Probably every owner of a domestic car has encountered a situation where the information on the dashboard about the fuel level in the tank did not correspond to reality. This is a fairly common and unpleasant phenomenon, characteristic mainly of older machines.

The VAZ-2114 fuel level sensor with an injector performs one simple but extremely useful task - it informs the driver about the remaining fuel in the gas tank. During the operation of the car, the contacts of the mechanism oxidize, and the sensor itself begins to function incorrectly.

On what principle does the device work and how to replace it if necessary?

What does the fuel level sensor consist of and how does it work?

The fuel level sensor can work properly for a long time. The mechanism itself is not one of the most painful areas of the VAZ-2114, but, like all other devices, sooner or later it fails. Its breakdown is most often due to the fact that the FLS is in unfavorable conditions.

The device body is quite fragile, which often leads to the sensor breaking due to mechanical damage. Among other things, constant temperature changes significantly reduce its service life. The fuel sensor of the VAZ-2114 is especially painful during the frosty season.

The main purpose of the fuel level sensor is to determine the fuel level in the gas tank and transmit the received data to the indicator, which informs the driver.

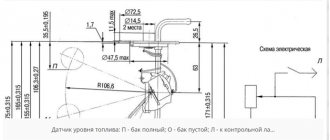

In a VAZ-2114 car you can most often find a sensor of the BM-150 type. Regardless of the design feature, the operation of each fuel controller is based on a measuring float made of lightweight material. The operating principle of the device is as follows: a unique signal corresponds to a certain amount of gasoline in the tank. The design also includes a lever and a resistor element.

Taken together, all the parts of the device make it possible to measure resistance, which has different indicators depending on the level of gasoline. Using a sliding contact, it is possible to turn on and off a special indicator on the dashboard.

A full tank has a resistance of 20 ohms, an empty tank has a resistance of 300 ohms.

Why does the sensor give incorrect readings?

The fuel level sensor of a VAZ 2114 car may not work correctly, giving false readings, for the following reasons:

- There is additional resistance in the circuit - the connectors have oxidized, deposits have appeared on the resistive layer and the sliding contact.

- The float casting was deformed, causing the float to fill with fuel. This cause of malfunction occurs infrequently.

- A coating has formed on the guide, making it difficult to move the float.

The fuel gauge indicator always shows that the tank is completely full if the float has come off the sliding contact. In addition, such a malfunction may be due to the fact that the wire that goes to the instrument panel has a short, causing the resistance in the circuit to decrease.

Common FLS malfunctions

Often, the driver can observe the following situation: while driving on a flat road, the instrument panel displays information about a full tank, and after driving off-road, about an empty one. The readings jump, which is clear evidence of a malfunction of the VAZ-2114 FLS. This disease often manifests itself due to wear on the contact tracks.

In some cases, the situation can be corrected quite easily - bend the slider so that it is located above the worn-out place in the diagram. But such a solution to the problem is not always appropriate. Sometimes you have to replace the entire regulator.

see also

Other malfunctions of the mechanism include:

- The pointer is at zero - most likely the problem is related to the limited travel of the float.

- The low fuel light does not light up - there may be a problem with the potentiometer.

- When starting the engine, the indicator does not light up - there is a problem with the electronics.

- Incorrectness of the data displayed on the instrument panel - you should check the tightness of the float.

If such symptoms of a device malfunction appear, experts also recommend checking all the wires securing the nut sensor. The fastening elements clamp the mass, so if they are not tightened well, the contact will appear and disappear. If the sensor does not show the fuel level of the VAZ-2114, then the contacts need to be cleaned, and if this cannot be done, then they can be completely replaced.

Car electrical equipment

1 — headlight block; 2 — gearmotors for headlight cleaners*; 3 — fog lights*; 4 — ambient temperature sensor; 5 — sound signals; 6 — engine compartment lamp switch; 7 — electric motor of the cooling system fan; 8 — VAZ 2114 generator; 9 — low oil level indicator sensor; 10 — washer fluid level sensor; 11 — front brake pad wear sensor; 12 — wire tips connected to the common windshield washer pump**; 13 — windshield washer pump; 14 — headlight washer pump*; 15 — wire ends for connecting to the rear window washer pump on VAZ 2113 and VAZ 2114 cars; 16 — low oil pressure indicator sensor; 17 — engine compartment lighting lamp; 18 — wire lug for connection to the wiring harness of the engine management system or to the wiring harness of the ignition system on carburetor vehicles; 19 — windshield wiper gearmotor; 20 — VAZ-2114 starter; 22 — coolant temperature indicator sensor; 23 — reversing light switch; 24 — low brake fluid level indicator sensor; 25 - battery; 26 — sensor for insufficient coolant level indicator; 27 — relay for turning on fog lights; 28 — mounting block; 29 — brake light switch; 30 — plug socket for a portable lamp; 31 — lamp for illuminating the headlight hydrocorrector scale; 32 — parking brake warning lamp switch; 33 — backlight lamp connection block; 34 — switch for instrument lighting lamps; 35 — steering column switch; 36 — alarm switch; 37 — front seat heating element relay; 38 — ignition switch VAZ 2114; 39 — rear fog light circuit fuse; 40 — fuse for the front seat heating elements circuit; 41 - door lock circuit fuse; 42 — front ashtray illumination lamp; 43 — ignition relay VAZ-2114; 44 — cigarette lighter; 45 — glove box lighting lamp; 46 — glove compartment lighting switch; 47 — heater fan electric motor; 48 — additional resistor of the heater electric motor; 49 — heater fan switch; 50 — heater switch backlight; 51 — lamp for illuminating the heater levers; 52 — gear motors for electric windows of the front doors; 53 — right front door power window switch (located in the right door); 54 — gearmotors for locking front door locks; 55 — wires for connecting to the right front speaker; 56 — gearmotors for locking rear doors; 57 — wires for connecting to the right rear speaker; 58 — door lock control unit; 59 — wires for connecting to radio equipment; 60 — headlight cleaner switch; 61 — rear window heating element switch; 62 — relay for turning on rear fog lights; 63 — block for connection to the heating element of the right front seat; 64 — switch for rear fog lights: 65 — switch for the heating element of the right front seat; 66 — fog lamp switch; 67 — switch for external lighting lamps; 68 — left front seat heating element switch; 69 — block for connection to the heating element of the left front seat; 70 — wires for connecting to the left front speaker; 71 — left front door power window switch; 72 — right front door power window switch; 73 — wires for connecting to the left rear speaker; 74 — side direction indicators: 75 — lamp switch on the front door pillars; 76 — lamp switch on the rear door pillars; 77 — lampshade; 78 — canopy for individual interior lighting; 79 — block for connecting to the wiring harness of the VAZ 2114 electric fuel pump; 80 — trunk light switch; 81 — instrument cluster: 82 — trunk lighting lamp; 83 — display unit of the on-board control system; 84 — trip computer (not in all models); 85 — block for connecting the wiring harness of the engine control system; 86 — rear external lights of the VAZ-2114; 87 — rear internal lights; 88 — block for connection to the rear window heating element; 89 — license plate lights; 90 - additional brake signal located in the spoiler.

Replacing the FLS on a VAZ-2114

Even a novice driver can repair the sensor with his own hands. Of course, the breakdown should not be serious, then replacing the failed element will not be difficult and will not take much time. For example, if a float breaks, you can always purchase a new copy on the automobile market. The old float is easily removed from the holder and a new one is installed in its place.

Oxidized wires are also often replaced with new ones if stripping them is impossible. The price of a new sensor is relatively low, so most often drivers prefer to simply purchase a new mechanism.

The process of replacing the FLS on a VAZ-2114 includes the following procedure:

- Remove the lower part of the rear seat and remove the upholstery, since the sensor is a structural part of the fuel pump. It is impossible to get to the mechanism without going through the module.

- Using a key number 7, release the two screws securing the gas tank cap.

- Then you need to unscrew eight more screws securing the edge of the lid.

- After these steps, the cover can be easily moved forward.

Checking the device with an ohmmeter

It is not always necessary to immediately replace the sensor with a new one. It happens that the problem lies in a completely different component of the car, for example, an injector. Also, if the meter is faulty, it may be possible to repair it.

Before replacing, check the sensor:

- To test the device, connect a resistance meter to its terminals. This indicator must be measured when the lever and float are in extreme positions or in the middle.

- In the lower position, meaning zero fuel level, the resistance should be 285–385 Ohms.

- In the central position, which means the tank is half full, the ohmmeter should show 100-135 ohms.

- The highest position is a 100 percent filled tank. The ohmmeter should read 7–25 ohms.

If in at least one position the readings obtained diverge from normal, repair or replace the sensor. After installing the new meter, make sure that the installation arrow on the module cover is directed towards the trunk. Otherwise, you will need to dismantle the system again and repeat the replacement.

How does the device work?

To understand the problem yourself, you need to understand how the fuel level is measured and information is transmitted to the device indicator. The circuit implemented in most vehicles includes the following main elements:

- a float made of lightweight polymer is immersed in the gas tank and is often combined with the pump block;

- gasoline sensor – lever-type potentiometer (otherwise known as rheostat);

- pointer arrow with scale;

- connecting wires.

In many modern cars, an electronic control unit is connected to the system.

The classic rheostat is an open coil of high resistance wire. A lever equipped with a contact and attached to the float rises or falls with the level of fuel in the tank, and the contact moves along the turns of the winding. The classic scheme works simply:

- The rheostat and the pointer device are connected in series in the circuit, both are powered from the vehicle's on-board network.

- When moving the float with the lever, the resistance of the potentiometer changes.

- A change in resistance causes an increase or decrease in the current in the circuit, to which the indicator arrow reacts. The scale is graduated according to the resistance values corresponding to the filling of the gas tank.

The updated version of the system works with the participation of a controller. The fuel level arrow receives a processed digital signal from the electronic unit that supplies power to the potentiometer. The principle of operation does not change, but the circuit allows you to obtain more accurate readings.

Heater diagram, rear window heating

- Mounting block;

- Ignition switch;

- Ignition relay;

- Heater motor switch;

- Additional resistor;

- Heater motor;

- Rear window heating switch with turn-on indicator lamp;

- Rear window heating element; K7 - Relay for turning on the heated rear window

Common problems

The fuel volume control system in the gas tank is susceptible to the following malfunctions:

- the pointer indicator lies at zero regardless of the amount of fuel remaining in the tank;

- the device does not display the fuel level correctly - it is lying up or down;

- the needle “jumps” or changes readings in a short period of time;

- The yellow minimum fuel indicator indicator does not light up.

Reference. In some domestic car models, the fuel sensor is lying from the factory. An example is the Chevrolet Niva SUV of the first releases, where the device greatly underestimates the actual level of gasoline. The driver, guided by the sign, pulled into a gas station, only to discover that the tank was full to the top.

There are several reasons why the needle drops to zero:

- Sticking or jamming of the lever.

- The float lost its seal and sank to the bottom.

- An electrical circuit is broken due to oxidized contacts or a wiring problem.

- Failure of the indicator itself or the lever sensor - potentiometer.

Fuel module

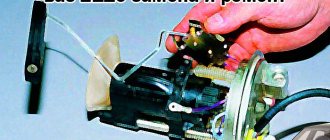

The fuel module is a single unit, which includes the pump itself, a fuel level indicator sensor assembled with a plastic float, an intake chamber, and a filter (mesh).

The fuel module for 1.5 and 1.6 liter engines is different.

Fuel module for engine 2111 (1.5I) – CODE 2112-1139009-12.

Fuel module for engine 11183 (1.6I) – CODE 21101-1139009-01.

Signs of a fuel pump malfunction

- The car won't start. A possible reason could be a non-working or semi-working fuel pump. The fuel pump must create a certain pressure in the fuel system for normal operation. But the cause of the malfunction can be not only the fuel pump; in any case, the first thing you need to do is measure the pressure in the fuel rail, check the spark and then draw the appropriate conclusions. More detailed information can be found here.

- The fuel pump does not “buzz” after turning the ignition key. Here, most likely, the issue lies in the wiring to the fuel pump. A separate article is devoted to this problem.

- Interruptions in engine operation.

- The car jerks at low speed. Again, the fuel pump itself may be fine; here the problem may be the low-purity filter (mesh) under the fuel pump.

What pressure should the fuel pump create?

The pressure created by the fuel pump must be at least 3.2 bar.

Operating pressure in the fuel rail for a 1.5 liter engine: from 285 to 326 kPa.

For a 1.6L engine: from 375 to 390 kPa.

If the pressure does not correspond to performance indicators, then the following elements may be possible causes of the malfunction:

How to replace the fuel pump?

The fuel pump must maintain constant pressure. If at 3000 rpm the pressure begins to gradually drop, then the fuel pump simply does not have time to pump. This fuel pump needs to be replaced. To replace the fuel pump, use the article.

Where is the ground for the fuel pump (fuel pump)?

The weak point on Samara is the weight of the fuel pump. Due to oxidation or poor contact, the car begins to start poorly, and in general there are problems with starting the engine. The fuel pump ground mount is located under the handbrake lever mount.

In any case, the first thing you need to do is check the pressure in the fuel rail, then draw conclusions.

Diagnostics and repair methods

To check and identify a malfunction, perform a number of preparatory work:

- Find a service hatch in the car that gives access to the electric fuel pump and float mechanism unit. Usually located under the rear sofa, where the fuel tank is installed.

- Unscrew the pressure flange and pull the assembly out through the hole. Clean all contacts and the rheostat plate, reinstall the unit.

- Prepare a “control” with a light bulb and a multimeter.

The first step is to accurately determine the “culprit” - check the sensor and pointer separately. The performance of the device is diagnosed as follows:

- Turn on the ignition and connect one terminal of the multimeter or test light to the ground of the car.

- Connect the second contact to the positive terminal of the wire going into the technological opening. The meter should show the voltage of the on-board network.

- Remove the positive terminal and short it to ground. If the instrument on the panel is working properly, the arrow will show a full tank. This means the fuel level sensor is not working.

- If there are 2 wires coming to the gas tank, connect them alternately to the vehicle ground. From one the control lamp should light up, from the second the pointer should move to maximum. If the listed symptoms are observed, change the sensor.

In the case when there is a voltage of 12 volts on the wires, but after a short to ground the pointer indicator does not respond, you will have to disassemble the dashboard and remove the device. Similar actions are taken when the minimum gasoline remaining indicator is not working.

It is somewhat more difficult to independently check the updated system installed in cars of recent years; simply shorting the terminals will not do anything. Using a multimeter, make sure that there is supply voltage on the wires, and then you need to connect another, working sensor to them. If the arrow on the instrument panel reacts when the float moves, the element should be replaced.

Thorough cleaning of the slider and rheostat turns helps in cases where the fuel level sensor simply lies. The moving contact can be carefully bent so that it passes along the unworn part of the turns. Clean the current-carrying strips of the potentiometer with a soft cloth soaked in alcohol to avoid damaging the surface of the element.

Some gasoline sensor malfunctions can be eliminated in a garage:

- a “sunken” float with a crack is replaced as an assembly with a lever or separately (depending on the make of the car);

- the torn conductors are connected using a conventional soldering iron;

- the damaged rheostat plate is replaced with a new one, provided that the spare part for your car is on sale.

At the moment, repairing the fuel level sensor is becoming irrelevant. Considering the cost of a new element, it is easier and more reliable to replace a non-working part.

If the indicator and the gas remaining meter are working properly, but the arrow of the device is lying, try making adjustments. Carefully bend the float rod in the desired direction and check the readings again. To achieve maximum accuracy, the operation will probably have to be repeated several times.

The constant presence of a small canister of gasoline in the car or the car owner voting on the highway with a request to refuel, all this is a consequence of the fact that the fuel sensor in the car does not work. The breakdown of this sensor does not affect the operation of the main mechanisms of the iron horse, but it significantly affects the comfort of using the car, since there is always a need to calculate how much the car has traveled since the last refueling and how many more kilometers can be driven without stopping at a gas station.

Author of the article: mudriy_lev Specialization: repair of auto generators and servos in cars. Place of work: service center. Experience: 2 years. Education: higher education - electrical engineer, secondary specialized education - mechanical assembly mechanic.

Let's look at the main reasons.

Potentiometer and its problems

Modern cars are equipped with a wide variety of fuel level sensors. The widest niche has been occupied by sensors based on potentiometers. This type of conversion of fuel level information into an electrical signal has many advantages. There are two types of sensors based on this method of measuring fuel level:

- lever (widespread)

- tubular (used mainly on large vehicles)

The float is not informative

Problems when the fuel gauge does not work are often related to the float. There are 2 types of floats installed on cars:

- hollow (plastic, plastic, metal)

- made of lightweight porous material

The first type of float faces the problem of mechanical damage. As a result, the indicator needle gradually does not reach the maximum when the tank is full more and more. The float fills with gasoline and the gasoline sensor shows the wrong level more and more every day. Repair in this case is carried out by replacing the float.

The second reason why the fuel sensor is lying is encountered by both types of float. As a result of mechanical damage to the gas tank, the float becomes jammed. In this case, the indicator will show either a single value or work only in a small range. Elimination of this breakdown is possible only by replacing the gas tank.