In a car, the starter is a very important component. It ensures that the engine starts by rotating the crankshaft for the first few revolutions. This is necessary to begin the process of ignition of the mixture in the chambers.

Today we will consider this unit applicable to the popular Russian model Lada Kalina. We'll tell you where it is and how to remove it.

What is the operating principle of the starter?

By turning the key in the lock of the Lada Kalina ignition unit, power is supplied to the terminals of the electromagnetic relay. This element, by means of a lever, moves the overrunning clutch to a position where the starter shaft gear meshes directly with the flywheel. In addition, voltage is supplied to the electric motor, the shaft of which begins to rotate, driving the engine. When the motor starts, the plunger moves back, bringing the assembly to its original position. Starter power is currently being cut off.

Discharged battery

Also, quite often a starter malfunction can be confused with a discharged battery. If the starter on your car does not rotate the engine, but only clicks of the solenoid relay are heard, then the battery is most likely discharged. The sound that the starter makes when the battery is discharged can be heard in the video.

When is a starter check required?

During operation, the device may malfunction, and therefore the engine will be unable to start. The Lada Kalina car unit is characterized by the following signs of malfunction, suggesting the need for removal and diagnostics for the purpose of further repair or replacement:

- turning on the starter is accompanied by the shutdown of other devices operating at that time;

- when the device starts, reduced crankshaft speeds are observed, which is not enough to fully start the engine;

- turning the ignition key does not activate the starter;

- the unit shows signs of “viability”, but the motor flywheel does not rotate.

Next we will tell you how to remove and replace.

Let's sum it up

To ensure that the starter of the Lada Kalina does not fail, it needs to carry out maintenance, otherwise it will require replacement. Do not overheat the device by frequent attempts to start the motor. Holding the ignition key in the appropriate lock position for more than 5-7 seconds can also cause harm. After the 45,000th mileage of the LADA Kalina car, it is necessary to disassemble the unit, replacing the lubricant and cleaning the surface of the collector. In addition, external contacts require inspection and cleaning.

How to change the starter, and most importantly, how to repair the starter yourself - these are questions that VAZ owners often ask. Therefore, in this article we will tell you how to replace the starter on Kalina.

To replace and repair the starter , we place the car on a pit or on a lift.

- Open the hood. Remove the terminal from the battery.

- For ease of access, you need to remove the air filter housing. To do this, remove the connector from the air flow sensor.

- Loosen the corrugation clamp and remove it.

- Remove the antifreeze return hose from the mount.

- Using head No. 8, unscrew the two fastenings to the front frame of the car.

Replacing the starter on an 8-valve Kalina

Having found out where the required unit is located, we proceed to replacement. To perform the work (removal, repair and installation), you will need the following tools and accessories:

- keys with dimensions of “8”, “10” and “13”;

- wrench with nozzles 13 and 15 mm;

- screwdrivers, both flat and cross-shaped;

- hammer, vice and pliers;

- drift (made of wood or soft metal);

- ohmmeter;

- a little lubricant of the “CV joint-4” type;

- two metal plates, a block of wood and a fine-grained sandpaper sheet.

After the preparatory work, we’ll figure out how to remove the device.

To make the replacement convenient, we place the LADA Kalina above the inspection ditch.

- We de-energize the on-board network (remove the terminals from the battery terminals).

- We dismantle the air filter housing along with the element.

- Using a wrench (socket) set to “13”, unscrew the nut holding the wire tip to the positive terminal of the battery. Remove the tip.

- Using a key set to “15” we unscrew the nuts securing the starter to the engine block. We remove the node.

The device is installed and connected to the LADA Kalina on-board network in the reverse order.

Fog lights Kalina

Lada Kalina wiper size

Kalina cooling system gets airy

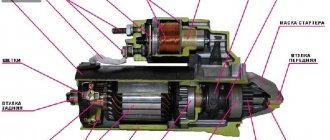

What is an engine starter

Any gasoline internal combustion engine is equipped with a part called a “starter”. This unit, that is, the starter, is a conventional electric motor. The voltage “+12 Volts” is supplied to it via one electrical cord. The body acts as the second wire.

There is always voltage at the supply terminal

A relay is mounted inside the starter, the contacts of which conduct the supply current. When you need to start the internal combustion engine, the contacts close. Let us immediately note: the voltage on the power wire always remains as long as the battery is charged. Therefore, before dismantling, be sure to remove the negative terminal from the battery.

Auto electricians know: when working with any equipment, the battery is completely disconnected from the network. It is easier to do this by disconnecting the negative terminal (you will need a flat key “10”).

If the battery is charged, but the starter does not turn, then first you need to check whether there is voltage at the contacts of the Ka-3 relay. This element is fixed in a single mounting block, and it is called: “Additional starter relay.”

Starter repair in a Lada Kalina car

In most situations, disassembling a unit in the Lada Kalina model for the purpose of repair is carried out to replace such elements as:

- brush holder in combination with brushes;

- traction relay;

- drive components.

Naturally, repair procedures are carried out on a removed device. How to remove it correctly?

Let's sort it out.

- We take the spike at “13” and unscrew the nut that secures the lower contact bolt of the traction relay, after which we remove the wire tip.

- Using a screwdriver (Phillips), we “defeat” a pair of screws holding the retractor relay block. We remove the element.

- We remove the spring along with the armature from the front cover of the relay.

- Disconnect the housing from the front cover. Here you will need to unscrew a couple of tightening bolts (key set to “8”).

- From the released housing we remove the armature together with the brush holder and the end cover.

- This cover is removed by unscrewing two screws with a screwdriver. The bearing seat contains a wavy spring washer.

- The brush holder itself must also be dismantled, after which the brushes are removed.

- We move on to the planetary gearbox, from which we remove the cover.

- Now we remove the three satellites and the rubber plug.

- We press the end of the drive shaft with our finger, and then remove the drive assembly located in the front cover.

- We arm ourselves with two screwdrivers, with which we open the eyelet present on the support, and then remove the drive lever.

- We use a wooden block against which we rest the end of the ring gear.

- We apply the grips of the open-end wrench (size - “13”) to the ring that limits the travel of the drive gear. We hit it with a hammer, forcing the ring to compress in this way.

- The locking ring must also be removed. We use a flat screwdriver.

- Next, we dismantle the gear travel limit washer.

- We remove the overrunning clutch assembly with the drive gear.

- Using a screwdriver, remove the retaining ring from the corresponding groove on the shaft.

- We also remove the washer.

- We pay attention to the ring gear in the planetary gearbox, which we pull off the drive shaft.

- We proceed to dismantling the bearing. To do this, we use the previously designated metal plates. We insert them between the bearing itself and the armature commutator, and then rest it on a vice. Use a hammer to carefully impact the end of the shaft (a drift will be required) until the bearing is completely pressed.

This completes the disassembly procedure.

Next, we inspect the commutator and armature winding. There should be no charring here. If it is present, then use fine sandpaper to “correct the situation.” When the burning is intense, there is no alternative to changing the anchor.

If we find scratches or material coating on the shaft journal, we also use “all-conquering” sandpaper, after which we polish the treated areas.

We arm ourselves with an ohmmeter to check the short circuit between the core and the windings. We pay attention to the ends of the windings - their soldering to the lamellas must not be damaged. Blackening of the winding or separation of varnish insulation from its surface is not allowed.

If the brushes are worn out, then replace the holder assembly.

The assembly of the starter assembly is carried out according to the reverse algorithm of actions.

How to get rid of unnecessary details

Under the hood of the Kalina-2 it is easy to find an air filter module that prevents access to the unit we need. This module must be moved to the side, but first the air intake sleeve must be disconnected.

Black box – filter module

The sleeve itself, attached to the bottom of the module, is simply pulled in the “left” direction. The whole process looks like this:

Remove the sleeve from the pipe

Just in case, here is a drawing of the node in question:

Filter module design

The figure shows the connector installed on the top of the module. The plug from this connector is also first disconnected, but first, the negative terminal is removed from the battery. Why do this, we discussed earlier. It turns out that there will be three preparatory steps: disconnecting the battery terminal, removing the sleeve from the filter side, disconnecting the plug.

Theoretically, replacing the starter looks easier if the air duct sleeve is disconnected on both sides (on Kalina 2 it covers the caps of the mounting screws). This statement is illustrated by the figure:

Engine starter for Kalina-2/Granta

We will have access to nuts “2”, but we will have to reach for the screw heads. However, there is nothing special here. Now, let’s remove the plastic module from the clamps:

Three rubber clips hold the filter module in place

After completing all the steps discussed, the module can be moved to the side.

Last step before dismantling the starter

Originals, analogues, articles and prices

The first modifications of the Lada Kalina were equipped with a starting device with the catalog number “21120-3708010-00” (KZATE). It was fixed to the block wall with three nuts.

After the release of the Lada Kalina with a cable-controlled gearbox, the method of fixing the PU changed to a screw one.

- 21120-3708010-00;

- 21901-3708023-00;

- 21120-3708045-00 (KATEK, KZATE, ZiT);

- 21901-3708051-00 (VALEO) (8 valves);

- 21902-3708056-00 (VALEO) (16 valves).

For automatic transmission type: Jatco – 21902-3708135-00.

The cost of PU varies depending on the modification. Base price from 3100 rubles. On models with a new type of fixation from 3400 – 3500 rubles.

Foreign analogues are no better in quality than domestic ones. The cost is 10 - 15% more expensive. Manufacturers: Blue Print, Bremi, Febi, Bilstein, Fenox, Glaser (see photo).

Where is the starter installed in a Lada Kalina car?

Many car enthusiasts wonder where the starter is located. As in many other brands, the PU is installed in the engine compartment, fixed at the end of the block on the flywheel side.