This car from Russia belongs to the second group of small class cars. Manufacturers began developing the design of the Lada Kalina back in 1993, and it went into production in November 2004.

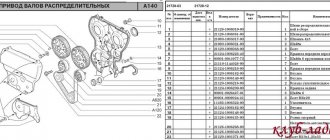

According to the results of a customer survey, this car took fourth place in the ranking of the popularity of cars in Russia. The engines of this model are equipped with a belt drive of the valve mechanism, so it will be useful for the owners of this vehicle, as well as everyone interested, to learn how to replace the timing belt on an 8-valve Lada Kalina.

Engine VAZ 21114

This power unit is an injection gasoline engine with a displacement of 1600 cm3. This is a modernized version of the VAZ 2111 engine. The cylinder block is cast from cast iron, four cylinders are located in one row. The valve train of this engine has eight valves. The injector made it possible to significantly improve the car’s dynamics and fuel economy. Its parameters comply with Euro-2 standards.

The valve mechanism drive uses a toothed belt, which somewhat reduced the cost of the power unit, but requires high-quality, timely maintenance of the timing drive. The design of the piston head provides recesses that completely eliminate the possibility of damage to the valve mechanism if the timing belt is damaged or installed incorrectly. Manufacturers guarantee a motor life of 150 thousand km; in practice, it can be more than 250 thousand km.

Replacement procedure

The operation is not particularly difficult, does not require any special equipment, and can easily be done by the hands of the machine owner. In addition to a standard set of wrenches, you will need a good slotted and flat-head screwdriver. Car jack, car body stand, wheel chocks, key for turning the roller in the tensioner. When replacing, you can use any flat horizontal platform on which the machine is installed. The vehicle operating instructions recommend replacing the belt at 50 thousand km, but many owners perform it earlier, at approximately 30 thousand km.

Replacing the timing belt Kalina 8 valves will take place in the following order:

- With the vehicle installed, apply the hand brake and install wheel chocks under the rear wheels. Use a wheel wrench to remove the wheel bolts of the right front wheel.

- Using a car jack, lift the front side of the car on the right side, install a stand under the body sill, and remove the front wheel on this side.

- Open the hood of the engine compartment, since further work will be carried out there.

- To dismantle the timing belt in the timing drive, it is necessary to remove the plastic protective cover, which is secured with three 10mm socket bolts.

- The next step is to remove the belt in the generator drive. You will need a “13” wrench, which is used to unscrew the tensioner nut of the generator set and move the generator as close as possible to the cylinder block body. After such actions, the drive is easily removed from the pulleys.

- Now install the timing drive according to the marks. You will need a socket wrench or a “17” socket, which is used to rotate the pulley on the crankshaft until they match.

- To dismantle the belt in the timing drive, it is necessary to stop the crankshaft pulley from turning. You can ask an assistant to engage fifth gear and press the brake pedal.

If this does not help, open the plug on the gearbox housing.

Insert the blade of a flat-head screwdriver into the hole between the teeth of the flywheel and the gearbox housing, and unscrew the bolt securing the pulley to the crankshaft.

- To remove the belt, release the tension roller. The bolt securing it is unscrewed, the roller rotates, the tension weakens, after which the old belt is easily removed. It is recommended to simultaneously change the tension roller, which is removed from the block, at the same time as the drive. There is an adjusting washer installed under it, which some “repairers” lose.

- Inspect the pulleys on the crankshaft and camshaft, paying attention to the wear of their teeth. If such wear is noticeable, the pulleys should be replaced, as the contact area with the belt teeth is reduced and they can be sheared.

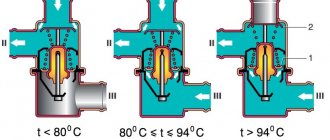

They also check the technical condition of the coolant pump, which is also driven by a toothed belt. Basically, the belt shearing occurs after the coolant pump is jammed. If the pump is changed, you need to drain some antifreeze from the engine cooling system.

- Install the new tension roller in its place. Do not forget about the adjusting washer between the cylinder block and the roller, otherwise the belt will move to the side when rotating.

- Installation of a new belt is carried out in the reverse order, but before that, check again how the gas distribution marks match. You need to start the installation with the camshaft pulley, then put it on the crankshaft pulley and the pump pulley. This part of the belt should be tensioned without any possible sagging, and the opposite side should be tensioned with a tension roller.

- Installing the pulley on the crankshaft will again require securing it from possible rotation.

- Next, put the protective covers in place and adjust the generator drive.

Kalina generator belt size

About the belt

In the Lada Kalina car, a poly-V belt is used as a drive for the generator and additional attachments.

This belt is designed to ensure reliable contact of the rubber part of the belt with the crankshaft, generator and air conditioner pulleys. It should be noted that the length of the belt directly depends on the type of engine installed in the car, as well as on the presence of a tensioner or air conditioner. In order to choose the right alternator belt for the Lada Kalina, you need to know the number of the engine installed on your car, as well as the presence of a tension pulley and air conditioning.

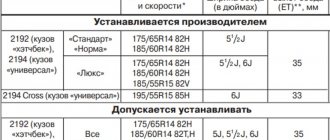

A total of 4 belt sizes are installed on Kalina, more about them below in the article.

Belt sizes

In total, 4 sizes of belts were installed on Kalina. Let's take a closer look at each of the belts and choose the right size belt for which engine. Of course, one of the best options for selecting a belt would be to remove the old one and buy a new one based on the sample, but often with prolonged use, the inscriptions on the belt are erased and it becomes impossible to see its size.

Engine without air conditioner and tensioner

In such an engine, the belt only drives the generator, and tension occurs by the generator itself using a tension bolt. The size of this belt is 883mm.

Belts are installed at the factory and are famous for their reliability and durability. Factory belt number 6PK823.

Engine without air conditioning, but with tensioner

This motor comes with a belt size of 882mm. In such an internal combustion engine, the generator stands statically, and tension occurs using a special roller. The factory belt is a strap with article number 6PK822, and when replacing it, it can be replaced with an analogue from the Russian manufacturer BRT882.

Engine with air conditioning and tensioner

In such an internal combustion engine, the longest generator belt is installed, since this drive needs to rotate not only the generator, but also the air conditioner. The length of the belt is 1018 mm, and the factory supplier, as always, is “Gates”. Factory belt number 6PK1018.

VAZ 21127 engine with 16 valves and air conditioning

This engine is more massive due to the enlarged cylinder head, so places had to be cut out for the location of many parts. The belt size for such an engine is 995mm, and the article number is 6PK995, of course, as always.

Now you know all the alternator belts installed on the Lada Kalina.

Belts can be replaced with analogues, but a prerequisite is to maintain the length of the belt.

Which belt to buy

The efficiency of the car engine depends on the quality of the parts used in the timing mechanism drive (tensioner roller, belt). When repairing or servicing a car, it is advisable to use original parts, but in some cases, non-original spare parts for automobile components have worked well.

The article number of the original timing belt is 21126–1006040 , which is produced by the RTI plant in Balakovo. Experts recommend confidently using parts from Gates, Bosch, Contitech, Optibelt, Dayco. When choosing, you should be especially careful, since under the brand name of well-known manufacturers you can buy a fake.

On Lada Granta and Lada Kalina cars, we check the condition of the timing belt of an 8-valve engine according to the maintenance regulations on a cold engine (15–35 °C) every 15 thousand km.

LADA > Granta

LADA > Kalina

Snapshot

The surface of the toothed part of the belt should not have folds, cracks, undercuts of teeth and separation of fabric from rubber. The reverse side of the belt should not have wear, exposing the cord threads, or signs of burning. There should be no delamination or fraying on the end surfaces of the belt. If defects are found on the belt or there is a significant discrepancy between the belt tension control elements (see photo above), the belt must be replaced. You should also replace the belt with a new one if traces of engine oil are found on it (before installing a new belt, the cause of oil getting on the belt must be eliminated) or when replacing the coolant pump.

Attention! Failure of the timing belt (breakage and cutting of teeth) can lead to valves sticking into the pistons due to mismatch of the rotation angles of the crankshaft and camshaft and, as a result, to expensive engine repairs.

We replace the timing belt in accordance with the maintenance regulations every 75 thousand km or if defects are detected on the belt.

To avoid damaging the crankshaft position sensor, it must be removed.

The timing belt used in the Lada Kalina model is a ring-type rubber product containing special teeth in a strictly defined quantity. The rubber base is reinforced with nylon threads.

The purpose of the belt is to ensure the transmission of torque from the crankshaft gear to the camshaft if the engine has 8 valves (or two if the head design is 16-valve).

The condition of this consumable component has a direct impact on the performance of the entire gas distribution mechanism. And basically the timing belt needs to be replaced.

Types of faults

In practice, there are three types of timing belt drive faults:

- loss of integrity;

- break;

- incorrect degree of tension.

The first option is dangerous due to belt delamination. Hanging threads will indicate this phenomenon. Sheared teeth are also quite common. Such damage is caused by incorrect adjustment of some components of the mechanism, including:

- gears on camshafts;

- crankshaft pulley;

- tension roller;

- cooling circuit pump;

The belt is tensioned using a special roller with an eccentric shaft. By rotating the roller, you can increase or decrease the tension level. The main thing here is to avoid excessive tension, which will adversely affect the condition and service life of the belt. Also, you should not leave a weakened belt drive, which threatens the teeth on the shaft gears jumping. In both cases, the timing belt in the Lada Kalina will stop functioning normally.

A belt break occurs if the owner of a Lada Kalina does not take timely measures to replace this important consumable component. When such a situation occurs, further operation of the 8-valve motor is impossible. The car should be transported by tow truck to the repair site. And the timing belt will need to be replaced.

Why change?

The manufacturer has established a periodic scheduled period for belt replacement, expressed in mileage. So the owner should tend to the specified procedure every 50 thousand km. It is possible earlier if the condition of the specified consumable requires such action.

Important! Taking into account the quality aspects of the parts in the gas distribution mechanism, which includes the belt, it is recommended to reduce replacement to an interval of 30 thousand km.

The belt drive in Lada Kalina needs regular inspection. Visual inspection should be performed at least once a month. To do this, you will need to remove the protective cover. If the previously mentioned signs of wear appear on the surface of the belt, then such an element of the system should be replaced immediately, which will avoid a sudden break.

An excessively worn timing belt causes the cooling system water pump to malfunction. A break on some engine modifications leads to bending of the valves on the piston bottoms. In some cases, loose strands of belt cords can become wrapped around the generator set shaft, causing it to malfunction.

Note that on older modifications of engines with 8 valves, bending of the valves is not observed when the belt breaks. Impact does not occur due to special technological recesses on the piston heads. New 8-valve units and modifications with 16-valve heads cannot boast of such a useful protective option.

Signs and reasons for replacing the timing belt Lada Kalina

The advantage of the 8-valve engines of the VAZ 2108 and subsequently the Samara 2 family was that when the timing belt breaks, the pistons do not meet the valves and do not bend them. Lada Kalina engines are structurally different from the previous model. And a break leads to the need for repairs.

Replacement frequency

It is regulated by the manufacturer. Usually this is about 80,000 mileage, but given the low quality of components, it is recommended to reduce this period to 50,000 km. In general, the best option would be a timely visual inspection of the part to determine the degree of wear. The first sign of wear will be microcracks, which are clearly visible on a tensioned belt.

If microcracks are found, there is still time to replace it in the near future. Because of this, the belt does not break immediately, since inside it is reinforced with thin and durable steel threads. This provides the belt with the ability to repeatedly withstand heavy loads and maintain its properties for as long as possible. Another sign of wear can be loose tension due to stretching. In this case, the engine will start to run noisily, and the dynamic characteristics will also weaken.

Many motorists, as well as auto repair shop workers, recommend replacing the water pump (pump) and the tensioner roller along with the belt.

The fact is that their wear is often not visually observed, and yet the process of replacing them is quite labor-intensive. Therefore, it is better to change these elements immediately, especially since manufacturers produce kits consisting of a belt and a roller. Some make parts with reinforced metal cord. They are somewhat stronger than regular ones and last longer, but they are also more expensive.

Wear factors

Despite the fact that the manufacturer recommends changing the belt no later than 80,000 kilometers, it is impossible to determine the exact frequency, since this is influenced by several factors. The following points influence the degree of wear.

- Quality. If instead of the original belt, which is installed at the factory, an analogue was installed, then its condition should be inspected at least once every 10,000 kilometers, and preferably more often. It is impossible to predict how long a spare part from a particular manufacturer lasts.

- Vehicle operating conditions. If the machine is actively used, for example, when working in a taxi, then the replacement period should be shorter. During long operation, the belt constantly heats up, which eventually leads to wear.

- Other factors. These moments include poor-quality replacement of the timing belt, when the new element begins to come into contact with other parts in the engine compartment in the immediate vicinity during operation, for example, a protective casing. It is better to correct the situation as soon as possible, otherwise the part will quickly fail.

If a car is purchased from the secondary market, it doesn’t hurt to ask the former owner in advance when exactly the belt was changed. It’s even better to play it safe and replace it along with other consumables that should definitely be replaced on a used car.

Cost of the replacement event

The price of a timing belt in a retail chain varies between 400-600 rubles. a piece. When the tension roller needs to be replaced, then we safely add about 500-600 rubles to the indicated amount.

The cost of the replacement service reaches 800 rubles, and if the roller needs to be replaced, then the expected depletion of the owner’s wallet will be about 1000 rubles.

When purchasing, we recommend considering the original version of the belt produced by VAZ. If this option is not available, then you can take a closer look at an analog product offered by one of the well-known brands.

Next, we present samples of belts with catalog codes. Here you will find the original product and its worthy imported substitutes.

Price: 800 rubles

The belt is in branded cardboard packaging, on the box there is a sticker with a QR code. The kit includes a sticker that indicates the date of replacement and mileage, as well as which of the components - roller, belt, pump - were replaced. This is convenient: you won’t have to struggle to remember when the last belt replacement was made and what exactly was replaced. In addition to branded and general designations, the belt is marked with a batch number.

Replacement

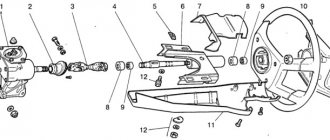

First, let's stock up on tools:

- keys to “10”, “13” and “17”;

- a large screwdriver with a slotted profile;

- wrench for installing the roller and adjusting the tension;

- jack;

- balloon wrench.

Before dismantling, you will need to set the timing belt to a special position (TDC). To do this, there are marks on the shaft pulleys, transmission housing and motor housing. So, replacing the timing belt step by step.

- Lada Kalina is located on a flat area.

- We jack up the right front side, and put wheel chocks on the rear wheels.

- Having opened the hood and armed with a size 10 wrench, unscrew the bolts (3 pcs.) holding the protective cover of the mechanism.

- The tension roller nut in LADA Kalina is unscrewed using a “13” wrench. The timing belt is loose.

- Now we dismantle the generator belt drive. To do this, we use a size 13 wrench to loosen the tensioning device.

- We look for the mark on the camshaft gear. It is presented in the form of a rectangular bead on the back surface of the edge of the gear itself.

- Rotating the shaft with a suitable wrench, align the indicated mark with the upper protrusion present on the mechanism housing fixation plate.

- We move to the box housing. It has a special window closed with a rubber plug. We pry it up with a long screwdriver and remove it.

- We see the flywheel of LADA Kalina. It has a mark that must be aligned with the triangular protrusion located on the left of the crankcase.

- If the phases are set correctly in advance (with the belt tensioned), then the two indicated pairs of marks must coincide. When this is not observed, we correct the position by rotating the shafts by the pulleys (you can spin the wheel by engaging 5th gear in advance).

- Next, we lock the flywheel using a screwdriver, pushing it through the crankcase window and resting it against the teeth.

- Now remove the generator set pulley.

- We remove the old LADA Kalina timing belt from the drive gears and roller.

- When installing a new belt drive, we check that the marks are not displaced. All manipulations are performed using the reverse algorithm.

- Tensioning is done by rotating the roller of the same name. We use a special key.

A correctly tensioned belt will allow you to use your fingers to rotate the idle branch (in the middle) 90 degrees. This will correspond to an applied load of 2 kgf.

- The roller fasteners can now be tightened to the required torque.

- We remove the screwdriver from the crankcase window and return the plug.

- After assembly, we check that the marks match (rotate the mechanism 2 full turns and look).

- We install the casing.

- Don't forget to put the wheel back in place.

During installation, it is important not to forget about the labels.

The timing belt replacement is complete.

Technology for replacing the drive of auxiliary units on Lada Kalina

- Specifics of the drive circuit on different modifications of Lada Kalina

- Recommendations for choosing a belt drive

- Regulations for periodic inspection and replacement of the alternator belt on Kalina

- Repair technology for the auxiliary drive system

- Tension adjustment

- Useful video tutorials on the topic

- How to replace the alternator belt on Lada Kalina

- How to tighten a belt

Lada Kalina from AvtoVAZLada Kalina The domestic auto industry continues to progress - AvtoVAZ presented a new generation Lada Kalina

. The model is equipped with a Jatco automatic transmission and an improved ventilation and heating system. Representatives of the plant claim that the new car has gotten rid of the problems associated with the electric power steering of the previous series.

This is all wonderful, but it was thanks to the first generation of the VAZ 1118 that repair techniques were developed that can be very useful to owners of new cars. Let's say the procedure for replacing the alternator serpentine belt on Kalina

absolutely the same for both models.

Specifics of the drive circuit on different modifications of Lada Kalina

The factory design provides for different lengths of standard gears, which depend on the configuration of the machine:

- without air conditioning – 882 mm;

- with air conditioning – 1018 mm.

The first VAZ 1118 models without air conditioning and a tension roller are equipped with a poly-V drive with a length of 823 mm

. Thus, with one belt from the crankshaft pulley, not only the alternator, but also the air conditioning compressor can be activated. The roller circuit allows you to adjust the tension.

Recommendations for choosing a belt drive

Gates

drive as standard .

As a replacement on the first models, you can use Dayco 825

.

Here you need to take into account that elastic specimens are marked with the “ Poly-V

” symbol; if it is absent, the product has a rigid structure.

Alternative drives for VAZ 1118 with air conditioning

:

- Roulunds Rubber 6PK1015;

- Dayco 6PK1005;

- Bosch 6PK1015;

- Gates 6PK1019.

Alternative drives for VAZ 1118 without air conditioning

:

- Bautler 6PK883;

- Dayko 6PK888;

- Finwhale BP6 883;

- Luzar LB 0118 1118-3701720 6РК 884;

- Roulunds Rubber 6PK884;

- BRT 882 mm (Balakovo plant).

Drive system repair

Regulations for periodic inspection and replacement of the alternator belt on Kalina

Many new owners of vehicles, either from prolonged joy or out of ignorance, remember the presence of a flexible connection under the hood only after the lamp on the dashboard lights up. The technical documentation of the vehicle indicates operational standards, after which the torque transmission elements must be removed and new ones installed:

- tensioner roller after 60,000 km;

- belt after 30,000 km.

Experts strongly recommend monthly scheduled maintenance of the rubber drive, consisting of simple external inspection steps. The part needs to be replaced if the following defects are detected

:

- cracks;

- abrasions;

- delamination;

- oiling;

- cuts.

A high-frequency whistle that appears when electrical consumers are turned on also indicates the need to replace the generator belt on Kalina or, at a minimum, to adjust its tension.

Repair technology for the auxiliary drive system

Sequencing

is similar for both models with and without air conditioning and consists of the following items:

- Remove the engine protection.

- Remove the right wheel and fender liner.

- Remove the expansion tank.

- Jack up the right side of the engine and unscrew the mount.

- By tightening the tensioner mechanism pin, loosen the belt tension.

- Remove the drive from the roller and then from all pulleys.

- Install the new part and reassemble in reverse order.

- Adjust the tension.

It is advisable to carry out work in an inspection pit in compliance with all safety measures. When changing the flexible connection, it is recommended to simultaneously install a new tensioner roller, but this depends on the desire of the owner and the condition of the unit.

Tension adjustment

After replacing the alternator belt on Kalina, making a rough adjustment and then starting the engine, it is necessary to more accurately adjust the drive tension

. To do this, we perform the following operations:

- loosen the tensioner rod locknut;

- turn the adjusting pin with a wrench to “8” until the result is achieved;

- tighten the locknut.

When gradually tightening the belt, you can use a simple canter scale, which you need to attach to the key at “8” and tighten the pin counterclockwise to a reading of 2 kg. A normal setting is considered when, with a force of 10 kgf, in the area between the generator and crankshaft pulleys, the deflection value will be within 8-10 mm.

More “advanced” owners have devices such as TsNT-Belt, the operation of which is based on the recognition of the known acoustic characteristics of drive devices.

Useful video tutorials on the topic

A video with a step-by-step operation will help you analyze in detail all the nuances of replacing and adjusting the tension