A heated rear window is a useful and very convenient option that helps keep your rear window fog-free and icy while still providing excellent visibility all year round.

Heating the rear window allows you to save money not only in winter, but also in autumn, when humidity rises and all the windows in the cabin begin to fog up. In a few minutes, the heated rear window melts ice and light snow, and also dries condensation that accumulates on the windows in case of rain.

All this is normal, but what if nothing happens when you press the button, in other words, what if the rear window defogger does not work? This is exactly what we will try to figure out today. You will learn how heating works, why it does not work and how to find a fault and repair the heated rear window of a VAZ.

How does the heated rear window work?

The heating principle is as follows. A voltage is applied to a conductive wire, called a heating element, causing the wire to heat up, thereby melting the snow and drying out the moisture. The heating system consists of a network of conductive wires, several fuses and a button. When the driver turns on the heated rear window, a warning light on the panel lights up and one of the relay contacts closes. The second contact is connected to the body, this is “minus”. Thus, current circulates in the heating system.

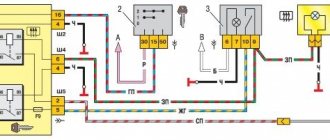

Rear window heating diagram for VAZ cars

Car electrical equipment

1 – headlight block; 2 – gearmotors for headlight cleaners*; 3 – fog lights*; 4 – ambient temperature sensor; 5 – sound signals; 6 – engine compartment lamp switch; 7 – electric motor of the cooling system fan; 8 – VAZ 2114 generator; 9 – low oil level indicator sensor; 10 – washer fluid level sensor; 11 – front brake pad wear sensor; 12 – wire tips connected to the common glass washer pump**; 13 – windshield washer pump; 14 – headlight washer pump*; 15 – wire ends for connecting to the rear window washer pump on VAZ 2113 and VAZ 2114 cars; 16 – low oil pressure indicator sensor; 17 – engine compartment lighting lamp; 18 – wire lug for connection to the wiring harness of the engine management system or to the wiring harness of the ignition system on carburetor vehicles; 19 – windshield wiper gearmotor; 20 – VAZ-2114 starter; 22 – coolant temperature indicator sensor; 23 – reverse light switch; 24 – indicator sensor for insufficient brake fluid level; 25 – battery; 26 – sensor for insufficient coolant level indicator; 27 – relay for turning on fog lights; 28 – mounting block; 29 – brake light switch; 30 – plug socket for a portable lamp; 31 – illumination lamp for the headlight hydrocorrector scale; 32 – parking brake warning lamp switch; 33 – backlight lamp connection block; 34 – switch for instrument lighting lamps; 35 – steering column switch; 36 – alarm switch; 37 – front seat heating element relay; 38 – ignition switch VAZ 2114; 39 – rear fog light circuit fuse; 40 – fuse for the front seat heating elements circuit; 41 – door lock circuit fuse; 42 – front ashtray illumination lamp; 43 – ignition relay VAZ-2114; 44 – cigarette lighter; 45 – glove box lighting lamp; 46 – glove box lighting switch; 47 – heater fan electric motor; 48 – additional resistor of the heater electric motor; 49 – heater fan switch; 50 – heater switch illumination lamp; 51 – backlight lamp for heater levers; 52 – gearmotors for electric windows of the front doors; 53 – power window switch for the right front door (located in the right door); 54 – gearmotors for locking front door locks; 55 – wires for connecting to the right front speaker; 56 – gearmotors for locking rear doors; 57 – wires for connecting to the right rear speaker; 58 – door lock control unit; 59 – wires for connecting to radio equipment; 60 – headlight cleaner switch; 61 – rear window heating element switch; 62 – relay for turning on rear fog lights; 63 – block for connection to the heating element of the right front seat; 64 – switch for rear fog lights: 65 – switch for the heating element of the right front seat; 66 – fog lamp switch; 67 – switch for external lighting lamps; 68 – left front seat heating element switch; 69 – block for connection to the heating element of the left front seat; 70 – wires for connecting to the left front speaker; 71 – left front door power window switch; 72 – right front door power window switch; 73 – wires for connection to the left rear speaker; 74 – side direction indicators: 75 – lamp switch on the front door pillars; 76 – lamp switch on the rear door pillars; 77 – lampshade; 78 – canopy for individual interior lighting; 79 – block for connecting to the wiring harness of the VAZ 2114 electric fuel pump; 80 – trunk light switch; 81 – instrument cluster: 82 – trunk lighting lamp; 83 – display unit of the on-board control system; 84 – trip computer (not in all models); 85 – block for connecting the wiring harness of the engine control system; 86 – rear external lights of the VAZ-2114; 87 – rear internal lights; 88 – block for connection to the rear window heating element; 89 – license plate lights; 90 – additional brake signal located in the spoiler.

Causes of rear window heating malfunction

- Switches. If the heat is not working fully, the fuse is likely blown and should be replaced.

- Break up. It also often happens that current-carrying wires burn out or break, as a result of which the current does not go beyond the break. A wire break can occur due to abrasion or breakage, for example, due to incorrect repair.

- Faulty button or relay. If the rear window defroster button or relay is faulty, no current will flow.

- Contacts. Oxidation, breakage or wear of contacts leads to an unstable current supply and, as a consequence, to poor heating of the wires.

Causes of faults and their detection

The heated rear window operates immediately as soon as the ignition is switched on, and should clear within a few minutes. But it happens like this:

- The power signal does not light up, although the button is pressed, the glass does not melt (it remains blurry);

- The heating does not work, but the indicator is on;

- Defrosting glass into strips;

- Insufficient heating. This phenomenon occurs if the glass is very cold. In this case, simply mechanically clear it of ice.

Rear window defroster timer

The root cause of other phenomena should be sought:

- In the control relay;

- Check the condition of the fuse in the box;

- Check that the connectors on both sides of the rear window are secure. Perhaps they should be removed;

- Also check for breaks in the power wires in the switch itself;

- If everything looks good here, check the conductive thread. When the engine is running, it is necessary to check the voltage approximately in the middle of each of the thread sections (strips). If the device shows about 6 volts, everything is fine. If the reading is about ten or, conversely, close to zero, then a break occurs. The technique will help determine exactly where the break is: a pointed electrode of the device, wrapped in wide foil, leads along a “suspicious” conductive tape. Where there is a surge, there is a break;

- But often the stones can be seen literally - the thread has spread in some area.

Finding a broken rear window heating

The search is to identify an interruption in the circuit. We check the relays and fuses (mounting block F8 (20A) and F8 (20A), as well as the button, if everything is in order, you should look for breaks in the filament. To do this, first carry out a visual inspection. Turn on the heating and observe where the strands heat up and where No.

If a visual search does not produce results, you can use a voltmeter or multimeter. To search for a break using a voltmeter, turn on the ignition and heating, then connect one probe of the device to the ground of the machine, and wrap the other in foil and move it to the center of the conductive wire. In this case, the device should show a result in the range of 5 V. At the point where the device shows 0 V or, conversely, increases by more than 10 V, it can be assumed that there is a break at this point.

If the rear window heater fails, a voltmeter will help you find the break. The device is connected to the positive terminal of the heater, and the second probe moves smoothly along the filament only from the side of the negative terminal. At the point where the voltage drops to 0V there will most likely be an open circuit. This is where you will need glass repairs.

Heated glass does not work on VAZ 21099

The rear window of the car allows the driver to control situations on the road. It's no secret that if the rear window fogs up, the view deteriorates and the driver has to drive “on the side” mirrors.

Naturally, this can lead to problematic situations and repair of the rear window defroster should be carried out as soon as possible. As practice shows, both the heating of the entire glass and several of its strands can fail.

Causes of failure of the VAZ rear window heater

First of all, it is worth remembering that the power supply to the heating is carried out through two terminals soldered on the glass. Heating threads emanate from them, which directly heat the glass and promote the evaporation of excess moisture.

Quite often, when installing the rear window of a VAZ, these terminals are forgotten to be connected (especially if you are dealing with amateurs), or they are broken during connection. In the latter case, the throughput of the conductor decreases, as a result of which it burns out over time, and the glass does not warm up, which leads to failure of the heating.

If the glass heating was damaged mechanically, which is also possible, the situation becomes similar to that described earlier. When mechanical damage occurs, the resistance of the thread increases, it overheats and fails.

There is a third way to damage the thread - a banal burnout. It occurs naturally, or due to the fact that the metal component has oxidized, worn out, or received natural damage. Practice shows that such disruptions in heating operation occur least often.

Repairing the heated rear window - how and with what?

- There are many options for repairing wires, one of which is a rear window heated wire repair kit. This category is represented on the market: Permatex and Quick. Such repair kits allow you to effectively repair large areas of damage, up to ten centimeters. The kit consists of stencils, a cylinder with polymer resin and the heating wires themselves. The repair is carried out as follows: we find the damaged area, prepare the required piece of wire, remove the protective film and glue the wire to the area using polymer resin. When everything is dry, the procedure can be repeated. After 1-2 days, turn on the heat and check the result.

- The second method of attaching rear window heating threads is to use conductive paste, such as Kontaktol. A special paste or glue that can conduct current is applied in a thin, clean layer to the damaged area. For more precise application of the paste, the work area can be sealed with tape. The paste takes about a day to dry, but if you have an effective heat source such as a hair dryer or a special heater, the drying time can be significantly reduced.

- There are also alternative “makeshift” methods for repairing heated rear windows. That's why some people use paint that contains copper-brass shavings. The paint is matched to the color of the threads, and the shavings are removed by shaving the material. You can use glue instead of paint. Alternatively, you can try connecting the break points using a soldering iron. I would like to note that in this case there will be a result, but it will not look very aesthetically pleasing.

This is my conclusion. I hope now you know what a heated rear window is, how to find its fault and how to repair the heated glass in several ways. That's all, thank you for reading to the end. I would be grateful if you share this article on social networks, it will help us in the development of this project. In addition, more people will know about our existence. Also, do not forget to leave your comments and add your recommendations to this article. All the best and see you again at VAZ repairs.

On VAZ cars, as on most foreign cars, the rear window is equipped with a heating function. It is very useful and is designed to maintain visibility through glass in bad weather.

Heating helps equally well both during rain and fog, when condensation forms on the glass, and in winter, when it is covered with a layer of frost.

But it also happens that the rear window heating 2114 does not work. There may be several reasons for this - we will look at them below, but first you need to understand - on what principle does the heating system itself work?

Why are the heated strips on the rear window damaged?

Thin heating filaments can either burn out from tension or be damaged by external influences. For what reasons is the rear window heated in parts most often?

Physical damage to threads

- The most common option is physical damage during transportation of goods. They put something sharp on the rear parcel shelf in a sedan, they carried something oversized in a hatchback, they carelessly cleaned or repaired the car. The threads are very thin and quite fragile - it’s easy to break them.

- The heating can be damaged by careless actions when gluing the tint film.

- chafed by the factory rubber seal or carelessly applied seal adhesive. This happens rarely, but it does happen - for example, the Opel Corsa has such a problem.

- Another option is when the thread is not damaged, but simply burns out over time. The likelihood of such an effect depends on the quality of the thread itself and the health of the vehicle's electrical system.

When the rear window heating does not work, drivers can simply ignore the problem. But this is simply unsafe in the winter and autumn seasons. So you not only deprive yourself of the opportunity to view through the rear window, remaining only with the side mirrors, but you may even be left without glass at all.

Continuing to use the rear window heating when some of the filaments have burned out and some are working is dangerous. In this case, a temperature difference occurs and in severe frost the glass may simply burst. If you have tinting, the glass will hang on the film. But without it, the glass crumbles and can injure you with fragments!

General concepts

In order for the glass to heat evenly and at a strictly defined temperature (sufficient to evaporate moisture, but not beyond safe limits), a special electrically conductive wire (thin flat wire) is used, which has a certain strictly standardized strength.

When current flows through it, it heats up, just like electric stoves and kettles, only at a much lower temperature. Thanks to this heating, in addition to the fact that it occurs evenly over the entire plane of the glass (after all, the wire is applied to it at equal distances), the latter dries quite quickly and is cleared of moisture.

Sometimes in winter it may seem to a car enthusiast that the heating is not working, because the glass does not defrost for a long time. In such a situation, there is a high probability that the heating is working properly, but its temperature is not enough to melt a significant layer of ice. You must manually remove the ice with a special scraper and then turn on the heat again.

Possible faults

There may be several reasons why the heated rear window of the VAZ 2114 failed.

The most common:

- blown fuse;

- the contacts in the fuse socket in the common block are coated with oxide;

- the switch is broken;

- the relay has failed;

- the heating element terminals are oxidized;

- internal network wiring burned out;

- The heating filaments themselves have broken.

The first two (and most common) reasons are quite simple to solve: you need to check the fuse and, if necessary, replace it with a new one (in the general block it is designated as F5). You should also check the contacts in the fuse box and clean them with sandpaper or a cloth soaked in kerosene.

If the fuse turned out to be good or was replaced, but the problem did not disappear, then the heated rear window button of the VAZ 2114 may have failed. You can check this, as well as the control relay, using a conventional tester (multimeter). To do this, in the first case, the output contacts “ring” in the on and off positions, and in the second, the supply voltage (its presence) on legs 1 and 9, as well as on relays 2 and 4 (the second one in the diagram) is monitored).

If all of the above elements have been checked and are working properly, you need to check with a multimeter all the wires included in the electrical circuit of the heating element. If a break is detected, the wire should simply be replaced with a new one.

Recommendations

Comments 11

I'll write here, maybe someone will help. New glass was installed. The heating works. But after 10-15 minutes the fuse that goes to the cigarette lighter (radio) blows out at 20.

The contacts are not sealed on the glass, have you checked?

I checked and they seem normal. You will need to remove and clean the contacts.

Same bullshit, today I'll go see an electrician

Post back later if it works.

poked with a tester, they said the glass needs to be replaced (((((

Badly. Thanks for the answer

poked with a tester, they said the glass needs to be replaced (((((

Looks like I also have glass in need of replacement.(((

I heard that there is some kind of special paste that you rub with it and the conductivity of the heating element is restored. I don't know how true this is. Well, the glass will have to be changed...

This paste is a conductive adhesive, available in radio stores... it is applied to the damaged areas of the glass heating element (visually it looks like a 1-2 mm break on the track itself. The restoration work looks like this: 1. Shine a flashlight through the glass along each track separately, along the entire length, we find the damaged areas. 2. LIGHTLY use a blade to make a couple of scratches on the path along the edges of the cliff and make a thin path of paste, thereby restoring the conductivity. 3. Wait for complete crystallization of the paste (from a couple of hours to a day, as in the instructions). 4. PROFIT!

If this paste is difficult to access in your region, you can make it yourself. Here are a couple of options:

Paint and shavings. The shavings are “mined” from a copper-brass bar with a file. The paint is preferably red, matching the color of the threads. Mix the shavings with paint (50/50) to a dough-like state. We make a stencil from electrical tape (adhesive tape). Turn on the heating and apply the mixture using a stencil. You will hear that “there is contact” by the reaction at the repair site. It should be a slight hiss. All. You can go right away.

Glue and shavings. A similar way to obtain a conductive mass is to use glue, for example BF-2, instead of paint. In both cases. If the area where the conductive thread is broken is large enough, then for reliability you can use a thin wire (core).

Source: www.drive2.com

Possible repair options

All the breakdowns described above, due to which the rear window heating of the VAZ 2114 does not work, are quite common and can be eliminated without much additional cost or effort. A much more serious problem is damage to the heater itself, namely the breakage of its heating wires.

If this happens, you can solve the problem in several ways:

- independently repairs broken threads;

- install a small removable heater connected to the cigarette lighter;

- install a full double-glazed window with a fan.

If the conductive threads break, the best option is to restore them. Installing additional heating elements in a car can significantly increase the load on its on-board network.

To find the exact break point, you should carefully examine all the strands under a magnifying glass.

If you detect a power outage, you can try to reset the heating in one of the following ways:

- Connect the cleaned areas with a paste of conductive material.

- Connect with thin metal filings. To do this, sawdust is applied to the tear, and a powerful magnet is placed on the other side of the glass, which will temporarily hold it. While the sawdust is attracted to the magnet, you should quickly apply a coat of paint or BF glue to it.

- Solder the break point using POS-18 or similar solder (low tin content).

- Fix the gap with a special glue for restoring heating wires (it should be noted that this is quite rare and is not found in all car dealerships).

By completing the repair in this simple way, you can completely restore the operation of the glass heating system, even if there are numerous breakdowns.

Damage to threads

Electric strips act as current conductors, heating up slightly due to resistance (the strips are connected in parallel - the voltage is distributed evenly). If even one heating strip is damaged, the current stops circulating in the system - the heating does not work.

To restore the heating strips, you will need to buy a special repair kit from a car store (do not buy the cheapest one, so as not to run into a low-quality product).

The set includes:

- special glue with high electrical conductivity (choose by color so that the “restored” area does not stand out);

- a brush for applying it;

- tape to mark boundaries.

Find the location of the chain break (often mechanical damage). Study the instructions for the restoration kit, pay attention to the drying time and the recommended method of application. Prepare the damaged area for repair - wipe it with alcohol using a lint-free, clean rag (remove dirt and grease). Apply strips of tape in the area of the tear on both sides of the tape (leave the appropriate width). Apply the special product in several layers (see the instructions for the quantity). Let the glue dry - often a day is enough. After this, remove the tape and check the operation of the unit.

This method is suitable for repairing rear window heating in domestic cars (for example, VAZ 2114, VAZ 2112, VAZ 2107, VAZ 2109, Lada Granta).

There are two more alternative methods for restoring a break:

- Using metal filings. You will need sawdust, a magnet and clear glue (preferably some tape). Description of the process: attach the magnet to the back side, pour sawdust onto the damaged area from the inside. Place tape under the bottom of the strip to prevent any metal shavings from sliding off. We fix the material on top with glue. Let it dry. Ready!

- The point here is that they use a mixture of non-ferrous metal shavings and paint. This substance should be identical in density to plasticine. Next, fix the tape, as in the previous version, and heat it up. Apply the material to the damaged area and wait half an hour (hissing is normal). Allow the glass to cool for another hour before using the heating fully.

Useful video

For more information, watch the video below:

- The VAZ 2114 stove does not heat well, does not heat, does not work. Causes of malfunctions.

- Do-it-yourself adjustment and tuning of VAZ 2114 headlights

- Replacement and repair of VAZ 2110 starter

The rear window heating on the glass does not work, a splinter is torn off on one side, and on the other there is a piece of glass, not a handle, what to do, how to connect which cable is needed and where, where to connect the plus and where less

I checked all the fuses, the ignition button, the heating wire itself, checked everything with a test, started the engine, I think it's relay 9043747, if it's a relay, how to replace a Lada 2114 car? Help if possible!

Good visibility is important for safe vehicle operation. In the autumn-winter period, due to air temperature changes, the windows fog up and visibility through them deteriorates. The issue of glass transparency is especially relevant at night, when visibility already leaves much to be desired.

An effective way to combat fogging of car windows is to insulate them. The windshield is usually heated by direct streams of hot air. Typically, the rear window and rear view mirrors are heated electrically. On the interior side, conductive tracks made of high-strength metal in the form of thin strips are applied to the glass surface. When electric current flows through them, thermal energy is released. The glass heats up and the water evaporates. After a few minutes the glass becomes transparent.

Heated windshield. DIY any car

Well, guys, winter is in full swing, snow is falling, ice is on the roads, the car needs to be warmed up in the morning, in general the weather is uncomfortable. But probably each of us has been struggling with the icing of the car windshield since the morning. Personally, I will never forget the freezing rain that turned my car into just a big piece of ice! However, the neighbor in the parking lot came, started the engine, turned on the heated windows (front and rear), after 3 - 5 minutes they thawed out, and he calmly drove away. But I had to hang around in the parking lot for about 30 minutes and wait until the stove melted a 2-3 centimeter layer of ice. Eh, I wish I could make the front heating myself! And you know, this is real...

Now many cars, so-called “ adapted for Russia ,” already come with threads in the windshield, which heat it up! It’s very convenient and very necessary, in my opinion, especially for our cold country. The problems of scraping ice with a brush disappear.

But many Japanese, German (and other) manufacturers simply do not have such elements! They are designed for a more or less mild climate, and therefore this does not even occur to engineers! Although we need it.

First, how does classic heating work?

As we know, car glass, especially the windshield and rear glass, consists of two layers, between them there is an adhesive composition usually similar to a film.

In the usual version, there is nothing else inside, but in the heated glass on the middle film, small wiring of the heating element is installed, so small that they simply cannot be seen from a distance of half a meter (that is, they do not interfere with driving at all). As you probably guessed, an electric current is applied to them, they heat up and help defrost the entire glass. Very comfortably. But this is not implemented on all brands and models.

Therefore, the question arises, is it possible to install it yourself? It turns out that it is possible, there are several solutions to this issue.

Any heated glass

Yes, you heard right, this is the simplest and most effective way. The fact is that now many companies that make non-original spare parts have long been stamping glass with threads for almost any model, as a rule, these are Chinese companies.

In addition to purchasing and installing, you will need to install wiring and make a switch. But I think this is not a problem, many people use the heated rear window. That is, when turned on, both sides, front and rear, are heated at once. Of course, this is not cheap; for an ordinary foreign car of class “B” or “C” , it can reach up to 10,000 rubles. And if you install the original (this also happens - for example, on higher-level trim levels there are heating), then the price can reach up to 30,000 rubles and this does not take into account the work and electrical wiring! But we don’t care about winter! It is also beneficial in autumn weather, when the steles sweat.

Strip heaters

However, if you put your hand on your heart, not all cars have such “lobovukov”, some cannot be found, even Chinese ones, for example, no matter how much I looked (for my Chevrolet AVEO ) I still couldn’t find it! Therefore, you need to be content with little.

By small, I mean heating the wiper area; if it is powerful enough, it contributes to the rapid thawing of the entire stele. So how to implement this?

Adhesive strips have been on the market for a long time, often transparent, but often not. We just glue them to the bottom near the panel, hide the wiring under the plastic, and again connect it to the rear heating.

Thus, the lower part, which is always covered in ice (snow), will quickly thaw, and then the rest of the canvas will be “finished off” by the car’s heater. Personally, I myself have seen this design many times, it works very effectively. It is also gratifying that our Russian manufacturers also produce, the strip does not take very much power - approximately 14 - 20 W, depending on the thickness and length. You can install it yourself, there is nothing complicated here, just glue it in the desired area and connect it.

Electrical diagram for connecting the heater

In order to successfully diagnose and repair the rear window heating system of a car at a professional level, you need to know the heater connection diagram and understand the principle of its operation.

The photo shows a typical diagram of connecting the rear window of a car to the on-board wiring. Let's look at how this works.

The supply voltage from the positive terminal of the battery through the ignition switch and fuses is supplied to the heater switch and to power contact 30 (or 87) of the relay. The negative terminal of the battery is connected to the body, one of the terminals of the window defroster is also connected to the body. When you press the heater power button, voltage is applied to the relay coil, the relay is activated, the power contacts close and connect terminals 30 and 87 of the relay together. Current enters the heater, travels through a group of wires connected in parallel, and returns through the housing to the negative terminal of the battery.

Rear window defroster malfunctions

The rear window defroster functionality is ignored until the glass fogs up or freezes. After turning on the heating, it suddenly turns out that after a few minutes the glass did not become transparent or visibility appeared only through part of the glass. Depending on the external manifestation, even without measuring instruments, you can immediately make an assumption about the cause of the breakdown.

Please note that the heated rear window and rear view mirrors can only be turned on when the ignition key is in the ON position. In some car models, the heater can only be turned on when the engine is running. This is done to avoid severe battery discharge, since the rear window defroster consumes current from 10 A to 25 A, depending on the car model. For comparison, a car headlight consumes only 5 A.

The heater does not turn on

If the indicator on the heated rear window button does not light up after pressing it, then most likely the fuse has blown or the key itself is faulty. If the indicator is on, but not a single wire heats up, the cause of the malfunction may be the relay or connectors for connecting the heating element to the wiring. In this case, using the documentation for a specific car model, it is necessary to determine the location of these parts and replace the faulty one. It is not always possible to quickly find the installation location of the relay, but there is a way to indirectly check its performance, which will be discussed below.

The glass is slowly fogging up

Sometimes it happens that after turning on the heating, the glass sweats for a period of time significantly exceeding several minutes. In this case, if it is not very cold outside, the reason may be poor contact of one of the connectors of the electrical circuit. As a result, the contact resistance increases, the current is limited and, as a result, the power allocated to the glass heater filaments decreases. To check for the presence of such a malfunction, it is necessary to measure the voltage at the input terminals of the heating element and battery with a DC voltmeter (multimeter or dial tester turned on in DC voltage measurement mode). The voltages should not differ by more than one volt.

Horizontal streaks of fog remain on the glass

And finally, the most common case of malfunction of the rear window heating system of a car is a break in one or more heater wires attached directly to the glass. This type of malfunction is immediately visible by the horizontal stripe of residual fogging on the glass after turning on the heating element.

The conductive tracks on the rear window have low mechanical strength and are easily destroyed upon contact with them. Therefore, it is prohibited to remove frost and ice from the glass with a scraper. Clean only with a soft cloth. It is also necessary to ensure that when transporting large objects they do not rest against the rear window. As a rule, individual heater filaments stop working due to their accidental mechanical destruction. After turning on the heating, streaks of fog or frost remain in the area of the damaged wire.

While renovating my apartment, I was carrying floor skirting boards in the car and didn’t notice how one of them leaned against the rear window. Some time later, when it was necessary to insulate the rear window, I saw the result of my carelessness. The two heater strips running through the center of the glass did not overheat, which greatly reduced visibility of the road. Upon visual inspection, a gap of approximately 1 mm wide was found on the non-functioning strips, as in the photograph. The question arose about the need to repair the heated rear window.

When is other heating system components needed to be repaired?

In 95% of cases, broken threads are to blame for rear window heating malfunctions. Therefore, we will dwell in detail on how to fix this particular problem. But other options for system malfunctions are also possible. You should know about them too.

When is it necessary to repair the heated rear window contacts?

If the heating system button turns on and lights up, but not a single thread heats, then most likely the problem is in the relay or in the heater contacts. You need to find the relay in the electrical circuit of your car and check its functionality with a multimeter. If faulty, replace it. If the relay is working, check the contacts.

The heating system contacts are located at two conductive busbars, which are located on the sides of the rear window. Often they are hidden behind the sealing elements and you cannot see the contact point between the threads and the tires without removing the seal.

Knowing the diagram of the heating system, it is easy to understand which bus is connected to ground and which is supplied with voltage. For example, in Renault Logan, the current supply bus is located on the right when viewed from behind the car. But even if you don’t have such information, just measure the voltage on the wiring in front of the buses: it will be 0V at ground, 12V at positive.

The following options are then possible:

- If the bus is working properly (the multimeter shows 12V on the current supply), and the glass does not heat up, then the problem is in the threads.

- If there is no voltage on the data bus, its contacts need to be repaired.

- If both buses show 12V, then the contacts on the ground bus need to be repaired.

Repairs are made using conductive adhesive. For this purpose, Permatex offers a professional kit “Repair of heated rear window contacts” under article number 213515.0.

First you need to clean and degrease the surfaces, then carefully remove the film from the contacts with sandpaper. Then wipe all surfaces with an activator cloth and leave to dry for five minutes. After this, apply one drop of glue and firmly press the surfaces together for a few seconds. You can turn on and check the functionality of the system after 24 hours.

When is the rear window heating button repaired?

If the heating button indicator light does not turn on and the system does not work, then the problem is in the fuse or in the button itself.

First you need to check the fuse. For example, in Daewoo Lanos it is marked as F7/30 on the diagram of the fuse box in the engine compartment, just like in the Chevrolet Lacetti (diagram). If it is faulty, replace it.

Then you need to check the button itself. To do this, you will have to pull it out of the seat and force the contacts to short-circuit. If the system works, the problem is in the button and it needs to be replaced. But let's be honest, this is one of the rarest system malfunctions. In addition to the threads, most often the problem is in the relay, or in the fuse, or in the bus contacts.

How to find the location of a broken glass heating filament

It is not difficult to determine which heater wire is in the reef, since fogging in the area where it passes does not disappear when the heater is operating. Therefore, in order to easily find a faulty thread during repairs, it is advisable to count the number of threads from top to bottom and remember which of them is in the break, so that then, during a visual inspection, try to find the place of its damage. But the thread break is so small that it is impossible to detect it visually. So a DC voltmeter, ohmmeter or voltage indicator will help in your search. To quickly find the location of a fault in the heating element, you need to imagine how it works and works.

The design of the heating element of the glass heating system

A natural question arises: why does it happen that only one or several threads in the heater do not work, while the rest work? To answer this question, you need to familiarize yourself with the design of the heating element.

The heating element of the rear window of a car is designed as follows. Two conductive bars 1 and 2 are attached to the sides of the rear window. Cores made of high-strength material are attached to these bars. Each wire has a resistance of approximately 10 ohms. The number of threads depends on the height of the glass. Thus, each wire is a separate heating element, the operation of which does not depend on the others. A parallel circuit for connecting heating elements is used. This circuitry ensures high reliability of the heating element, since the break of one or more wires does not lead to a complete stop in its operation.

Finding a broken heater filament using a voltmeter

To work, you will need any DC voltmeter with a measurement limit of 15 V. Any tester with a dial scale or a digital multimeter will be suitable as a voltmeter. Before starting work, you need to turn on the heating element.

Since one of the heating element buses is connected to the car body, the negative terminal of the voltmeter can be connected to the car body; Any screw or bolt screwed directly into the housing will do. The alligator clip is more convenient to attach to the trunk lid lock bracket.”

Since it is difficult to see visually with transparent glass whether the heating element is heating up, touching the positive probe of the voltmeters on bus 1, and then on bus 2, you will immediately understand. Bus 1 should be +12 V, and bus 2 should be 0 V. It's possible that your car's left bus is grounded and the right bus is energized. If the busbars are not accessible, measurements can be taken by touching any of the wires with a probe at the points of connection with the busbars, that is, where they exit the rubber seal. In the photo these are points 1 and 5.

Using a voltmeter it is easy to determine which part of the heating system is faulty. If the heating element is turned on, the power indicator on the button is on, and there is 12 V on bus 1, but there is no heating, then the wiring on bus 1 is OK. If there is no voltage on bus 1, it means there is a bad contact in the power supply terminal on bus 1, or the relay is faulty. If 12 V is present not only on bus 1, but also on bus 2, you need to look for a bad contact in the terminal for connecting the cable to bus 2 or in the circuit connecting the cable to the vehicle ground.

Finding the location of the thread break

After checking the heater power system, you can begin to determine the location of the heating wire break. The wire represents a tape resistance of about 10 ohms, so the voltage at different points has different values. Therefore, at point 1 the voltage will be 12 V, at point 3 - 6 V, and at point 5 - 0 V. Therefore, even without knowing which of the wires is in the break, it can be easily determined by measuring the voltage in the middle of the length of all threads . On broken wires the voltage will be 12 or 0 V. If the voltage is 12 V, the break point is on the left, and if 0 V, then on the right.

Now just slowly bring the probe to the break, instead of a sudden change in voltage, there will be a break. For example, in the photo this is a piece of thread between 6 and 7 points.

Finding a broken thread using an ohmmeter

Using a multimeter or pointer tester in resistance measurement mode “title =” How to measure “> you can also successfully find the location of the wire break. Grounding won't work.

If the wire break is unknown, you need to connect one end of the ohmmeter probe to the ground terminal, and touch the center of the heater wires with the other one in turn. The wire on which the ohmmeter shows resistance is twice as large and will be broken. For reference: the resistance of all wires in relation to bus 1 or bus 2 should be 2-3 ohms. If the filament breaks, the ohmmeter will show 4-6 ohms.

If a damaged wire is detected, it is necessary to move the probe tip from the center to any direction. If the resistance increases as the probe moves towards busbar 1, then the break occurs in the gap between busbar 1 and the contact point of the probe. For example, at the point indicated by points 1 and 2. As soon as the probe passes the gap, the resistance will sharply drop several times. If the resistance decreases, this means that a wire break occurs between the probe and bus 2. For example, at the point indicated by points 3 and 4. Then you need to move the probe towards bus 2, and when the resistance drops sharply, at that moment there will be a pause.

Locate broken threads with an automotive tester probe

If you do not have a voltmeter or ohmmeter, you can find the break point of the heating element filament using a homemade automotive tester probe, consisting of a single LED and a current-limiting resistor. I made the tester for myself a long time ago, although I have measuring instruments. The homemade car tester is always in the glove compartment of my car, and I have had to use it more than once.

Detecting a broken wire using a tester probe is no different from searching with a voltmeter. The indicator in this case will not be an arrow or number, but an LED glow.

Before you start searching for a damaged filament using a probe, supply voltage must be applied to the heating element. First, the presence of voltage on bus 1 is checked, the LED should be lit, if the LED is not lit, then the error lies in the power supply circuit of the power supply. Next, the voltage on bus 2 is checked; the LED should not light up; if it lights up, it means the contact at the point where the wire is connected to the bus or housing is faulty.

To find where the heater filament breaks, you need to slowly, lightly touching the filament, move it along the end of the probe. At the point where the LED goes out or lights up and the wire breaks. For example, in step 6 the tester LED will light up, but in step 7 it will not. In my case, the wire breaks were large, and the tester was only useful for checking the quality of the repair.

How to find a breakdown

To find out exactly what the reasons for the failure are, you only need a standard voltmeter, which every self-respecting car enthusiast should have. By simple manipulations with this measuring device, the problem will be identified very quickly.

You should start checking the heating element filaments with the following steps:

- the metal tips of the probes are wrapped in tin foil (this will avoid damage to the tracks);

- turn on the ignition;

- check whether the heating button is pressed;

- one probe is applied to the plus of the heating element mounted on the rear window;

- the second is installed approximately in the center of the thread.

If the device shows 6 volts, this means that there is no damage in this area. If the tester produces 12 volts, the gap is located somewhere in the segment between the probes.

If there are 10 volts, we can confidently say that the gap is located between the minus and the center of the track. In this situation, connecting one probe to the negative output will allow you to more accurately determine where the damage is located. At the same time, the second one must be carefully guided along the thread from the plus to the opposite end. Finding the exact location of the break is indicated by an increase in voltage from zero to 5 volts.

If you don’t have a voltmeter at hand, then the break will also be easy to find visually. To do this, you will need to wait until the windows in the car fog up, and only then turn on the heating. Where the track remains operational, the moisture will begin to evaporate noticeably. Condensation will remain in de-energized areas. It is these sections of the heating element that will need to be examined in detail. To do this you will need a magnifying glass.

If the heating is completely out of order, it can be replaced with a removable model, which is attached to the glass using special suction cups. It is connected to the car's electrical network, like many other devices, through the cigarette lighter.

There are also modifications on sale in which an additional fan is installed. But this option is not very practical because it requires too much electricity.

Methods for repairing heating element filaments

There are several ways to restore the functionality of a heating wire at home.

Using conductive pastes and adhesives

The simplest and most effective is with the help of special repair kits, for example DONE DEAL DD6590, designed for repairing threads and contacts of the rear window heating for both amateurs and professionals. The good thing about this method is that it does not require tools or materials. It is enough to apply a little conductive paste according to the attached instructions to the place where the syringe thread is broken, wait for the paste to harden and complete the repair. But this set costs more than $15.

The second method is similar to the previous one. But instead of a proprietary set, purchased conductive adhesives are used, for example. Glue is applied to the place where the thread breaks, covering the entire part of the thread by one centimeter on each side. To obtain a neat look, use a stencil made of electrical tape or adhesive tape. For reliability, glue is applied twice. It is recommended to lay a piece of tinned copper wire with a diameter of 0.3-0.5 mm between the layers of conductive glue.

It is believed that conductive paste or glue for repairing glass heater wires can be made independently by mixing paint or glue with brass filings in a one-to-one ratio. The resulting composition is applied through a stencil in a thin layer until the thread breaks in several layers. But the reliability of this technology has not been confirmed by practice.

Electroplated copper deposition

Another method is copper electroplating. The method for repairing the heater filament looks interesting. But from personal experience I can say that the reliability of such coatings at home is low. Therefore, I hesitated to use this technology.

Using soft soldering

The mechanical method of restoring the integrity of the rear window heater filaments using soft soldering has become widespread. I tested the reliability of this method when repairing the rear window heating threads in my car. The step-by-step instructions below, based on my experience, will allow you to easily repair your heater wire yourself in minutes with virtually no cost.

On the advice of Internet theorists, I made a big mistake and tried to clean the thread with sandpaper. As a result, instead of breaking a thread 1 mm wide, a break of more than 1 cm occurred. The thread ribbon is very thin, only a couple of tens of microns, and can be erased even with the finest grit sandpaper instantly. However, the heater wires are not covered with anything, and it is enough to degrease the welding area with a rag moistened with alcohol or acetone.

If the width of the wire break is less than 1 mm, you can do without soldering an additional conductor. In my case, the gap width was large, and I had to prepare a piece of copper wire for the jumper in advance. A current of about 1 A flows through the heater conductor, based on this we select a wire with a cross-section of 0.17 mm 2, which corresponds to a diameter of 0.45 mm, according to the table of wire sections. The length of the copper jumper should be equal to the width of the wire break plus 2 cm. Before soldering, the jumper must be tinned with a thick layer of POS-61 tin-lead solder. There is no need to tin the heater wire.

To ensure that the solder adheres securely to the heater wire, before soldering the jumper, coat the wire in the soldering area with a brush with a thin layer of zinc chloride flux.

After this, the jumper is pressed against the heating wire and heated for a second with a 12 W soldering iron. The hand is moved to the side. The jumper should be kept on a string. Trying to pull it out to check the quality of the solder is unacceptable; it will fall off and tear off a piece of the heater wire. Unfortunately, this has not been tested empirically. As a result of the experiments, we had to solder a jumper 5 cm long.

After soldering one end of the jumper, the other is pressed tightly against the wire and is also heated with a soldering iron. At the end of welding, the glass is thoroughly washed with water to remove residual acid flux.

Finally, for reliability, even if this is not necessary, I covered the jumper welded on top with transparent superglue “Moment” based on cyanoacrylates, the heat resistance of which is about 70 ° C. The heater does not heat up to the above temperature.

As a result, the time to repair a broken thread with your own hands, taking into account all the preparatory work, was no more than ten minutes. The repaired threads have been in use for more than three years.

Eliminating the break

Patching a cliff in general is not a difficult task, and there are several ways to solve it. The most commonly used is electrically conductive paste. Before repairing, it will be necessary to secure the broken area with adhesive tape (two pieces - one for each fragment of the track). The ends of the thread are cleaned and washed with alcohol. The paste is then applied to them and left to dry for at least 24 hours.

You can also restore the functionality of the rear window heating element using:

- glue (type BF);

- metal filings;

- magnet

Sawdust is quite easy to make using a file yourself. In turn, any magnet will do. It should be placed on the outside of the window, and metal dust should be placed on the inside, where the heating element is located. Then the joint remains to be treated with glue and varnish. Any oil paint can also be used.

Heating can be repaired quite effectively with a soldering iron. Here you will need solder containing a small amount of tin (for example, POS-18); in this case, instead of flux, use zinc chloride. But this method is suitable only if the cliff is small. You will have to fill a large area with either copper or silver wire.

In addition, it should be noted that now in stores there are also special adhesive compositions for repairing heating filaments. But for some reason they are currently not in demand.

The video below will help you understand in more detail how to repair a damaged rear window heater: