The rattling of the gearshift knob of a VAZ 2110 car is not such a rare occurrence. There are several ways to fix this problem.

As is already known, to eliminate any problem, it is necessary, first, to establish the cause of its occurrence. There can be many reasons for the rattling of the VVAZ 2110 gearbox lever.

For example, rattling may appear due to the installation of a backlash-free gearshift lever from LADAKalina, since in the absence of play, all vibration from the gearbox goes directly to the gearbox lever in the VAZ 2110 interior (in the photo below: on the left is a backlash from a VAZ 2110, on the right is backstage without play from LADAKalina).

You can clearly look at the scenes with and without play (from VAZ 2110 and LADAKalina, respectively).

Another reason that leads to rattling of the gearshift knob may be wear of the gearbox and engine mounts, as well as other parts responsible for damping vibration of the gearbox and engine.

It is worth starting to eliminate gearbox lever chatter by replacing the gearbox lever ball joint (produced from the bottom of the car) or the gearbox lever repair kit (carried out from inside the car). This gives a small effect, but it is best to start with this.

Usually, drivers of a VAZ 2110 car solve the problem of gearbox lever rattling by simply pressing the gearshift knob and fixing it with hand, so we will direct the first method in this direction. It consists of installing a locking spring for the gearshift lever.

Gear shift system - what can break?

It is very likely that the culprit of the chatter will be the lever itself or the system that is used to transmit the translational movements of the lever to the shift mechanism in the transmission. If the rattling occurs only on the lever, but is not transmitted to the entire body, most likely the problem is hidden in this module. If the car does not have a large engine crankcase protection, you can put the car on a lift or drive into a pit and inspect the elements yourself.

The following parts may break:

- seals in the lever itself - just remove the protective covers in the cabin and see what condition the rubber seals and bushings are in, whether there is any play in them, and also evaluate the source of the chatter;

- gear shift lever - in some brands of cars it is made in the form of a complex mechanism and often fails, small plastic bushings wear out and cause vibrations in the lever;

- gear selection fork - this again depends on the design of the car, but very often it turns out to be the cause of the lever rattling in first gear when starting to move, it is more difficult to see;

- connecting elements of the lever and the rocker - usually these are metal tubes with connections that tend to fail over time, so sometimes they need to be revised;

- fastening parts of the rocker - sometimes the device simply unscrews and begins to play, and there may also be problems with engaging some gears, the lever may jam.

These are common causes of lever rattling, but in such a situation the unpleasant sensations will be noticeable not only when driving in first gear. Each touch of the lever will bring unpleasant emotions; you will not recognize the behavior of your car. It will be difficult to find the moment to change gear and find out the correct amplitude of movement of the handle during the trip. Therefore, problems with these nodes need to be eliminated as quickly as possible, without expecting that something else serious and expensive will break.

Vibration when starting from automatic transmission

In an automatic gearbox, jolts at start occur due to severe wear of the clutches, clutches and planetary gears. It is also a matter of a malfunction of the hydromechanical transmission and electronic control system inside the gearbox or dirty oil channels coming from the pump. This is caused by improper operation and the use of poor quality lubricant.

Heavily worn rubbing parts begin to slip when the gearbox is loaded. Malfunction of the electronic control unit valves prevents the required oil pressure from forming in the system, and during a torque converter malfunction, torque is poorly transmitted from the engine to the gearbox. This is caused by severe play in the shaft bearings, as well as breakage of the petals of the drive and driven gears of the torque converter.

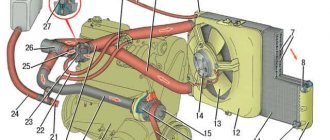

Engine mounts - it’s better to immediately check the integrity

The main element of vibration under the hood is always the power unit and gearbox cushions. Typically, the rear cushion, which holds both the gearbox and the engine, is responsible for lever rattling, but this greatly depends on the design of the car. It is impossible to find a definite answer to the question of how to check pillows yourself. You can watch videos of masters and craftsmen and use their advice, but the fastest way to do this is with the help of specialists at a service station. This is an accurate and quick diagnosis on a lift.

You can check these details yourself like this:

- ask an assistant to get behind the wheel, open the hood, stand in front of the car and give the command to start the engine - if there is strong vibration, there is a problem with the airbags;

- again, ask your assistant to start the car with the hood open, stand on the side of the car and command a smooth start, see if the entire power unit shakes along with the lever;

- with the car turned off, use gloved hands to shake the engine from side to side, it should give in a little, but very moderately; in no case should there be any metallic knocks;

- lift the car onto an overpass or select a convenient diagnostic pit, then use a flat mount to check the quality of fixation of the engine mounts in the lower part and their play;

- in general, listen to the operation of the power unit at idle speed - is there any vibration, is there a knocking or dull tapping when switching to different speed modes.

If at least one of these symptoms is present, you need to start replacing the engine mounts. Doing it yourself is also not advisable unless you have experience. An incorrectly positioned power unit on the cushions will rattle and cause even more problems. It is important to find a specialist who can properly adjust the cushions, set the motor perfectly and test its operation in all modes. This is the only way to hope to fix problems in your car. Otherwise, repairs will only make the situation worse.

How to remove vibration and noise from a gearbox (rear bearing from a Priora)

Reinforced rear bearings began to be produced for ten-speed gearboxes, which are not only more reliable, but also quieter due to their design features.

For a long time I was haunted by an article from ZR. I remember reading the Priora test in “60 Hours Behind the Wheel” and came across the following information:

“To avoid similar incidents in the future, the designers decided to replace the standard bearing 6-50305A2ESH1 with a more durable 750305AU. Its dynamic load capacity is 20,800 N versus 19,000 N for the old one. The new bearing has a double-sided seal that prevents wear and tear products from entering the rolling surfaces. It would seem that there is a magnet in the crankcase to collect steel particles. But it cannot control aluminum and brass particles, which are considered the most dangerous. They are firmly pressed into the race tracks, interfering with the balls, which leads to noise and knocking.

Next to the rear bearing of the primary shaft, a similar one works on the secondary shaft. This one seems to be in order, but they decided to replace it with a new one - it’s more reliable, and there won’t be any confusion during assembly.”

From the very first thousand kilometers I was bothered by the noise of the gearbox in second or third gear. And when braking with the engine in fourth or third, it completely blew my mind. And the dream was ripening to change these damn bearings, God willing, at least it would howl less. Moreover, the plant doesn’t even look in this direction.

But what about the owners of cars that have a gearbox with an outdated bearing? Experts say: our case is an isolated one, there is no need to recall the cars. The factory carried out tests several times, and the rear bearing coped with its task.

All units, without exception, are tested at the stand.

The story can end here - the unpleasant story ended quickly and happily. There is, however, one “but”. The unfortunate rear bearing has long been a concern for owners of front-wheel drive VAZs. Even on cars with low mileage, it begins to sing at idle, and by 60 thousand km its noise becomes annoying.

It is unlikely that the factory workers did not know this. Unlike the outdated 1.5-liter carburetor engine with a torque of about 106 N.m, the updated 1.6-liter VAZ-21114 and VAZ-21124 already produce 120 and 131 N.m, respectively. The load on all parts of the box, including bearings, has increased. And if the box modernization described here had been carried out in a timely manner, Priora would have finished our test in triumph, and not on a rope.

CV joint - why could it be the culprit?

Another problem that can cause such unpleasant moments during operation is a breakage of the CV joint on one side. The problem is that this mechanism does not always break, with obvious consequences such as crunching when turning. It is involved in the transmission of torque to the wheels, so it may well result in uneven transmission of this torque and twitching when starting in any gear as a consequence. This is also important to remember when diagnosing problems with such manifestations in the car.

The CV joint is more difficult to check, but you can do the following:

- Turn the wheels on a stationary car all the way and pull the axle shaft with your hand near the entrance to the CV joint; often broken elements will give a play that can be felt without special tools;

- You can also check the CV joints on the go - find a flat area and perform several circles with the steering wheel turned completely to one side, listen for extraneous sounds in the suspension;

- You can also check this element in a pit by carefully examining the boots; most often the CV joints fail when the boot breaks, dirt gets into the mechanism and simply destroys it;

- Service specialists check and give a final verdict on this part only after removal from the installation site, but usually in this case it is better to replace the CV joint with a new one;

- If you are not sure that the problem is in the CV joints, do not rush to change them, check for other reasons, since lever rattling in first gear is not the most likely symptom of their failure.

At the station, with a superficial diagnosis, the hinges may be sentenced to replacement along with the clutch, rocker and other parts. This suggests that the specialist does not want to understand the problem, but wants to make money from you. It is extremely unlikely that all the elements responsible for the possible jerking of the lever in first gear simultaneously fail. If the service station presents a huge list of problems, you will have to find another station and re-diagnosis. In general, this is very important to understand when choosing a specialist to service your car.

Reason 1 – spark plugs

Spark plugs are the first thing to check when the Priora jerks while driving. If they were rarely changed and the car was filled with low-quality fuel, carbon deposits could appear on the electrodes. This leads to misfires, as a result of which the car begins to twitch while driving.

The cost of candles for Priora varies greatly depending on the manufacturer. The simplest ones cost 250 rubles for four pieces.

You can change it yourself if you have a spark plug wrench, or contact service. The service costs from 400 rubles depending on the technical center.

Clutch is the main, but not the most common element

If you read the opinions of forums on this issue, you will find that it is the clutch that is most often condemned by “armchair experts” in this situation. This is indeed very similar to a broken clutch, but you should check all the above options before repairing or replacing it. You may be able to avoid significant financial investments by eliminating minor problems and eliminating the unpleasant effect of jerking the gearshift knob when starting off. If all else fails, move on to the clutch issue.

Here are some secondary indicators of the breakdown of this mechanism:

- when starting off, you hear a specific smell, especially if you like to drive dynamically, this is the clutch elements burning out, which cannot be restored in any way, they need to be replaced;

- it is impossible to get underway consistently, since the clutch pedal is taken in a new place every time, this is a sign of complete wear of the device, the entire assembly should be replaced or diagnosed;

- slipping is felt, due to which a dip is formed in the process of starting off or switching to another gear, this dip is very noticeable in low gears, less so in higher gears;

- the car is unstable, there may be twitching when releasing the gas pedal in fourth or third speed, and then a jerk when pressing the gas when the car is braking with the engine;

- The car can jerk in other situations, the clutch fails very unpredictably and can bring the most unexpected results in the form of unpleasant manifestations.

If you notice a number of other manifestations, you should immediately begin repairing this unit. Driving with a failed clutch is unsafe, as at some point you may simply not move. It’s good if it’s within the city limits, where you can ask your friends to help or call an inexpensive towing service. If this occurs on the highway, you will have to pay a lot for the evacuation of the car and subsequent repairs at any nearby service center. So such problems should be eliminated immediately.

We suggest watching a video on how to eliminate the beating of the lever when starting:

Reason 4 – fuel filter

This is perhaps one of the most common reasons why the Lada Priora twitches.

Like any other filter, the fuel filter becomes clogged over time. The reason is low-quality fuel and dusty air, so it is better to refuel at proven gas stations.

You can check a clogged filter yourself using a conventional pressure gauge, tube and clamp. For this:

- Unscrew the cap from the fuel rail fitting.

- Using the tire nipple cap, unscrew the spool and connect the pressure gauge, securing the tube with a clamp.

- Start the car and check the pressure reading. If it is less than normal - 3.8-4 kgf/cm2, the cause of the twitching most likely lies in the filter.

At a service center, a pressure check service will cost about 300 rubles.

You can replace the fuel filter at home. The part costs about 300 rubles. If there is no desire or opportunity, contact the service center. There they will charge from 500 rubles for the service.

Let's sum it up

Modern cars rarely provide the owner with surprises in the form of unexpected problems. But domestic budget transport, as well as old foreign cars, very often demonstrate such unpleasant consequences. This may be a consequence of the failure of a small part in the gear shift system, or it may be a consequence of the failure of some complex mechanisms that will cost a lot of money during repairs. In any case, this problem needs to be eliminated. If the lever shakes when starting, other components of the car also receive increased loads. This can cause serious damage that can be expensive to fix.

If you don't know where to start diagnosing, use the four points presented above. The reason for the twitching of the lever when starting to move is usually hidden precisely in them. If this does not help, most likely the problem is hidden in the box itself. This could be a broken tooth on one of the gears or failed fastenings of important parts. It is best to contact a specialist and carry out repairs, but you need a reliable specialist who accurately understands the design of your car. Ask around on forums or with other owners of the same cars if you don’t have a good specialist in mind. Have you encountered such problems on your car?

Reason 5 – mass air flow sensor or ECU firmware

A malfunction of the mass air flow sensor on a Priora leads to the control unit receiving incorrect data on the amount of incoming air, as a result of which the air-fuel mixture is not prepared correctly, and the car may begin to twitch. The malfunction is determined using diagnostics at a service center.

The price of the sensor is not at all budgetary for a Priora - about 4,000 rubles. You can change it yourself. To do this, first disconnect the negative battery terminal, then the wire connector and unscrew the pipe clamp. After this, use a wrench to unscrew the two screws securing the air filter housing and carefully remove the sensor.

Inappropriate ECU firmware leads to the same symptoms. The air-fuel mixture is not prepared correctly, and interruptions may occur during engine operation. This can be caused by improper chip tuning or a malfunction of the “brains” themselves. In any case, only competent diagnosis will help here. It usually costs about 500 rubles. After diagnosis, the technician will tell you exactly how to solve the problem.

Defects that appeared after replacing the clutch

What does it mean to replace the clutch? This action means changing the driven or driven clutch disc; often both parts are changed at once. In this case, the release bearing must also be replaced. After such an operation, side defects are suddenly revealed that were not there before the repair.

If we think logically, then there are few reasons for the appearance of new malfunctions. Typically this is:

- Unqualified repairs;

- Defect of new spare parts;

- Erroneous diagnostics, as a result of which not all or the wrong parts were replaced, and previously hidden problems manifested themselves in full.

In general, the issue of the appearance of new unpleasant signs is very difficult and is individual in each specific case, but these signs have common characteristic features.

If there is a knocking noise after replacing the clutch

As a rule, the cause of knocking after replacing parts is defective parts. In particular, there are dangling damper springs in the driven disk. Therefore, before installing such a spare part on a car, you need to carefully inspect it. Parts of the disk may also be poorly riveted. » alt=»»> Knocks in the clutch area can occur due to a crack in the release bearing bushing (the bushings are often made of plastic). Even at the site where the bushing fits on the flange of the gearbox input shaft, play may form, which also leads to a knocking sound.

The knocking noise occurs due to a broken clutch basket petal, but such a defect occurs infrequently. Another reason for the knocking is a broken starter housing in the Bendix area; it rattles when the car moves. A tooth on the flywheel crown may break off, and it will also knock when touching the rotating parts.