18.07.2019

| (Votes: 7, Rating: 4.43) |

Issues discussed in the material:

- How do brakes work?

- What are the main causes of front brakes sticking?

- What other faults can cause the front brakes to jam?

What daily manipulations does every person who moves during the day by car do? He gets into his car, starts the engine, warms it up a little and starts driving. And here an unpleasant surprise can await him: the car does not move! If this has not happened before, then it is difficult for the driver to understand what is going on, especially if his driving experience is not yet very long. The reasons why the front brakes stick can be different. To learn how to distinguish and eliminate them, you must first understand the theoretical side of the issue.

Causes of probable malfunction

One of the main problems that arise in the brake system of the Lada Priora is the “acidification” processes that occur on the surfaces of the moving elements of the caliper.

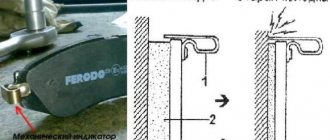

An obvious sign of a malfunction is an uneven change in the shape of the brake pad, squeaking when stopping the car, as well as a clear increase in the vehicle's travel distance when braking.

All this indicates that the caliper needs replacement or, at a minimum, repair with detailed diagnostics:

- checking the piston for malfunctions;

- degree of mobility of the components of the braking system;

- inspection of components for metal oxide and oxide formations;

- condition of protective anthers.

When inspecting the guide elements that go into the front caliper, you should pay attention to unnatural grooves, chips and other signs of deformation.

If any, the parts also need immediate replacement. As for safety measures when operating a Lada Priora car, you should not neglect regularly changing the brake fluid, which needs to be done approximately every 50 thousand km.

What to do in such a situation

If you were able to diagnose creaking and signs of wedging in this unit, you need to perform a number of measures.

And here it is not necessary to contact a car service. You need:

- put the car on a jack;

- remove the wheel;

- unscrew the caliper;

- remove it;

- unscrew the problematic piston;

- remove the piston from the cylinder;

- visually inspect the element;

- check for chips, damage, corrosion;

- if there is rust, clean it;

- if severely damaged, replace;

- drain the working fluid from the element;

- remove the sealing ring;

- clean all surfaces;

- dry;

- fill in new hydraulics;

- assemble in reverse order.

When putting the assembly back together, pay special attention to not accidentally damage the old boot. If you notice cracks on it, then no restoration will help. Replacement only.

Removing the caliper

Replacement occurs in the following order.

First, you need to raise the car (using a jack) and remove the wheel whose brake system has a malfunction. On the Lada Priora, the front caliper is attached to the bracket using M 17 tie bolts. One is located at the top of the entire structure, and the other at the bottom. They are tightened quite tightly, therefore, for more accurate and easy screwing of them with a spanner wrench, it is recommended to pre-treat them with a penetrating lubricant. Having loosened the bolts with a wrench, it is then better to screw them together with a special “ratchet”, which will significantly speed up the whole process.

If you intend to completely replace the caliper (that is, the entire assembly), you should first unscrew the brake hose. If not, then you can leave it in place.

If removing the caliper was necessary to replace other components, then, when removing the guide for the pads and the pads themselves along with the bracket from the disk, for greater convenience it is necessary to fasten the caliper to the suspension spring. Next, you need to free the part by disconnecting it from the brake hose, which must be plugged so that all the fluid does not leak out of it. By unscrewing the brake hose leading to the caliper, you can unscrew the bolts. The part can then be removed from the disk.

How to avoid caliper failure

The procedures described above for completely cleaning the caliper are very complex and require a lot of time. To ensure that they are carried out as rarely as possible, be sure to lubricate the caliper surface with special grease or WD-40 every 6 months to avoid corrosion.

It is also recommended to inspect the caliper annually for corrosion, damage, dirt, and boot rupture.

Welcome! Brake cylinders - thanks to them, braking is carried out, and without the pistons that are in them, these cylinders will not work at all, so if a piston fails, then you have to go to a car store and buy a new brake cylinder, because driving without brakes is scary and even more dangerous , but not in all cases the pistons stop working forever, sometimes they can be revived, and we will write in detail about how to do this in this article.

Note! To work, you will need to stock up on: A jack to lift any side of the car, as well as a wheel wrench and you may also have to stock up on bricks, and you may also need a basic set of wrenches and sockets!

Summary:

How to understand that the pistons of the brake cylinder are not working? Let us answer this question before we move on to the repair of pistons, namely inoperative (That is, the pistons do not move in the cylinder), the pistons are recognized if they do not move at all and stand in one place, as a result of which the car, namely the brakes, begins a number of problems occur, that is, the car cannot drive normally because it constantly slows down even though you don’t press the brake pedal at all, or it may be that the car will drive but it will brake much worse than it should, in general, let’s figure it out Why do these cylinder pistons fail?

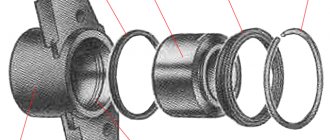

From time to time, the sealing ring (indicated in the photo below by an arrow) that fits the piston in a circle either wears out, or micro cracks form in it through which dirt begins to get into the piston itself, where the lubricant is located, and as a result the piston becomes unusable.

And also, the piston can simply sour in the brake caliper, and this can happen because of our roads, which in winter are mostly sprinkled with sand and salt, and the brake system is located in the very bottom of the car and therefore is subject to heavy braking. and in general, when moving, all this salt flies which little by little brings the situation to the point where the piston simply rusts, otherwise it simply sours, and therefore it will then be very difficult to move it from its place and thus it stops moving and therefore stops working.

By the way, you can very easily understand if your piston is somehow soured, if your car’s fuel consumption on the highway increases, and also if the car, as already mentioned earlier, starts to drive worse, and also if you notice that In neutral gear, the car began to slow down a little, this can also be understood if the car begins to skid on a winter road from braking, all this indicates that your piston has stopped working.

Caliper repair and pistons replacement

The front caliper of the Lada Priora has only two moving parts: a guide and a brake piston. When the first one sours, the entire mechanism loses mobility. As a result, the caliper reacts poorly to braking forces and gradually ceases to cope with its task of compressing the disc. Pressure begins to be transferred only to the inner pad, which leads to greater wear compared to the outer pad.

The brake system is the most important complex in the design of a car, which is responsible for the safety of its passengers. That is why maximum attention should be paid to this system - diagnostics should be carried out regularly, and delaying repairs is completely contraindicated.

A little history

The first to create such a model of brakes (disc type) was Frederick Lanchester (Great Britain). It was in its design that a caliper was used that pressed the pads. However, technology at that time did not allow the creation of reliable disc brake systems.

Disc brakes were revived in aviation, and in the 50s they began to be installed on cars - first on sports models, and then on production ones. The first car with serial front disc brakes was the Chrysler Crown Imperial (in 1949).

The importance of this component is difficult to overestimate, because the brake disc and pads are passive components, while the caliper plays an active role. Due to this, the pads are pressed. Therefore, the brake caliper is the most important component.

Front brake caliper - design types

The development of these mechanisms is reflected in their division into 2 categories, depending on the layout:

- Fixed design - it consists of a body made of metal, and there are working cylinders on both sides of the brake disc. Their arrangement is symmetrical. In this case, the body itself is fixed on the steering knuckle. At rest, the pads are held in place by special springs, and during braking they are compressed, causing them to be pressed against the surface of the disc. To ensure the operation of such a design, it is required that brake fluid be supplied simultaneously to all cylinders, which is achieved through a whole system of hoses, pipes and various tubes. Such brakes are highly efficient, making them ideal for cars with powerful engines and large weight - racing and executive models. World famous brands - Brembo and others - specialize in such calipers.

- A floating caliper is the fundamental difference between such a caliper and a fixed one in that one of the pads is in a constant position. Its design involves the presence of a bracket, as well as a cylinder, which is fixed on the inside. Typically, such calipers are single- or double-piston. The braking process is as follows - the piston presses the pad and presses it against the disc, and at the end of this phase, the bracket (floating type) begins to move towards the piston, sliding along the guides. Due to this, another pad is pressed against the surface of the disc.

Let's consider the reasons for poor braking of the VAZ 2110.

Brake system

your car is equipped with a vacuum booster and is quite effective. A decrease in braking efficiency or the car skidding when braking should be a signal for an urgent brake check.

Air in the system.

If the brake pedal becomes “soft” and becomes “harder” after several consecutive presses, it means that air has entered the hydraulic brake drive. It could get into the system during its repair, replacement of brake fluid, depressurization of the system due to damage to pipes and hoses, or a drop in the level of brake fluid in the master cylinder reservoir.

To remove air from the system, it is necessary to bleed the brakes.

The vacuum is not working properly

The reason for the loss of braking efficiency may be poor performance of the vacuum booster.

To quickly check it, press the brake pedal several times with the engine off to remove the vacuum in the booster, and then, holding the pedal, start the engine. If after starting the engine the pedal drops a little, the vacuum booster is working.

1.If the pedal remains motionless, check the integrity and reliability of the connection of the vacuum booster hose with the fitting on the engine inlet pipe.

2. and with a check valve. Replace or repair the faulty hose. If the hose is in good condition, the vacuum booster needs to be replaced.

Check the brake pads

If braking is accompanied by beating and pulsation of the brake pedal, you should first check the condition of the front disc brakes.

3.Installing the car

on a jack, remove the front wheel and inspect the brake disc. The thickness of the brake disc must be at least 10.8 mm. The surface of the disc should be flat and smooth on both sides. If the disc surface is covered in places with rust, which usually happens after a car has been parked for a long time with the brakes not dried, try cleaning the working surface with fine emery cloth. If this procedure does not help, you will have to have the discs polished or replaced with new ones.

4.Check the mobility of the brake pads. To do this, use a screwdriver to try to remove the pads from the brake disc. If the pads cannot be moved apart, it means that the piston is stuck in the brake cylinder.

Correct handbrake movement

According to the manufacturer, the parking brake lever stroke should be:

- when adjusting 2-4 clicks;

-in operation 2-8 clicks. Correctly adjusted parking

The brake should hold the car on a 25% slope.

If, when braking the vehicle with the parking brake,

When the lever is raised more than 8 clicks, the vehicle will be held on the slope. If the lever stroke is less than 2 clicks, the wheels may partially lock while the vehicle is moving. In both cases, the parking brake must be adjusted.

If you liked it. Share with a friend or girlfriend or a plus from the heart. Thank you so much, friends. (Social networks connected in August 2013)

Working principle of brake caliper

The brake caliper performs its main task - it provides the necessary braking force required to slow down or stop the car.

Pressing the brake pedal causes pressure to build up in the brake line. It is transmitted to the caliper pistons, which at this time strictly parallel fixes the pads relative to the disc. When braking, the calipers compress the pads on both sides of the disc, causing it to slow down. But there is another effect. It involves heating, as friction energy is transformed into heat. This significantly heats up both the disc and the pads and calipers. The temperature of the brake fluid also increases.

This effect places certain demands on manufacturers. So the front brake caliper must have the following characteristics:

- high heat transfer rates;

- strength;

- high resistance to heat (so that increased temperature does not deform the caliper components).

Video: General principle of operation of the rear caliper

Rear brake jammed: reasons

Typically, the structure of the rear caliper is complicated by the parking brake. The mechanism includes a number of elements:

- coupling;

- spring;

- balloons;

- stock.

When damage occurs in one of them, it affects the operation of the clamping device.

Mechanics quickly identify problems caused by problems with the handbrake. The main symptom is poor performance of the brake mechanism when trying to press on the pedals. There are also indirect manifestations: uneven wear of the linings, creaking, braking of the rear axle.

Symptoms of a problem

There are several common signs of a failing brake caliper:

- increased force - this is what needs to be applied to completely stop the machine;

- the car pulls to the side during braking;

- the pedal becomes “soft” - pressing it requires a fairly weak force;

- brake pedal pulsation;

- slight resistance in moving the pedal to the floor;

- brake sticking;

- blocking the rear brakes with great force, etc.

Caliper repair methods

Caliper malfunctions can be different. However, we can highlight the most common cases, as well as recommendations for eliminating them.

Brake pads jam in caliper

This is noticeable when, with the caliper removed, the pads do not move freely. Usually the reason is rust on the stationary caliper pads, which prevents the pads from moving.

To eliminate the problem, you should arm yourself with sandpaper, a metal brush and a file (but only a small one). Then you need to clean off the corrosion from the metal, and then lubricate the surface with a high-temperature type lubricant. However, there should be no wear on the caliper - pits from corrosion. If they are present, cleaning will not help - the pad will not be pressed tightly enough or will not move away from the surface of the brake disc quickly enough.

Sometimes such a defect can be eliminated with a file (subject to insignificant wear), but usually you have to buy a new part of the caliper (fixed).

Something else useful for you:

Video: Passat front caliper rebuild

Corrosion on the caliper piston

It can be triggered either by a defective boot or a long downtime of the machine.

To eliminate the problem, it is recommended to remove and disassemble the caliper. Remove the rust-damaged piston from it and polish it with a special paste or fine rust. After this, thoroughly wash the piston seat with WD-40 and reassemble the caliper. Installing new cuffs won't hurt either. But the best option would be to buy a new piston or caliper assembly.

The caliper guides are jammed

It is necessary to achieve free movement along the guides. To do this, you will need to dismantle the pads, then reassemble the brake caliper and try to move it along the guides. If sliding is difficult, it is recommended to take measures - inspect the guide for bends or breaks, lubricate them, clean them, etc. It is necessary to achieve free movement.

How to carry out independent repairs if the caliper is stuck on the road

If the driver notices signs indicating that the brake mechanism is jammed, the following is urgently required:

- Stop the car. Turn off the engine.

- Take a small board, attach it to the caliper, and knock lightly.

Of course, there is no 100% guarantee of the effectiveness of this method, but when there is absolutely no time, like other available means, they resort to it.

It is best to carry out self-diagnosis. The algorithm is as follows:

- leave the car cold for at least 15 minutes;

- drive 100 meters to warm up the vehicle;

- stop the car, test each wheel - which one will be the hottest, that’s where the caliper is stuck.

Next, carry out the following actions:

- jack up the vehicle and remove the wheel;

- when the handbrake cable is jammed, clean it with universal lubricant WD-40;

- If the piston is jammed, use the plank method described above.

When the driver does not have the skills to carry out emergency repairs, it is better to call a tow truck to take the car to professional mechanics.