The appearance of the new LADA model in 2015, namely the Vesta WTCC, became a real breakthrough in the field of racing cars of the Russian automobile industry as a whole. For the first time, the Lada Vesta WTCC was presented at the Moscow International AutoVaz Auto Show; it is specially designed to compete at the WTCC World Touring Championship, starting in 2015. We were able to see the racing car in action during test runs at the Magny-Cours circuit in France. The bar set by AVTOVAZ at the show was fully justified: Lada Vesta’s aerodynamic and speed indicators are not inferior to foreign competitors. The Constructors' Championship was won at the championship. The triumphant entry onto the podium of the Russian Lada Sport Rosneft driver at the international stage in Argentina is unforgettable, and before that the racing team won prizes in the Russian championship. In their interview, its participants say that the Lada Vesta is a spectacular, improved car in which they competed. Previously, racers rode the 110th model and after it there was the Lada Priora WTCC. The concern in Tolyatti plans to continue the development path of the Lada car in order to develop interest in the Russian brand’s car in the world. The product has the potential to win first places, which is open to racing professionals and amateurs.

What does the racing version of Lada Vesta wtcc look like?

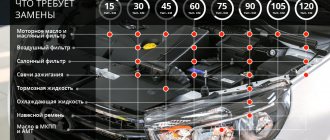

We can safely say that the racing Lada is the best sedan body solution ever designed in the history of the Russian automobile industry, for which we should thank the British automobile designer Steve Mattin. In appearance, the car reminds us of its predecessor, the Lada X-Ray. But what are the fundamental differences between the car and other racing sedans of the brand? 1. Let us note the weight of the model - 1100 kg, while the length, width and wheelbase are 3698/1950/2685 mm. 2. The new aggressive design is different from all other Lada sports cars. It owes a lot to the atypical appearance of the radiator grille and its delicious combination with the oblong cut of the headlights. 3. Powerful and modern equipment of the lightweight body also does not go unnoticed. Each of its elements is strengthened and tightly adapted to the ring track, which adds dynamics when picking up speed. 4. A spoiler is appropriately installed to create acceleration and driving time. 5. The notches on the car’s profile remain unchanged. The car is equipped with 18-inch wheels made of the strongest aluminum alloy. 6. The car has an engine that largely exceeds all the characteristics of previous sedans, which is another achievement of the Russian automobile industry. The complete look of the racing Lada looks very stylish and bright. It’s not scary to call this car the pride of Russian racers.

Racing success

Be that as it may, at the first start of the new racing series, which took place in May 2004, four cars entered, and in June the number of participants increased to 11. Even with such a high cost of the “entrance ticket,” participation in the race could theoretically pay off, given the enormous attention press and fans for the Revolution series. But it didn’t pay off, since the cars were of poor build quality, constantly broke down, and repairs cost a pretty penny. The front suspension caused major criticism; it was poorly tuned, and the shock absorbers regularly overheated. The engine and gearbox worked well, but had an extremely limited resource and required a rebuild every 250-500 km. The brakes, clutch and rims couldn't handle it. In general, “Revolution” at the start turned out to be an extremely crude and capricious machine.

Nevertheless, the plant constantly made improvements. For the 2005 season, the Togliatti team strengthened the front suspension, replaced the rear MacPherson struts with a multi-link, and increased the base engine output to 170 hp. In general, the Lada Revolution has become more reliable, and breakdowns due to technical reasons are almost a thing of the past. In 2006, AvtoVAZ prepared a more productive version of the SuperSport with 215 hp. As a result, the dynamic data of the car has increased significantly. The Lada Revolution SuperSport accelerated to 100 km/h in 5.9 seconds, and its top speed was 260 km/h. In addition, the car's aerodynamics were again corrected, while the cooling system was improved. In 2007, the VAZ-21086-29 engine was replaced by the more durable 16-valve VAZ-21124, and the five-speed manual was replaced by a six-speed cam.

Gearbox wtcc gearbox

Due to the fact that the Lada Vesta WTCC is intended for racing with sharp extreme turns, where quick gear changes are necessary, the gearbox must, first of all, be short-throw and of high quality. Therefore, the Xtrack transmission, a manufacturer from the UK, was selected and installed for the Lada. This 6-speed gearbox has an external setting and an adjustable “preload” of the inter-axle disc differential, which varies depending on road conditions. The driving wheel is the front one. 3-disc clutch from AP RACING. We must not forget about the dry sump lubrication system, which ensures stable operation of the car, taking into account all sudden changes in its position.

Body and wheelbase of Priora WTCC

The mass of the racing Priora (with a pilot) was 1150 kg. A real original body kit gave the car excellent aerodynamics and another air intake, which increased the downforce several times. The rear beam had to be lengthened (the lining on the rear arches widened the body by 10 cm), as well as the front one, the wheels were moved out, the stabilizer was changed to a sports kit, and a limited-slip differential was added for comfortable cornering at speed. The competition version was equipped with OZ 17” radius wheels with Yokohama 240/610 tires.

The rear and front suspension matched the car - McPherson independent springs, Sachs gas-filled shock absorbers and coil springs. The body was left with four doors, but was equipped with a welded safety cage. The brakes at the rear are AP Racing (300 mm) non-ventilated discs, with two-piston calipers, at the front – also AP Racing (300 mm) discs, only ventilated, with four-piston calipers.

It is also worth mentioning the steering: the steering wheel was installed with a hydraulic power steering developed by BMW, and the steering rack was from ZF Friedrichshafen AG. It was constantly modernized. As an example, a very sensitive steering wheel with a short-throw rack is not very convenient on a section with serpentine roads, which is why the gear ratio of the rack was changed for the Porto track, from lock to lock, it went not in two and a half turns, but in exactly two.

Suspension characteristics

For the Lada Vesta, the suspension was made by AVTOVAZ together with its subsidiary Lada Sport, the MCPHERSON type suspension. Well, now in detail about the suspension itself. The lower link allows you to play with the steering, but repair work is currently underway on it, so it is fixed. Braking mechanisms from AP RACING Vesta, with experience of early use on Grant, have proven themselves reliably, so they were installed on the new car. The shock absorbers are equipped with OHLINS gas and have 3 adjustment parameters. Adjustable stabilizer and power steering.

How sports Ladas are made: production with your own eyes

The blog comes back to life and invites you to take a virtual tour of the LADA Sport plant, where they make civilian sports cars (the construction of WTCC cars is so shrouded in secrecy and mystery that before work on Vesta began, the windows in the building were even tightly tinted).

How do standard VAZ engines boost up to 118 horsepower? How much do the spare parts that give the Lada Granta the Sport prefix cost? How many cars can the company's sports division produce per day? We (representatives of wheel.ru)

We arrived at the Lada Sport plant and found out everything.

The area in front of the Lada Sport office building is covered with snow. On it, dozens of sports Kalinas are waiting to be sent to the dealer. If you go around the building, you can see the assembly shop, and a little further away - a new spare parts warehouse, which is going to be put into operation in the near future. Production is expanding, and the new warehouse will come in handy.

There is silence in the assembly shop - we are on our lunch break. Half-assembled cars are frozen on transport carts, workers are resting at tables in the areas, talking quietly. They looked surprised - they clearly weren’t expecting us, and in general guests don’t come here often.

But there is something to see. Capital journalists visiting Togliatti should show the workshop of Lada Sport LLC, a subsidiary of AVTOVAZ, as an example of how the production of VAZ cars can be organized if everything is done correctly. Of course, the production volumes here are not the same as on the main assembly line - only about 10 cars leave the workshop every day. But the production culture itself is surprising.

Vladislav Nezvankin, who heads LADA Sport, knows very well how to assemble cars in order to avoid most of the typical annoying little things - both many years of work in the VAZ structure and his own engineering and sports experience have an impact. But luck also had an effect - the construction of the sports department’s own assembly shop and the launch of the first model, Granta Sport, came at a time when the “big brother”, AVTOVAZ, was actively implementing the Renault-Nissan quality system.

The sports division has absorbed the new production methods like a sponge, as can be seen at first glance. Cleanliness, order, near each post there is a stand with a detailed diagram of the technological operation and instructions for identifying defects. In a word, what shop managers, foremen and workers have to be taught and retrained on the main conveyor belt of an automobile plant arose here from the very beginning.

In a separate room is the engine section, where serial engines 21126 with a lightweight connecting rod and piston group are sorted out. For sport versions, these engines are equipped with original phase camshafts, modified intake and exhaust systems (the muffler “can” now has the embossed Lada Sport inscription), the controller receives new firmware. The engine brought to mind in this way produces 118 hp. and 154 Nm (versus 98 hp and 145 Nm for the serial one)

.

And the general scheme for assembling a car is as follows: a luxury version of a regular car, not a Lada Sport, is used as a “base”, but a bare body comes from the factory, which is already “stuffed” with both serial and original components during the assembly process. Among the latter (there are 56 of them in total) are original shock absorbers, springs, all-round disc brakes (the front ones have a larger diameter), new seats, gearshift and parking brake handles, stylish bumpers and sills, nameplates and emblems with the symbols of the sports division... Closer By the end of the assembly, the body is “married” with a modified engine, original wheels with Nankang tires are installed and the car is sent to the control post.

As a result, the VAZ car acquires more impressive dynamics, refined handling, external gloss and an appearance in the spirit, if you will, of a “street fighter”. Yes, it doesn’t reach the level of a truly sports “car”, and in total all the technical solutions are of a distinctly “budget” nature, but when you look at the “Grant” or “Kalina” with the Sport nameplate, something else comes to mind: how accurately the aspirations are captured young audience! Everything that was previously done by young fans of the brand in garages on their knees is now offered for immediate purchase. And with a factory warranty.

By the way, especially for those who like to do everything with their own hands, it has been calculated: independent purchase of original Lada Sport components and installation of them on a “regular” Lada will cost about 150,000 rubles, while the price difference between the two mass-produced models is only about 50,000 rubles. You don’t spend money on a “whole” car and convert it into another, you don’t need to spend time working and selling unnecessary components, you don’t lose the factory warranty. In other words, the value of the car is 150,000 rubles, and the price differs from the usual “Granta” by only fifty dollars.

Probably, for many, the above calculations are already obvious, because Lada Sport car sales are going well. At least, it is almost possible to reach the stated figure of about 3,000 cars in 2014, even despite the outbreak of the crisis. From January to early December, 2,700 cars were assembled, 2,400 of which were sold. About 220 cars are sold every month. By the way, production is quite flexible and is adjusted to market demands: today on the commodity floor there are Kalinas, and in the assembly there are Grants. This means that next month, after processing information from dealers, it will be possible to return to hatchbacks or stay with sedans...

Of course, in some moments, “big brother” holds back. For example, it is impossible to make more cars in red, which matches the image of the sport version - the plan for painting the bodies at AVTOVAZ is not coordinated with the “athletes”. And the quality of individual components, apparently, leaves much to be desired - the operation of “sports” Ladas often reveals small but unpleasant flaws associated not with the build quality or design flaws, but with spare parts.

I would like to think that the sports division of AVTOVAZ will cope with its current problems - the company is promising. And Lada Sport is not only about production. More likely, it’s even like this: initially Lada Sport is not a production. This is engineering. Strongly tied to motorsport and aiming to improve serial VAZ products using racing technologies. While on the sidelines of AVTOVAZ you can still hear phrases like “Nezvankin has his own technologies, we have ours,” they say, refined small-scale “racing” production does not fit in with the daily problems of the main conveyor, but now Lada Sport is already significantly influencing both the serial production of the plant and on his image as a whole.

It is no secret that it was Lada Sport that prepared the design of the Largus VIP and Largus Super VIP cars for the top management of AVTOVAZ, and then transferred it to Pilot Industrial Production (EPP). It is no secret that it was here that the exclusive Granta Sport with a liftback body and an automatic transmission for the head of Tatarstan was born. Engineering at Lada Sport is as flexible as production. It allows you to quickly solve and efficiently implement almost any task in metal, using the existing VAZ “designer”, Renault-Nissan components and your own developments.

The next development of Lada Sport, embodied in the series, will be Kalina NFR, which has a naturally aspirated engine with a power of 140 hp. (Huff drove the lucky ones on the Tolyatti-Ring highway)

. The result will be a car that is fundamentally different from the usual Kalina: the engine compartment will be considerably rearranged, in particular, the engine will be placed on an original subframe. The gearbox, drivetrain, and brakes will be different—some they will modify on their own, others they will borrow from foreign partners. Such a machine should go into production in the summer of 2015. There will be an even more extreme version - the 200-horsepower Kalina NFR Turbo...

What Lada Sport is not in a hurry to talk about with journalists, to put it mildly, is the sports version of Lada Vesta. “We don’t look that far yet” - that’s all that can be heard on this score... They’re lying! Even as they look, it is no coincidence that AVTOVAZ’s branded team in the world touring championship WTCC, from next year called Lada Sport ROSNEFT, is preparing the racing “Vesta” for the start of the season.

And probably the people sitting in an inconspicuous building behind a concrete fence on Borkovskaya Street in Tolyatti are going to get a serial Vesta to create a sports version that can be sold to ordinary consumers - advertising is already guaranteed! Moreover, these sports links are in the same chain: both the production of serial sports cars and the world touring team are parts of the Lada Sport structure. This also includes teams in the Russian circuit and rally championships, a children's karting school, the sale of original components, our own branding in car dealerships... At the beginning of sales, in the spring of 2013, there were only 25 car dealerships selling Lada Sport cars, but by now there are already 82 of them A whole industry!

In general, does advertising of a production car through racing work in Russia? One could doubt this right up until the 2014 Moscow Motor Show - there the Vesta concept for the WTCC was the best show-stopper among all brands, surpassing even its “relatives” in the form of the XRAY crossover and the prototype of the regular production Vesta in terms of the amount of human attention.

In a word, Lada Sport is on the right track. And this is especially obvious when you look at the clean workshop where 118-horsepower cars with a VAZ rook on the grille are assembled. By the way, a somewhat similar atmosphere can now be found in the production of the usual Kalina, Granta and Datsun, and in the OPP workshops where Largus VIP is assembled and the nuances of assembling Vesta for the Izhevsk Automobile Plant are worked out... And in the future, you see, and the main conveyor in Togliatti will reach this level.

Based on materials from https://www.kolesa.ru/

Photo by Ilya Bakeev

Braking system

The braking system is dual-circuit and without a booster, but with front and rear brake force adjustment. 4 and 2 piston front and rear brake calipers from AP RACING. Front and rear ventilated brake discs 380 and 260 mm. The braking system is made more than adequately and also has high ratings from racers. Speed characteristics of Lada Vesta WTCC.

With a huge engine performance of 380 horsepower, the engine volume of the Lada Vesta will be 1.6 liters. In the future, AvtoVAZ will improve the model to an engine capacity of 1.8 liters, the trick of this engine is that it can work with two types of fuel. Returning to the topic of the current Vesta, we note that when creating the engine, the engine from the Lada GRANT Sport was used. But modernization did not bypass him either. The car is capable of accelerating to 265-275 km per hour. Engine. The engine, from which 380 horsepower is squeezed, has a displacement of 1.6 liters. Torque - 440 Nm at 4 thousand revolutions per minute. The engine itself was specially manufactured by the French company ORECA. It is more advanced than its predecessors, as it has become lighter and more dynamic. The engine is equipped with a control system from Magneti Marelli. The intake system and the engine shield are treated with thermal insulation material - this is a feature of this engine. As for the lubrication system barrel: it is located to the right of the wing. In general, the technical equipment of the engine is in no way inferior to foreign competitors; the car is capable of leading the team to prizes.

Body kits

The body kit is from ORECA, manufactured by the same company that makes the engine. A thoughtful and carefully designed shape allows you to achieve an ideal aerodynamic balance, with the correct configuration of the elements of this body kit.

Such technical advantages allow the car to reach speeds of up to 275 kilometers per hour. But such a result can only be achieved by properly configuring the body kit; the speed and maneuverability of the car depend on this.

Wheels

The creation of tires for the Lada Vesta WTCC was undertaken by YOKOHAMA. Since there are no pit stops in WTCC racing, due to the long time required to change wheels, a set of tires is required for each race. There are two races in total, and replacement is carried out if damaged. There are two types of tires used for racing: dry and wet. Before the race, they are prepared - warmed up with heating pads. The size of alloy wheels is 10x18 inches. Made from aluminum alloy. Interesting fact: during tests at the Magny-Cours circuit, the Lada Vesta WTCC performed worse on wet surfaces than the Granta WTCC in ideal conditions.

Unfulfilled dreams

Lada Revolution III - model of a sports car for public roads

The 2008 season was the last in the history of the Lada Revolution racing series. By that time, the organizers had accumulated serious financial difficulties, and AvtoVAZ, due to frequent changes in management, had noticeably cooled down on the racing. Soon the global economic crisis broke out and finally finished off the project.

In fact, the Lada Revolution turned out to be a pretty good racing car. After a number of improvements, reliability problems have practically disappeared. The sports prototype was quite fast and at the same time left huge scope for creativity of teams and engineers. In addition, based on the Revolution, VAZ intended to produce a road sports car, and in 2008 they prepared a very good prototype. New, even more powerful racing cars with carbon monocoques and modern turbo engines were planned for the future. But as they say, it didn’t work out.

Body

When creating Vesta, AvtoVAZ paid great attention to body design. Its especially reinforced frame allows riders to feel safe during the race. The mounted units are made of carbon fiber (one of the criteria of the T1C category in which the Lada Sport Rosneft team competes). Numerous reinforcements have been introduced into the design, the presence of which increases downforce during movement. For example, the massive powerful spoiler mentioned above. Vesta’s weight is only 1104 kg, so before the race it is necessary to add ballast to the required 1100 kg. The length of the body is 3698 millimeters. The width is 1950 millimeters, and the wheelbase is 2685 millimeters. The body type is a sedan with a safety cage welded into it. The housing of the LED headlights is made of the same carbon fiber. All in order to lighten the weight of the sports car. Interior equipment. The difference between the interior and all previous models immediately stands out: the air conditioning cools only the rider’s helmet, the console with the power and ignition toggle switches is on the right, there is also the engine start console, fire extinguishing systems, and windshield wiper controls. The OMR seats are made of the same carbon fiber and are adjusted to the rider in advance. For example, before racing on tracks passing through city streets, James Thompson raised the mounts, since in such cases a wide view is necessary. The MOTERS telemetry system is used to control the car. Therefore, the instrument panel shows the driver the necessary information so as not to distract attention from the road too much.

WTCC body kit for a regular Priora – price

The powerful WTCC body kit for the Priora is as follows:

- Hood trims;

- Front bumper;

- Front wings;

- Thresholds;

- Rear bumper;

- Rear arch trims.

The total mass of all parts is 18.7 kg. The original kit, produced in Togliatti, is very difficult to get - it was not put into mass production, but its price is approximately 50-70 thousand rubles. But the same kit produced by other companies can be purchased for 30 thousand rubles, but these investments will not be enough - you will have to modify the suspension, expand the wheelbase, and also move the gas tank flap and rear door handles.