What is DMRV

This control device is installed on the inlet pipe. The signal coming from it is a direct current, the voltage value of which indicates the incoming air volumes.

It consists of the following elements:

- filter;

- fixing ring;

- inlet;

- thermocouples;

- detachable terminal;

- outlet flange.

The air passing through it cools the thermoelement, which is responsible for determining the ambient temperature. The rest ensure its heating to operating levels.

The energy consumption spent on this, in turn, indicates to the ECU the mass flow of oxygen at a given time.

Symptoms of a problem

Failure of this monitoring device can occur for several reasons.

If it breaks down, the Check Engine light on the instrument panel will flash. Usually this is also accompanied by the display of code 33 or 34. In addition, the symptoms of a breakdown are indirectly:

- loss of power of the power unit;

- significantly increased fuel consumption;

- slow acceleration;

- poor engine starting or inability to start;

- unstable idle speed.

It is worth pointing out that exceeding the gasoline consumption indicator often indicates a faulty pump. However, in no case should you forget to check the mass air flow sensor.

An incorrect fuel to air ratio causes the resulting mixture to not burn properly. It is this circumstance that does not allow the car to accelerate quickly. Another symptom worth mentioning here is jerky acceleration if you sharply squeeze the gas.

Whether it is a rich or lean mixture, in none of these cases does normal detonation occur. This, in turn, leads to poor engine starting. Often, excess gasoline burns out in the muffler - as a result, periodically loud pops are heard there.

Consequences of sensor failure

When, for various reasons, the sensor fails or produces incorrect readings, the controller changes the operating algorithm. He begins to prepare the air-fuel mixture, focusing on the throttle position meter and lambda probe. Due to the lack of data previously received from the mass air flow sensor, the electronic unit “does not know” about the real amount of incoming air and cannot mix it with gasoline in optimal proportions.

By switching the controller to emergency operation mode, you can determine the main symptoms of a malfunction of the mass air flow sensor:

- on the driver’s dashboard, the control unit turns on the Check Engine light display, indicating problems in the fuel supply or ignition system;

- idle speed is unstable - it either rises to 1500 rpm, then drops to zero (the engine stalls);

- “When cold” the engine starts with great difficulty;

- incorrect preparation of the combustible mixture causes an increase in fuel consumption, regardless of driving conditions and operating mode;

- There is a decrease in the power of the power unit and frequent unreasonable jerks while driving.

Note. The inclusion of the Check Engine indicator does not provide the driver with specific information about the nature of the breakdown. The inscription calls for diagnosing engine systems using a computer connected to the service port. In this way, you can check the performance of the mass air flow sensor and other sensors in a service station.

Indirectly, a malfunction of the flow meter is indicated by the appearance of black smoke from the exhaust pipe. If the vehicle does not have an on-board computer and it is impossible to track instantaneous gasoline consumption, it is worth unscrewing 1-2 spark plugs from any cylinders and inspecting the electrodes. A layer of black soot will confirm excessive enrichment of the mixture due to emergency operation of the electronics.

Diagnostics

During diagnostics, first of all, the clamp holding the air supply pipe to the mass flow sensor is loosened. You will need a Phillips screwdriver here. The corrugation itself must also be inspected. Its inner surface must be clean and dry. The presence of traces of dampness or condensation indicates a failure of the air filter. Its malfunction usually leads to rapid failure of the mass air flow sensor.

Next, use a 10mm wrench to unscrew the sensor clamps, after removing which it is necessary to carry out an external inspection. It is important to pay attention to the seal - it is normally located at the very edge of the flange. Displacement of it leads to contamination of the internal elements of the sensor.

Checking the performance of the mass air flow sensor is carried out using a multimeter. The procedure is as follows:

- disconnect the terminal supplying the sensor;

- the tester probes are connected to the wires (red to yellow and black to green);

- in this situation, the mass air flow sensor begins to function in emergency mode, that is, the air supply occurs according to the latest data received from it.

- when the supply circuit does not close when the motor is turned on, then we can say with confidence: it is the sensor that is faulty.

- up to 1.02 – mass air flow sensor is working;

- up to 1.03 – slight wear;

- up to 1.04 – operability preserved;

- up to 1.05 is the maximum permissible norm.

Anything that exceeds the level of 1.05 volts indicates a breakdown of the sensor.

Stories from our readers

“Fucking basin. "

Hi all! My name is Mikhail, now I’ll tell you a story about how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was broken, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the tenth years.

Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not a new one, on credit is unreasonable. My salary is 24k a month, so collecting 600-700 thousand is almost impossible for me. I started looking for different ways to make money on the Internet. You can’t imagine how many scams there are, what I haven’t tried: sports betting, network marketing, and even the volcano casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that I could make money was currency trading on the stock exchange, they call it Forex. But when I started delving into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, studying trading strategies. I tried it on a demo account, then opened a real account. To be honest, I didn’t manage to start earning money right away, until I understood all the mechanics of options, I lost about 3,000 rubles, but as it turned out, it was a precious experience. Now I earn 5-7 thousand rubles a day. I managed to get the car buy after half a year, but in my opinion this is a good result, and it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone)) If If you want to change your life like me, then here’s what I advise you to do right now: 1. Register on the site 2. Practice on a Demo account (it’s free). 3. As soon as you get something on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY! I also advise you to download the application to your phone, it’s much more convenient to work from your phone. Download here.

Repair

If you don’t want to spend money on buying a new device, it makes sense to try to repair the old one.

It is sometimes possible to restore its functionality by washing it. It is best to use a carburetor cleaner for this. To wash, you need to unscrew the screws holding the thermocouple. The tube of the jar with liquid needs to be cut so that the stream goes out to the side. It is inserted directly into the upper valve of the sensor (approximately 10 millimeters) and the resistor installed there is washed with a stream. The procedure is repeated up to 3 times, with pauses of several seconds. It is important to remember that the above element is very fragile, and mechanical damage will most likely ruin it. Under no circumstances should you use cotton wool or brushes. The same applies to airflow.

Next, you need to completely dry the filling of the air flow sensor, only after this the parts can be returned to the housing. Then all that remains is to check the control device for functionality. This is done in the same way as described earlier.

Source

Payment via PayPal

How to check the MAF on a VAZ 2110 with a multimeter

After selecting payment via PayPal, the PayPal payment system will launch, where you need to select the payment method: bank card or PayPal account.

If you already have a PayPal account, then you need to log into it and make a payment.

If you do not have a PayPal account and you want to pay using a bank card via PayPal, you need to click on the “Create an Account” button - shown with an arrow in the picture.

PayPal will then prompt you to select your country and provide your credit card information.

After specifying the information required to make the payment, you must click on the “Pay Now” button.

Mass air flow sensor, what kind of “beast”?

The Priora air flow sensor, as its name suggests, generates the amount of air required to compose the air-fuel mixture. The air passing through the sensor is counted by a sensitive element located inside the sensor. The air flow sensor sends all measurements taken to the electronic engine control unit, which in turn adjusts the fuel and air parameters to supply the cylinders with a fuel mixture that has already been prepared for normal operation of the internal combustion engine.

Design

The mass air flow sensor consists of the following elements:

- Frame;

- Electronic element;

- Filter;

- Sensitive part;

Symptoms of a problem

Since the sensor is electronic and if it fails, the “CheckEngine” lamp will necessarily light up on the car’s dashboard. But not in all cases the sensor fails completely. When the sensor is dirty or old, it begins to incorrectly read the air volume, which significantly affects the formation of the air-fuel mixture.

In case of such a breakdown, the “CheckEngine” warning light will not light up.

Signs:

- Engine speed fluctuates;

- Difficulty starting in all temperature conditions of the internal combustion engine;

- Increased fuel consumption;

- Uneven engine operation at idle;

- Loss of vehicle dynamics;

If you find such malfunctions on your car, first of all you need to inspect the air flow sensor.

conclusions

It is quite easy to determine the malfunction of the mass air flow sensor VAZ-2112 16 valves. To do this, you need to know the direct and indirect reasons that contribute to the diagnosis, as well as carry out testing in the most basic ways.

Other symptoms of a faulty mass air flow sensor :

- Check Engine error appears;

- Increased fuel consumption;

- Doesn't start well when hot;

- The car began to accelerate slowly;

- Engine power lost.

- Etc.

How to check the mass air flow sensor

Examination

Checking the mass air flow sensor is carried out using a multimeter, diagnostic tool or oscilloscope. In most cases, car enthusiasts do not have equipment that can diagnose sensor failure.

In this case, let's consider checking with a regular multimeter, which almost every driver has or is otherwise inexpensive.

Checking the mass air flow sensor with a multimeter can only be done with a sensor that is installed on an engine without an E-GAS system. The frequency sensor installed in conjunction with the electronic throttle cannot be checked using a multimeter. Checking such a sensor is carried out with a diagnostic device using ADC channels or using a diagram on an oscilloscope.

You can also check the frequency sensor using the ELM327 diagnostic tool; read how to do this in our article.

Verification Process

To check the sensor you will need two needles and a multimeter. The principle of determining the performance of the mass air flow sensor is carried out by measuring the voltage between the contacts.

Checking the circuit

Initially, the sensor's power circuit is checked.

- We switch the multimeter to the DC voltage measuring mode at 20V.

- Remove the connector from the mass air flow sensor.

- Turn on the ignition on the car.

- We connect one of the multimeter leads to the motor housing, and the second to Pin No. 2 on the connector (there is a numbering of contacts on the block). The voltage at Pin No. 2 must be at least 12V.

If the readings do not match and are significantly less than those indicated, you should check the battery, computer and power supply circuit of the mass air flow sensor.

Sensor check

Let's start checking the sensor; to do this, connect the mass air flow sensor connector if it is removed.

- We set the DC voltage measurement limit on the multimeter to 2V or 2000mV (in different versions of the multimeter, this value is indicated differently).

- We measure the voltage between terminals 1 and 3 with the car ignition on and off. We check the readings with the table below.

| Voltage (V) | State |

| 0.99…1.01 | Condition of the new sensor |

| 1.01…1.02 | The sensor is in good condition |

| 1.02…1.03 | Normal state of the air flow sensor |

| 1.03…1.04 | Needs replacement soon |

| 1.04…1.05 | The sensor practically does not work, it needs replacement |

| 1.05...and higher | The sensor is completely faulty and urgently needs replacement |

Also, one of the good checks of the mass air flow sensor is to replace it with a known good one, for example from another similar car.

Purifier selection options

How to clean the flow meter? The modern market offers many products for cleaning regulators; let’s look at the most effective options:

- Liqui Moly. This manufacturer, as you know, produces not only cleaning products, but also motor and transmission oils, as well as other types of liquids. If you believe the official information provided by the manufacturer, then this product belongs to the high-quality category. Accordingly, the cost of such a MAF cleaner will also be high. In fact, Liqui Moly cleaners cope with their tasks quite effectively - this product perfectly removes dirt from the sensor. If the flow meter was in working order at the time of cleaning, then after that it will work for a long time. The use of Liqui Moly is relevant in both gasoline engines and diesel power units.

- Alternatively, you can use alcohol to clean the device. This method is considered one of the oldest, but nevertheless the most effective. Due to its chemical properties, alcohol is good at removing clogs that accumulate on the sensitive component of the air flow sensor. Despite its effectiveness, today this method is not used so often and is usually used by unscrupulous technicians at service stations. The client pays for a special substance, for example, Liqui Moly, and in fact the cleaning is carried out using alcohol.

- The next option is fluid for carburetor engines. This option is considered one of the most effective and frequently used. Using carburetor fluid, you can effectively clean it, and as practice shows, such a product allows you to remove all contaminants.

- Another product sold in spray form is Liquid Key. This cleaner is used to remove all kinds of contaminants, not only from the flow meter, but also from other mechanisms and components.

- A universal tool for performing many tasks is WD-40. This liquid is used by our compatriots to clean all kinds of components, remove rust, get rid of squeaks, etc. Not so long ago, our car enthusiasts began to use it to clean flow meters (the author of the video is the Gen channel MB W140 Germany).

Replacement

- We take out the sensor and install a new one in the reverse order.

- Don’t forget to remove the rubber ring from the old sensor and install it on the new one.

MAF Lada Priora

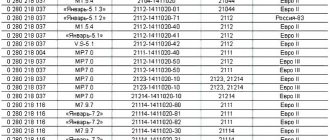

LADA Priora cars were produced for more than 10 years, and were equipped with a range of engines of 6 modifications (4 of them with 16 valves). This does not mean that air flow sensors (MAF) are of the same variety. Together with the January 7 series and BOSCH M7 9.7 ECU controllers, the Priora engines were equipped with a mass flow sensor 0 280 218 116. Flow meters of this series are produced both by the German concern BOSCH and by numerous domestic and Chinese manufacturers. Differences in cost and reliability, and Russian products were most often equipped with electronic parts from the same BOSCH.

Mass air flow sensors installed on Priora with 16 valve engines have proven themselves to be reliable devices that do not fail without external reasons. In addition, in the event of a breakdown, flow sensors provide incorrect information for a long time with an error of 15–20%, which can be calculated from the following symptoms:

- an unheated engine may stall immediately after starting;

- gasoline consumption gradually increases;

- when moving uniformly in a straight line, the engine runs unevenly;

- the slightest overload leads to loss of traction;

- at idle, the rpm briefly hangs in the 1500 zone;

- when using approved gasoline AI 92, power is sharply lost;

- It is difficult to start the engine at low temperatures.

Liqui Moly

How to clean the MAF sensor? One option is cleaning fluid from Liqui Moly. The company is known to many car enthusiasts as a manufacturer that makes only high-quality products for cars. In addition, the ratio between reliability and price is at an optimal level. As for the use of liquid for cleaning the mass air flow sensor, most vehicle owners have already become convinced of its effectiveness. This has not been proven by a single procedure. And if the sensor is in working condition, then even after cleaning it will last no less.

The liquid can be used for both diesel and gasoline engines.

Sources

- https://zapchasti34.ru/motor/priznaki-neispravnosti-dmrv-kalina.html

- https://ladaservice.info/lada-kalina/elektrooborudovanie-lada-kalina/dmrv-lada-kalina/

- https://gt-models.ru/testy/raspinovka-dmrv-kalina.html

- https://ilifia-club.ru/dvigatel/datchik-dmrv-kalina.html

- https://avtozam.com/vaz/lada-kalina/granta-dmrv/

- https://FokSevmash.ru/servis-i-uhod/neispravnosti-dmrv-kalina.html

- https://CarFranceSpb.ru/dvigateli/priznaki-neispravnosti-dmrv-kalina-8-kl.html

- https://gil-service.ru/ts/dmrv-granta.html

[collapse]

Why does a faulty mass air flow sensor affect the operation of the internal combustion engine?

To form the correct proportions of the fuel-air mixture (the stoichiometric ratio per 1 kg of gasoline is 14.7 kg of air), the ECU controller needs to know the mass of air entering the combustion chambers. It is this data in the form of a variable voltage value that comes from the mass air flow sensor. The calibration graph of a working flow meter on a Priora shows that with the throttle valve closed (air flow 0 kg/hour), the MAF ADC voltage is approximately 1 V.

The graph also shows the accuracy with which (up to 1/1000 volt) the signal readings change with increasing air flow. This indicates the high sensitivity of the flow meter sensor system. The slightest malfunction and the data will be distorted.

As a consequence, there is a violation of the formation regime of the fuel mixture and a sharp deterioration in the characteristics of the internal combustion engine.

What to do if there are signs of a flow meter malfunction

First of all, carry out an inspection. To do this, you need to disconnect the negative terminal of the battery, disconnect the connector of the cable going from the mass air flow sensor to the computer, and carefully remove the flow meter. On Priora it is located near the air filter housing, after which the intake manifold air duct begins. For dismantling, you will need a Phillips screwdriver (loosen the clamp of the air duct pipe) and a size 8 wrench (bolts attaching to the filter).

There should be no cracks or dents on the case, the connector contacts should not be oxidized. Dust, and possibly water or oil stains, will most likely be found inside the MAF channel. This is the main reason for the massive failure of sensors: under normal operating conditions, mass air flow sensors live a long time and do not cause problems for car owners.

A dirty sensor must be blown off dust using an intense stream of air, then carefully washed with a special product or alcohol. Washing is done with an aerosol jet (when using the product) or pressure from a syringe (with alcohol). While the device is drying, be sure to wipe off dust from the air ducts and the filter housing inside. It is recommended to combine this procedure with replacing the air filter.

Causes of problems

The air flow meter becomes unusable for the following reasons:

- a lot of dust and dirt gets on the measuring elements, because the car owner rarely changes the air filter;

- on heavily worn engines, gasoline and oil vapors penetrate into the mass air flow sensor through the crankcase ventilation pipe;

- a hole in the corrugated air duct from where dust is sucked in;

- accidental damage due to unqualified repairs;

- break in the wires connecting the sensor connector to the controller.

In addition to the above reasons, natural wear and tear of the device also occurs. The service life of a new mass air flow sensor is 50–250 thousand km, depending on the make and origin of the car.

Checking the mass air flow sensor using a multimeter

It is advisable to use a digital multimeter, with measurement accuracy up to hundredths of a volt in the range of 2, 10, or 20 V DC voltage.

- Checking the supply voltage from the ECU controller is carried out with the connector disconnected and the ignition on, without starting the engine. At contacts No. 2 and 4 there should be 12 V and 5 V, respectively, relative to contact No. 3 (ground). This is the supply voltage of the device and the variable resistor with a platinum thread.

- Checking the signal voltage at rest is carried out with the connector connected, the ignition on, and the engine not started. It is necessary to firmly insert the probes from the back of the connector into contacts Nos. 3 and 5.

- A working sensor will show 1 volt ± 0.02 V. If the voltage is outside the error of 0.05 V, the sensor is faulty.