The engine mount on any domestic car is a rubber-metal silent block on a bracket. It connects the cylinder block body to the stationary parts of the car. On the VAZ 2114, the factory provides three such supports:

- the front one, also known as the bottom one, connects the crankcase to the beam;

- the right one, also known as the side one – between the engine and the spar;

- rear - attached to the gearbox housing and body.

Also, sometimes an additional mount is installed on the VAZ 2114, which is attached to the cross member on one side and to the clutch housing on the other.

It is widely believed that the main task of airbags is to provide ride comfort. This is only partly true. In fact, their main task is to minimize the transmission of engine vibrations to transmission parts. With a rigid connection, the gearbox would become a consumable item; in 30-40 thousand kilometers its “internals” would wear out completely. Therefore, in particular, rubber in silent blocks cannot be replaced with polyurethane.

How to check engine mounts on a VAZ 2114?

To diagnose the mechanism we need:

- A pair of jacks;

- Bar or board;

- Mount.

The check occurs in order:

- We drive the car onto a straight platform or into a garage with a flat floor.

- Raise one of the front wheels using a jack. Then we place a second jack under the engine pan and press it against it, through a board or block, to relieve the tension on the cushions.

- We lie down under the car and inspect the engine mounts. There should be no cracks or tears on the rubber elements. Also, they should not be hardened or peeled off from the metal part.

When a visual inspection does not help to detect the problematic element, it is worth checking for the presence of play between the support and the body. To ensure a complete inspection, use a pry bar to tilt the mechanism to the side.

If problems are identified in the elements, then it is better to immediately begin replacing the engine mount, since the motor is not securely mounted and because of this, other pillows receive a load higher than that for which they are designed. Subsequently, they may also fail, which will further weaken the reliability of the structure.

Engine mount malfunctions

The main damage to a pillow is loss of elasticity. The support is made of rubber, which loses its properties with prolonged use.

This is due to constant loads accompanied by changing weather conditions (cold, heat). In the future, the pillow will begin to deteriorate: it will crack and delaminate.

To prevent destruction of the rubber support, it is necessary to inspect it regularly. If damage is detected, the part should be replaced, otherwise strong vibration and extraneous knocking will be felt in the cabin, which will soon affect the operation of the engine.

It is better to replace the airbags in a timely manner than to later spend money on expensive repairs or purchasing a new engine.

The cost of engine mounts depends on the manufacturer, the minimum price for the front support is from 600 rubles, the rear and left ones are 500 rubles each. Average prices start at 1,200 rubles for the front, and 900 rubles for the rear and left.

It is possible to buy a set of three pillows from 3,500 rubles.

To replace engine mounts at a car service center, you will be asked for 1,500 rubles, but you can replace them yourself.

Replacing the front support

- Place the car on a level surface. Be sure to raise the handbrake or engage first gear. For safety, you can support the rear wheels.

- Remove the engine protection to gain access to the mounts.

- To remove the load from the support, place a jack under the oil pan and raise the engine. It is imperative to place a spacer between these elements in the form of a board.

- When the engine is supported by the jack, we inspect the mounting location of the cushion. We unscrew the bolt that connects the bracket to the support.

- After this, you can disconnect the pillow from the motor unit.

- We clean the fixation points and install the new part in the reverse order.

It is possible that in order to replace the front cushion, you will need to further lift the engine, since the mounting location of the old one has been worn out.

SIGNS OF WEAR

Since the function of the engine mount is to dampen vibrations, if they are noticeable even at idle, this indicates a problem.

Among other signs of wear on the airbags on the VAZ 2114:

- Vibration of the gearshift lever. This indicates that all motor vibrations are transmitted to the box.

- If you open the hood, strong vibrations of the engine are visible.

- Uneven car operation. The fact is that when the silent blocks are heavily worn, the crankcase begins to move slightly relative to the clutch. Because of this, the crankshaft position sensor (CPS) constantly produces different signals. The ECU is forced to mistakenly “catch” the revolutions to eliminate the imbalance.

Replacing the left support

- The beginning of the replacement actions coincides with the previous example, but in this case we place the jack under the gearbox.

- When the support is freed from the load, unscrew the bolt securing it to the body.

- Then unscrew the two bolts that attach the cushion to the gearbox housing.

- We also clean the contact area and install a new part.

Inspect the condition of the bolts before installing the support; they may need to be replaced.

Design and technological features

Since in the “fourteenth” model the entire load from the engine falls on the front suspension, accordingly, the chassis is made of materials with an increased margin of safety, and its design must strictly comply with established standards. Durable rubber mounts of the VAZ-2114 engine are used as a damper for vibrations of the power unit under various loads.

Since high demands are placed on this part, it is extremely important to purchase only original and certified supports, since only they are suitable for use in our conditions. In the design of the front part of the car frame and its suspension, the engine mount is one of the important elements, while its independent replacement is quite within the capabilities of a car owner who has even the most minimal concepts in plumbing

In the design of the front part of the car frame and its suspension, the engine mount is one of the important elements, while its independent replacement is quite within the capabilities of a car owner who has even the most minimal concepts in plumbing.

The main thing in the repair process is to complete the entire technological sequence of actions, then the installed part will serve for a long period of time.

Replacing the rear support

- Just like with the left cushion, we need to place a jack under the gearbox.

- First, unscrew the bolts securing the support to the car body, and then to the box body.

- We clean the mounting area and install a new part.

Having finished the work, we check the correctness of the actions performed and the reliability of the connections. Afterwards you can start the engine.

How to change supports

To replace, you will need to purchase front, left and rear airbags. Experts advise replacing the entire set during repairs, since after replacing one part, another one may break after a while. The average cost of parts is 2000 rubles. If you have the necessary tools, you can do the repair yourself and save on car service.

List of tools

To replace the pillows we will need:

- 2 good jacks;

- metalworking tools;

- scrap;

- steel rope;

- glue.

Tip: At some stages you will need to lift a lot of weight, so it would be a good idea to invite a neighbor or a fellow car enthusiast here.

Replacing the front airbag

The repair of each support has its own characteristics. Replacing the front airbag is carried out as follows:

- Put the car in 1st gear or the handbrake so that it does not move.

- To gain access to the support, remove the upper engine protection.

- Raise the engine with a jack. To avoid damaging its lower part or other elements, place a wooden board underneath.

- When we have freed the support from the load, we can unscrew the bolt that connects it to the bracket.

- We unscrew the bolts connecting the pillow to the motor.

Removing the bolt that secures the cushion to the engine - We remove the old part and install the new one.

Assembly of the unit

After purchasing all the new components, you only have to do a few simple steps:

- Compress the spring using a puller. It must be installed in such a way as to engage at least three turns.

- Install rubber pads on the spring; they can be secured with tape or tape.

- Place the bump stop on the rod and the boot on top.

- Install the rod into the hole in the body and tighten the nut.

- Secure the lower part of the shock absorber to the rear beam by aligning the holes and inserting the bolt. Tighten the nut.

Check the tightness of all threaded connections. After a run of 50-100 km, it is recommended to re-tighten all the nuts. When replacing the rear struts of a VAZ-2115, use nuts with plastic bushings - they are much more reliable.

avtoexperts.ru

In today's article we will talk about such important elements of the transmission as gearbox mounts. Many car enthusiasts do not even know what they look like or where they are until these products make themselves felt with various types of malfunctions.

In order to understand and promptly respond to emerging problems with gearbox mounts and resolve the issue with minimal means, we will try to talk about their purpose and malfunctions in more detail.

Gearbox support for VAZ 2114: new on the left, old on the right

Purpose

The gearbox supports are designed to secure it to body elements, as well as to suppress vibration and noise when driving.

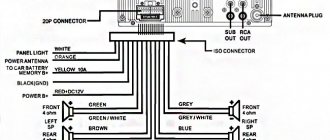

Manual transmission cushion VAZ 2112

Device and types

Depending on the design of the vehicle, gearbox supports can be made in different designs. Depending on the type of cushion, the boxes can be rubber-metal or hydraulic.

Rubber-metal

This type of product is a simple design consisting of two metal plates between which there is wear-resistant rubber.

Rubber-metal box cushion for VAZ 2110

This is the cheapest and most popular type of pillow. Recently, some manufacturers have begun to replace rubber with polyurethane due to its increased wear resistance. This type of support is available in both collapsible and non-dismountable versions.

Hydraulic

These cushions are a more modern design and are able to effectively smooth out any vibrations, adjusting to the operation of the power plant.

The support itself is a housing with two chambers located in it, with a membrane between them. Both chambers contain a hydraulic filler. The purpose of the membrane is to eliminate slight vibration when the car is not moving quickly on a flat highway and the engine is idling.

Hydraulic support

The liquid in the chambers is responsible for the vibrations that appear at speed. The changing pressure forces it to move between the chambers of the support, increasing the stiffness of the cushion, while dampening almost any strong vibrations.

Basic faults

On average, the service life of gearbox supports is about 100 thousand kilometers or more. However, during long-term operation of the vehicle, the power unit supports experience various loads, plus temperature changes, which negatively affects their condition. The rubber of the cushions loses its elasticity, delaminates, or cracks, and eventually completely collapses.

Collapsed automatic transmission support of Volkswagen Tiguan

Large loads on the gearbox supports occur when starting and braking the vehicle. At the same time, if the driver prefers an aggressive driving style, that is, he starts abruptly and brakes sharply, then the airbags simply will not be able to last their service life and will fail ahead of time.

Tired Fiat Albea gearbox cushion

Malfunctions also include collisions with various obstacles, when the support bracket itself may be damaged. In addition to this, oil or antifreeze leakage that gets onto the rubber base of the cushion can also reduce the service life of the support. Plus, there is a high thermal load in the engine compartment with simultaneous splashes of cold water.

Signs of a faulty support

A failed gearbox cushion will make itself felt with characteristic signs. So, when driving or braking the car, unpleasant clicks, jolts, knocks, squeaks and noise will appear in the area of the front of the car.

When driving over various uneven surfaces, shocks will again appear in the front of the car, as well as vibration and feedback to the gear shift lever. Plus, when the support wears out, a characteristic squeaking and clanging sound often appears and can interfere with speed.

On rear-wheel drive car models, if the gearbox mounts are worn out, shifting gears will be difficult, plus the car will vibrate while in motion.

A support malfunction can also be determined by structure-borne noise, for example, when starting and stopping the engine, as well as when the load changes.

Checking status

The condition of the supports can be checked visually. Upon inspection, the product should not show cracks (most often appear along the edges), tears, delaminations, or hardening of the rubber. Sometimes, when hardening, the rubber part peels off from the body of the pillow, which will be visible upon inspection.

Transmission cushion requiring replacement

When the silent blocks of the gearbox supports wear out, the gearbox linkage fastenings may break, the cushions may become deformed with the appearance of cracks, and eventually the support may burst.

For the presence of backlashes

The malfunction of the gearbox cushion can be determined in the inspection hole or overpass during its inspection. You need to apply force to the box, moving it sideways or up and down, while looking at the condition of the support. You can also apply force to the support using a pry bar. A worn part will “move” with its internal part. The working support in this case will look like a single whole, elastically resisting the applied load.

In addition to the supports themselves, their mounting bolts may fail, which will be visible from the sagging box.

General replacement scheme

Dismantling and installing a new gearbox cushion on most car models can be done with your own hands, without turning to car service professionals. It is enough to have an inspection hole in the garage, not be afraid of dirty work and purchase a minimum list of tools.

To work you must have:

• Jack;

• the necessary set of tools (the list is indicated in the repair manual for this vehicle);

• Safety stands for the engine;

• New product.

Operating procedure

• The car is placed on the inspection hole, the handbrake is raised and supports are installed under the wheels;

• The battery and battery stand are removed (depending on the design of the car model);

• The body is lifted with a jack, and a reliable piece of board is placed under the power unit across the inspection hole. If the garage has a manual hoist, then only the engine itself is raised;

• Stops are placed on the board and the body is lowered onto them from a jack, thereby unloading the supports;

The photo shows the replacement of gearbox cushions using the example of an Audi 80

• The gearbox support fasteners are released and removed;

Unscrew the bolts and dismantle the support

• Before installing a new cushion, you need to place it on the future location and check the alignment of the holes in the support and the holes in the body. If necessary, you can lower or raise the body a little with a jack;

• A new product is installed, the fasteners are made using the torque prescribed by the manufacturer, and everything is assembled in the reverse order.

Installed a new gearbox cushion. Photo — Drive2.ru

Finally

To extend the service life of the supports, we recommend choosing a gentle driving mode, avoiding sudden acceleration and braking. Also, periodically pay attention to the condition of the power unit cushions in order to replace them in a timely manner. It is recommended to check them at every scheduled maintenance or when signs of malfunction appear.

If oil or coolant gets on the supports, clean and wipe them dry, keeping the rubber from corroding.