Hi all! I can’t say that car horn malfunctions occur very often and everywhere. But we cannot exclude a situation in which the signal does not work.

Car horns are safety features. Moreover, they must be present in all vehicles and be in good condition. This will allow you to give a timely signal to other road users, inform about the approach, and prevent collisions and other dangerous situations.

But at some point it happens that the sound signal located on the steering wheel suddenly stops working. It is necessary to address the issue of diagnostics as soon as possible, since it is dangerous to continue operating the car with a non-working horn.

Possible malfunctions: signs and causes

There are several signs of a malfunctioning sound signal on a VAZ 2110 or 2112:

- The sound signal has disappeared. The driver presses the steering wheel or the corresponding button located on it, but there is no beep.

- The beep appears and disappears. When the driver presses the steering wheel, the signal may start to work, but then immediately disappears.

There may be several reasons why the horn refuses to function:

- One of the most common reasons is the failure of a safety device. In this case, the integrity of the horn itself will not be compromised, which greatly simplifies the repair procedure.

- Failure of the horn itself. If after replacing the safety device the sound does not appear, you can try to check the functionality of the horn by dismantling it and directly connecting it to the battery. If the device is working, then when connected to the battery it will begin to emit a corresponding signal.

- The reason may also be a short circuit in the vehicle's on-board network.

- Another cause of the problem may be worn out clamping contacts located on the steering column. This problem often occurs in the cars of our compatriots. In any case, the clamping contacts wear out over time due to use; this cannot be prevented. As an option, you can try to increase the service life of the contacts; to do this, they need to be treated with graphite lubricant from time to time.

- Worn slip ring on the steering wheel. As stated above, there is no escape from wear and tear, so sooner or later every car owner will face such a problem. As in the previous case, you can try to increase the service life of the slip ring by applying graphite lubricant to it.

- Oxidation of contacts on the steering wheel. With prolonged use, deposits will begin to accumulate on the internal contacts, which makes it impossible to transmit the impulse to activate the horn.

No sound

Neither signal makes any sound other than a squeak? Then the problem lies somewhere in the wiring. Now is the time to check the fuse, which is most likely hidden deep down in the dash, driver's side dash, or under the hood - or just about anywhere in the front half of the car if it's not in one of the obvious places. Find the location of the fuse box and special fuse in the owner's manual.

Inspect the instrument panel cover or check your owner's manual to determine which fuse protects the signal circuits. If the S-shaped strip is broken (fuse on the right), replace the fuse.

If the metal strip inside the fuse appears to be broken, replace it with another of the same amperage rating. It is very rare, but fuses fail for no apparent reason. If the fuse is bad, chances are you have a problem that will cause it to blow again, sooner or later.

Malfunctions of the electrical signal circuit:

1) check the presence of incoming mass or voltage on the signal itself (on old systems, “plus” is constant, but the signal was controlled by “minus”). If there is a plus and a minus that appears, when you press the horn, replace the signals themselves (the signals are non-separable and must be replaced if they fail);

2) Check the supply voltage (fuse, relay, mounting block);

3) Power button on the steering wheel (contacts, adjustment of switches and three-lever), presence of mass on the steering column;

— the signal wheezes or disappears:

— the sound signal appears spontaneously when turning the steering wheel:

1) Incorrect adjustment of the steering column switch (too much “pressed” towards the steering wheel);

2) Ground circuit on the steering column (signal control wire);

It should be noted that on some KALINA and PRIORA models the signals are connected to the anti-theft system (signals the opening or closing of doors, acts as a security system and alarm), and some reasons for the malfunction of the signals may be associated with it.

If you find an error, please select a piece of text and press Ctrl+Enter.

Principle of operation

The operating principle of car signals is based on the cyclic closing and opening of contacts. This causes the membrane to vibrate. The volume, tone and strength of the current consumed are determined by the gap between the armature (moving contact) and the core (fixed contact). Depending on the current consumed, the signals can be switched directly by the switch or via a relay. Sound signals in a car can be hornless (noise) or horn (tone). The set of sound signals includes noise and tones, configured to work together. The main purpose of the sound signal is to attract the attention of other road users, especially when there is not enough visibility.

Sound signal of vibration type, hornless. The switch with a ring button is installed on the steering wheel. On the VAZ-2101 car, two signals are installed - low and high tones. The signal consists of a body, an electromagnet 3, an armature 4, contacts 6, a membrane 7 and a resonator disk 5. When you press the button, the electrical circuit is closed, and current from the battery flows through the closed contacts 6 into the winding of the electromagnet 3. At the same time, the electromagnet attracts the armature 4 , which bends the membrane 7 and simultaneously opens the contacts 6. The electrical circuit is interrupted, the electromagnet is demagnetized, and the armature moves back under the action of the elasticity of the membrane, as a result of which the contacts close, a closed electrical circuit is formed again, the armature is attracted again, and the process repeats. This creates frequent vibrations of the membrane (up to 100 vibrations per second) and sound appears. The sound tone of each signal is adjusted by screw 1 located on the rear wall. When the screw rotates clockwise, the sound intensity increases, and when rotated counterclockwise, it decreases.

Reasons why the signal may not work

- The fuse has blown and needs to be replaced with a new one. You can find out which fuse is responsible for the signal here.

- A short circuit in the wiring often causes a non-working signal; you can see the wiring diagram for the VAZ 2110 here.

- The horn stopped working due to a breakdown of the horn itself.

- The clamping contacts have become unusable or simply oxidized.

- Another common reason why the signal does not work is wear of the contacts in the steering wheel.

Why did the horn stop working?

If the warning signal on the VAZ-2110 does not work, including the fan, you should not immediately contact a service station.

You can identify the cause of the malfunction and eliminate it yourself, taking into account the advice of professional technicians. Most often, the signal may stop working due to the following reasons:

- A fuse that has become unusable. To fix the problem, you will need to replace the burnt element, which must match the color and value of the previous one. This procedure does not take much time; it can be completed in just a couple of minutes. But if after a short time the new fuse blows again, this problem needs to be solved at a service station.

- If after replacement the sound signal does not appear, this will indicate a short circuit in the electrical network. To eliminate the cause of the problem, the owner’s experience is rarely enough, so the right decision would be to seek help from experienced professionals.

- The sound signal stopped working due to a breakdown of the horn itself. If replacing the fuse did not produce any result, and the audible brake light still does not work, then most likely the horn itself is broken. It will be difficult even for an experienced car enthusiast to cope with the problem on his own, since in order to identify the cause of the breakdown, you need to connect the part to the battery. If you decide to check the signal yourself and the element does not start functioning after connecting to the battery, the easiest way is to buy a new horn and install it.

The sound signal does not work • MOYMEKHANIK.RF

A sound signal in a car is an element that the driver may not use for a fairly long period of time (this simply will not be necessary).

And one day, faced with a situation that requires its operation, the driver may suddenly discover that the car’s horn does not work or the engine emits blue smoke. Only a car mechanic knows the reasons.

This is not just an unpleasant fact, but in different situations it can lead to the most unpredictable consequences, because with the help of a sound signal the driver notifies about the approach of a car, potential danger, etc.

To avoid such troubles, it is not so difficult to check its operation every day when leaving home by beeping once or twice. And yet, let's look at the main reasons why a car's horn may not work.

Keep in mind

You can name a number of situations and factors due to which a car’s sound signal can fail and stop working normally. The most common among them:

- blown fuse;

- faults in the signal relay;

- unstable contacts (under the steering wheel hub, in the switch, etc.);

- the signal pressure stand is stuck;

- the signal adjustment is disrupted or the plates inside the mechanism are stuck;

- slipped terminals or breaks in connections;

- the signal connection is loose or the winding is burnt out;

- Dirt and water got inside the mechanism.

To understand how to fix problems that arise, you need to know how a car horn works .

Therefore, if you yourself do not understand the nuances and subtleties of the operation of this element, then you should not experiment; it is better to entrust the process of diagnosing and troubleshooting to specialized specialists.

To anyone who has encountered a similar problem and requires help, the experts from the “My Mechanic” service are ready to offer their services.

Our recommendations

Malfunctions in the operation of the sound signal are usually detected at a time when it is absolutely necessary. And if you are faced with such a problem, you should not delay your trip to a car service center. And although the sound signal does not directly affect the performance of the car and safety while driving, it must be in good condition.

Car horn repair

Car horn

Sound signal operation diagram

How important is it

The technicians from the “My Mechanic” service know how a car’s horn works and determine the possible causes of problems with the horn, following clear operating instructions: checking the fuse for integrity, the serviceability of the relay, the integrity of the contacts, checking whether the engine is overheating or not, etc.

Sometimes it is enough to simply tighten the screws on the contacts, but sometimes you may need to replace the entire signal. It’s better to entrust the process of identifying a malfunction and eliminating it to a technician, then you can be sure that the next time your car’s signal will not let you down if necessary!

Signs that indicate you need this service

- Fuse burned out

- The sound signal does not turn on well

- The sound signal is faulty

Source: https://MyMechanic.ru/services/horn-does-not-blow-inspection/

VAZ horn repair

The absence of a sound signal on a car is a malfunction that affects traffic safety. The ability to promptly warn or attract the attention of pedestrians, as well as other road users, directly with the horn, can help avoid creating an emergency situation or an accident.

A malfunction such as the absence of a sound signal on VAZ family cars is quite easy to diagnose and repair with your own hands. To do this, you need to study the connection diagram (it is very simple) and follow the instructions to carry out the necessary checks.

It's time to stop

In fact, expressing your displeasure by beeping is completely inappropriate. The taxi driver will continue to behave in the same way on the road, regardless of your signal. In cities, it is illegal to use your horn in a residential area unless there is a traffic situation where you really need to do so, otherwise you will face a fine. In general, beeps are not intended to give your teenage son the opportunity to signal to his girlfriend that he has been waiting for her on a date. A short horn will help attract the attention of a pedestrian who steps out onto the roadway without looking around, or of some mother who is driving her children to the section, chatting on the phone and looking in the rearview mirror at her whining offspring.

Is a Volga horn good?

Is it possible to use a signal from the Volga in the “ten”, how to install it and how to connect it yourself? In the VAZ 2110 it is allowed to install a Volga horn, and the latter can be either old or new model. There is no particular difference between these details, except that the tonality will be slightly different. And, of course, the cost. But keep in mind that installation by simply replacing the device will not work.

The bottom line is that two cables are connected to the standard device - one with a negative output, which comes from the button on the steering wheel, and the other with a positive one. The latter is permanently connected; it also powers the ventilation device of the radiator unit. But in Volga devices, only one cable is used - positive, since the mass in this case is supplied through the body, that is, from the attachment to the vehicle body. In addition, you must also take into account that both systems use different current consumers - the standard options require no more than 5 amperes, while the Volga ones require 8 amperes each. The result is 16 amperes (video author - Master Bruce).

Accordingly, to correctly connect a product from Volga to a VAZ 2110, you will need a four-pin relay; you have several options for installing it:

- in the vehicle interior, in the mounting block with fuses;

- in the engine compartment, but in this case, please note that the relay should be securely insulated to prevent moisture from entering.

Fuse and relay box

The fuse and relay box is located on the left, lower part of the instrument panel. It is accessible by pressing the button and folding the lid down. To remove fuses, there are special non-conductive pliers in the upper left part of the mounting block.

1 - K5 - high beam relay . If the high beams in two headlights do not work, check this relay. If one of the high beam headlights does not work, check fuses F3 and F13, as well as the lamps and the high beam switch.

2 - K4 - low beam relay . If the low beam in both headlights does not work, check this relay. If only one low beam headlight does not work, check fuses F2 and F12, as well as the lamps themselves and the light switch.

3 - K1 - lamp health control relay.

The sound signal of the VAZ 2110 has disappeared, what should I do?

The sound signal on VAZ cars has disappeared. Then 98% it is on the steering column that the box with the wiper switches and turn signals has moved down a little. And the contact disappeared and the signal stopped working. Because There's practically nothing left to break there. But the steering column often becomes loose and goes down a little lower, causing the signal to disappear. Pull the steering column up towards the steering wheel, if it has moved up a few centimeters, check whether the signal is working or not. Next you need to tighten the steering column clamp. Remove the protective cover and tighten the clamp. If tightening the clamp does not help and the steering column still moves down a little, then you can put something under the clamp and tighten it. In this case, it takes approximately 1 minute to check what the problem is. The signal is not working. You pull the steering column protective cover up closer to the steering wheel (there are 2 contacts there that stop contacting the washer) after you pull it up closer to the steering wheel, the contact should appear and the signal should work.

The signal contacts are marked in a red circle and make contact with the washer located under the steering wheel. 98% of the reasons why the signal does not work is because there is no contact in this place with the washer, see photo.

Every car must have a working horn. Thanks to the horn, the driver can prevent an emergency situation on the road and avoid a possible collision. But it often happens that the horn refuses to work. For what reasons does the sound signal on the VAZ 2110 not work and how to fix this problem - read below.

Repair and operation of the VAZ 2108 2109 21099 car

The sound signal of the VAZ 2108 2109 21099 is directly related to the safety of driving a car, since with its help the driver comes into contact with other road users. Therefore, the sound signal must always be in good working order.

Steering wheel horn switch

But it often happens that it doesn't work. Let's look at the possible reasons: 1) Fuse F8 has burned out (it may differ depending on the type of mounting block) in the mounting block. 2) Relay K8 is faulty (it may differ depending on the type of mounting block) in the mounting block. 3) The sound signal itself is faulty.

4) Poor contact in the audio signal circuit.

Let's go in order:

1) Fuse F8 protects the K8 relay circuit and the sound signal itself from a short circuit. If fuse F8 has burned out, then you first need to make sure that the electrical circuit of the VAZ 2108 2109 21099 sound signal is not shorted.

VAZ 2109 sound signal circuit

If the short circuit remains, the new fuse will also burn out. It is necessary to find and eliminate the cause of the blown fuse. 2) If relay K8 is faulty, then when you press the signal on the steering wheel it will not close +12V to the sound signal. A faulty relay must be replaced.

3) The sound signal is located in front of the radiator of the cooling system.

Sound signal VAZ 2109

To get to it you need to bend or remove the decorative radiator grille. Checking the sound signal is simple. One of its contacts is constantly connected to ground; the second contact must be supplied with +12V from the battery. To do this, take a piece of wire about a meter long.

We securely connect one end of the wire to the +12V battery, and connect the other end to the sound signal. If the signal does not work, then it is faulty. The sound signal of the VAZ 2108 2109 21099 has a volume control, you can try turning it. Or disassemble the signal itself; perhaps a visual inspection will help determine the cause of the malfunction.

4) Poor contact means that +12V does not reach the audio signal.

A common reason is poor contact here

If your fuse is intact, the relay is working, the horn itself and the switch on the steering wheel are working, then most likely the problem is in the wiring.

Either in the mounting block, or on the sound signal itself of the terminal oxidation. You can check whether the voltage is coming to the sound signal or not using a multimeter.

One person presses the signal on the steering wheel, and the second measures the voltage on the sound signal in front of the radiator.

Other common causes

Quite often you can find the following causes of problems:

- The sound signal may disappear due to worn-out clamping contacts located on the steering column. To prevent rapid wear of the wires, experts recommend periodically lubricating them with graphite lubricant, after removing the steering wheel of the car. Such treatment will help not only prevent wear of the element, but will also extend their performance;

- Worn contact steering ring can also cause the horn to fail. To eliminate it, you will need to carry out similar measures that were described in the previous paragraph;

- Quite often the signal on the VAZ-2110 stops functioning due to oxidation of the steering internal contacts. Since a lot of deposits accumulate on the elements, they become an obstacle to the sound signal, so the car horn stops working. To eliminate the breakdown, it will be enough to disassemble the car’s steering wheel, carefully clean the internal contacts and correctly assemble the steering wheel.

We hope that the information in this article will make it much easier to identify the cause of the sound signal malfunction and quickly fix the problem yourself. Remember that if the sound signal on a VAZ-2110 does not work, it is better not to ignore the problem, but to try to solve it. Numerous videos created by repair specialists will help with this.

Fuse OK

Now you need a 12-volt diagnostic light or voltmeter. You should also find the owner's manual, or at least a graphical representation of the signal's electrical circuit.

Start by checking the 12 volt signal connector.

Using a simple voltmeter, examine the horn connector to see if there is 12 volts when the horn button is pressed and the ignition is on.

One leg of the circuit is supported by a car metal frame, so you need to check between a good ground point and the wiring connector to the signal. If there is no voltage at the connector, check the signal relay.

Check the 12-volt voltage at the signal relay when the ignition is on. 1 – diagnostic lamp. 2 – signal relay connector.

The horn relay switches high voltage current to horns when signaled by a low voltage current button in the steering wheel. This is a simple, single throw, single throw (SPST) relay packaged in a small metal or plastic box with five spade terminal connectors. If you're unlucky, your engine has a relay that's built into a larger fuse box that also controls several other functions on your vehicle, such as the headlights or turn signals. This part is much more expensive. Consult your owner's manual for where the relay is located, as it, like the fuse box, can be located almost anywhere under the hood or under the dash - and not necessarily near the fuse box.

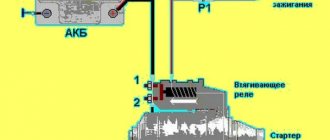

The horn relay increases the low voltage coming from the horn button to the higher voltage needed to operate the horn. 1 – battery. 2 – sound signal. 3 – closed contacts. 4 – signal button. 5 – relay coil. 6 – relay.

A simple SPST relay would have a constant 12 volt supply to it, a lead wire that goes through the wiring harness to the horn, another lead wire that goes to the horn switch in the steering wheel, and a ground. Check that voltage is entering the two terminals of the relay and leaving it through the other two terminals when you press the switch. If not, try grounding the lead wire that goes to the horn button to force the relay to pull in. If the horn buzzes, the relay is good, but the horn button or wiring is faulty. You can simply replace the relay if it is the problem. Otherwise, you will have to do some serious diagnostic work to find the open circuit.

Air signal connection

If you need to connect not an electric, but an airborne sound signal, the connection procedure will be almost the same as described above. The difference is that the wire from the relay does not go to the sound signal itself, but to the compressor (the engine that supplies air to the signal). And the pneumatic signal pipes are connected to the compressor through tubes.

When you press the horn, air from the compressor is supplied to the horns. With the help of a membrane installed in them, a sound signal is obtained.

You can read about how to connect the headlights yourself in our article How to connect the headlights.

Symptoms of problems

How can you even determine that the horn is not working or has some kind of malfunction? It's actually extremely simple.

There are 2 main signs of problems with a car horn:

- The signal doesn't work at all. When you press the button, the driver, like other road users, hear absolutely nothing. This is a clear indication that the system has failed;

- The signal appears periodically. There is also a slightly different situation when the horn does not go off with every press. That is, they pressed it once, everything works, but when you try to honk again, the horn goes silent, there is no reaction to the press. Then the situation repeats itself.

There is nothing complicated or unusual in determining the nature of the malfunctions. But now we need to understand why this happens and where to look for the reasons.

The feasibility of self-repair

So does it make sense to repair the horn yourself? If we take into account the recommendations described above, then the repair is advisable only if the car owner is as careful as possible when performing it. After all, during the repair work, there is a high probability that an inexperienced car enthusiast will damage the wiring in the unit or connect the contacts incorrectly. Therefore, if you have never encountered a repair procedure before, it is better to entrust this matter to specialists or simply replace the horn assembly.

Methods for troubleshooting

If the horn circuit is broken and the horn stops working, then there are several options for solving the problem:

- First you need to diagnose the safety device. If this part is burnt out, then you just need to replace it with a new one; the device is located in the mounting block. The replacement process will not take much time; any car enthusiast can cope with this task. If replacing the fuse gave results, but after some time the horn stopped working again, then most likely the reason lies in voltage surges in the on-board network. Overload contributes to accelerated burnout of the fuse element, so you will have to look for the source of the load and solve the problem. To do this, use a multimeter or seek help from an electrician.

- If the horn itself malfunctions, the device must be replaced. If diagnostics by direct connection to the battery do not produce results, then most likely the reason lies in the device itself, which needs to be changed.

- Short circuit. To diagnose, you will need a multimeter and a little experience. Using a tester, you can find a short circuit, but if you have never encountered such a problem before, it is better to seek help from specialists.

- If the clamping contacts or slip ring are worn out, then the failed elements must be replaced. It is not a fact that you will be able to buy new contacts or a ring, so most likely you will have to change the horn assembly.

- Another reason why the horn does not work is oxidation of the internal contacts. Over time, as mentioned above, dirt and deposits accumulate on them, which leads to the obstruction of sound. You can try to disassemble the steering wheel of the car, then clean the internal contacts and assemble the steering wheel (the author of the video is the channel Alexander Amochkin Kolomna AAK).

Correctly connect the car signal

Home > On the computer > connect > Connect the car signal correctly

Let's consider a universal diagram of a car sound signal:

- The so-called anchor.

- Device rod.

- Nut for adjustment.

- Lock-nut.

- The first tungsten contact of the horn.

- Another tungsten contact.

- Capacitor element.

- Core.

- The housing that contains all the components.

- Activation button located on the steering wheel.

- Resonator disk.

- Membrane.

- Winding.

- This is a relay contact.

- Another anchor.

- Relay coil.

- Signals.

In accordance with the connection diagram, when the driver presses the control button, a current begins to pass through the winding, which ultimately magnetizes the core, which in turn attracts the armature.

With this anchor, the rod that bends the membrane begins to move, and thanks to the nut, the contacts open, which helps interrupt the electrical circuit. All elements, in particular the disk, rod, anchor and others, return to their original position using a spring and membrane.

In this case, the contacts close, which again leads to the passage of current through the winding. The process of opening the contacts is carried out by pressing the horn button on the steering wheel (the author of the video is the channel pribambas sender).

Possible malfunctions: signs and causes

By what signs can you determine that a car horn needs repair:

- The steering horn does not work. When the driver presses the steering wheel button, the sound device does not work.

- The device sometimes works, sometimes it doesn’t. When you press the button on the steering wheel, the horn first sounds and then disappears.

As for the reasons why a device may fail, there are many:

- A fuse located in the fuse block under the hood or inside the vehicle has blown. In case of such a problem, the operation of the horn can be restored, since it is not damaged. The car may also, in addition to the fuse, have a relay.

- The horn itself is broken. If you replaced the safety element, but this did not help solve the problem, then you need to check the horn itself. To do this, the device will need to be removed, and its contacts will need to be connected directly to the battery. When connected directly, a functional horn will sound.

- In some cases, the reason lies in the appearance of a short circuit in the vehicle's electrical network. A short may affect the connection circuit, so you must first check the functionality of the fuse socket. Sometimes the horn may not work correctly due to circuit damage and current leakage.

- Also, the cause of the malfunction sometimes lies in worn-out clamping contacts located on the steering column. A malfunction of this type is more typical for domestic cars. As a result of long-term use, the springs begin to wear out over time, which leads to the fact that the impulse through them cannot be transmitted from the button to the buzzer itself.

- It also happens that the slip ring wears out right on the steering wheel.

- If the contacts are not worn out, then they could simply oxidize. Long-term use, as well as lack of maintenance, lead to deposits forming on the contacts over time. As mentioned above, this problem can cause difficulty transmitting the signal to activate the buzzer.

- The contact blades are located under the steering wheel hub. This petal may burst over time; sometimes the cause should be sought in the jamming of the pressure rack.

- The horn winding is burnt out.

- Sometimes the horn malfunction is due to a damaged electrical connection or an accidental disconnection of the terminal directly on the signal itself.

- Sometimes the reason for a non-working signal may be a break in the cable on the steering wheel on cars equipped with an airbag (video published by the channel Learning to drive a car. All secrets for beginners).

Do-it-yourself signal diagnostics and repair

How to check and repair the horn yourself? For diagnostics, you will need a tester (preferably a digital multimeter, but if you don’t have one, you can use a regular one), crimping pliers, pliers, and a utility knife. Prepare spare wiring and a service manual for the machine.

Checking with repairs is performed as follows:

- The functionality of the fuse and relay is checked; you need to find the mounting block. A more precise diagram is indicated in the technical documentation, but usually the safety device is located in the power supply unit; it can be installed in the dashboard. Once you have located the block, examine the diagram on the back of the block cover to find the fuse. Dismantle the device that is responsible for the operation of the horn and carefully inspect it - if there is an open circuit, this indicates that the fuse is not working.

- But if the device is intact, this does not mean that it is functional. You need to diagnose it using a tester. Set the multimeter to the resistance measurement mode with sound (if we are talking about a digital tester and it has such a function). If you have an analog multimeter, before diagnosing you will need to calibrate the tester; to do this, short-circuit its probes with each other and move the regulator to zero. Then press the tester probes against the contacts of the safety device. If the part is working, then the multimeter will show 0 Ohm, but if not, then if there is no change on the display, we can conclude that the resistance is too high. This indicates a broken fuse and the device needs to be replaced.

- After this, if the fuse is working, you need to find the relay block, which is located either in the engine compartment or in the interior of the car - use the service book to search. Typically the relays are located in the same fuse box. The easiest way to check the operation of the relay is to swap the devices with other similar parts. In most cases, relays are interchangeable, so if after replacing the device the horn starts working, then you can understand that the reason was in the relay.

- You should also check the steering horn switch; a tester is also used for this. If there is no power supplied to it, then of course the button will not be able to respond to pressing.

What else to pay attention to

Very often, the appearance of such malfunctions occurs due to the fault of the rear lights, or more precisely, in the places where the connectors with wires and lamp sockets are connected. Using a measuring device or a test lamp, check the presence of power at the rear light connectors with the brake pedal pressed or the wires on the switch connected to each other. If it is missing, you should carefully check the condition of the wiring harness.

Oxidation of contacts in connectors or sockets of electric lamps can be removed using available means. It is not advisable to use sandpaper for this, even very fine sandpaper. Alcohol-containing liquids are best suited for this, as they remove the resulting oxidation.

Source