Few people were excited about domestic cars in the late 1990s and early 2000s. And it was at this time that AvtoVAZ produced the legendary Ten - VAZ 2110 and its modifications in the form of a station wagon and a hatchback. The top ten has won people's trust due to its very affordable price, relatively high reliability and simplicity of design. But the engines in this car clearly cannot be called the best.

The VAZ 2110 was produced with carburetor engines for a couple of years after the start of production, then engines with injectors appeared. The most popular was the famous “gear” - 1.6 16V, which became the most popular in the last years of production of this car. Sixteen valves livened up the engine a little, but there is no need to talk about the sporty nature of the car.

Today we will talk about some possibilities for modifying the Tens:

- how to tune original engines for maximum power;

- what engines from foreign cars are suitable for the VAZ 2110;

- how to replace the engine legally and drive the car on the roads;

- how much does it cost to replace the engine on a Ten with an engine from a foreign car.

So, let's go!

Description

VAZ engineers were tasked with designing an engine with improved parameters while maintaining the dimensions of the previously produced VAZ-21120.

The result of the work was the birth of a new engine model - VAZ-21124. In mid-2004, the first “124 motor” , production of which continued until 2013.

The VAZ-21124 is a 1.6-liter four-cylinder in-line gasoline engine with a power of 89 hp. s and a torque of 133 Nm.

The engine was installed on VAZ cars:

- 2110 sedan (2004-2007);

- 2112 hatchback (2004-2008);

- 2011 station wagon (2004-2009);

- 2013 Samara 2 coupe (2010-2013);

- 2014 Samara 2 hatchback (2009-2013).

The most important difference from its predecessor is the increase in working volume. It was believed that this would significantly increase engine power, which in fact, unfortunately, did not happen. It even decreased slightly.

But thanks to the implemented innovative solutions, the VAZ-21124 received many positive factors. The most striking are the elimination of valve bending when the timing belt breaks, equipping the exhaust tract with a catalyst, installing individual ignition coils, etc.

The cylinder block is traditionally made of cast iron. Unlike the VAZ-21120, it has become taller. This made it possible to increase the piston stroke by 4.6 mm. Accordingly, the working volume has also become larger.

The cylinder head is aluminum, interchangeable with other internal combustion engines of this series. The head has two camshafts and 16 valves equipped with hydraulic compensators. Now there is no need to regulate the thermal clearance of the valves. Cast candle wells.

Thanks to changes to the block and its head, the compression ratio was increased to 10.3. This ensured the use of AI-92 gasoline.

The intake manifold has become plastic and is combined with the receiver. For the first time at VAZ, the graduation station is equipped with a catalyst. This innovation made it possible to raise emission treatment standards to the Euro 4 standard.

The pistons are standard, with an additional counterbore and three rings, two of which are compression and one is oil scraper. To cool the piston heads, special oil nozzles are installed.

The power system also received several changes - the design of the fuel rail was updated, the drain line was removed, and a bypass valve was installed on the fuel pump to relieve excess pressure.

High-voltage wires have disappeared from the ignition system, since the coils are installed on the spark plugs and additionally fixed in the valve cover.

To dampen vibrations arising from torsional vibrations, a multifunctional damper is mounted on the crankshaft.

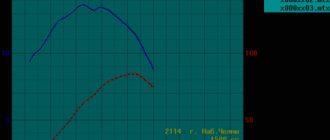

Thus, the VAZ-21124 became an updated standard VAZ engine with a slightly increased volume. The presented graphs confirm the validity of what has been said.

The VAZ-21124 did not receive an increase in power due to the installation of a catalyst. In return, it was possible to increase the degree of exhaust purification to Euro 5 standards (on some engine modifications).

How to improve the power of a standard VAZ 2110 engine

We can talk about improving power in more or less budgetary ways only in the context of VAZ injection engines. However, there are not many dozen carburetor cars left on the roads. Usually, VAZ 2110 owners who don’t have enough power from the stock engine simply want to do chip tuning of the ECU and get a serious increase in power, but it’s not that simple.

It should be taken into account that VAZ designers saved a lot when developing and assembling these engines. This means that the intake and exhaust will not be the best in their class, the fuel supply system will have its limitations, and some sensors, even after tuning the ECU, will not fully carry out the computer’s instructions.

For normal tuning you will need to perform the following set of actions:

- Air filtration system. It is worth installing a zero resistance filter and allowing the engine to breathe more easily.

- Throttle valve. There is no point in modifying it in any way. You can look on the market for a new damper with a larger hole diameter. This will allow you to immediately get a small increase in power.

- Inlet receiver. It’s worth replacing it with a more efficient one, but you can’t save money here. So, if you want to increase the power of your car on a budget, skip this point.

- Tuning camshafts will also not be cheap, but it is worth undertaking for good results. In the stock version, the shafts do not cope with the tasks very effectively, and replacing them with tuning parts will clearly add power and torque to the motor.

- An exhaust manifold. If air intake is already easier, the engine also needs to breathe out easier. Sports-type exhaust manifolds for the VAZ 2110 engine will greatly change your impression of operating a Russian car.

- Computer. And only at this stage can you touch the ECU settings in the Ten and adjust all the parameters to the new parts. It is important to manually configure all the necessary parameters after installing the above elements.

By the way, the increase in power can be quite serious. Up to 30-40% of stock values. But, of course, it is worth considering that tuning has many nuances. The service life of the engine will decrease, you will have to look into the piston group more often, change the rings, and treat the cylinder head. Also, consumption will obviously increase, miracles do not happen. But the machine will start to bring a lot of pleasure for relatively little money. If you wish, you can continue to work with the engine more deeply and get even more interesting changes. But remember that tuning engines with mileage over 200,000 km is deadly for such engines.

Specifications

| Manufacturer | Concern "AvtoVAZ" |

| Engine volume, cm³ | 1599 |

| Power, l. With | 89 |

| Torque, Nm | 133 |

| Compression ratio | 10.3 |

| Cylinder block | cast iron |

| Number of cylinders | 4 |

| Fuel injection order | 1-3-4-2 |

| cylinder head | aluminum |

| Cylinder diameter, mm | 82 |

| Piston stroke, mm | 75.6 |

| Number of valves per cylinder | 4 (DOHC) |

| Timing drive | belt |

| Turbocharging | No |

| Hydraulic compensators | There is |

| Valve timing regulator | No |

| Fuel supply system | injector |

| Fuel | Gasoline AI-95 (92) |

| Environmental standards | Euro 3 |

| Resource, thousand km | 150 |

| Location | transverse |

| Engine weight, kg | 121 |

About LADA 2109 engines 1st generation (1987 - 2011)

VAZ 2109 (Lada Samara), popularly known as a nine, is a five-door hatchback, a continuation of the Samara line. It was developed in 1987 using the three-door hatchback VAZ 2108 as a basis. The nine itself became the basis for the creation of the VAZ 21099.

The car gained wide popularity thanks to its fast design, good engines for those times, and a practical five-door body. All this, coupled with its low cost, as well as a wide selection of spare parts, made the VAZ 2109 very attractive. This attractiveness was passed on to its successor, the VAZ 2114. In contrast to the VAZ, the injector was installed as standard on the 2109 engines (power unit 2111).

In addition to the injector, the 2109 was equipped with a carburetor with a displacement of 1.1 l, 1.3 l and 1.5 l. Such engines can be seen if you look under the hood of the 2108.

In the article we will look at the engines themselves for the VAZ 2109, their characteristics and weaknesses.

ENGINE VAZ 2108

The 1.3 engine is the base for the eight, it was developed from scratch, and is structurally similar to the 21011 1.3 liter engine. there is nothing in common. This engine became the basis for the creation of power units for installation on the Samara family with a displacement of 1.1 liters and 1.5 liters. This is an in-line carburetor type engine, has 4 cylinders and an overhead camshaft. The timing drive uses a belt.

Regarding the service life of the engine, it is fair to say that careful and quiet operation, proper and constant maintenance will allow you to exceed the official 120 thousand km and the service life can be 180-200 thousand km.

ENGINE DISADVANTAGES

In terms of disadvantages, the following are most often noted. The parts of the cooling system wear out quite quickly. Frequent oil filter replacement and valve adjustment will be required. Oil leaks often occur due to unreliable seals of the valve cover, fuel pump and distributor sensor. It should be noted that unreliable Solex-type carburetors in general, and EPHH in particular.

If the timing belt breaks, the valves may bend. Also, over time, problems with ignition and engine tripping may occur. In addition, due to ignition problems, the engine may detonate. Another reason for this may be low-octane, low-quality fuel. Detonation is indicated by black smoke coming out of the exhaust pipe and loss of power.

ENGINE VAZ 21081

Engine VAZ 21081 1.1 l. is an analogue of the power unit 2108 1.3. However, it has a crankshaft of less stroke, and as a result, reduced traction. This is an in-line carburetor-type engine with four cylinders, an overhead camshaft, and a timing belt. As for the resource, if you ensure careful operation and quality maintenance, you can count on an official 125 thousand km.

The difference between 21081 and 2108 is due to the reduced piston stroke and, as a result, the reduced displacement. In addition, the difference is a lower cylinder block compared to 2108.

ENGINE DISADVANTAGES

The VAZ 081 engine is rare, as such engines were exported. This is probably for the best, since this is a frankly frail unit. It should also be remembered that if the timing belt breaks, the engine may bend the valves. ENGINE VAZ 21083 This engine is the progenitor of the current power units for Lada; it became the basis for 16 valve engines 2112, 124, 126 for Priora, 127, 114, 116, 194 for Kalina.

The replacement for this engine was the same injection-type version. VAZ 2108 1.5 l. is an in-line carburetor-type engine with four cylinders and an overhead camshaft. The timing drive uses a belt; if it breaks, the valve slide will not bend.

ENGINE DISADVANTAGES

If we talk about the weaknesses of the engine, we need to mention the following. The valves need to be adjusted. Parts of the cooling system wear out quickly. Frequent oil filter replacement and valve adjustment will be required. Oil leaks often occur due to unreliable seals of the valve cover, fuel pump and distributor sensor. It should be noted that unreliable Solex-type carburetors in general, and EPHH in particular.

The fastenings of the exhaust pipe may break off, since steel nuts are used rather than brass. In addition, the engine may knock, which indicates the need to adjust the valves. The engine may misfire, and in this case the cause must be sought in the valves, a clogged carburetor, or faulty electrics.

ENGINE 2114 / 2111

The VAZ 2111 engine, which is popularly called 2114, is generally the eighty-third engine. However, unlike 21083, 2114 uses an injector rather than a carburetor. In addition, the 2114 is characterized by the presence of a floating connecting rod pin and a different camshaft. Finally, the 2114 has more power. Engine VAZ 2114 1.5 l. in-line, injection, with four cylinders, has an overhead camshaft, the timing drive uses a belt. In this case, if the belt breaks, the valve slider does not bend.

ENGINE DISADVANTAGES

As for the shortcomings, the following are noted. It is necessary to adjust the valves, parts of the cooling system wear out quickly, frequent replacement of the oil filter is required, problems with the valve cover seal, fuel pump and distributor sensor. The exhaust pipe fastenings may break because steel nuts are used rather than brass. In addition, the speed often begins to float. The engine may trip. Often the engine does not warm up to the desired operating temperature. The problem is most likely with the thermostat. In addition, the engine may knock and make noise, usually due to unadjusted valves.

| Engine | VAZ 2108 | VAZ 21081 | VAZ 21083 | VAZ 2114/2111 |

| Years of manufacture | 1984 — 2004 | 1984 — 1996 | 1987 — 2004 | 1994 - present day |

| Cylinder block material | cast iron | cast iron | cast iron | cast iron |

| Supply system | carburetor | carburetor | carburetor | injector |

| Type | in-line | in-line | in-line | in-line |

| Number of cylinders | 4 | 4 | 4 | 4 |

| Valves per cylinder | 2 | 2 | 2 | 2 |

| Piston stroke | 71 mm | 61mm | 71mm | 71mm |

| Cylinder diameter | 76 mm | 76 mm | 82 mm | 82 mm |

| Compression ratio | 9,9 | 9 | 9,8 | 9,8 |

| Engine capacity | 1295 cm cube | 1100 cm cube | 1499 cm cube | 1499 cm cube |

| Engine power | 64 hp /5600 rpm | 54 hp /5600 rpm | 73 hp /5600 rpm | 78 hp /5400 rpm |

| Torque | 95 Nm/3400 rpm | 79Nm/3600 rpm | 106 Nm/3600 rpm | 116 Nm/3000 rpm |

| Fuel | AI93 | AI91 | AI93 | AI93 |

| Fuel consumption | ||||

| city | 8.6 l/100 km | 8.2 l/100 km | 7.9 l/100 km | 8.8 l/100 km |

| track | 7.1 l/100 km | 7 l/100 km | 7 l/100 km | 5.7 l/100 km |

| mixed | 8.2 l/100 km | 7.7 l/100 km | 7.8 l/100 km | 7.3 l/100 km |

| Oil consumption | 50 g/1000 km | 50 g/1000 km | 50 g/1000 km | 50 g/1000 km |

| Overall dimensions of the engine (LxWxH), mm | 540x422x561 | — | — | — |

| Engine weight | 127 kg | — | — | 127 kg |

| Engine oil | 5W-30 5W-40 10W-40 15W40 | 5W-30 5W-40 10W-40 15W40 | 5W-30 5W-40 10W-40 15W40 | 5W-30 5W-40 10W-40 15W40 |

| How much oil is in the engine | 3.5 l | 3.5 l | 3.5 l | 3.5 l |

| When replacing, pour | 3.2 l | 3.2 l | 3.2 l | 3.2 l |

| Resource | ||||

| according to the plant | 120 thousand km | 125 thousand km | 125 thousand km | 150 thousand km |

| on practice | up to 200 thousand km | — | up to 250 thousand km | up to 250 thousand km |

| Tuning | ||||

| potential | 80-90 hp | — | 180+ hp | 180+ hp |

| without loss of resource | — | — | up to 90 hp | up to 120 hp |

| The engine was installed | VAZ 2108 VAZ 2109 VAZ 21099 | VAZ 21081 VAZ 21091 | VAZ 21083 VAZ 21093 VAZ 21099 VAZ 2110 VAZ 21111 VAZ 2115 | VAZ 21083 VAZ 21093 VAZ 21099 VAZ 21102 VAZ 2111 VAZ 21122 VAZ 2113 VAZ 2114 VAZ 2115 |

Reliability

The reliability of the VAZ-21124 internal combustion engine is indicated by the fact that it exceeds the mileage life established by the manufacturer. There are engines that have gone through more than 300 thousand km without major repairs. This is clearly visible from the communications of forum members. Thus, Maxim writes: “... an engine with a long service life. Mileage 330 thousand. Doesn't take oil. Replace the timing belt according to the regulations, every 45-50 thousand km, pump every 100 thousand. The oil was 5-40 synthetic.”

The manufacturer constantly makes changes to the design of the motor in order to increase its reliability. There has been a decrease in electrical failures (due to the abandonment of high-voltage wires, the installation of individual coils and other innovations).

Two more important reliability criteria - “stickless” pistons

The piston bottom is counterbored to prevent collision with the valves and the thermal clearance of the valves is adjusted without the participation of the car owner (due to the installation of hydraulic compensators).

The internal combustion engine has a fairly high safety margin. As a result of properly carried out tuning, you can painlessly remove 130-150 hp from it. With.

Reliability is indirectly indicated by the fact that VAZ-21120 engines can be easily purchased on the secondary market, but VAZ-21124 engines are not so easy to find.

Thus, the only conclusion that emerges is that the VAZ-21124 is a reliable power unit with timely and correct maintenance.

Let's sum it up

If the engine in your VAZ 2110 is sick, it can be overhauled inexpensively. The cost of a major overhaul with your own hands with the purchase of simple spare parts does not exceed 4-5 thousand rubles. The service will charge you about 10,000 rubles more for the work. But in general, this is much more profitable than swapping for a more powerful engine from a foreign car. This only makes sense if you already have a donor engine, and you also have permission from AvtoVAZ to install this engine.

In other cases, you can justify such a colossal investment in the old Ten only by your enthusiasm and desire to build a real racing car. However, in this case, you also need to add to the amount the price of improving the suspension and steering, braking system and other parts of your car. Otherwise, the car will simply be powerful, but it simply won’t be able to accelerate to its maximum speed.

Weak spots

Unfortunately, the updated engine still has old weak points. Traditionally, the electrician is lame. Failures in the operation of sensors (DPKV, MAF, DPS) cause unstable (floating) idle speed. Additionally, the cause of this phenomenon may be an excessively dirty throttle valve or a malfunction in the idle air regulator.

Troubling at idle speed is not uncommon. Here the cause must be sought in faulty ignition coils or spark plugs. It must be remembered that tripping can be caused by burnt-out valves.

Extraneous unauthorized knocks are inherent in internal combustion engines. Most often they indicate wear of the hydraulic compensators. Less often - for wear of the CPG.

Weaknesses make themselves felt in cases of violation of the order and rules of engine maintenance. In any case, if any malfunction is detected, the engine urgently requires diagnostics at a specialized car service center.

Maintainability

All car enthusiasts note the high maintainability of the engine. Indeed, a cast-iron cylinder block allows cylinders to be bored repeatedly, which means that major overhauls of the internal combustion engine can be done several times.

There are no problems in selecting spare parts for restoration. They are available in any variety in every specialty store. The only trouble that an inexperienced car owner can run into is experiencing the possibility of purchasing counterfeit products. The Chinese manufacturer is considered especially “dangerous” in the supply of such spare parts.

The interchangeability of parts, assemblies and mechanisms from other engines in the VAZ 16V line is of great help to the car owner when repairing the unit.

The repair itself is simple and accessible to anyone who has little experience in performing such work. Many car enthusiasts take advantage of this and restore engines in garage conditions.

By the way, car services are also happy to take on this work due to its simplicity.

What is this?

The VAZ 2109 engine is understood as a unit that converts energy of any type into mechanical work and sets the car in motion. The engine of a car of this brand is quite powerful. Its advantage is maintainability and low cost of parts.

Structurally, the engine is represented by the following elements:

- Cylinder block.

- Piston rings.

- Piston.

- Crank mechanism.

The motor can fail for various reasons:

- Violation of service rules.

- Using low quality oil.

- Natural wear and tear of unit parts.

- Contamination of structural elements.

An experienced car owner understands that it’s time to look for a new engine for a VAZ 2109 by the following signs:

- Increased oil consumption.

- The appearance of black or white puffs of smoke from the exhaust.

- Formation of carbon deposits on spark plugs.

- The engine operates intermittently at idle.

- Increased fuel consumption.

- Emission of gases from the ventilation system.

- Unit overheating.

- The appearance of extraneous sounds from the engine compartment.

- Reduced oil pressure.

- Detonation.

Tuning

There is a possibility of tuning the internal combustion engine of the VAZ-21124. In this regard, there are several ways to refine the motor. The most common are boring cylinders to a larger diameter (up to 88 mm) with replacing the CPG, changing the intake-exhaust tract, installing sports camshafts with increased valve opening phases and retrofitting with additional throttles (individual for each cylinder).

Each method of tuning the engine increases its power.

A maximum of 200 hp can be squeezed out of the engine. With. At the same time, such modifications significantly affect the reduction in the life of the internal combustion engine, increase the frequency of its failures and contribute to the need for serious repairs.

Thus, a significant increase in power promises the car owner significant costs for remaking the engine, increases the risk of premature failure and ensures a short service life. If you are satisfied with these factors, all that remains is to choose a tuning method.

The VAZ-21124 engine has proven itself among car enthusiasts as a simple, reliable, economical and durable unit with high maintainability. But this characteristic is valid only in cases where the engine maintenance regulations are observed.

Source

Engine VAZ 21124

The 1.6-liter 16-valve engine of the VAZ 21124 was produced by the concern from 2004 to 2013 and was first installed on models of the tenth family, and then for some time on the Samara 2. This engine was replaced on the assembly line by a 1.5-liter 16-valve power unit with the index 2112.

The VAZ 16V line also includes: 11194, 21126, 21127, 21129, 21128 and 21179.

Factors influencing price

Buying a new engine is expensive. Therefore, those car owners who need a working engine for a VAZ 2109 are looking for the most profitable option in terms of price and quality. Motorists note that the cost of the engine differs at different sales points. This is due to the influence of a number of factors on the price. For example, the price depends on:

- Part quality.

- Type of unit.

- Originality.

- Manufacturer.

- Places of purchase.

- Engine volume.

- Power of the power unit.

- Implementer policies.

- Seller popularity.

- Cost of delivery of goods.

Technical characteristics of the VAZ 21124 1.6 16v engine

| Type | in-line |

| Number of cylinders | 4 |

| Number of valves | 16 |

| Exact volume | 1599 cm³ |

| Cylinder diameter | 82 mm |

| Piston stroke | 75.6 mm |

| Supply system | injector |

| Power | 89 hp |

| Torque | 131 - 133 Nm |

| Compression ratio | 10.3 |

| Fuel type | AI-92 |

| Ecological norms | EURO 2/3 |

Design features of the Lada 21124 16 valve engine

First of all, the internal combustion engine differs from the previous 1.5‑liter VAZ 2112 in a higher block. And an increase in the piston stroke by 4.6 mm made it possible to increase the engine displacement to 1.6 liters. Thanks to the holes in the piston bottoms, this power unit does not bend if the valve belt breaks.

This motor has received a number of modern design solutions. In addition to the previously used hydraulic compensators, it was the first to use individual ignition coils. And the catalytic collector allowed it to comply with strict environmental standards of EURO 3 (later EURO 4).

Popular blogger Evgeny Travnikov compares the characteristics of the 24th and 26th internal combustion engines

The Russian-language manual for this engine is here

The VAZ 21114 and 21124 engines are described in the article ZaRulem

Peculiarities

The company's engineers produced the VAZ 2110 8-valve engine from 1995 to 2000. This power unit was produced in the city of Tolyatti, and it was based on its predecessor 21083. After the production of the engine was suspended, it was replaced by the VAZ-21102 fuel-injected internal combustion engine.

This is a classic in-line naturally aspirated engine running on gasoline for manufacturers. Its design includes four cylinders, giving a total working volume of 1.5 liters. The engine's peak power is 72 horsepower and its maximum torque reaches 104 Nm.

The engine block of the VAZ 2110 is traditionally made of cast iron with increased strength. The cylinders are machined directly into the block and it is not lined. The cylinder head is cast from aluminum. The crankshaft is made of cast iron, and it is fixed using five supports.

The material used to make the pistons was also classic - aluminum, only now they have steel inserts. The pistons are designed with two compression rings and one oil scraper ring. The connecting rods are made of steel and forged. The upper head contains a bushing made of a bronze-steel alloy.

The gas distribution mechanism is driven by a belt. If it is not replaced in time, it may break. But the VAZ 2110 1.5 engine is advantageous in that if the belt breaks, the pistons do not come into contact with the valves. The engineers managed to achieve this thanks to the fact that they made special grooves in the piston bottom.

The structure of the cylinder head provides for the presence of one camshaft and 8 valves. There are no hydraulic compensators in the design, so the thermal clearance of the valves will have to be adjusted independently. A combined lubrication system is used, and the gear-type oil pump is used.

A carburetor is used as a power system, only it has a semi-automatic start function. The carburetor was installed from a partner company - Solex, only this time it was different from the others, since it had two chambers.

Most owners of cars with such engines say that the power system is completely unpretentious to the quality of the fuel used. But despite such statements, it is necessary to choose gasoline solely based on the manufacturer’s recommendations.

The design uses a contactless ignition system. The high-voltage coil is installed dry and has a magnetic circuit, but there are other versions of the motor that provide for the installation of an oil-filled coil with an open magnetic circuit.

The VAZ 2110 engine cooling system is liquid, and is characterized by forced circulation of liquid. It is designed as a closed type, which allows it to provide an optimal operating temperature range not only in severe frost, but also in fairly hot weather.

Finding the VAZ 2110 engine number is not very difficult, since to do this you only have to dismantle the air filter housing. After this, you should pay attention to the place where the block connects to the flywheel, and above it you will find an identification number.

Reviews of engine 21124 its pros and cons

This power unit at one time replaced the 1.5-liter VAZ 2112 engine and, in theory, should have become more powerful than its predecessor, but in reality it turned out to be even a little weaker due to the catalytic converter. The owners were upset that with the transition to a larger volume, the power did not increase.

Great progress was the emergence of individual coils; there were much fewer failures in the ignition system. In all other respects, this is a typical VAZ engine of its time.

We install the finished engine

We put the 2112 engine on the “nine”, since the power units of the models are similar to each other. You will also need a fuel pipe of a suitable diameter (you can take a steel one, but copper is better) and a gas tank from the same 12th model. The following work is carried out:

- We dismantle the old power unit, disconnect all pipes and electronics. In order to remove and install the engine, a crane is needed for convenience, since the entire assembly is heavy. This is a major problem in the garage.

- When the engine is removed, you can install a new one in the seat. It is worth immediately checking the condition of the seals and gaskets if the unit is used. Also check the belt tension.

- Next you need to replace the entire fuel system: tank, fuel pump, fuel lines.

- An excellent replacement for the “nine” tank is the analogue from 2112. The parts are the same in size, but their design is different, which is not an obstacle to installation.

- For fuel lines you need to take copper tubes, which bend better.

- Now you can start wiring the injector. If the “nine” was produced in 2002 and younger, then there will be no special problems with connecting the wires, but for older models you will have to make new holes manually.

- You need to install an absorber and a gasoline filter. They are usually placed under the bottom and secured with studs.

- We install the sensors, change the wiring to one that is suitable in length.

- Installing the generator will have to work hard, since the original mounts do not fit. Find suitable ones, replace them and you can install them. If the gearbox is not changed, then it will have to be sharpened with a grinder.

- The starter will have to change the bendix from 12 to 9 teeth.

- The last modification is the exhaust system. The pipes will not fit, so they will need to be welded. Fitting helps put all the parts in place.

Maintenance regulations for internal combustion engine VAZ 21124

The service book recommends that you undergo zero maintenance at a mileage of 2,500 km and then service the engine every 15,000 km, but on the forums they advise reducing this interval to 10,000 km.

To replace, you will need from 3.0 to 3.5 liters of 5W-30/5W-40 oil, as well as a new filter. It is advisable to change the spark plugs and air filter every 30,000 km, and the timing belt every 45,000 km. Adjustment of the thermal clearances of the valves is not required; the unit is equipped with hydraulic compensators.

Installation of a 16 valve engine on a VAZ 2109. More power my lord

- Installation of the whole unit;

- Replacing the cylinder head.

- First, the old motor is dismantled, here everything happens according to the usual scheme;

- We are preparing the new engine for installation. To do this, you need to replace all consumables. Usually they change seals, gaskets, belts;

- The power unit is put in place and attached to the pillows;

- They installed a tank from 2112. It fits perfectly. The difference is in the design of the fuel pump and the presence of sensors. If you don’t have such a tank at hand, you can leave your original one. But you will have to install an external fuel pump from the Volga;

- The next step is to install the fuel line. It is best to use copper tubing. It's more flexible. If you decide to install steel, then heat it on fire before fitting. This will allow you to bend it as needed without any problems;

- Wiring is being installed. On cars younger than 2002, no modifications will have to be made. There is already a hole for the wires coming from the injector, as well as other elements necessary for fastening. If the car is older, you will have to cut the hole yourself. Studs are placed under the bottom for attaching the absorber and gasoline filter;

- The wiring will have to be redone. Some sensors have short wires. In this case, we lengthen them;

- To install the generator you will have to buy new mountings, otherwise you will not be able to install it;

- The box won't fit a little. You need to try it on and grind off the extra corners with a grinder. It's a matter of a couple of minutes;

- The starter installed on 2109 has 11 teeth, it will not converge with the flywheel. Therefore, replace the bendix, take one with 9 teeth;

- The exhaust system will also have to be overhauled and adjusted.

- First, the engine is removed from the car and disassembled. To do this, remove the cylinder head, pan, dismantle the pistons;

- New pistons from 2112 are installed. They have more reinforced connecting rods, and they also have recesses for the valves;

- Replace the fuel pump;

- Shorten the cylinder head mounting bolts. 12 holes are drilled in the new cylinder head;

- A hole of 8 is drilled in the block and a thread is cut for the knock sensor;

- They install a pump from 2112, at the same time install a thermostat from “Samara”;

- Change the breather;

- All that remains is to assemble the entire body kit for the engine, install the wiring and configure the unit.

Common problems of internal combustion engine 21124

The idle speed most often fluctuates due to a dirty throttle. Another reason can be glitches of the mass air flow sensor, crankshaft and throttle position sensors, as well as IAC.

The culprits of engine trouble are usually clogged injectors, faulty ignition coils or spark plugs. This happens a little less often due to burnout of the valves.

Various types of noise from under the hood are usually caused by worn hydraulic compensators or a stretched timing belt. However, this may also very well be a sign of critical wear of the ShPG. In this case, professional diagnosis is required.