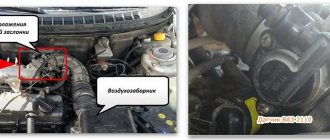

More than 6 years (or 35k km) have passed since the purchase of the car! While interested in car maintenance, I came across posts that say that e-gas is very “capricious” in terms of cleanliness. And it requires more frequent and thorough cleaning. Yesterday I chose the time, armed myself with tools and carb cleaner and rags. I unscrewed the air duct pipes with a positive screwdriver. Then, using a screwdriver with a hex bit (I don’t know what the size is called), I unscrewed 3 of the 4 bolts. The fourth bolt is located in the place with the name - “you’ll get horseradish.” He unscrewed it with an L-shaped Chinese hexagon, remembering the design engineers of AUTO VAZ, not with an evil, quiet word))) ... Here is the throttle in his hands!

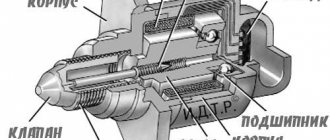

I wiped off as much oily slurry as I could from the receiver... It’s great, of course, to feed the air-oil-gasoline mixture into the engine. At first glance, it (the throttle) is certainly not so dirty, but still there was a small step of settled crankcase gases! What the hell is wrong with installing an air filter at the inlet if there is a crankcase gas pipe in front of the throttle... fucking ecology. Well, okay... I digress)... I took the throttle, rags and a bottle of cleaner. It spilled copiously... soot flowed onto the rags... tin. There is not so much of it there. In view of the fact that many people say that it is ABSOLUTELY IMPOSSIBLE to touch the damper! I will refute this myth. I removed the top cover, which unscrews with an asterisk or TORX... whatever you like. And I turned the damper with the drive (steel) gear.

Without this, it would not be possible to thoroughly rinse the unit. Returned the cover to its place. This is how open the throttle is by default.

A rubber silicone ring is installed on the throttle seat. It was in more than good condition. I didn’t change it, wiped it with a rag and lubricated it with silicone grease. I screwed the throttle in according to the “worked out” scheme (... using a screwdriver with a hex bit (I don’t know what the size is called) I screwed in 3 of the 4 bolts. The fourth bolt is in the place with the name “you can’t get it.” It was screwed in with an L-shaped Chinese hexagon, remembering the engineer .-designers of AUTO VAZ not with an evil quiet word)))). I returned the air duct to its place, first coated it with silicone grease in the places where the pipes came into contact JUST LIKE THAT. I did not carry out training on the damper. It started up well, cleared its throat a little and drove better, it seems to me. But for now this is apparently a placebo effect. I don't travel much. I took a spin around the area. It drives well, but so far at idle it shows about 1.1 liters per hour. Apparently the ECU needs to sort this out. I'm not worried yet. I couldn't break anything there! I'll add it later. Later came! 2 days have passed. During this time, I carried out training on the throttle body according to the manufacturer’s recommendations, and tightened the clamps on the pipes. Legal 0.9 l/h and about 10 kg of air in their rightful places on the bk screen. I will say on my own behalf: the ride has become more pleasant! I don’t encourage anyone, but I support them in this matter, because the throttle was clean from the factory ;). Thank you for reading.

Two ways of learning: using the gas pedal, using a scanner. Training XX. Complete procedure with pedal training. Train the throttle valve to open fully. Train the throttle valve to the closed position. Training function of air flow at XX Why it didn’t work Training using a scanner

Electronic gas pedal VAZ 2114: advantages of use and principle of operation

Since 2011, all cars produced by the AvtoVAZ concern are equipped with an electronic gas pedal, including VAZ 2114 models produced after 2011. The e-pedal has many advantages, but also due to the novelty of the mechanism used for AvtoVAZ, there were a number of shortcomings. Many motorists who bought a car with e-gas VAZ 2114 encountered problems after some time.

Electronic gas pedal

The simplest way to carry out adaptation

Now the question of whether it is necessary to adapt the throttle valve after cleaning should definitely not arise if there were still doubts. The easiest way to carry out the operation is to simply reset the battery terminal. Just to begin with, it is worth warming up the engine well to operating temperature, for which you should take a short trip. Then, turning off the engine, disconnect the negative terminal of the battery and wait. Depending on the brand of car, the waiting time can be 10-30 seconds or 15-20 minutes.

During this period, all ECU parameters should return to the original (factory) settings. Next, all that remains is to connect the terminal and start the engine - the speed should return to normal.

Mechanical and electronic pedal

But first, let’s talk about why it was necessary to remake an old, reliable system that works without interruptions. There are several reasons for this.

When controlling the throttle position directly with your foot using a cable, there is a slight delay between opening the valve and adjusting the mixture, this leads to the following consequences:

- the wrong mixture produces a large amount of C02;

- non-compliance with EURO-5 and EURO-4 standards;

- when the gas pedal was fully pressed, much more fuel was consumed than necessary, which increases the overall consumption;

- direct control of the mixture by a person leads to the possibility of operating the internal combustion engine in critical modes at high speeds or changing the mixture too sharply, which negatively affects the service life of the engine.

In order to avoid these problems, engineers decided to protect human access to direct control of engine operating modes; in the VAZ 2114 with e-gas, the throttle valve is controlled by the ECU, taking into account the position of the gas pedal, but not 100% subordinate to it.

This allowed us to achieve:

- uniform opening of the throttle valve, without jerking;

- synchronous change in the composition of the mixture and opening of the damper;

- saving fuel and increasing engine life;

- possibility of installing anti-skid and traction control systems.

e-gas VAZ 2114

In theory, everything looks great and all the changes seem only for the better. But the electronic gas pedal of the VAZ 2114 has problems that appear because during production the device was not sufficiently tested and a crude product was released onto the market.

Cleaning the throttle valve

It is necessary to clean both the damper and the inside up to the narrow opening (where you can reach it). It is necessary to wet a rag with a specialized liquid or solvent. You can also flush the injector. It must be taken into account that this is a very strong chemical, and after using it you must wash your hands immediately, otherwise you can get a chemical burn.

First, the nuts are unscrewed and the decorative trims are removed from the Volkswagen engine. After this, 3 metal brackets are moved and the corrugated pipe connecting the air filter to the throttle valve is removed. The staples are rigid and you must act very carefully so as not to damage the plastic parts.

For convenience, the air filter cover can be removed. Then the power supply and the hose coming from the adsorber are disconnected.

Now you need to unscrew the four throttle valve bolts with a hexagon. To disconnect the cable, you need to pull it out of the bracket; the flap can be rotated in the direction of removing the cable. Disconnect the two hoses containing coolant flow. It is recommended to prepare two plugs in advance to prevent leakage during the cleaning process. After this you can see the golf throttle.

E-gas VAZ 2114 problems

Often the main disadvantages of electronic gas are these aspects:

- Delay in the car's response to pressing the accelerator pedal.

- Problems with floating speed, gas sticking and self-actuating.

- Impossibility of quick car tuning.

The delay is formed due to the fact that the signal from the pedal is first transmitted to the ECU and only after processing, the electric drive on the damper begins to smoothly change its position. In newer cars, this delay has been reduced thanks to better software and faster hardware. The e-gas equipment of the VAZ 2114 can also be reflashed, increasing the power and pedal response speed, but lowering the environmental standard to EURO-2.

Repair e-gas VAZ 2114

In early versions, motorists often encountered incorrect operation of the e-gas, the speed fluctuated, there might be no reaction to the gas at all, or there could be sudden jumps in engine speed. All this was the result of faulty wiring made by AvtoVAZ; if such faults occur, it is better to replace it with a braid from PES SKK.

Owner reviews

Owners of LADA XRAY who independently performed the throttle valve zero adaptation procedure note that the car stopped twitching and acceleration became smooth.

Some reviews from Drive2.ru (link to post):

It really works! This morning I did this operation and the car drove much better, especially at low speed. Why is this not done during pre-sale preparation?

- Throttle sensor Lada Granta 8 valve

I’ve been suffering with this problem for half a year, but here it’s 3 minutes! I even wrote to AvtoVAZ, they sent me... to the dealer.) Now, after carrying out the above mentioned manipulations, I’m driving for the second day without twitching!

In the morning I carried out these manipulations at an ambient temperature of -10 and an engine temperature of 50 degrees. The car is unrecognizable - all the twitching is gone. Acceleration became smooth, and fuel consumption seemed to drop slightly. I rode all day long.

Let us remind you that we previously published an information letter from AVTOVAZ, which tells us what to do in case of vibrations and jerks when starting off a LADA car.

Key words: ECM Lada XRAY | ECM Lada Vesta | ECM Lada Largus | ECM Lada Priora | ECM Lada Granta | ECM Lada Kalina | ECM 4x4 | esud niva | universal article

Share on social networks:

Found an error? Select it and press Ctrl+Enter..

E-gas malfunctions

Sometimes the cause of malfunctions is a breakdown of the idle speed sensor on a VAZ 2114 with an electronic gas pedal, also called IAC. If the ECU indicates an error and the engine idle speed is too high and does not drop, mostly 2000, then the throttle assembly needs to be replaced, or you can try cleaning the terminal contacts.

Malfunctions of the electronic gas pedal of the VAZ 2114

If the electronic pedal is faulty and does not respond to pressing the accelerator pedal, and the engine speed is frozen at around 2000 rpm, do not despair and call a tow truck. With such a problem, you can move around, carefully releasing the clutch, slowly but surely you can get to your home or service center.

If you have some kind of malfunction related to the electronic gas pedal, then in the control unit you will most likely be able to find the following error codes:

- P2122 - indicates low voltage of the accelerator pedal position sensor. This sensor works on the principle of changing its resistance, and the ECU, passing current through it, recognizes it and, based on this, knows the position of the pedal. Low voltage corresponds to high sensor resistance. This can be solved by cleaning the contacts, soldering them, or replacing the pedal assembly if that doesn’t help.

- 2123 is the reverse error P2122, the voltage on the same sensor is too high. A breakdown or short circuit in the wiring, as well as failure of the sensor, is possible.

- 2127 – low signal level of the second accelerator pedal position sensor. Since this unit is quite responsible and performs an important function, it uses two sensors for accuracy and reliability. They are located in the same building, the sequence and methods for eliminating the error are the same.

- 2128 is a clone of error code 2123, only it is responsible for the second sensor.

- 2138 - the code indicates a discrepancy in the readings of these two sensors; perhaps contact has been lost with one of them or it has broken down. To solve the problem, you also need to clean the contacts, check the wiring for serviceability and test the pedal itself. The test consists of measuring the resistance of both sensors in different pedal positions and comparing the readings. If they are different, you need to change the pedal assembly.

Pinout e-gas vaz 2114

Nowadays, the electronic pedal has been worked on and most of the problems have been solved, now it works without failures, but fans of fast driving still flash their ECUs, noting improvements in the car’s response to the pedal.

This is primarily due to the fact that manufacturers are forced to impose restrictions from the factory in order to comply with EURO standards and increase engine life. Amateur firmware removes these restrictions, allowing the control unit to open the damper faster.

In Samara, and in particular with the electronic gas pedal of the VAZ 2114, problems were often encountered on models of the first years of production; after some time, the shortcomings were corrected and at the end of production, copies with reliable e-gas rolled off the assembly line.

Didn't find the information you are looking for? on our forum.

Before training, fulfill the following conditions:

- Warm up the engine. The engine temperature is 70-95 degrees, otherwise it won’t learn (this is hard to catch!). The coolant temperature should be 70-99 degrees, about 72* in the cooling system already gives 90* on the dashboard

- Warm up the gearbox, drive for 10 minutes. The radiator fan should not work.

- After warming up, turn off the engine for at least 10 seconds.

- Battery voltage is more than 12.9V (with the engine not running);

- Selector in P or N (automatic transmission).

- Electrical loads are turned off (air conditioning, headlights, heated rear window, cars with “Eurolight” - turn on the dimensions )

- Steering wheel in neutral (zero) position;

- Vehicle in a nearly horizontal position

If at least one of these conditions is not met, learning XX will not occur.

Feel the speed of flight! I’ll say right away that with the installation of the sensor and its correct configuration, the car began to simply fly . TPS Pilot non-contact I thank the smart, honest, temperamental people for their reviews and dissemination of information.

The throttle valve is fully open.

The purpose of this procedure is to teach the gas pedal to fully open the throttle. It must be performed every time the connector is disconnected from the gas pedal or from the ECM (ENGINE CONTROL SYSTEM i.e. engine control unit). The engine is hot and the servo will open it completely in 2 seconds. The servo drive is activated by the engine temperature.

- Make sure the accelerator pedal is completely released.

- Turn the ignition key to the “ON” position

- Wait 2 sec

- Turn off the ignition

- Wait 10 seconds.

- Turn the ignition key to the “ON” position

- Wait 2 seconds.

- Turn off the ignition

- Wait 10 seconds

I want to go for a ride with you! On one paid Pilot there seemed to be no problems; the automatic transmission generally shifts smoothly. And I recently installed the Vagovsky one, I think the original one is better, and why does the box get stuck sometimes from first to second. I'm going to change the TPS Pilot to this device. It works better smoothly . From the intersection it's a nice thing to pedal 1 2 3 perfectly switch themselves in time. TPS Pilot non-contact I thank the smart, honest, temperamental people for their reviews and dissemination of information.

Train the throttle valve to the closed position.

The purpose of this operation is to learn the fully closed position of the valve lever, observe the output position sensor. This must be done every time the connector from the electrical linkage or ECM has been disconnected. The engine is hot and the servo will completely close it in 10 seconds.

- Make sure the accelerator pedal is fully released.

- Turn the ignition switch "ON".

- Turn the ignition switch “OFF” and wait at least 10 seconds.

- Make sure that the valve lever moves for more than 10 seconds, this should be confirmed by sound (chirping, buzzing).

You can't escape the gift! In the end, I want to thank the guys who are involved in this project, I hope their thing will serve me for a long time. By the way, this version is suitable for both manual and automatic transmission, I have an automatic transmission, so for me this is a godsend, I would say! TPS Pilot non-contact I thank the smart, honest, temperamental people for their reviews and dissemination of information.

Air flow training function at idle

All time intervals described below must be performed very accurately using a stopwatch!

- Check the condition of all items listed in the PREPARATION section (which were noted above).

- Follow the instructions for “Accelerator pedal release teaching function”.

- Follow the instructions for “Wide throttle learning function”.

- Start and warm up the engine to normal operating temperature.

- Turn the ignition OFF and wait about 10 seconds.

- Make sure the accelerator pedal is fully released.

- Turn the ignition key to the “ON” position

- Wait 3 seconds.

- .Start the process

- Quickly press (all the way!) and release the gas pedal 5 times within 5 seconds

- Wait 7 seconds. with gas released

- Press all the way and hold the gas pedal for 10 seconds

- After 10 seconds, the CHECK ENGINE engine malfunction indicator (- diagnostic mode) will flash for 10 seconds.

- The check will light up constantly. End of process

- After this, quickly and completely release the accelerator pedal.

- Also quickly start the engine (without touching the accelerator pedal) and let it idle for 20 seconds.

- Accelerate the engine two or three times to make sure that the idle speed and ignition timing are correct (700-800, depending on the load of electrical devices and engine temperature)

This is a super-duper mega-PANACEA ! I got a little tired of fiddling with the flow meter, or as it is often called a shovel. While surfing around my favorite lancruiser.ru I came across a link from Pilot Engineering. I read their local forum and came to the conclusion that this is a super-duper mega-PANACEA! The advantage of this converter is its flexibility of configuration. He even supports ShPLZ! Replacing the flow meter with a non-original one without firmware! Pilot + BLUETOOTH ConverterThank you to the smart, honest, temperamental people for their reviews and dissemination of information.

Why didn't it work?

Point 24 - on automatic. The last 3 seconds are not needed, you don’t have to wait 3 seconds, but immediately release the gas pedal and start the engine.

If it doesn’t work right away, then get a little creative with 3 and 7 seconds. From practice, it works out 5-10 times.

If it doesn’t work, then before repeating it is necessary for the car to drive for at least 10 minutes.

Sometimes, when the throttle on Nissans built before 2003 is heavily contaminated, the throttle “does not learn.”

I set the speed to the required speed for training by turning off 2 injectors and removing the ventilation pipe, after which I trained sequentially, with 2 nozzles, with 3 nozzles, and with a ventilation pipe.

Train with 1-2 injectors disconnected, then again with them connected.

I couldn't slow down! I tried to teach it as shown, the speed floated 1800-2000, it helped by removing the terminals from 2 injectors and turning off the low beam

With a faulty mass air flow sensor, the learning procedure may not be completed. and it’s better not to start it!

The burning CNESC ENGINE sensor went out after removing all the seals from the battery overnight.

If it is heavily soiled, you can wash the throttle “in parts” - first one half is cleaned, then the second half is cleaned. During the training procedure, remove the crankcase ventilation hose and train with the hose removed. then again - with already dressed. During training, on cars with automatic transmission, move the selector to R, as soon as the tachometer needle moves slightly up, the selector returns to R.

If there is a Eurolight, the throttle training must be done with the dimensions on.

I removed the terminals for 8 hours at night, the error was reset, I warmed up the engine to the required temperature. 10 minutes of driving to warm up the box, removed the (-) terminal and plug on the throttle, disconnected the pipe and moved the flap so that it was completely open, then returned everything to its place, the learning process is further described by AnriBlog, only one thing, after the check lights up smoothly, Immediately release the gas pedal and start immediately. Everything else is as described. AnriBlog thank you for the link.

I want to go for a ride with you! On one paid Pilot there seemed to be no problems; the automatic transmission generally shifts smoothly. And I recently installed the Vagovsky one, I think the original one is better, and why does the box get stuck sometimes from first to second. I'm going to change the TPS Pilot to this device. It works better smoothly . From the intersection it’s a nice thing to pedal 1 2 3 perfectly switch themselves during TPS Pilot contactless I thank the smart, honest, temperamental for the feedback and dissemination of information.

- Connect laptop to car

- Log in to the VAG COM program

- Selection of control unit -> Section 01 - Engine -> Measurements -> 01 channel -> read

- Starting the car

- Warm up the engine to a temperature of 80-81 degrees IMPORTANT! We monitor the engine temperature using the computer via channel 01, and not using the arrow on the instrument panel. (the panel will already show 90 when the actual engine temperature is 70 degrees)

- Turn off the ignition

- Turn on the ignition but do not start the engine

- Go back to Dimensions -> Engine

- Reset errors. Poll fault memory -> Erase errors (if any)

- Let's go back to Fault memory interrogation -> Engine

- Engine -> Adaptation -> channel number 00 -> Read -> Save -> Done, return

- Basic settings -> Group 098 (For vehicles with a cable-operated throttle valve, select channel 98. For vehicles with an electric throttle valve, select channel 60) -> Start -> changes in the windows: 01 -> 00 and 0000 -> 00100 -> Done, return.

- Let's go out

- Close the program

- Turn off the laptop

- Turn off the ignition

- We take out the key

- We first remove the USB cable from the computer, and then the cable connector from the car. PS When the engine warmed up to the required temperature, the program speed showed 800-832, the arrow on the instrument panel almost stood still. After adapting the throttle valve, having performed a test start of the engine, I saw that the revolutions according to the program showed 768-800, the revolutions arrow was in place. Before adaptation, my revs froze when coasting and braking. After adaptation the problem went away.

Feel happy! After I started it I was delighted to see an even XX 1200 at -18 when cold. then the rpm dropped to 1000 and stayed there until it warmed up, after which it was 850-900. The dynamics and smoothness of acceleration have improved. In general, my happiness has no limits. TPS Pilot non-contact I thank the smart, honest, temperamental people for their reviews and dissemination of information.

Feel the speed of flight! I’ll say right away that with the installation of the sensor and its correct configuration, the car began to simply fly . You lightly press the gas and you fly. The interruptions in work disappeared, the car began to accelerate smoothly and the throttle response increased. Also, the sound of the engine itself has become more pleasant. What is very pleasing is the Pilot contactless sensor. I thank the smart, honest, temperamental people for their reviews and dissemination of information.

Take the eternal TPS Pilot! After installation, I will note good engine traction throughout the entire range, and a decrease in gasoline consumption (insignificant, but nonetheless). Well, in general, I recommend it to everyone as a modern alternative to long-outdated contact sensors. TPS Pilot non-contact I thank the smart, honest, temperamental people for their reviews and dissemination of information.

[juiz_sps buttons=”facebook, twitter, google, vk”]

For many, this is new, and perhaps you are reading about it for the first time.

The fact is that many drivers complained about e-gas, its malfunction, etc.

Subsequently, AvtoVAZ issued an information letter containing instructions for adapting e-gas.

When repairing a car: replacing the controller, or after removing the battery, you need to adapt the electronic gas pedal