Print this article Font size 16

Every car, regardless of manufacturer and configuration, must be equipped with seat belts. This is an international requirement, the violation of which entails very serious consequences. Moreover, both for the manufacturer and for the owners of such cars.

As you understand, the VAZ 2110 is no exception, and therefore the design of its interior includes seat belts.

Device type

Features of penalties

If a traffic police officer finds an unbelted passenger in the car, he will issue a double fine. The driver will also suffer the same fate and will be fined RUB 1,000. Why, you ask, since the motorist is not to blame? In fact, law enforcement officials do not think so.

According to the law, it is the responsibility of the car owner (driver) to monitor the condition of the car, including its internal systems, and timely replacement of the seat belt. The driver can make payment within 20 days, in which case the fine will also cost him 500 rubles

Particular attention should be paid to small passengers and restraints for their safe trip.

Replacing the coil

In some cases, do-it-yourself seat belt repair requires completely replacing the reel. If after these steps the tape still does not come out of the reel, this action most likely cannot be avoided.

Typical signs when the coil should be replaced are the absence of changes after cleaning this system. If, after taking it out and lubricating it with a new substance, as well as bending the metal tab, the belt still does not come out, you need to purchase a new mechanism.

For each brand of car it is necessary to select its own special type of device. Therefore, it is necessary to show the old reel in the store. This will allow you to choose the right mechanism.

What does a jammed belt mean?

If the seat belt does not pull out of the installation socket, it is most likely jammed. To understand what this means, you first need to understand how it works. When the belt does not extend, this indicates a failure of the locking mechanism or that the belts were jammed as a result of an accident. But first, let's look at the principle of operation.

Vehicle seat belt

Inside the blocking device there is a sensitive element responsible directly for blocking, which is made in the form of a ball. This ball, moving through a system of levers, clings to the body of the coil gear. If the belt is retracted too quickly, the spool disc puts more force on the screw surface, thus blocking the ball.

In such cases, the strap does not retract and cannot be turned off in any way. In such cases, even an attempt to slowly latch the element may not help - it simply jams and no longer retracts, does not work.

Causes

If your vehicle's security system won't retract, or the lock is stuck and cannot be disengaged, there could be several reasons for this. Before we move on to how to disassemble and disconnect a belt that does not work and does not retract, let's talk about the reasons. There are not many of them, so we will not dwell on this point for long. After all, in order to repair the latch of an unfastened strap, you need to know what is not working and why. So, the reasons:

- First of all, the belt usually does not retract due to wear. Or rather, not specifically the wear of the belt, but in principle the locking system. Also, this may not be related to the entire system, but to one of its components. If the buckle of an unfastened strap is jammed, does not retract, and you cannot disengage it, then, without a doubt, the problem is in the mechanism. But if the element was not fastened, that’s half the trouble. It will be much worse if it jams during operation.

- The second reason is the breakdown of one or another component. As a rule, it concerns not an unfastened belt, but a fastened one. If a breakdown occurs or a defect appears in the operation of one of the components, this is usually associated directly with the fastened structural elements of the system. In this case, only repairs will help you and nothing more. Or, of course, you can always replace failed parts.

- Another reason is blocking after an accident. Typically, the design of the strap is made in such a way that in the event of a traffic accident, the squibs of the mechanism are activated. In this case, the lock of the device jams and it is no longer possible to disable it.

Depending on the car model, the driver may receive a signal that the straps are stuck. This signal can be either audible or appear on the instrument panel. The signal may also appear on the on-board computer screen, if available. In any case, if the car is equipped with “brains”, the driver will receive a corresponding signal.

What will be required for repairs?

For the reasons mentioned above, sometimes the seat belt does not extend. What to do ? Advice from experienced auto mechanics will help. First of all, you will have to disassemble the casing and remove the coil. In some models, you will have to dismantle the seats in the place where the breakdown occurred.

To do this, you need to prepare screwdrivers (flat and Phillips), as well as spanners. Their diameter should be different. You should also purchase a multi-purpose lubricant. The seats must be protected from accidental contact with oil. You will also need napkins and wire.

Repairs can be simple or more complex. In some cases, you have to completely change the coil. For some machine models, you will need to prepare special tools. But repairing a seat belt yourself will help save quite a lot of money in the family budget.

How to repair

After finding out the reasons for the malfunction of the seat belt reel, we will figure out how to repair it and what is needed for this. In this procedure, the main thing is to thoroughly clean the belts.

Required Tools

To resolve a malfunction of the seat belt buckle, the device will need to be cleaned. This will require certain tools and accessories.

- Short shaped screwdriver.

- A 17 mm wrench is better than a socket type.

- Flathead screwdriver.

- Clothes pin for office work.

- A syringe with a thin tube.

- Gasoline for lighters.

- A piece of polyethylene to protect the seats from dirt.

- A piece of steel wire.

Step-by-step instruction

After preparing the instrument, you can begin repairs and cleaning in the following order:

- Using a curved screwdriver, unscrew the screws that secure the decorative trim of the belt.

- If the lock is faulty, pull the belt all the way out and secure it with a clothespin.

- Using a wrench, unscrew the coil mounting bolt and pull it out. To prevent the device from winding up, secure it with the same clothespin. This will make the lock easier to clean and repair.

- Put the device down and sit somewhere else. To clean and disable the lock, you need to find the inertia coil cover. It can be detected by thicker metal. Shake the coil - the cap will be located where the noise is heard.

- To remove the protective cover, you need to pull out the 4 plastic clips. This can be conveniently done with a flat screwdriver or thin wire. The clips must be held with your hand so that they do not jump out and get lost in the cabin. Next, hook the trim with a screwdriver and remove it, setting it aside.

- After this, the locking device becomes available. It is made in the form of a box containing a cylinder and a ball, as well as a rocker arm that locks the lock. The device can be easily removed.

- Check the operation of the locking rocker - ideally, it should move easily along the axis of rotation. The mechanism must be placed vertically so that the upper part is inclined towards the blocking ball. If the vertical position is not maintained, the rocker arm will jam. It should move easily, otherwise the rotation axis needs to be cleaned. To do this, use prepared lighter gasoline. Rinse the mechanism with it so that the rocker rotates easily on the axis without delay.

- Now you need to get to the inertial mechanism. It is located under the plastic gear, and itself is made of steel. Remove the gear and set it aside.

- Look at the middle of the gear hole - there is an eccentric in it. When the seat belt is pulled out suddenly, the teeth block it. The place under the eccentric needs to be cleaned; to do this, pour gasoline into the hole. Hold the belt with your hand to prevent it from unwinding. To do this, temporarily remove the clothespin. Make sure that gasoline seeps into all parts to ensure proper cleaning.

- Take the removed inertial coil so that the plastic guide with the spring can be held with your finger. Try wrapping and rewinding the safety tape several times with your other hand. Pull it sharply and the lock should be activated.

The device is assembled in the reverse order. Be careful when assembling, as an incorrectly assembled mechanism can cause malfunctions. Check in advance that all parts work correctly and move easily. If it is difficult for you to make repairs yourself, then it is better to contact a car repair shop. After all, erroneous actions will only lead to further malfunctions that will cause trouble on the road.

How to change the front seat belt on a VAZ 2110

Simple step-by-step instructions for replacing the front seat belt on VAZ 2110, 2111, 2112 cars.

1. Use a screwdriver to pry up and remove the lower decor. overlay.

2. We also remove the top decor with a screwdriver. overlay.

3. Unscrew the upper belt fastening bolt.

4. Now remove the bolt with plastic seal 1, spring washer 2, sleeve 3 and washer 4.

5. Then unscrew the screw of the upper fastening of the lower trim of the B-pillar.

6. And unscrew the screw of the front fastening of the lower trim of the B-pillar.

7. After this, unscrew the rear fastening screw of the lower trim of the B-pillar.

8. And unscrew the screw for the middle fastening of the lower trim of the middle pillar.

How do they work

Before starting repairs, it is important to understand exactly how seat belts work, what are their features, and what devices generally take part in protecting the driver and passengers.

- The coil lock is made on the basis of a ratchet mechanism, which is locked by a sensitive element. Its role is played by a pendulum with a semi-spherical support. In some cases, this is a ball of metal placed in a sphere with a large diameter.

- The pendulum or ball moves, while the ratcheting gear of the reel is fixed to the body through a system of levers.

- A flywheel disc is located on the gear axis on screw splines.

- When the straps are slowly tightened, the disc rotates with the shaft due to friction, but does not lock the reel.

- If you make a jerk, the disk will put more pressure on the screw surface, acting by inertia, overcome the friction force and block the ratchet, moving along the screw splines.

Article on the topic: Which thermostat is better for the VAZ 2114? How to change it yourself (video)

Checking status

When driving, the driver and his passengers must wear seat belts.

This node will only provide security if it is used. The problem for many of our citizens is that they wear seat belts not for the sake of safety, but to avoid fines for violating traffic rules. That’s why many people simply throw on the tape without putting it into the lock, creating an imitation of a fastened belt for the traffic police.

You should always be sure that your seat belts are functioning properly. Therefore, it is recommended to check them periodically.

There are several useful recommendations for this.

- Check whether the belts are twisted due to improper use.

- If the tapes are twisted, they may jam and retract incorrectly.

- Pull the belt out to its full length, straighten it and return it to its original position.

- Remove the tape completely and let it come together on its own.

- If the device jams when pulling in and out, check the condition of the tape, dirt, grease and other defects.

- Washing can only be done with a mild soap solution. If it is impossible to rinse with a weak solution, the belt must be replaced.

- Make sure the belt attachment points are secure and in good condition. All bolts must be tightened tightly.

- Check the condition of the device's fastenings to the body. Sometimes on a VAZ 2110, traces of corrosion appear in that area. All corroded elements must be replaced.

When replacement is required

There are several situations in which it may be necessary to replace just the tape or the entire device assembly.

We invite you to familiarize yourself with these situations in a special table.

How to repair seat belts of a VAZ-2110 car

All vehicles must be equipped with seat belts. And although in the VAZ-2110 the manufacturer made them as functional and wear-resistant as possible, this part is also not protected from breakdowns.

Possible problems:

- the belt jams and does not want to come out of the groove, both when pulled out sharply and when trying to pull it out slowly;

- the reel feeds the strap slowly, does not release it at all, or cannot place it in the technological space allocated for this;

- problems arise with the belt coming out from its seat, especially at sub-zero air temperatures;

- The lock does not hold the straps.

Most often, the causes of breakdown are mechanical defects that can be easily fixed on your own. However, it is worth considering that the manufacturer categorically does not recommend repairing elements of the driver/passenger protection system outside of service centers. Amateurish repairs can cause deterioration in the functionality of the belt and its failure to fulfill its tasks in a critical situation on the road.

Belt diagnostics

If, while using a seat belt in a VAZ car, the driver feels something is wrong, you need to check the quality of the device. What does that require?

- Make sure the belt feeds correctly. You need to check whether it is initially twisted. If the belt runs unevenly, it may well jam.

- Pull the belt out completely, straighten it and release it, checking that it is completely assembled. If this does not happen, you need to check the condition of the belt, blocker, and perhaps you need to clean out any debris or foreign bodies that are preventing the belt from working properly.

- Look at the fasteners. The belt must be tightly secured. A common problem in VAZ-2110 cars is rusting of the belt attachment points to the body. If there are already traces of corrosion, you need to thoroughly clean them or replace the rust-affected segments.

A dirty belt can be washed with soapy water. If you cannot clean it with this product, you can try more aggressive cleaning agents or completely replace this component, because Excessive contamination will not have the best effect on the functionality and safety of the belt.

What to do if the seat belt does not extend? We fix breakdowns

Even with new cars, there are situations when the seat belt does not extend or is pulled out, but with considerable force. Most often, this behavior of this protective device is observed in winter. The situation is unpleasant, to say the least - simply stalemate. The car is fully functional, but you cannot drive it without risking a fine. The seat belt does not extend for two reasons. This could be either a broken ratchet in the reel, or a frost-resistant lubricant was used when assembling the belt reel. If the temperature drops slightly, after standing overnight on the street or in an unheated garage box, the lubricant thickens to a semi-solid state, blocking the movement of the ratchet. Peculiarities of repair work There should not be any difficulties when independently repairing the belt coil. Problems may arise later if the car is involved in an accident and someone in it is injured due to improper functioning of the seat belts. According to official documents such as:

- UNECE Regulations No. 14 – 05;

- UNECE Regulations No. 16 – 04;

- GOST R 41.14 - 2003 (regarding the certification of cars with seat belts);

- GOST R 41.16 – 2005 (regarding certification of seat belts),

- independent correction of malfunctions in operation or unauthorized penetration by a manufacturer’s representative into the internal structure of safety belts is strictly prohibited, and if the facts of such actions are confirmed, the manufacturer is released from liability.

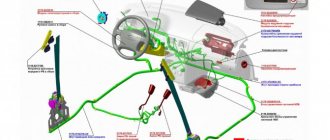

Due to the text of the State Standards summarized above, all subsequent measures to repair the coil fall heavily on the driver. It should be noted that many manufacturers of security systems reasonably do not believe that our domestic drivers have ever heard of these rules. Insuring themselves from inevitable litigation, they manufacture reels either in a non-disassembled version or with a mechanism that cannot be reassembled. Repair procedureThe design of the inertial ratchet mechanism of the reel consists of:

- housings;

- spiral configuration springs;

- coils;

- inertial disk;

- ball;

- guide ratchet;

- ratchet lock.

The order of work to repair the coil:

the front seats are moved forward as much as possible, the seat backs are also tilted forward and access to the coil mount is opened; the coil is dismantled; the belt is fully extended and the side of the blocker placement is determined by the presence of a plastic square; Important: an error with the determination will lead to disassembly of the coil from the spring side, which can severely cut your face and hands! by pulling out the four pistons, the housing cover is removed in a horizontal position; the coil is disassembled and access to the ratchet is opened; old thickened grease is removed from all moving parts; The reel mechanism is filled with frost-resistant lubricant, for example, Tsiatim 201 or a similar analogue (silicone-based lubricant can be used). Reassembling the coil occurs in the reverse order

Some, trying not to repeat history when the seat belt does not stretch, and in order not to repeat a similar repair procedure again, simply throw away the block with the ball. They argue for their actions that even without this mechanism, the belts will work and lock when the car turns over. This does not take into account the fact that the belts must also operate in the event of sudden braking or a strong sliding impact on the car body. When removing the ball, in such situations the belt will not work and the chances of injury increase. AutoFlit.ru

Checking the condition of the seat belt

To ensure proper operation of seat belts, they should be checked periodically.

In order to do this, you need:

- check the condition of the straps for mechanical damage;

- find out if the straps are twisted (to do this, the belt must be pulled out to its full length, if necessary, correct it and return it to its original position);

- check the movement of the belt - it should retract on its own (otherwise, you should inspect the place where it enters the retractor and, if there is dirt in it, clean it with a soap solution);

- check the locking force of the lock - it should firmly hold the metal tip of the belt, preventing it from being removed without pressing the button.

If during such a check damage is discovered that cannot be eliminated by washing and blowing with air, the entire device should be replaced.

Seat belt jammed: what to do, how to repair

› Salon

Any mechanism in a car can sooner or later fail and cause trouble for the driver. Sometimes this is not noticeable, but sometimes it immediately causes inconvenience. For example, this happens with seat belts. They serve to protect the driver and passengers from dangerous movements during an accident or sudden braking, thereby preventing injury.

This device was invented a long time ago, and throughout its use it has saved many people’s lives. A non-functional seat belt must be urgently replaced or repaired, as driving with it is dangerous. Moreover, this is a violation of the Traffic Rules.

When the seat belt does not extend, the problem can be solved using simple DIY methods.

Main causes of failure

If the seat belt in your car does not extend, it means it is jammed. To troubleshoot, you need to understand how the mechanism works. Most likely, the blocker has failed. Inside there is a sensitive element in the form of a ball, which performs blocking. It moves with levers and engages with gears. If it retracts quickly, the flywheel exerts more force on the screw surface and blocks the ball.

When the lock jams, even slowly pulling the belt does not help. Let's look at the possible causes of breakdowns.

- Most often, the belt does not extend due to excessive wear and tear on the locking system. This is due to failure due to wear of some parts of the mechanism. It’s good if such a malfunction is detected only when the driver is fastening it. It is more dangerous if the coil jams while the car is moving.

- The device is blocked due to a traffic accident. The design of the blocking device is made in such a way that if there is a strong impact, the squibs that are installed on some car models can be triggered. In this case, the lock is completely jammed and there is no way to unlock it.

- Breakage of some parts. There is only one way out - replace the defective parts or the assembly mechanism.

The driver may receive a signal that the seat belt is faulty. The type of signal depends on the vehicle model: in the form of a burning light or sound.

Coil problem

Modern seat belts are equipped with a special reel on which the belt is wound. It has a complex device that allows you to block the belt from being pulled out during a sudden jerk or a road accident. A problem may arise with such a reel if parts wear out, dirt gets in, starts to jam, or parts break.

In such cases, it is necessary to take immediate action, as this puts the driver and passengers in danger while driving. You can fix the problem yourself if you follow certain recommendations, which will be discussed in the following sections. But how can you check that the coil is working properly and that there are no problems before driving the car? There are methods for this.

Diagnostic methods

Let's look at the procedure and methods for checking the condition of seat belts. For example, let's look at how to carry out diagnostics on a Ford Focus car.

If an accident occurs and the airbags deploy, the belts must be replaced with new ones.

Insufficient belt retraction

If the belt does not retract well, check how the decorative covers are installed to make sure they are not touching the belt tape. Also check to see if the belt is rubbing against the retractor. If this is the case, then loosen the fastening bolt and align the device so that the tape is in the middle.

Most cars have 2 front and 3 rear retractable seat belts. They are equipped with double protection by sensitive elements.

- Vehicle motion sensor – blocks the belt during braking, sharp turns, descents, and ascents.

- Belt movement sensor – blocks it when pulled sharply.

These systems must function properly. To check them, special control methods are used.

First way

This will require the participation of two people. The first way is to slow down. During the inspection, people in the vehicle must not interfere with the operation of the seat belts.

- Choose a flat section of road with good visibility.

- The driver must sit in a comfortable position with the seat belt fastened and correctly adjusted.

- Drive no faster than 10 km per hour.

- Brake sharply to stop the car. If the locking is working properly, the belt will lock.

- The check is performed twice for the front and rear seats.

Causes of malfunctions

Among the common reasons when a problem or malfunction of the seat belt occurs in a car are the following:

- it has worn out, or rather the locking elements or other parts have become unusable;

- it cannot be pulled out due to sharply negative temperatures or wear of the roller mechanism;

- the reel lock is broken;

- after an accident, the squibs of the mechanism may work and the belt will be blocked;

- does not stretch, jam or jam.

These are the main most popular types of belt failures, but there may be more possible causes.

Sequence

the front seats are moved forward as much as possible, the seat backs are also tilted forward and access to the coil mount is opened; the coil is dismantled; the belt is fully extended and the side of the blocker placement is determined by the presence of a plastic square; Important: an error with the determination will lead to disassembly of the coil from the spring side, which can severely cut your face and hands! by pulling out the four pistons, the housing cover is removed in a horizontal position; the coil is disassembled and access to the ratchet is opened; old thickened grease is removed from all moving parts; The reel mechanism is filled with frost-resistant lubricant, for example,

Repair of inertial seat belt

Over time, the seat belt in the VAZ 2110 begins to jam, that is, it does not allow you to pull the belt out of the reel, even when you pull it very slowly. Or in winter, the belt is difficult to pull out of the reel and you have to put in a lot of effort to fasten it.

Many owners of tens face two unpleasant moments when using seat belts:

- The seat belts jam even when you pull them out very slowly.

- Seat belts are too tight in the cold

According to UNECE Regulation No. 14-05; 16-04, GOST R 41.14; 41.16. Belt malfunctions (does not hold the lock, the reel lazily retracts the strap or does not fix it, etc.) cannot be eliminated yourself! Any tampering with the design or installation method of the seat belt relieves the manufacturer of the seat belt from liability for proper operation of the seat belt and any injuries sustained in an accident. Some locks, retractors, etc. They are specially made so that after disassembly they can no longer be reassembled. But blowing with compressed air is permissible; Therefore, you do all actions with seat belts at your own peril and risk. The author is not responsible for any damage and injury associated with tampering with seat belts.

How seat belts work:

The coil lock is made on the basis of a ratcheting mechanism, locked by a sensitive element - a pendulum with a hemispherical support or a metal ball located in a sphere of larger diameter. The ball or pendulum, moving, fixes the ratchet gear of the reel to the body through a system of levers. A flywheel disk is installed on its axis on screw splines with a small angle.

When the strap is pulled out slowly, the disk only rotates with the shaft due to friction, without locking the reel.

note

When the belt is jerked, the disk, by inertia, presses harder on the screw surface, overcomes the friction force and, moving along the screw slots, blocks the ratchet. In order to repair the seat belt reel with your own hands, you need to: Remove the seat belt reel.

It is not necessary to remove the seats for this, just move them forward and tilt the backrests forward. We determine the side where the locking device is located (as a rule, this is the thicker half). You can determine this by shaking the belt near your ear, where the ball will be strumming, there is a blocker there.

Or you can completely unwind the belt, the blocker is on the side where there is a plastic square on the sidewall.

Remove the cover (you need to remove 4 pistons). Be careful not to let the insides fall apart! The cover must be removed in a horizontal position.

- We disassemble the seat belt reel (without effort) and get to the locking ratchet.

- Having reached the rubbing parts, we remove the thickened lubricant, which looks like a dry substance and only interferes with the smooth operation of the locking mechanism.

Nearby, in a rectangular body with a tab, there is a ball that blocks the belt when the reel body is tilted. Lubricate the seat belt reel mechanism. And you need to lubricate with a lubricant that does not thicken in the cold (litol, CV joint, fiol, engine or transmission oil are not suitable). You need frost-resistant lubricant Tsiatim201 (or its equivalent), or a good silicone lubricant.

In addition, for more precise operation of the seat belt mechanism, you can bend the bracket, or rather, bend the copper tab on which the ball acts. The fact is that due to the weight of the ball, it bends slightly and the belt works worse and worse.

That is, you need to reduce the bending angle of the copper tab so that when the coil is in a vertical position, the latch does not engage with the teeth of the coil. We check that when the coil is tilted, the lock is activated.

There are opinions that you can simply throw out this block with a ball and the seat belts will work without problems, however, this latch is activated not only when the car turns over, but is also an inertial mechanism and will block the belt even during sudden braking or strong shaking of the body. Therefore, there is no need to throw anything out of the seat belt reel.

Repair process

Now that we have dealt with the signals and reasons for blocking a fastened and unfastened seat belt, let’s move on to the repair process. Cleaning seat belts is one of the main tasks in this process, so we will consider this procedure separately. So, what should you do if you receive a signal that the lock is jammed? How can I clean it or turn it off? You will learn more about this below.

Tools

To disable the lock if a corresponding signal appears, the entire mechanism will need to be cleaned. To do this, you need to thoroughly prepare in advance and collect all the necessary tools. so what to prepare:

- a Phillips screwdriver, preferably a short one;

- flat head screwdriver;

- a wrench set to “17”, it will be more convenient to use a socket wrench;

- stationery pin;

- syringe with tube;

- some gasoline (lighter fuel is ideal).

Step by step instructions

When the entire list of tools is ready, you can begin repairing and cleaning.

- Using a Phillips screwdriver, unscrew the screws that secure the strap protection.

- If the lock is not working, pull the strap out to its full length and secure it with a clothespin.

- Take a wrench and remove the screw that secures the element coil. The screw must be removed from its installation location. To prevent the element from starting to unwind, you can attach it directly to the same spool using the same clothespin. In any case, in order to disable and clean the lock, it must be locked to make further actions easier.

- Put the reel aside and sit in the next seat. To disable and clean the lock, you will need to find the lid behind which the inertial device is hidden. As a rule, it is slightly thicker in design. Shake the coil - under which cover you hear the noise - under that one it is located.

- Now to dismantle the protective cover you will need to remove four plastic pistons. This can be done using a slotted screwdriver or a thin knitting needle. The pistons should be supported by hand so that they do not fly out and you do not have to look for them and collect them throughout the cabin. Then pry up the cover with a screwdriver and remove it. Set the lid aside.

- Your view will now be presented with the first mechanism of the component. It is a kind of box with a cylinder and thus a locking ball and a so-called rocker inside, which jams the lock. This mechanism can be dismantled freely from the installation site.

- Check the functionality of this rocker - ideally it should move freely along the axis of rotation. This device should be positioned vertically with the top angled toward the locking ball. One way or another, the rocker arm must be positioned vertically so that it does not jam. If you feel that the so-called rocker arm does not move freely, then you need to clean its rotation axis. Pour some gasoline and rinse the device until it rotates freely on the axis, without the slightest jamming.

- Now let's move on to the second, inertial device. It is located under the gear, which is made of plastic and in most cases is made of steel. The gear comes off freely, so remove it.

- Note the center of the serrated hole. It contains an eccentric with teeth. It is these teeth that jam the strap when it is suddenly pulled out. The space under this very eccentric needs to be cleaned. Pour a little prepared gasoline around the entire perimeter of the hole, add a little fuel to the center. At the same time, hold the strap, preventing it from winding up, for which you can temporarily remove the clothespin. Make sure that the liquid gets into all parts of the element, otherwise cleaning it will be useless.

- Take the dismantled spool with one hand so that the plastic guide along with the spring can be supported with one finger. Using your other hand, pull and wrap the safety element several times. Also pull it a few times until the device itself engages. Next, hook it on the reel one more time. These steps should be repeated several times.

5. This is what the inertial mechanism looks like, which should be filled with gasoline.

At this point, the process of cleaning the mechanism can be considered complete. You should carry out all further assembly in reverse order. Do everything correctly, because an incorrectly assembled mechanism will cause breakdowns in the near future with regular use of the straps.

Also check in advance whether all elements of this node work correctly and move freely. If this is not the case, then the cleaning should be repeated, because what is the point if everything is not cleaned. Only with the right approach to such repair work will you be able to avoid major mistakes and carry out all actions correctly.

If you are not sure that you can do all the steps described in this article correctly, then we recommend that you contact a service station with this question. After all, if the seat belts are locked, you need to do everything correctly, and incorrect actions will only cause further breakdowns, which you are unlikely to want to encounter. In any case, washing the components is not the most radical measure, because you will always have time to change the mechanism.

Seat belt device

If the belt does not come out of its slot, it is most likely jammed. To fix the problem, you need to understand the principle of this element of the car. With such a breakdown, there is a high probability that it is the locking mechanism that is not working correctly. Sometimes the belt may not stretch after an accident. There is a special technology for eliminating such breakdowns.

First of all, you should understand the seat belt design. There is a special element inside the locking mechanism that is responsible for fixation. It looks like a ball that moves through levers. At the same time, it clings to the gears of the coils.

The seat belt latch reacts when it is pulled out too quickly, blocking the ball. It is in this system that problems may appear over time. In this case, the belt may not stretch or, conversely, may remain locked in the fastened position.

Effect of frost

Sometimes the seat belt latch may not work due to extreme cold. This will not require changing any parts. In some older vehicles, the insulation of the mechanism may not be sufficient. This causes the belt to jam.

In this case, the oil that lubricates the system becomes thicker in the cold. You will have to disassemble the coil and lubricate its elements with a special substance. It must be frost resistant. This, for example, could be silicone grease or lithol.

In some cases, the situation can be corrected by bending the metal “claw” of the ball mechanism at a smaller angle. When the coil is positioned vertically, the retainer should not come into contact with the gear teeth. This should only happen when the bobbin is tilted.

These simple steps will prevent the squib from accidentally firing. Otherwise, you may be injured during the repair process.

The coil housing needs to be opened. Most likely, the spring of the tape return mechanism has failed. This element can be replaced. It will be easier to get it out than to install it in its original place.

Operating principle and main malfunctions

All seat belts are built on the same principle and may differ only in certain small details. The locking system of their coil is based on the operation of a ratchet mechanism when exposed to a sensitive element (the role of the latter can be played by either a pendulum or a steel ball placed inside the sphere).

They operate as follows:

- under the influence of inertia, the sensitive element moves, fixing the ratchet gear through a system of levers;

- when the belt moves slowly, the flywheel disk, located on the helical splines of the ratchet gear, rotates along with its shaft without locking the belt reel;

- during a sudden movement or jerk, the disk, moving by inertia, moves along the screw slots and, due to the friction force, blocks the coil.

Despite this seemingly not too complicated design, seat belts still break, thus losing the ability to normally perform their main function.

So, the most common damage to their mechanism are:

- belt jamming (in some cases, even when pulling it out very carefully);

- heavy belt travel (especially in a car with an unheated interior in the cold season);

- reel sluggishness (retracts the strap poorly);

- failure of the coil (does not hold the strap at all);

- lock breakdown.

In all these cases, the only correct solution can be to replace the VAZ 2114 seat belt. This is due to the fact that manufacturers’ instructions and existing rules directly prohibit independent repair of seat belt mechanisms, since very often after such intervention they cease to function correctly.

This, in turn, can lead to extremely tragic consequences in the event of a traffic accident. For the same reason, some belt models are made non-separable or do not allow reassembly after their mechanism has been opened.

The only available option for repairing them is to blow them with compressed air, which allows you to remove the dust accumulated in the mechanism.

Popular faults

There are several main problems associated with domestic “ten” belts:

- The belt is jammed. Moreover, this can happen even with gradual, slow pulling of the device.

- The belt comes out of its seat tightly when it freezes.

- The lock does not hold the device.

- The reel slowly pulls out the strap.

- The reel cannot properly secure the strap, etc.

There may be more problems, the most common of which is mechanical damage to the tape.

IMPORTANT!!!

There are international rules and state standards that relate directly to seat belts. They say that trying to fix the breakdown of this unit yourself is strictly prohibited. Any intervention in the design without the knowledge of official service centers entails not only the removal of responsibility from the manufacturer.

If the mechanism is not repaired correctly, it can lead to injury in accidents because the device no longer works properly after the intervention.

Shoot carefully

It is also worth noting that some locks, belt retractors and other system components are designed in such a way that the car owner cannot put them back together after disassembly. The only possible option is blowing with compressed air.

All operations related to seat belt repair are carried out solely at your own peril and risk. No one will be responsible for the consequences. Repair instructions exist, but before using it, think carefully about whether it is worth attempting to repair this unit yourself.

How to unlock

Naturally, if the belt is stuck, it is best to turn to professionals. But, if you don’t have enough money, but have a lot of free time, and also if you want to learn something new, you can perform this operation yourself. There are several options that we will now share with you.

Squib with bushing

First, you need to remove the entire seat belt mechanism. In most cases this does not cause problems. Although in certain cars, to dismantle this device you will have to remove the front wheels. Now we are looking for access to the squib (it is the one that blocks the entire system). With the mechanism in hand, look for the spring. Carefully unscrew all the bolts to remove it (sometimes it may fly out). Next, remove the belt and, without twisting it, set it aside. Afterwards you will see the squib shell, which needs to be removed from the belt (use an asterisk key for this purpose). The next step: you need to remove the cover of the device (it can be fixed not only with bolts, but also with sealant). In this case, we recommend using a stationery knife. In front of you will be a nylon bushing with six copper scraps (they are the ones that block the belt). These pieces need to be removed. Do not touch the bushing while doing this. Reinstall the squib and screw this device into the mechanism body

It is important that before installing it in place, tighten the belt with your own hands - a few circles will be enough. Why do this? After such manipulations, the spring will weaken slightly. Place the spring in its place and secure it. Work completed

If the strap still does not work, it will have to be replaced.

Rack

Using a ribbed strip, it will be possible to unlock the belts if they are jammed after a traffic accident.

- Remove the mechanism, and then disassemble the tensioning device.

- Disassemble the squib.

- Next you will see a gear rack (they are already broken, remove it and replace it with a new one).

- Your next steps: after dismantling the gear, you will notice a lot of debris and dirt - they need to be removed.

- Reassemble in the reverse order of disassembly.

Removing and installing rear belts

Rear seat belts are an extremely necessary item to protect passengers from injury in the event of an accident. Unfortunately, many drivers previously neglected safety and abandoned them due to small fines for their absence. Now the situation has changed for the better, and many are interested in how to install them. We’ll talk about this too, but first we’ll find out how to remove the seat belt on a VAZ 2114.

For this you will need:

- ratchet;

- head at 17;

- screwdriver with a thin slotted blade.

Necessary tool

The belts are dismantled in the following order:

- Remove the seat belt buckles located on the floor.

- Use a screwdriver to pry up the plastic cap located near the threshold and remove it.

Removing the plug

- Unscrew the fastening bolt located under the cap.

- Unscrew the fastening bolt located on the side pillar.

- Open the trunk.

- Find the retractor coil bolt in the trunk (closer to the passenger compartment) and unscrew it. To perform this operation, it is best to use a ratchet with an extension.

- Remove the coil.

- Insert the second part of the belt and its fasteners through the hole in the shelf, and then completely remove the entire device.

Removing seat belts VAZ 2114

The rear seat belts of the VAZ 2114 should be installed in exactly the same order, but in reverse order. After installation, check the condition of the lock and the smooth running of the belt.

Design and operating principle

The design of the protective device in question is represented by a retractor reel, a lock and a tape. High-strength material is used to make the tape; this element is fixed to the body in several zones as follows:

- in the area of special traction with a lock;

- on the counter;

- in the threshold area.

The main purpose of the lock, in turn, is to lock the belt. This element is located near the seat. A movable tongue made of durable metal simplifies the operation of the belt; it is located directly on the belt. You can find a retractor coil on the car body pillar. Its purpose is to forcefully wind and unwind the tape. The design of the retractor reel provides for the presence of an inertial locking mechanism, due to which, in the event of a sudden stop, the movement of the belt is stopped and the person remains in a fixed position, not being able to go into free flight through the windshield.

The principle of operation is nothing complicated: the action of a coil with a blocker is based on a gear mechanism that rotates it. The closing of this mechanism occurs through a pendulum; it can have a ball or spheroid support with a lever system.

Smooth unwinding of the tape promotes rotation of the support along with the reel gear, while sudden tension leads to blocking of the flywheel.

Design and operating principle

The design of the protective device in question is represented by a retractor reel, a lock and a tape. High-strength material is used to make the tape; this element is fixed to the body in several zones as follows:

- in the area of special traction with a lock;

- on the counter;

- in the threshold area.

The main purpose of the lock, in turn, is to lock the belt. This element is located near the seat. A movable tongue made of durable metal simplifies the operation of the belt; it is located directly on the belt. You can find a retractor coil on the car body pillar. Its purpose is to forcefully wind and unwind the tape. The design of the retractor reel provides for the presence of an inertial locking mechanism, due to which, in the event of a sudden stop, the movement of the belt is stopped and the person remains in a fixed position, not being able to go into free flight through the windshield.

The principle of operation is nothing complicated: the action of a coil with a blocker is based on a gear mechanism that rotates it. The closing of this mechanism occurs through a pendulum; it can have a ball or spheroid support with a lever system.

Smooth unwinding of the tape promotes rotation of the support along with the reel gear, while sudden tension leads to blocking of the flywheel.