The VAZ-2113 car is a three-door hatchback produced by the Volzhsky Automobile Plant. This is a budget model with decent technical and driving characteristics, suitable for young people planning to purchase a vehicle as their first learning car, or for citizens with low incomes who cannot afford an expensive foreign car. Considering the vastness of the family of VAZ cars, many people confuse various examples, in particular the “thirteenth” model with the usual “eight”, but before we take a closer look at what the “thirnashka” car looks like, it’s worth knowing the history of this legendary car.

VAZ 2113: History of creation

This car is an advanced analogue of the famous VAZ-2108 car, which at one time became a real mainstream of the Soviet automobile industry. The G8, released in 1984, became not only one of the first front-wheel drive Soviet cars, only the LUAZ-969V appeared before it, produced by the Lutsk Automobile Plant from 1966 to 2002 and an innovative model for its time.

It was with the G8 that a completely new era began for VAZ cars, which finally abandoned copying Fiat models and created a product with its own design and interior.

Actually, the exterior was developed by VAZ specialists - Vladislav Pashko and Viktor Kryazhev, under the leadership of chief designer Mark Demidovtsev. The interior was created by Vladimir Guba, a VAZ employee who completed an internship in Germany at the plant of the world famous company Porsche.

VAZ-2113 – front view

It was the G8 that became the first-born in the long-lived dynasty of Lada Samara cars. This family includes model 2109, the same hatch, but a five-door, the series of which started in 1987, as well as the most prestigious Russian sedan of the 90s - Lada Samara 21099. At the beginning of the 2000s, the entire line was restyled and, accordingly, each model of the family acquired a new index in the name.

Thus, the updated version 2108 received the index 2113, that is, the model that we are considering in this article.

In fact, the VAZ-2113 is not a full-fledged generation change of the G8, but only its restyling on the previous platform - Gamma.

Simply put, the developers largely retained the body contours of the G8, but still carried out a fairly extensive upgrade to the exterior. In addition, they modernized the interior, modernized the engine equipment, completely replacing the carburetor internal combustion engines with more advanced injection engines.

Cars with the prefix “super” | Russian Car

We learned that a real limousine can be made from an ordinary pre-wheel drive Lada back in 1994, when at one of the Auto Shows a version of the VAZ 21099, Amadeo 500, extended by half a meter, from the Togliatti company Master Design, was shown.

Photo stolen from the Internet

The idea was bold to the point of absurdity, but... “Ninety-nine” was, to put it mildly, of little use as a base for stretch. However, with the appearance of Amadeo, something clicked in the public consciousness, stereotypes wavered and collapsed. It became possible to think about a limousine based on Lada. All that remained was to wait for a more suitable base model. Which naturally became the “Ten”, VAZ 2110.

The Ten, stretched by 175 mm, called VAZ 21108, is where the history of the Tolyatti company Super-Auto began. It began on January 24, 1997, although no one will remember what exactly happened that day. Then, at the beginning of 1997, VAZ vice-president for technical development (and, concurrently, Kadannikov’s friend) Konstantin Sakharov agreed with the management of AvtoVAZ maintenance to rent one of the buildings of the Togliatti-VAZ Auto Center. They decided to call the company, not without pretension, Super-Auto, because they wanted to make the most prestigious and expensive modifications of the “Ten”. On the list of Super-Auto founders you can find the former director of the OPP Sergei Perevezentsev, the chief VAZ technologist Vladimir Peresypkinsky, the head of VAZ social security Alexander Pushkar and the future chief designer of VAZ Vladimir Guba. The name of the last Super-Auto is still associated...

The company’s website says that the first car was not a limousine, but an ordinary “Ten”, only with an Opel 150-horsepower engine (VAZ 21106). There is information that they also made several samples of a pickup truck from the long-wheelbase Niva. However, this is not confirmed by other sources: 21106 and VAZ 2129 Pickup were produced in those years by the Togliatti company Motorika.

It is known for certain that in 1998 the VAZ 21108 “Premier” appeared - the same stretch on the 2110 platform. It also had a simple 8-valve engine.

I note that the official history of Super-Auto, posted on the company’s website, is replete with ambiguous passages: “a specialized structural entity operating under the auspices of AvtoVAZ OJSC,” “a specialized partner of AvtoVAZ OJSC...” With this, of course, the founders of the company emphasize the proximity to the “parent” enterprise . Legally, Super-Auto did not have and does not have any relation to VAZ; it is a completely independent enterprise, neither a subsidiary nor a structural unit (which, for example, Bronto and OPP were). Although Super-Auto’s informal ties with VAZ are stronger than those of other “subsidiaries”...

In 2004, the 21128 engine with a volume of 1.8 and a power of 105-107 hp was developed for the VAZ 21108. Of course, on the basis of the VAZ, having wasted it. This engine was assembled at the VAZ OPP. As the director of Super-Auto Alexey Rodionov said (he was the one who was involved in the preparation of production ten years ago), the engine turned out to be good, but... unstable. There were problems with the honing of the blocks (this was done by a contractor) and with the quality of the ShPG. As a result, each engine is a lottery; one could go 300,000 km without major repairs, the other barely reached 30,000 km.

Alexey Rodionov, General Director of Super-auto. Started working for the company in 2001 as a support engineer

At first, there weren’t many long “Ten” cars made, a few dozen cars a month. But even this volume was profitable due to the high added value. The VAZ 21108 turned out to be in demand among the VAZ management, who were not supposed to drive foreign cars on official business. But I no longer wanted to drive standard VAZs. With the help of Bronto, they even made two armored vehicles with Opel engines for Vitaly Vilchik, the then director of VAZ. These cars, having changed several owners, are still alive and are now in private hands. True, the armor was removed from them long ago. By 2000, production of 108s jumped to 500 units and became very good; other models were forgotten for some time in the wake of success.

But Super-Auto has never produced real limousines with an interior partition. Although such cars existed in nature, they were single products of other Tolyatti companies, for example, Spetsavto. Super-Auto also had a joint project with Spetsavto – a coupe based on the “Ten” (LADA 21128 Coupe Sport). Unfortunately, not many of these machines were produced at both sites, although the machine turned out to be spectacular.

Photo of the Dozens coupe still hangs in the office of the director of Super-Auto

The designers of Super-Auto then made the front suspension on a subframe, widened the track, boosted the engine to 125 hp... But they managed to assemble only five or six cars - the demand for such an exclusive was low. It's time to refocus on something more widespread.

And such a product turned out to be cars of the “tenth” family with the 21128 engine. For a long time they became the hallmark of the company. And when the Priora appeared, a 105-horsepower engine was adapted for it, this car bore the index 21703.

In the mid-2000s, Super-Auto won a number of tenders and supplied cars to government agencies, primarily the Ministry of Internal Affairs and the Federal Penitentiary Service. Government contracts will henceforth become a good support, but also a reason for a series of minor scandals. They say that the company manages to win tenders by offering by no means the lowest price; on the free market, exactly the same cars are sold cheaper... Then the son of Vladimir Guba, Anton, was at the helm of the Super-auto, who became the de facto (though also de jure) owner companies. But in 2008, he left the position of general director and began to develop a company with a similar name - Super-Auto Holding. However, all more or less significant events in production are still under his control.

There were also slightly adventurous projects. For example, in 2007, Super-Auto, together with the company Apal, planned to produce an ersatz Stalker SUV with a plastic body.

Stalker 2154 Photo stolen from the Internet

The conductors were welded and the purchase of equipment was prepared. But 2008 came - a time that, to put it mildly, was not very suitable for venture projects. Nobody dared to make a risky investment and they didn’t start making Stalker on Super-Auto.

At the height of the 2008 crisis, the model was obviously in demand. After thinking and counting, we decided to make Samara-2 with engines from Priora (21124 and 21126, 87 and 98 hp, respectively). This was rational from the point of view of cost (no original parts were used in the machines) and was in the trend of the then demand. Production volume immediately soared from 200 to 600 pieces per month! And even though the margins of the powerful Samara were small, they allowed the company to go through the 2008-2009 crisis with relatively small losses. And even create a material and financial reserve for future developments.

Assembly of VAZ 2114 Super Auto

LADA 144 16v Super-Auto is still produced, it is in demand among young people. But, of course, its days are numbered: VAZ has just reported the cessation of production of 2114, inventory will not last long.

Super-Auto also makes pickups based on the long Niva/Lada 4x4 and special vehicles - ambulance, police, rescue. This is an inheritance from the company Motorika, which went bankrupt in 2011, from which the original production equipment was bought. At first, such machines were assembled directly in the workshop of the former Motorika, but it went to creditors for debts and the equipment was moved to the main site.

Special machines are made according to specific orders and as a result of won tenders. For example, at the end of September Super-Auto received a contract for 30 ambulances for the Chelyabinsk region. On average, 30-40 such machines are produced per year.

Taxi project based on Largus, shown at the 2012 Motor Show

Let's see how the Super-Auto assembly plant works

The entire plant is one large workshop, divided into two parts. Even three, if you count the small pickup truck assembly area.

2114 bodies from VAZ come in the so-called “first configuration”, they are also called “upholstered assembled bodies”. In fact, these are cars without a power unit and chassis elements, with an almost completely assembled interior.

The bodies are placed on technological carts with wheels; the car will move on them until it “grows” with its own wheels. For the time being, it will remain in a small storage facility on the very left side of the workshop.

The first operation is to fill in the VIN. Super-Auto has its own manufacturer code and stamps the original VIN parallel to the VAZ one. Both are recorded in the PTS.

Then, at seven stations, they complete the interior assembly - they attach the dashboard, the steering column with a rack (standard, unfortunately, although they could have installed a “short” one), and finish some things in the interior. They change the electrical wiring for a sixteen-valve engine (there is a different ignition switch harness). “Torpedo” has to be filmed. All these operations take 4.5 hours.

They also install tuning spacers between the front shock absorber cups:

Among the abundance of “fourteeners” I see the body of a white Priora and ask Rodionov: are you getting ready? He answers evasively: I’ll tell you that later...

We move to another part of the workshop, where, as they say, “the mechanics are done.” That is, they turn the body into a car.

The machine is moved from the trolley to the lift

On twelve two-post lifts, power units, suspensions, brakes, and wheels are attached to the vehicles. This is not even a slipway assembly, but simply an assembly: one machine - one post. In most cases, the “mechanics” is managed by one master, a universal one, capable of laying brake pipes and connecting the engine to the electrical wiring. He is given a little more than seven hours for all operations.

LADA 144 16v differs from “just the fourteenth” in a number of components. For example, the rear beam, front struts, wheel drives are all “Prior”. Compared to 2114, the ground clearance increased by 30 mm. VAZ, by the way, officially approved all these alterations. “One hundred and fourteenth” turned out to be heavier than 2114, but lighter than Priora. Therefore it is more dynamic.

Paintwork protection is not total, but is still present; protective capes are required to be worn on the front panel and front fenders.

Power units are assembled in a separate section, connecting the box to the engine:

The power unit is supplied to each lift on an original trolley...

...and already here the wheel drives are inserted into it:

After the car is assembled, it is removed from the lift and rolled onto one of two stands for adjusting wheel alignment angles:

The stands are excellent, modern, no worse than VAZ ones.

The machines are also checked for leaks in the sprinkler chamber:

Then – road tests, which absolutely all cars undergo. This is 30 km under your own power plus checking the brakes on the stand. Problems identified during run-in are eliminated in the finishing area. The guys from this area are clearly not without work...

The process of assembling one car from unloading the body to signing all the papers takes 14.5 hours. Two work shifts, in short. The plant itself operates seven days a week, and the working day lasts 11 hours. Two teams of 30 people each work according to the “two by two” scheme.

In the far corner of the workshop there is a large five-axis machining machine CHIRON MILL 2000, which Super-Auto is proud of: expensive, they say, a million dollars, anything can be done on it.

We bought the machine with the intention of making a cylinder block for our engine. But in the crisis year of 2008, the engine project had to be slowed down...

Now they don’t do anything on this machine. But preparations are underway for the production of blades for high-load gas turbines. This has nothing to do with the automotive industry; the customer for these blades is completely different, from the chemical industry.

Pickup trucks are the exact opposite part of production.

Bare primed bodies are received from OPP and another contractor paints them.

Why don't they paint directly into the OPP? - I ask. But we can’t reach an agreement yet,” they answer, “Although the OPP is literally two steps away, across the fence.” Their painting line is a bottleneck, they can barely cope with their products...

According to VAZ technology, many seams are treated with anticorrosive

First of all, the interior parts are mounted into the painted body.

Then the car is moved from the cart to a lift to install the “mechanics”.

The power unit assembled with the front suspension, axles, and axles are transported on trolleys...

There are a total of four lifts operating on Niva – these are piece production, hand-made. From 40 to 60 per month, that is, at best, a couple of cars per day.

A 4 mm thick polyethylene protective “trough” is placed in the cargo compartment:

Next is the awning, which comes in two types, high and low.

There are also orders for a “clean” pickup truck, without an awning.

And this is the finished roof for the sanitary version of the Niva.

That's it, the car is assembled, now the mandatory wheel alignment, brake drums and a thirty-kilometer run-in are required.

What's next?

All this is wonderful, Samara with a powerful engine, Niva pickup... But these models are hopelessly behind progress. Even if there is a demand for them now, this does not mean that there will be one tomorrow. VAZ discontinued Samara altogether. But LADA 144 16v was the basis of the Super-auto production program until the last days! What will the company do now, without its basic product? What will be produced when the flow of “fourteeners” dries up?

At first they plan to rely on pickup trucks and possible orders for special vehicles.

And then – Priora. It was not for nothing that Rodionov smiled slyly: the Priora is already being “run” through the entire technological cycle, looking at what needs to be changed.

Of course, this will not be a standard Priora, but a more powerful one. Super-Auto plans to return to the 1.8 engine, only now with a power of 123 hp. They say this is a new development, and not a modernization of the previous engine 21128. Although it is possible that it will carry the same index. The Priora itself from Super-Auto will be called 21703-28.

The increased working volume was obtained without boring the 126th block. This engine uses new camshafts, with increased “lift” (up to 8.5), and the compression ratio is lowered by half a unit. This not only makes the engine more knock-resistant, but also evens out the torque characteristic. At 2200 rpm it produces 145 n.m, and at 4000 – 165 n.m. Which, as we see, is at the limit of the gearbox's capabilities. Of course, this cannot but affect its service life, alas... The Priora with the new engine is a little louder, although it fits into GOST noise standards. In any case, the certification testers had no complaints regarding this part. They plan to receive OTTS any day now, before the end of this year.

Such a car will cost 25-30 thousand more than a Priora with a 21126 engine.

Changes are also being made to the assembly process. Gradually, Super-Auto is moving towards creating its own conveyor belt. Its similarity will be organized at the beginning of next year. There, cars will be moved manually along guides from post to post. This is due to the fact that VAZ cannot produce the Priora in the “first configuration”; you will have to take a bare painted body and assemble the car completely, as is done on the Lada Sport. Accordingly, nine mini-conveyor posts are added. And in the future, a mechanical floor conveyor will be installed; according to Rodionov, it will be profitable to work with it at a volume of 650 vehicles per month. LADA 144 16v, by the way, was produced in a not much smaller quantity. But with the Priora, a more expensive car, they don’t expect such indicators right away; it would be better to reach 300.

You will laugh, but the long-wheelbase Priora has not been removed from production, there are simply no orders for it now. The last cars were made in 2012, 16 of them, for VAZ management, equipping them with a modernized version of the old 1.8 engine. Now such motors will no longer be able to be assembled. But a more perfect one will appear soon! This means that all is not lost for model 21708.

And then... Next, Super-Auto wants to make a powerful version of the Grant. But if VAZ has no special objections to Priora, then Granta 1.8 will directly compete with VAZ’s Granta Sport. Apparently, this is why it is not possible to reach an agreement with the plant on the supply of vehicle kits. Although the project is completely ready for implementation. This is what Granta looks like in the Super-auto version:

As you can see, this car is not only remarkable for its engine. The spectacular body kit was made by the in-house designer of Super-Auto (formerly VAZ, of course), he also refined the interior with aluminum-look inserts and beautiful stitching in the upholstery of the seats. The front seats will be sporty, even sportier than on the Grant Sport.

Search sketches for sports Grants

Such a Grant should cost 7% more than the VAZ one, that is, again, like the GS. True, it has a slightly different ideology: only power, no modifications to the chassis. Here are its characteristics, taken from the presentation booklet:

Will it work?

Now Super-Auto is capable of producing up to 15,000 cars per year. Only Priora and pickups cannot select this resource. Granta would be very helpful! Alas, in any case, you will have to sell it yourself: having entered the VAZ sales network several years ago, Super-Auto did not compete with the basic models, but now the plant has similar products. Knowing the tough character of VAZ Vice President for Marketing Artyom Fedosov, I am almost sure that he will not allow Grant from Super-Auto into VAZ sales.

But, as you know, big changes are coming at VAZ...

Like(7)Dislike(0)

When using the material, please make a link to the Russian car.

rusautomobile.ru

Body

The rear of the model was left almost unchanged, the bumper was only slightly altered, but the front part was subjected to significant modifications. In particular, the wide, rectangular front headlight blocks of the classic “eight” were replaced with narrow oblong monoblocks, round in shape.

Body of VAZ-2113

In addition, the front radiator grille and bumper were changed, which acquired a more complex geometry aimed at reducing drag. Also, the body of the restyled version was equipped with an aerodynamic body kit including the following elements:

- Side moldings;

- Side skirt fairings;

- Spoiler on the rear door.

Similar features were available immediately at release, and in the basic configuration of the model, which certainly pleased buyers.

In general, the body was made more streamlined and elegant, and coupled with additional aerodynamic elements, it was possible to somewhat improve the car’s throttle response and handling at high speeds.

— GC “Super-Auto” — production of exclusive and special cars

The production process of a car takes place under careful quality control in several stages. The body, as the most important part, is manufactured directly in the body production of JSC AVTOVAZ. Assembly is carried out in specially equipped Super-Auto workshops at complex stations equipped with all the necessary equipment and tools. It’s not a stretch to say about such cars that this is a hand-assembled car - almost all technological operations are carried out manually by the company’s specialists, as, for example, on the famous one. Next, a complete bench diagnostic of the finished vehicle and its road tests are carried out, followed by adjustment of the units. Each car goes into a sprinkler chamber, where the interior is tested for moisture resistance. Then the cars are tested on a roller stand. And then each car travels from 10 to 15 kilometers under the control of an employee of the company’s quality control department. And if, after such a serious check, any problems are discovered, the company’s specialists eliminate them before the car reaches the finished product lot.

The warranty period for the car is two years or 30 thousand kilometers. Service is carried out at all service centers. Super-Auto has the necessary production facilities to organize the production of cars in a volume of more than 10,000 cars per year.

Includes:

- 2 main production buildings with a total area of about 10,000 m2, including a car assembly shop, component warehouses, auxiliary areas and premises.

- Body welding area with an area of 786 m2, located on the territory of JSC AVTOVAZ in the areas of assembly and body production.

- 2 administrative buildings with a total area of more than 1,500 m2, where household and office premises are located.

Technology

The technological flows of the enterprise are built taking into account the complete production of a car, ensuring its high quality.

Welding and finishing of the body of specialized cars, such as LADA Priora Premier, is carried out at a specialized welding site located on the premises of JSC AVTOVAZ, equipped with modern welding equipment, tooling and tools that allow obtaining high quality body geometry and its front surfaces. The body is manufactured on the basis of a set of serial body parts supplied by JSC AVTOVAZ and a set of original parts manufactured by third-party suppliers.

Body painting is carried out in the painting line of the main production of JSC AVTOVAZ in strict accordance with the factory technology for preparing and painting bodies.

After completion of all operations, the painted body is transported to the vehicle assembly workshop of the Super-Auto Group of Companies.

The assembly production of the car assembly shop is organized on the basis of manual point-by-point assembly using modern universal assembly equipment, equipment and tools. Manual assembly, plus the responsibility of each post for the quality of the work performed, as well as strict control by the quality control department ensure the high quality of the car.

www.super-avto.ru

Interior and instrument panel

Some interior details of the G8 have migrated into the cabin, including a molded ceiling and interior door panels. The rest of the decoration, including the two-spoke steering wheel, was borrowed from the restyled versions of the 9 and 99 (VAZ-2114, 2115), which were released a few years earlier.

The instrument panel has changed significantly compared to the G8. The dashboard, as well as the body, received smoother and more elegant lines in contrast to the archaic angular console of the original model.

Dashboard VAZ-2113

VAZ also added additional auxiliary gadgets. The basic assembly offers: vertical steering wheel adjustment, backlight with adjustable brightness level, headlight level control, exterior anti-dazzle mirrors, rear window cleaner and washer, on-board control system with display unit.

Innovations available in the highest trim level - "Lux" - include heated seats, headrests in the rear seats, an on-board computer, and fog lights. Otherwise, the model does not offer any special frills. For example, there is no air conditioning or multimedia system. However, regarding the last aspect, the developers came to the rescue and at least equipped a slot on the panel for installing a radio.

About refilling the air conditioner

After installation, the air conditioner must be recharged. In addition, this device will have to be refilled at least once every 3 years, since up to 10% of freon can leave the system within a year, even if the circuit has never been depressurized. Freon R-134a is now used everywhere as a refrigerant.

And to pump it into the air conditioner you will need special equipment, for which you will have to go to a spare parts store.

And you need to buy the following there:

- set of couplings and adapters;

- hose kit;

- R-134a freon cylinder;

- pressure gauge

Refueling sequence

Let us list the main stages of pumping freon into the system.

- There is a plastic cap on the low pressure line in the air conditioner. It is carefully cleaned of dust and opened.

- The fitting located under the cap is connected to the hose on the cylinder using the adapter included in the kit.

- The car engine starts and idles. The crankshaft rotation speed should not exceed 1400 rpm.

- The air conditioner turns on maximum air circulation throughout the cabin.

- The freon cylinder is turned upside down, the tap on the low pressure adapter slowly opens.

- The filling process is constantly monitored using a pressure gauge.

- When cold air begins to flow into the car interior and the hose near the adapter begins to become covered with frost, the refueling procedure ends.

Video: refilling the air conditioner yourself

Chassis, transmission and engine

As for the chassis, the “thirteen” offers a MacPherson strut suspension similar to the “eight” at the front and a torsion beam at the rear, as well as front disc and rear drum brakes. The gearbox is exclusively mechanical, with 5 speeds, regardless of the configuration.

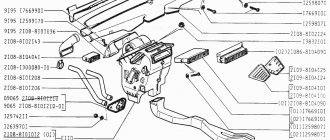

Chassis VAZ-2113

The range of power plants is represented exclusively by gasoline engines with distributed injection. In total, 5 types of engines were installed on the trinashka:

- VAZ-2111. Four-cylinder unit, volume 1.5 l (1499 cm³), power 77 hp. at 5400 rpm. Found on the first basic models from 2004-2007.

- VAZ-21114. Four-cylinder engine with a volume of 1.6 liters (1596 cm³), power of 82 horses at 5200 rpm. It is standard on assembly models from 2007-2011.

- VAZ-11183. Four-cylinder 82-horsepower engine with a volume of 1.6 liters (1596 cm³). It is available in luxury and standard trim levels, which were released from 2011 to 2013.

It is worth noting that the thirteenth models of the “Samara” family were equipped with two more types of engines:

- VAZ-21124. The engine has 4 cylinders and 16 valves, a volume of 1.6 liters (1599 cm³) and a power of 89 horses. The unit was installed on models with the “norm” configuration, produced from 2010 to 2013.

- VAZ-21126. Four-cylinder engine, volume 1.6 liters (1597 cm3), power 97 hp. With. Found on some models, produced in 2010-2013, in the “Standard” configuration.

These engines were installed on Ladas of Samara, but not produced by VAZ, but by the company of AvtoVAZ’s subsidiary, Super-Avto CJSC. This enterprise, also based in the city of Tolyatti, next to the Volzhsky Automobile Plant, and since 1997, has been producing modifications of Lada models to order from the parent company, including analogues of the 2113. By the way, on such hatchbacks, on the back of the trunk door, under the Lada branding ”, there is an inscription - SUPER-AVTO.

Engine VAZ-2113

Trinashka engines are quite simple in design, unpretentious in maintenance and have excellent maintainability. If you have the desire, as well as the Internet to search for the necessary information, even a beginner can handle the repair of these units.

About installing climate control

In short, installing climate control on the VAZ 2114 is for enthusiasts. Ordinary owners of “fourteenth” models do such things extremely rarely, limiting themselves to a simple air conditioner, the installation sequence of which is given above. The reason is simple: installing climate control on a car that is not the newest is not economically feasible.

To do this, you will need to purchase electronic heating system control units. One or two (depending on how many control zones are planned to be installed). Then they will need to be connected to the on-board network, which will require major changes to be made to it. Not every driver can do this task. Therefore, you will need a specialist whose services are very expensive. Taking all this into account, the owner of a VAZ 2114 should think: does he really need climate control?

So, it is quite possible to install an air conditioner on a VAZ 2114 on your own. All you need to do is buy a ready-made device at any auto parts store and carefully study the installation instructions. Difficulties can arise only at the stage of refilling the air conditioner. Therefore, you should only refill this device yourself as a last resort. If possible, it is better to entrust refueling to professionals with the appropriate equipment.

Reviews

In 2013, the white three-door hatchback VAZ-2113 rolled off the assembly line of the Volzhsky Automobile Plant, the last of the line of these cars and the production of “trinashki” was closed. Nevertheless, the model is still in great demand among Russian citizens, as evidenced by numerous positive reviews.

The “Thirteenth” model is praised for its reliability, good handling and dynamics, maintainability, affordable price, and most importantly, high potential for tuning. Car owners also leave negative reviews - mediocre comfort, noise while driving, outdated design. However, for its price (on average 150-200 thousand rubles), the VAZ-2113 completely covers its shortcomings with its advantages.

Post navigation

What is better VAZ 2112 or VAZ 2114?

What is better VAZ 2112 or VAZ 2114? You are young, energetic and so old that you are ready to buy a car. Do you need a car...

Torpedo tuning for VAZ 2114

Many car owners want their car to be comfortable. For this purpose, tuning is performed. The most popular “target” for tuning is…