 has article number 2108-3510010TM |

| Point of sale | You should not buy from market traders. There are many good, trusted spare parts stores in any city. Don’t be shy to ask for certificates, documents for parts |

Choosing wisely

Now there are a lot of fakes on the market. Such parts cost the same as the originals, but last much less.

Installing a new cylinder

The layout of the VAZ-2109 master brake cylinder is the same as on classic series cars:

After this, you need to install new cuffs and pistons and fix the device in place. But it is much better to change the main brake cylinder of the VAZ-2109. How to do it yourself:

- Secure the cylinder body with two nuts on the vacuum booster.

- Install the brake pipes.

- Secure the expansion tank to the cylinder.

After this, it is necessary to fill the system with fluid and bleed the brakes. If this is not done, there will be air pockets inside the system that will not allow maximum braking efficiency to be achieved.

Algorithm for removing the GTZ VAZ 2108

- Remove the reservoir cap from the brake fluid and brake fluid, remove the reservoir from the brake fluid, using something wooden to remove it from the seat.

- To prevent brake fluid from getting on electrical wiring and other elements, you need to place some kind of rag under the turbocharger. After this, use a special key, which eliminates the possibility of “licking” the edges, to turn off the pipes.

TJ is toxic, leaves stains on clothes, plastic, rubber. It is better to leave marks on the tubes with paint or a marker.

How to disassemble the GTZ VAZ 2108?

Once the brake master cylinder is removed, disassembly can begin. Provided that you are not going to completely change the GTZ, but only want to change worn out elements (rubber seals, cuffs and brake pistons). Check the condition of the parts and, if necessary, replace faulty parts. The pistons are removed simply by hand or by supplying compressed air to the nozzle of the second chamber; the openings of the tank must be closed. Before assembly, make sure there are no burrs or scratches on the surfaces of the cylinders; if there are any, you will have to completely replace the VAZ 2108 GTZ.

If repairing the VAZ 2108 GTZ is impractical and you are going to completely change the master brake cylinder, then put the brake reservoir on it and put everything in place. Further details on how to install a new GTZ on a VAZ 2108.